Hydroforming

Hydroforming process simulation using VDLOAD subroutine in Abaqus

€ 170.0Dive into the intricacies of hydroforming simulation in Abaqus alongside the VDLOAD subroutine with our comprehensive guide. This tutorial delves into the essence of the Abaqus hydroforming simulation, unraveling the nuances of the hydroforming process simulation. Hydroforming, a specialized metal shaping technique applicable to diverse materials like steel, copper, and aluminum, is explored in depth.

In the workshop component, we specifically focus on advanced hydroforming simulation using the VDLOAD subroutine, highlighting its pivotal role in specifying fluid pressure on sheet metal forming. Learn how to apply the Functional Fluid Pressure Loading feature for precise control over fluid pressure dynamics. Additionally, explore the Smooth Amplitude option for defining part displacement seamlessly, without introducing dynamic changes during problem-solving.

Conclude your exploration with a comparative analysis of simulation outcomes, dissecting scenarios with and without fluid pressure using Abaqus hydroforming simulation. Engage in discussions on subroutine writing, delving into the intricacies of incorporating Fluid Pressure Loading into your simulations. This guide offers a natural progression through hydroforming and VDLOAD, providing valuable insights for efficient and accurate simulations.

Hydroforming simulation in Abaqus

€ 39.0Notice: This package will be available one week after purchase.

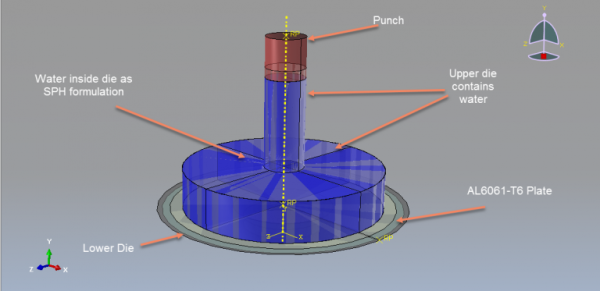

Hydroforming is a metal forming process that allows the shaping of various metals, such as steel, stainless steel, copper, aluminum, and brass. It is a cost-effective and specialized form of die molding that utilizes highly pressurized fluid to shape the metal. Hydroforming can be classified into two main categories: sheet hydroforming and tube hydroforming. Sheet hydroforming uses a single die and a sheet of metal, while tube hydroforming involves expanding metal tubes using two die halves. Hydroforming simulation in Abaqus is a valuable tool for optimizing the hydroforming process. It enables engineers to predict and analyze important factors such as material flow, stress distribution, thinning, and wrinkling during the forming process. By accurately simulating the hydroforming process, engineers can optimize key parameters like fluid pressure, die design, and material properties to achieve the desired shape with minimal defects. In this package, you will learn hydroforming process simulation with the SPH method and using time-pressure curve.

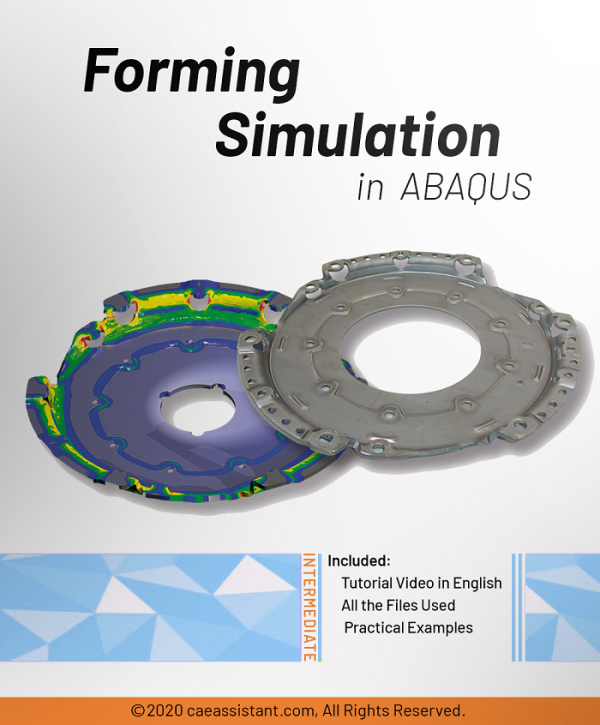

Simulation of forming in ABAQUS

€ 70.0The forming in Abaqus is one of the most important manufacturing processes that can be used for producing different components. In this package, you will learn how to simulate the forming process in Abaqus and you can see the behavior of the material along this process. This package contains some examples that cover rolling, hydroforming, extrusion, ECAP, Cold forging, and drilling processes.

Notice: You can access this package 3 days after purchase.

Forming simulations in ABAQUS

€ 170.0

In this training package, different types of forming simulations are presented along with different tips. These points include increasing the solution speed, different types of plasticity and damage models, different solvers, Lagrangian, CEL, and SPH methods and etc.