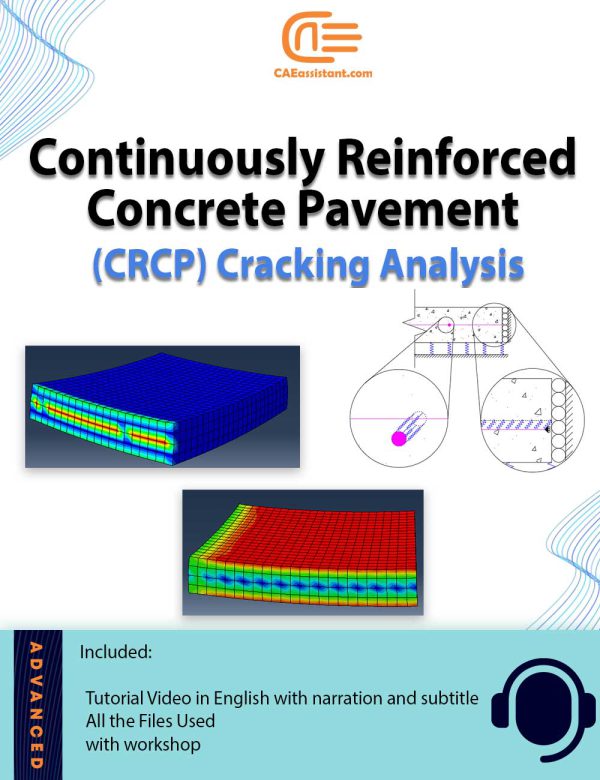

continuously reinforced concrete pavement (CRCP) Analysis

|

The increasing adoption of continuously reinforced concrete pavement (CRCP) in highway pavement design is driven by its demonstrated superior performance. Critical to evaluating the long-term effectiveness of CRCP is the understanding of early-age cracks, which has garnered significant interest from highway departments. This Abaqus Continuously reinforced concrete pavement modeling project aims to establish precise design parameters for CRCP and analyze the formation of crack patterns. By accounting for stress factors such as environmental conditions and CRCP shrinkage modeling, the project offers valuable insights into predicting the likelihood of crack initiation and propagation within the concrete slab. These insights are instrumental in enhancing the durability and performance of CRCP structures, thus advancing the efficiency and effectiveness of highway infrastructure. |

