Forming

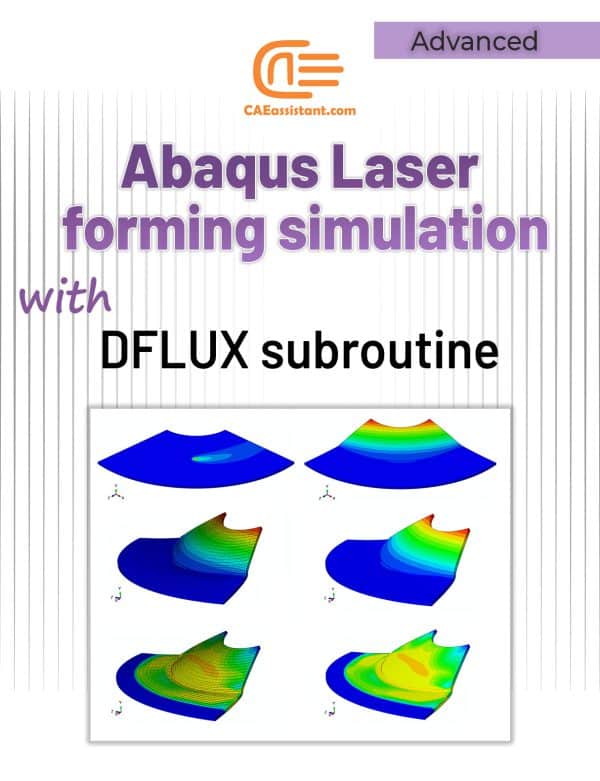

Laser forming simulation tutorial in Abaqus

The laser forming process is performed by applying thermal stresses to the workpiece surface by heating the surface with a laser beam. These internal stresses induce plastic strains in the part resulting in local elastic-plastic deformation (Laser-induced plastic deformation). In this laser forming simulation tutorial the DFLUX subroutine is used to apply heat flux (Gaussian heat distribution) dependent on location and time in finite element simulation. For example, the linear heating processes of laser forming and welding (with a slight simplification) can be simulated by this subroutine. In the linear heating process, by applying heat flux to the surface of a sheet, a thermal gradient is created in its thickness. This thermal gradient causes permanent deformation of the sheet. To simulate the laser forming process, it is necessary to apply a time and location-dependent heat flux to the sheet. In this type of loading, a heat flux is applied on the plate, which is defined using the DFLUX subroutine, including the laser power, movement speed, beam diameter, absorption coefficient, and laser movement path according to the designed experiments (Laser forming process parameters). To verify this Abaqus laser forming simulation, the simulation results and experimental results of sheet deformation (U) are compared. The displacement of the sheet in the simulation is in good agreement with the experimental results.

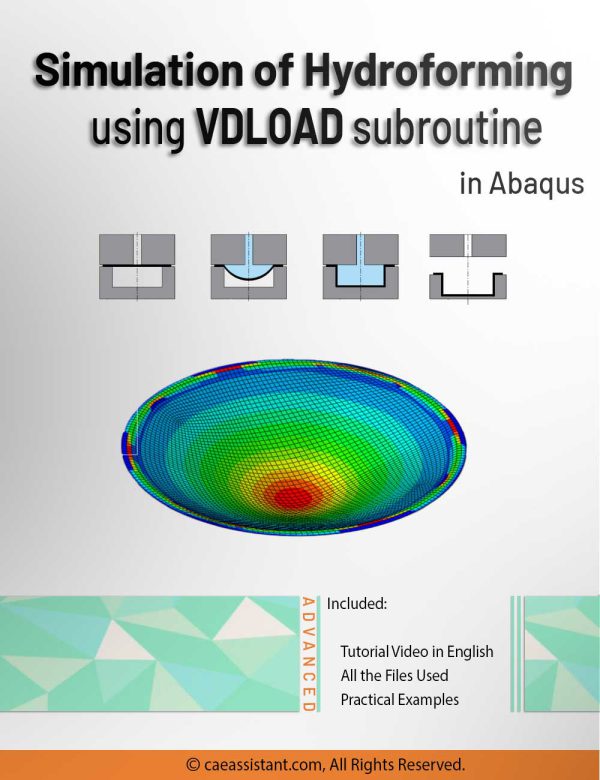

Hydroforming process simulation using VDLOAD subroutine in Abaqus

Dive into the intricacies of hydroforming simulation in Abaqus alongside the VDLOAD subroutine with our comprehensive guide. This tutorial delves into the essence of the Abaqus hydroforming simulation, unraveling the nuances of the hydroforming process simulation. Hydroforming, a specialized metal shaping technique applicable to diverse materials like steel, copper, and aluminum, is explored in depth.

