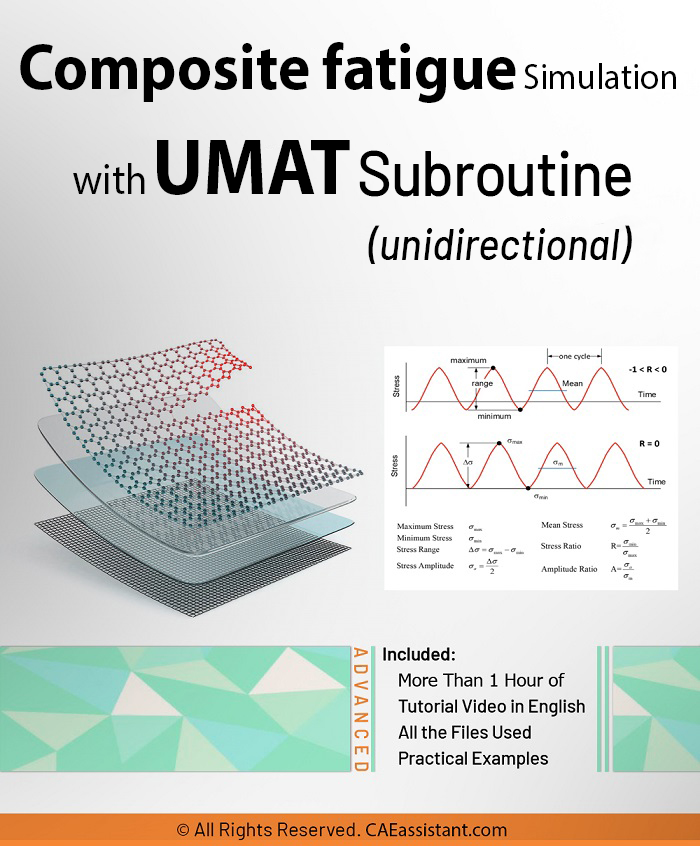

Composite Fatigue Simulation with UMAT Subroutine in ABAQUS (unidirectional)

€ 420.0

The composite fatigue training package completely teaches how to simulate and analyze a fatigue composite model with the help of UMAT Subroutine in Abaqus software. In this training package, we have provided all the files needed for your training, including articles, theories, how to write subroutines, and software settings.

Rated 4.69 out of 5