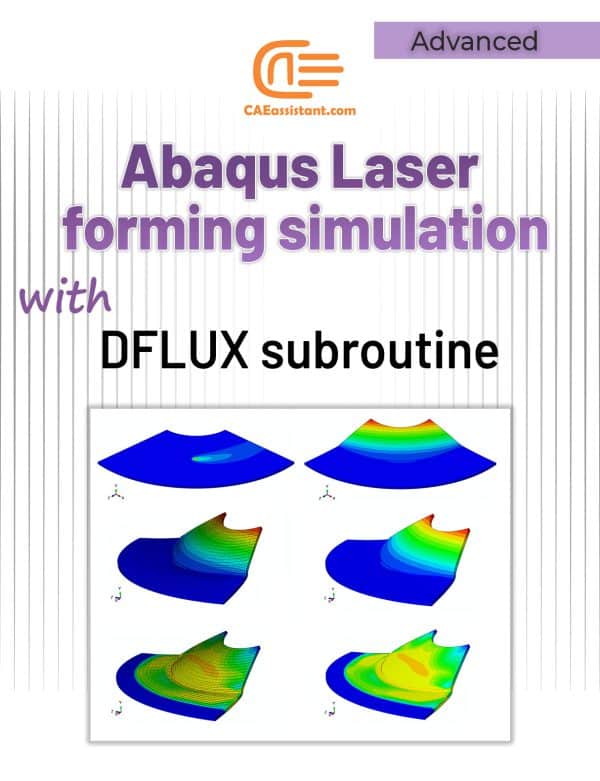

Laser Forming Process Tutorial in Abaqus

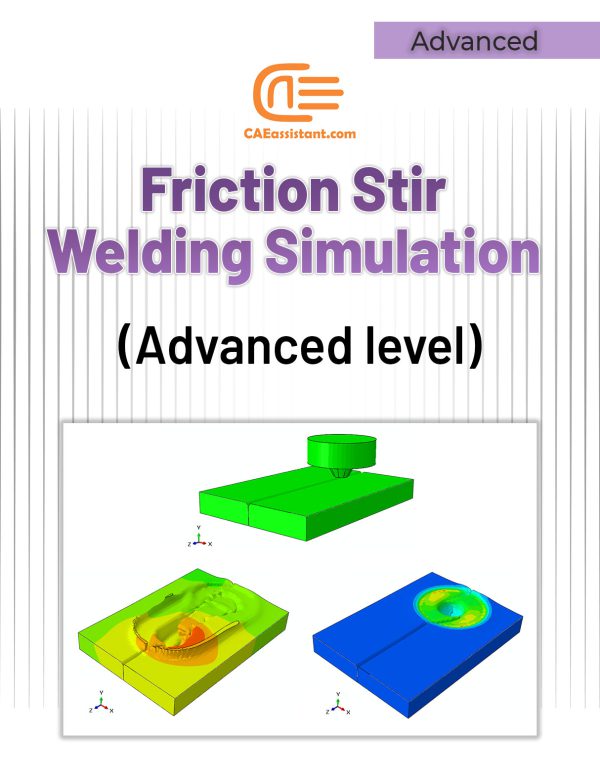

Friction Stir Welding simulation Tutorial | FSW Advanced level

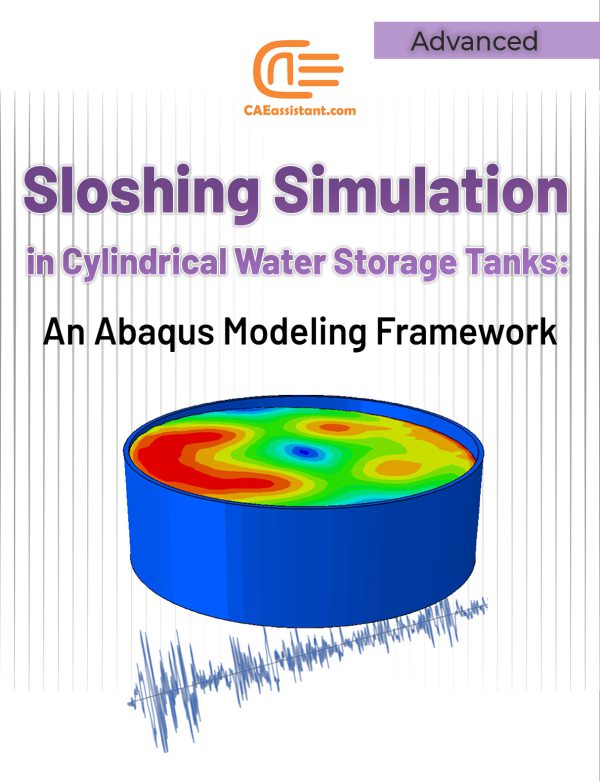

Sloshing Simulation in Cylindrical Water Storage Tanks: An Abaqus Modeling Framework