In the workshop component, we specifically focus on advanced hydroforming simulation using the VDLOAD subroutine, highlighting its pivotal role in specifying fluid pressure on sheet metal forming. Learn how to apply the Functional Fluid Pressure Loading feature for precise control over fluid pressure dynamics. Additionally, explore the Smooth Amplitude option for defining part displacement seamlessly, without introducing dynamic changes during problem-solving.

Conclude your exploration with a comparative analysis of simulation outcomes, dissecting scenarios with and without fluid pressure using Abaqus hydroforming simulation. Engage in discussions on subroutine writing, delving into the intricacies of incorporating Fluid Pressure Loading into your simulations. This guide offers a natural progression through hydroforming and VDLOAD, providing valuable insights for efficient and accurate simulations.

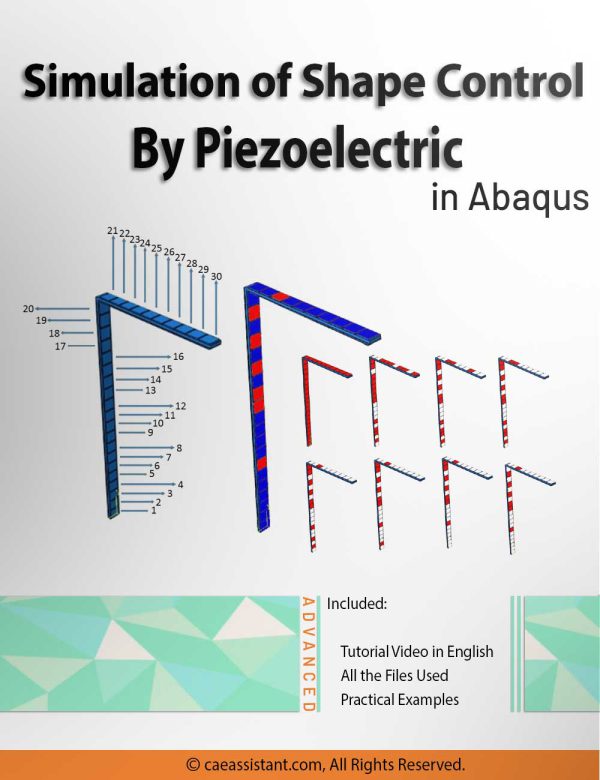

Simulation of shape control by piezoelectric in Abaqus

Piezoelectricity refers to the accumulation of electric charge in certain solid materials due to mechanical pressure. This phenomenon, known as the piezoelectric effect, is reversible. Some materials exhibit direct piezoelectricity, which involves the internal production of electric charge through the application of mechanical force, while others exhibit the inverse piezoelectric effect.

By harnessing piezoelectrics, it becomes possible to control the geometrical changes of objects in response to external forces. However, it is important to note that utilizing this property in all situations would not be cost-effective. Therefore, it is more practical to use piezoelectric structures selectively, specifically in special applications. One approach to determining the optimal placement of piezoelectric elements for controlling the geometric shape of various objects under internal or external forces involves utilizing the Abaqus and MATLAB software linkage. This software combination, along with optimization algorithms such as the particle swarm optimization algorithm, can be employed to achieve the desired objectives. By leveraging these tools and data, the primary goal of controlling object shape can be successfully accomplished.

In this training package, you will learn about piezoelectric and piezoelectric modeling in Abaqus, the particle swarm optimization algorithm, linking Abaqus and MATLAB, and how to use these tools for shape control.

Notice: Software files and A full PDF guideline (Problem description, theory, ...) are available; Videos are coming soon.

