Get the best advanced engineering courses on Abaqus

Get the best advanced engineering courses on Abaqus

How will Advanced Engineering Courses help me?

ABAQUS FEA Training (Free cantilever beam tutorial)

Abaqus for beginners (Mechanical Engineering)-Free Version

Python scripting in ABAQUS-(FREE Version)

UMAT Subroutine (VUMAT Subroutine) in ABAQUS-Free Version- UMAT Abaqus example

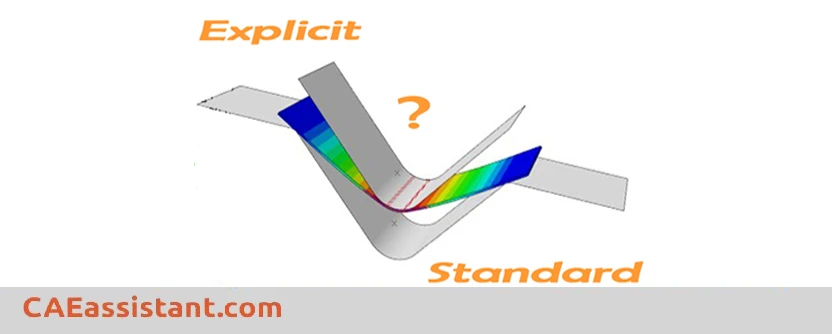

"UMAT Subroutine (VUMAT Subroutine) introduction" is used when the material model is not available in ABAQUS software. If you follow this tutorial package, including standard and explicit solver, you will have the ability to write, debug and verify your subroutine based on customized material to use this in complex structures. These lectures are the introduction to writing advanced UMAT and VUMAT subroutines in hyperelastic Martials, Composites, and Metal, and so on. Watch Demo

"Advanced UMAT Subroutine (VUMAT Subroutine)" training package helps Abaqus users to prepare complex UMAT and VUMAT subroutines. This training package is suitable for those who are familiar with subroutine or want to learn UMAT/VUMAT subroutine Professionally. Equations for computational plasticity based on kinematic stiffness are also discussed. In addition, metal damage has been implemented based on Johnson Cook's model. Watch DemoAdvanced Finite Element Analysis of Off-Axis Tunnel Cracking Laminates

An Efficient Stiffness Degradation Composites Model with Arbitrary Cracks | An Abaqus Simulation

FREE ABAQUS TUTORIAL PDF

Golden Package

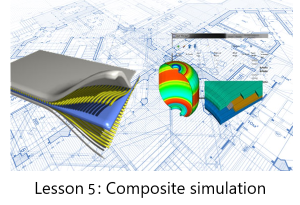

Composite simulation for experts-Part-1

Abaqus for Civil Engineering Part-1

ABAQUS Projects Package

ABAQUS course for beginners | FEM simulation tutorial

Bio-Mechanical Abaqus simulation Full package

This video tutorial package offers a comprehensive guide to biomechanical simulations using Abaqus, covering a range of applications from dental to orthopedic and cardiovascular analyses. The workshops delve into finite element method (FEM) simulations, exploring static loading on human teeth, crack growth in bones under bending, bone drilling, and the behavior of titanium foam implants. Each tutorial emphasizes the importance of precise modeling and meshing techniques, utilizing dynamic explicit procedures, Johnson-Cook material models, and various contact and boundary conditions to simulate realistic biomechanical behaviors. Additionally, the package includes fluid-structure interaction (FSI) simulations for blood flow within coronary vessels, addressing both Newtonian and non-Newtonian models, and demonstrates the integration of computational fluid dynamics (CFD) with structural analysis for enhanced accuracy. The lessons complement the workshops by introducing fundamental FEM concepts, solver selection, explicit analysis considerations, and damage modeling, ensuring users gain a solid understanding of both theoretical and practical aspects of biomechanical simulations in Abaqus.