Cold Forming Simulation Using Abaqus CAE | Residual Stress Analysis

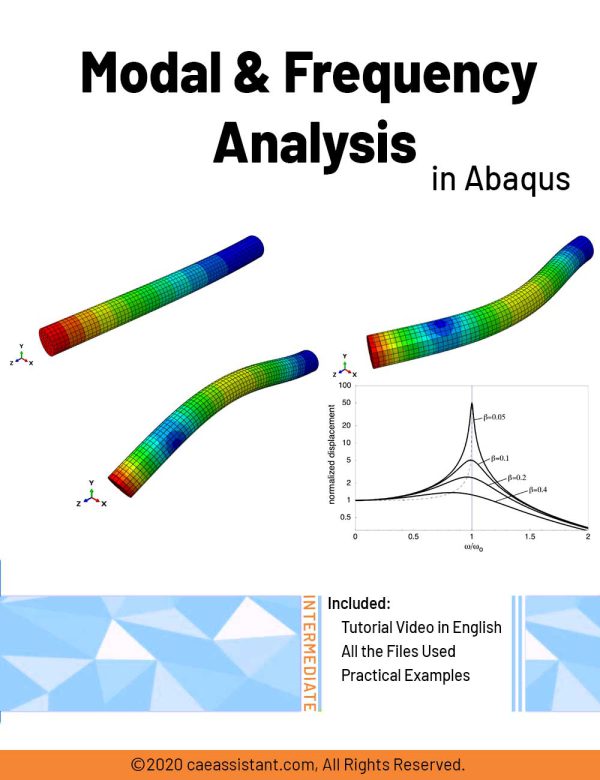

Modal and Frequency Analysis in Abaqus | Abaqus modal Analysis

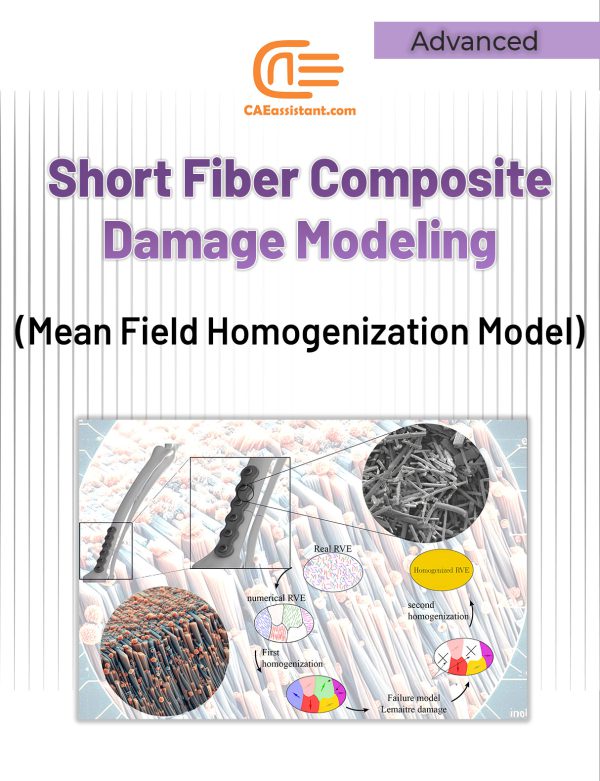

Short fiber composite damage (Mean Field Homogenization Model)

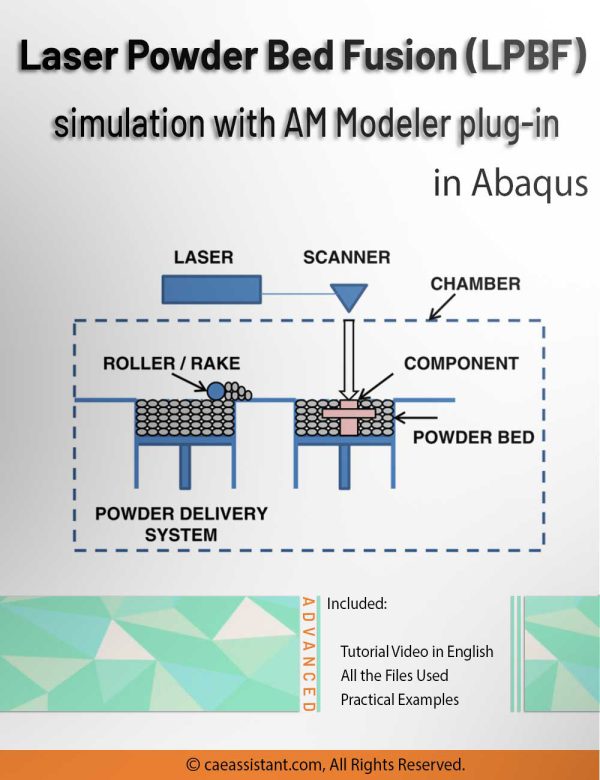

LPBF Printing Simulation in Abaqus | 3D Printing with Laser Powder Bed Fusion Process (LPBF) Method