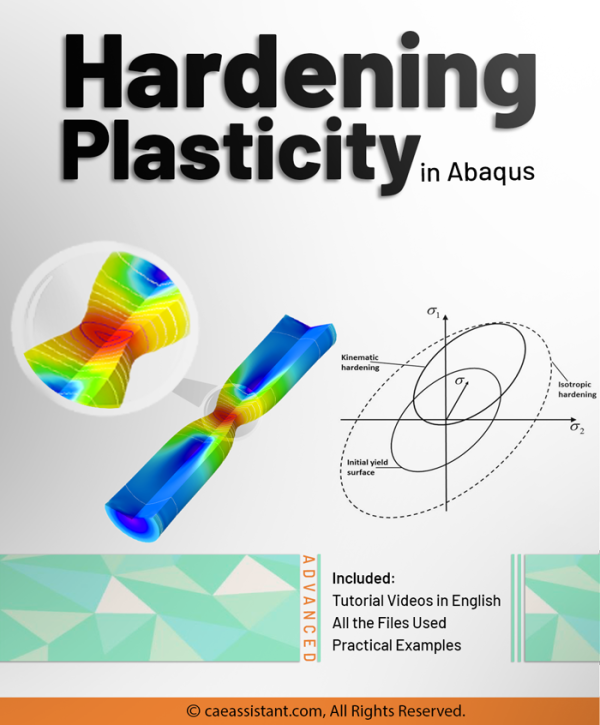

Hardening plasticity in Abaqus

In this package, hardening plasticity in the Abaqus software using Abaqus material models or UMAT subroutine or UHARD subroutine is discussed. It should be mentioned using a subroutine to define hardening could be more professional and this package tries to familiarize users with these subroutines for hardening definitions. So, if you want to write these subroutines for your customized project in the hardening plasticity field, I recommend you the "UMAT Subroutine (VUMAT Subroutine) introduction" and "UHARD Subroutine (VUHARD Subroutine) in ABAQUS".

Lemaitre Damage model implementation with VUMAT Abaqus

The Lemaitre damage model is now widely used to deal with coupled damage analyses for

various mechanical applications.

In this package, Firstly, we try to introduce the Lemaitre damage model, including damage mechanics and formulation of the Lemaitre damage model. Then, writing the Lemaitre subroutine is reached step by step. To do this job, the flowchart of the subroutine, Writing the subroutine line by line, implementation of the subroutine in one element and verification is done. In the last chapter, we implement this subroutine in a complex problem, the upsetting process.

Academic or Business Membership

Payment Yearly

Why should you choose this Membership?

Abaqus DLOAD Subroutine and VDLOAD Subroutine

This training package helps Abaqus users to prepare complex DLoad and VDLoad subroutines. With the help of these workshops, you can get acquainted with the basic and comprehensive way of DLoad and VLoad subroutine writing and their applications. By viewing this package as an engineer, you can do basic projects with complex loads.

Module by module Abaqus Training

If you are new to Abaqus software and the topic of finite element analysis, you definitely need to get acquainted with the user interface of this software and the general features of each module.

In this software, we perform different simulation steps in the following different modules and at the end, we receive the analysis results from the software solver.

In this package, you will learn how to work with the software in each module and perform your simulation in each module properly.

Introduction to VFRICTION and VFRIC Subroutines in ABAQUS

This tutorial help you in cases where the classical Columbian equations are more complex and cannot be implemented by the graphical ABAQUS environment. This package introduces and teaches how to write these two subroutines. This introduction contains explaining different optional and mandatory parameters of VFRICTION and VFRIC subroutines.

Customized Package

UMESHMOTION subroutine in ABAQUS

If you want to define motion for mesh nodes, you must use the UMESHMOTION subroutine. This subroutine helps you to specify Mesh Motion constraints during adaptive meshing. In this tutorial package, you will learn when you need to use the UMESHMOTION subroutine and how to use it. This package contains three workshops: “writing UMESHMOTION subroutine in forming process”, “writing UMESHMOTION subroutine in rolling process”, and “Tread wear simulation via UMESHMOTION”. The Archard model is used in the wear process, which is very popular in academic and industrial projects.

Forming simulations in ABAQUS

In this training package, different types of forming simulations are presented along with different tips. These points include increasing the solution speed, different types of plasticity and damage models, different solvers, Lagrangian, CEL, and SPH methods and etc.

Pre-Order Now

Coming soon...