We also offer a similar budget-friendly package that includes all the workshops from this package. However, since it does not include the lessons, it is available at a lower price. You can purchase it on our website at a more competitive rate than similar platforms.Golden Package

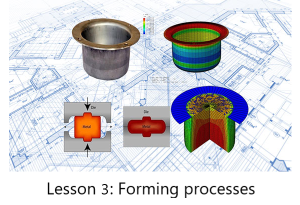

Curing process simulation in Abaqus

Composite Fatigue Simulation with UMAT Subroutine in ABAQUS (unidirectional)

UMAT Subroutine (VUMAT Subroutine) introduction

This package is usable when the material model is not available in ABAQUS software. If you follow this tutorial package, including standard and explicit solver, you will have the ability to write, debug and verify your subroutine based on customized material to use this in complex structures. These lectures are an introduction to write advanced UMAT and VUMAT subroutines in hyperelastic Martials, Composites and Metal and so on.

Watch DemoABAQUS course for beginners | FEM simulation tutorial

Additive Manufacturing or 3D Printing Abaqus simulation

Abaqus Crack Growth | Practical Examples

Abaqus Concrete Structure Modeling | Practical Examples (Part 4)

Abaqus Concrete Structure Modeling | Practical Examples (Part 3)

Abaqus Concrete Structure Modeling | Practical Examples (Part 2)

Computational Predictions for Predicting the Performance of Structure

This package focuses on developing and applying predictive models for the structural analysis of steel and concrete components subjected to fire and subsequent earthquake loading. To accurately simulate the complex behavior of these structures, finite element analysis (FEA) using ABAQUS is employed. The Taguchi method optimizes the number of samples needed for FE analysis, and this method is used with SPSS after explanation its concept. However, due to the computational demands of FEA, various machine learning techniques, including regression models, Gene Expression Programming (GEP), Adaptive Network-Based Fuzzy Inference Systems (ANFIS), and ensemble methods, are explored as surrogate models. These models are trained on large datasets of FEA results to predict structural responses efficiently. The performance of these models is evaluated using statistical metrics such as RMSE, NMSE, and coefficient of determination.

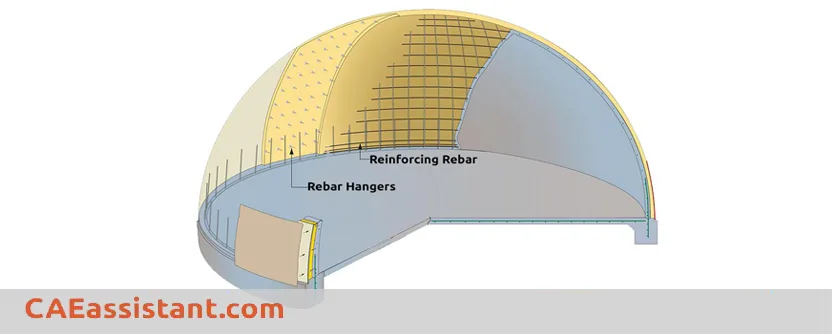

Damage Prediction in Reinforced Concrete Tunnels under Internal Water Pressure

This tutorial package equips you with the knowledge and tools to simulate the behavior of reinforced concrete tunnels (RCTs) subjected to internal water pressure. It combines the power of finite element (FE) modeling with artificial intelligence (AI) for efficient and accurate analysis. The Taguchi method optimizes the number of samples needed for FE analysis, and this method is used with SPSS after explanation its concept.

By leveraging Artificial Intelligence (AI) techniques such as regression, GEP, ML, DL, hybrid, and ensemble models, we significantly reduce computational costs and time while achieving high accuracy in predicting structural responses and optimizing designs.

Computational Modeling of Steel Plate Shear Wall (SPSW) Behavior

This course equips engineers with the tools to design and analyze Steel Plate Shear Wall (SPSW) and Reinforced Concrete Shear Walls (RCSW) subjected to explosive loads. Traditional Finite Element (FE) simulation is time-consuming and requires numerous samples for accurate results. This package offers a more efficient approach using Artificial Intelligence (AI) models trained on FEA data. You'll learn to develop FE models of SPSW and RCSW in ABAQUS software, considering material properties, interactions, and boundary conditions. The Taguchi method optimizes the number of samples needed for FE analysis, and this method is used with SPSS after explanation its concept.