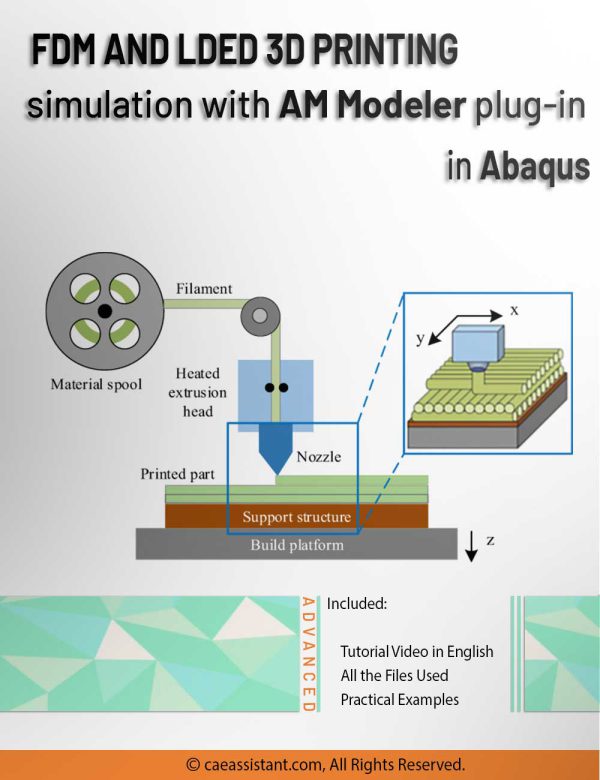

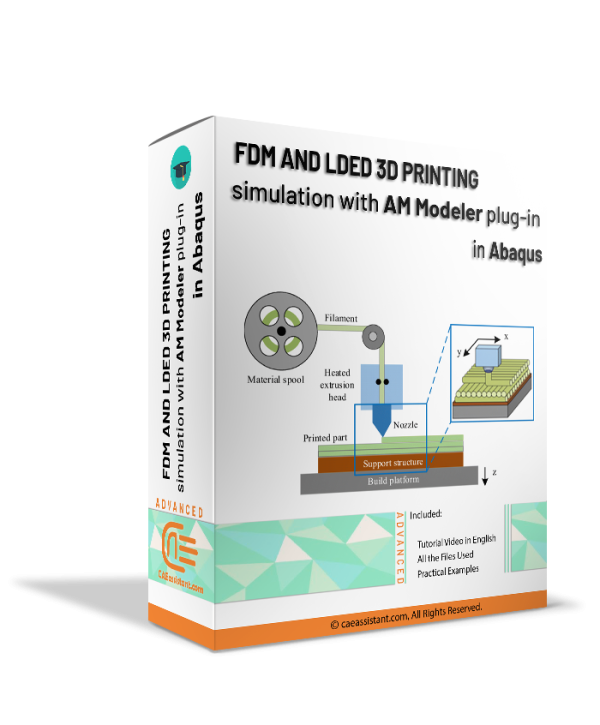

FDM Simulation in Abaqus | Simulating 3D Printing with Fused Deposition Modeling

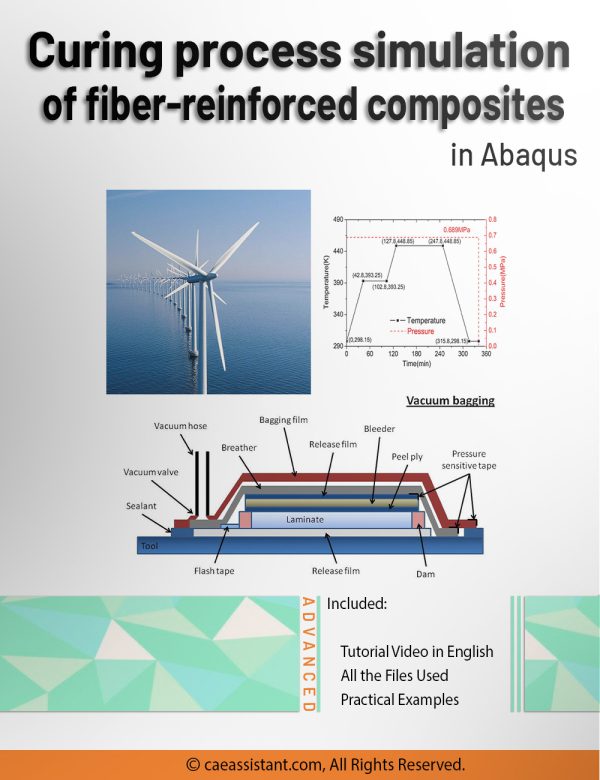

Curing process simulation in Abaqus

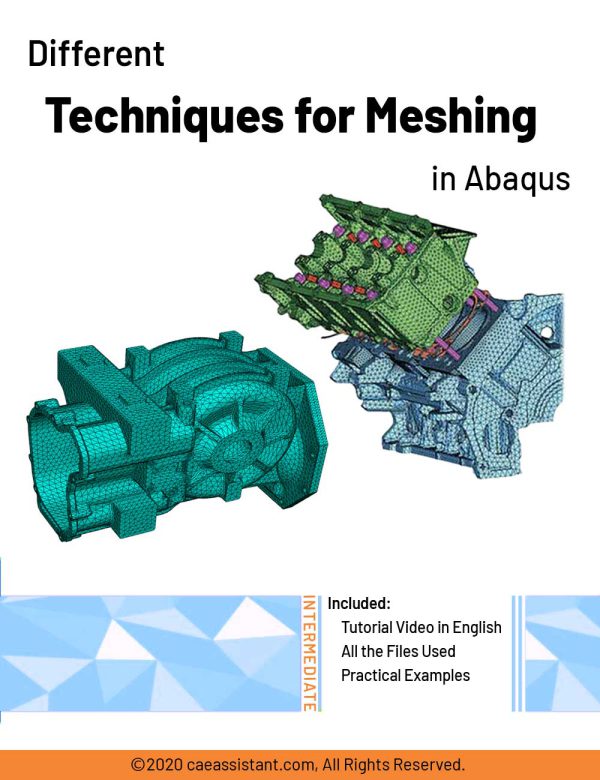

