Forming

Cold Forming Simulation Using Abaqus CAE | Residual Stress Analysis

Have you ever heard of cold forming process? It refers to the reshaping of metals into desired forms at room temperature. It suits well for parts requiring high precision and a good surface finish. While cold forming offers many advantages, it is important to consider the potential for residual stresses within the material. The residual stresses in cold-formed components can influence their behavior, potentially affecting the quality of the final product. Experimentally measuring these stresses can be challenging. Numerical simulations offer a solution for cold forming residual stress analysis. Among the available numerical methods, Abaqus cold forming simulation has gained significant attention from researchers and practitioners. This training explores Abaqus cold forming analysis in detail. It includes three workshops that cover different steps in the cold forming process. For validation purposes, we have compared the results for the numerical simulation of cold forming with a reference solution for each workshop.

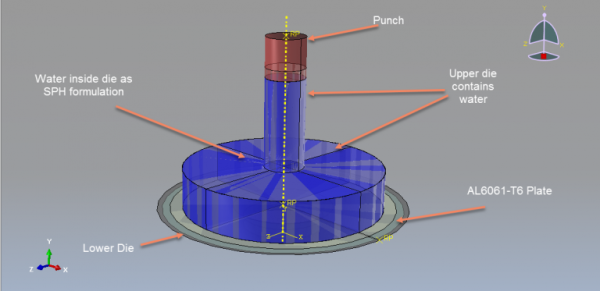

Hydroforming simulation in Abaqus

Notice: This package will be available one week after purchase.

Hydroforming is a metal forming process that allows the shaping of various metals, such as steel, stainless steel, copper, aluminum, and brass. It is a cost-effective and specialized form of die molding that utilizes highly pressurized fluid to shape the metal. Hydroforming can be classified into two main categories: sheet hydroforming and tube hydroforming. Sheet hydroforming uses a single die and a sheet of metal, while tube hydroforming involves expanding metal tubes using two die halves. Hydroforming simulation in Abaqus is a valuable tool for optimizing the hydroforming process. It enables engineers to predict and analyze important factors such as material flow, stress distribution, thinning, and wrinkling during the forming process. By accurately simulating the hydroforming process, engineers can optimize key parameters like fluid pressure, die design, and material properties to achieve the desired shape with minimal defects. In this package, you will learn hydroforming process simulation with the SPH method and using time-pressure curve.

ABAQUS Projects Package

If you need common industrial simulations in the fields of forming, fracture, explosion, impact, etc., this package can provide you with comprehensive training along with an instructional video file and software file. You can quickly meet your educational needs in learning the elementary and intermediate level of Abaqus software using this package.

Simulation of forming in ABAQUS

The forming in Abaqus is one of the most important manufacturing processes that can be used for producing different components. In this package, you will learn how to simulate the forming process in Abaqus and you can see the behavior of the material along this process. This package contains some examples that cover rolling, hydroforming, extrusion, ECAP, Cold forging, and drilling processes.

Notice: You can access this package 3 days after purchase.