We then delve into AI modeling using MATLAB. Explore various methods like regression, Machine Learning (ML), Deep Learning (DL), and ensemble models to predict the behavior of SPSW and RCSW under blast loads. Statistical analysis helps compare model accuracy. By combining FE analysis with AI models, you'll gain a powerful tool for designing blast-resistant structures while saving time and resources.

Abaqus advanced tutorials on concrete members

Welcome to the "Abaqus Advanced Tutorials on Concrete Members" course, designed to provide civil and structural engineers with cutting-edge expertise in finite element modeling (FEM) and simulation using Abaqus. This advanced-level course focuses on the detailed modeling of complex concrete and composite columns under various loading conditions. Topics include the simulation of tubed reinforced concrete columns, concrete-filled double skin steel columns, and fiber-reinforced polymer (FRP) composite columns. Participants will delve into axial and eccentric compression loading scenarios, with a special focus on hollow and tapered cross-sections. The course also emphasizes comparing simulation results with experimental data from published research, ensuring practical relevance and accuracy. By the end of the course, learners will be equipped with the necessary skills to tackle advanced structural analysis challenges using Abaqus, reinforcing their understanding of concrete member behavior in real-world applications.

Abaqus basic tutorials on concrete beams and columns

Welcome to the “Abaqus Basic Tutorials on Concrete Members,” a comprehensive course tailored for civil and structural engineers seeking to master finite element modeling (FEM) of concrete structures. This tutorial covers key concepts such as plain concrete beam and column modeling, reinforced concrete members, and fiber-reinforced polymer (FRP) composites. The course guides learners through the application of boundary conditions, material properties, and various loading conditions in Abaqus. Key topics include plain concrete beam and column modeling, reinforcement modeling with steel bars and stirrups, and fiber-reinforced polymer (FRP) reinforcement techniques. Participants will also explore comparing simulation results with experimental data, as well as interpreting critical outcomes such as stress distribution and failure modes. Through hands-on workshops, learners will simulate structural behaviors under axial, lateral, and compression loads, ensuring a practical understanding of FEM for concrete members. By the end of this course, participants will be proficient in using Abaqus to model and analyze concrete structures, reinforced elements, and advanced composites, providing them with a strong foundation for structural analysis and design.

Abaqus Crack Growth | Practical Examples

Abaqus Concrete Structure Modeling | Practical Examples (Part 4)

Abaqus Concrete Structure Modeling | Practical Examples (Part 3)

Abaqus Concrete Structure Modeling | Practical Examples (Part 2)

Abaqus Concrete Structure Modeling | Practical Examples (Part 1)

Abaqus steel material and structures | Practical examples

Latest Blogs

Our Vendors

Our Consultants

Here in CAE assistant, Our team of experts works on advanced engineering courses for example Abaqus course, focusing mostly on solid mechanics engineering. We provide simulation tutorials for, “shape-memory alloys”, “3D printing manufacturing process” & other topics. We aim to produce contents that cover advanced levels of each topic rather than focusing on general and elementary courses that can be easily found on the internet & YouTube. Packages also include sample codes to apply advanced theories in the analysis software.

The finite element method (FEM) approach can be used to solve problems in a variety of engineering and mathematical physics fields, such as structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. It is quite impossible to find analytical mathematical solutions to model the behavior of physical systems with complex geometries, loadings, and material properties and these differential equations typically cannot be solved because of the complex circumstances of the problem. FEM is a comprehensive tool to solve many problems and boost innovations in engineering. The main advanced engineering course that we currently cover is FEM in various software like Abaqus, Comsol and Ansys.

What is Abaqus CAE?