Different Techniques for Meshing in Abaqus

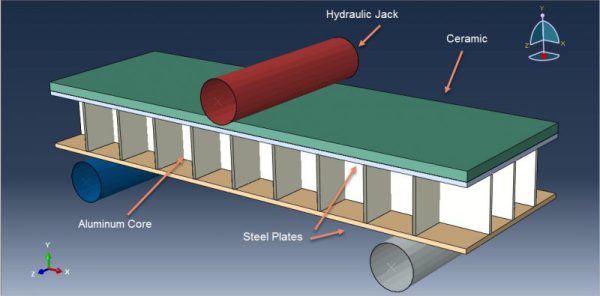

Johnson-Holmquist damage model in Abaqus

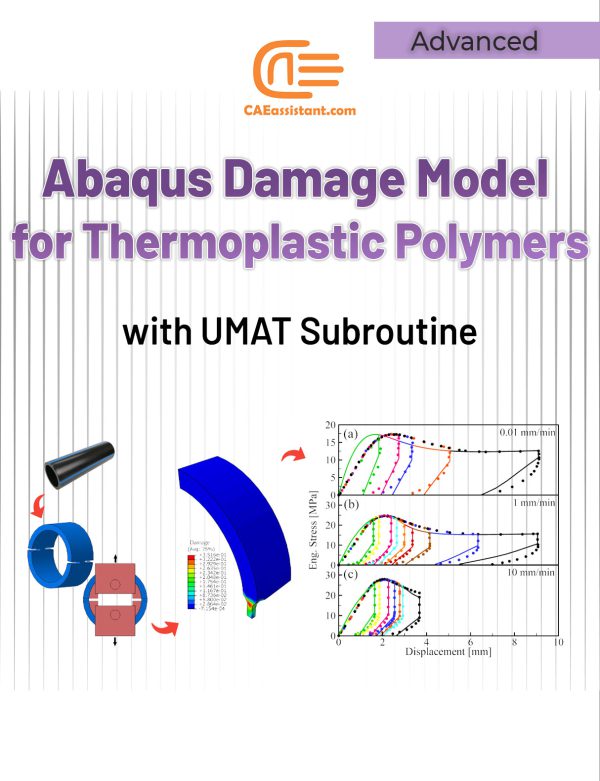

Damage Properties of Thermoplastic Polymers with UMAT Subroutine

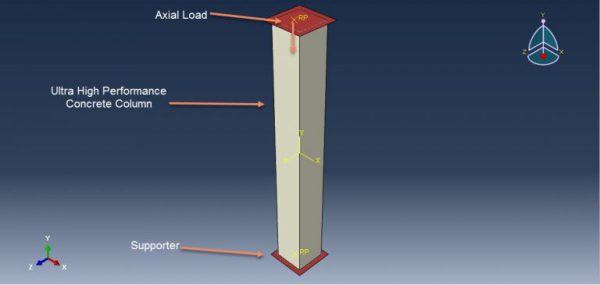

UHPC (Ultra-High Performance Concrete) structures simulation in Abaqus

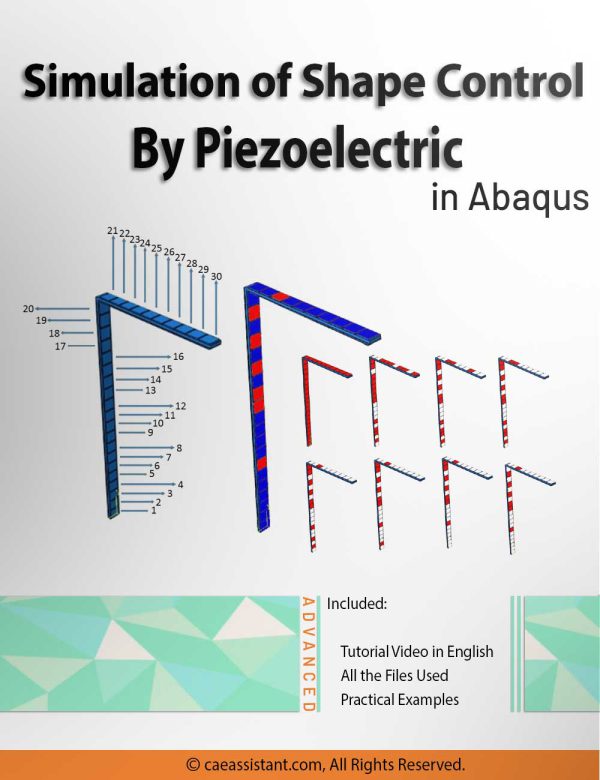

Simulation of shape control by piezoelectric in Abaqus

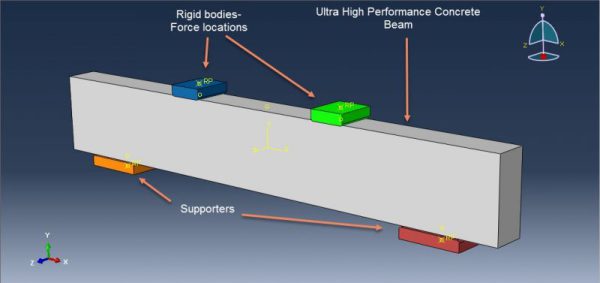

Ultra-High Performance Concrete (UHPC) beams simulation in Abaqus

Techniques of simulating Large and Complex models in Abaqus

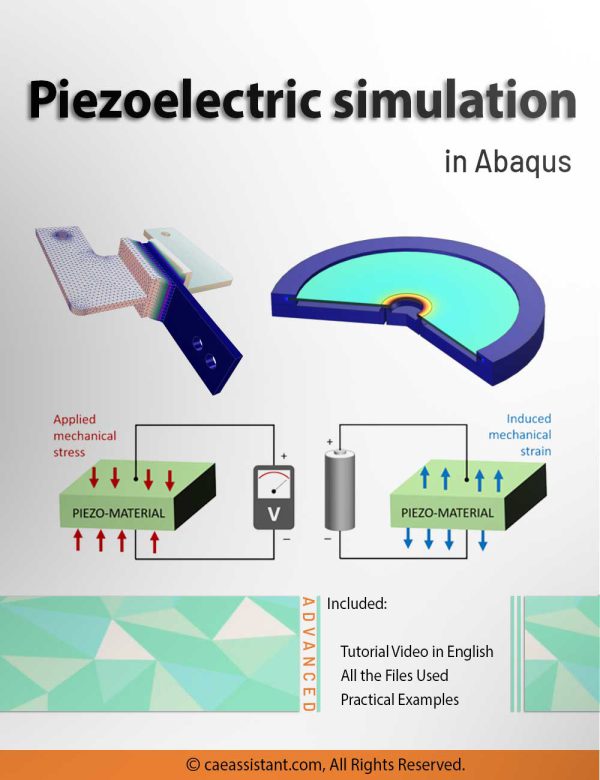

Piezoelectric simulation in Abaqus

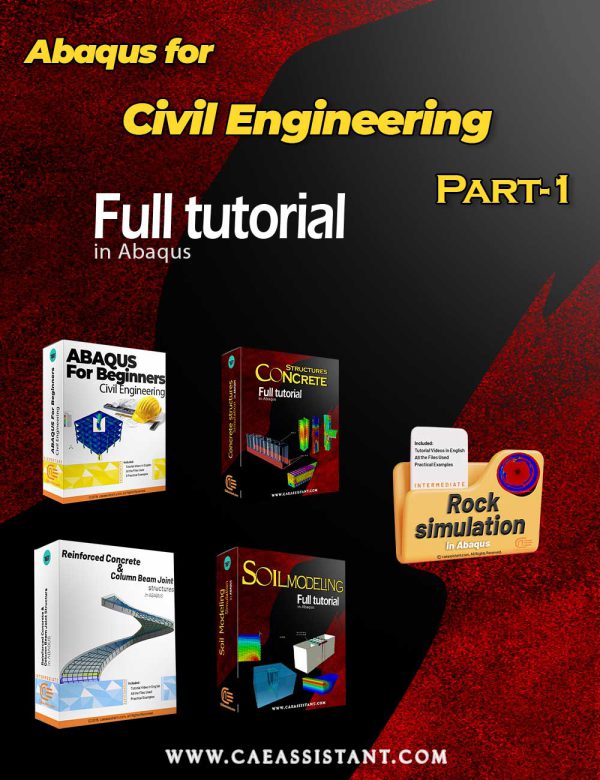

Abaqus for Civil Engineering Part-1

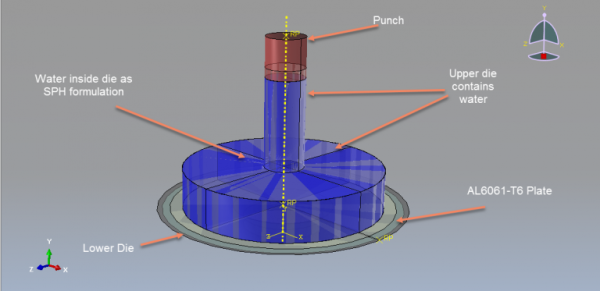

Hydroforming simulation in Abaqus