Abaqus CAE is used for pre-processing (modeling and analysis of mechanical parts and assemblies) as well as viewing the results of finite element analysis. The automobile, aerospace, and industrial products industries use Abaqus because of the software’s extensive material modeling capabilities and adaptability (for example, users can design their own material models so that novel materials could likewise be simulated in Abaqus), the product is popular among non-academic and research institutes in engineering as well. Abaqus CAE is the perfect software for production-level simulations when various fields need to be coupled, because it offers a good selection of multi-physics features, including coupled acoustic-structural, piezoelectric, and structural-pore capabilities.

You can find the best training courses for ABAQUS software on CAEassistant.com; as well as courses from the primary and step-by-step training of each Abaqus module to the implementation of the most complex theories in this software fore example Abaqus fracture.

What is our innovation in CAEassistant.com?

The CAE assistant community is rapidly increasing its coding speed by using basic codes of the main and essential theories of solid mechanics and their video tutorials, leading to accelerated industrial and scientific development.

Want to join us?

Are you a solid mechanics expert? Do you have the ability to provide advanced engineering courses, especially Abaqus training courses?

We can help you publish your scientific research so that researchers and innovators can benefit from the methods and results. You can create a video course as an educational package with us on the CEAassistant.com website. Join us and share your knowledge with the world.

CAE assistant aims to provide advanced engineering courses, focusing on specific topics rather than general and elementary topics, which is why our services stand unique in the industry, differing our products from websites such as Udemy and Coursera.

Whether you’re a seasoned Abaqus user or just starting out, our comprehensive blog articles and informative posts are packed with valuable insights and practical tips to elevate your Abaqus simulation skills. Delve into our wealth of knowledge and discover how to optimize your Abaqus workflow, enhance your computational efficiency, and gain deeper understanding of complex engineering scenarios. Whether you’re looking for tips on pre-processing, contact modeling, dynamic analysis, or post-processing techniques, our blog is your one-stop resource for mastering Abaqus simulation and achieving superior results.

Explore our comprehensive Abaqus tutorial page, featuring free PDF guides and detailed videos for all skill levels. Discover both free and premium packages, along with essential information to master Abaqus efficiently. Start your journey with our Abaqus tutorial now!

Explore the transformative role of AI in mechanical engineering with our comprehensive article. From understanding AI fundamentals to its applications in CAD, CFD, and FEA, and emerging technologies like digital twins and quantum computing, we cover it all. Equip yourself with the knowledge to harness AI for innovative solutions and future advancements in the field.

Explore advanced composite damage and fatigue analysis techniques with our insightful articles. Learn about unidirectional composite materials damage, their damage mechanisms, and failure criteria, as well as how to simulate these damages in Abaqus. Dive into the fatigue analysis of composite fatigue analysis, understanding fatigue damage, behavior, and simulation using the UMAT subroutine. Enhance your knowledge and simulation accuracy with these comprehensive guides.

Speaking of damage and damage in composites, the Hashin Failure Criteria is a crucial tool in evaluating the structural integrity of composite materials, allowing engineers to predict different failure modes such as fiber breakage and matrix cracking.

Learn more the complexities of composite material failure with our deep dive into the Tsai Hill failure criterion. This essential tool empowers engineers to predict the onset of failure in composite structures, ensuring safety and reliability in critical applications.

Learn about the composite curing process. This blog post will explain how composite materials are cured to achieve their desired properties. We will discuss different curing methods and the importance of optimizing the curing cycle. Additionally, we will explore how simulation tools like Abaqus can be used to predict and improve the curing process.

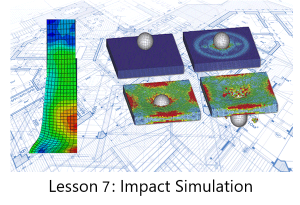

Abaqus Element deletion is a powerful technique for simulating material failure by removing elements from a model when they meet specific damage criteria. This method enhances the accuracy of simulations involving fracture, impact, or fatigue, making it essential for engineers aiming to realistically model material degradation and failure.

Fatigue analysis is essential for understanding how materials respond to repeated or cyclic loading, as even stresses below their breaking point can lead to crack formation and eventual failure. This type of analysis helps engineers predict when a component might fail, taking into account the stages of fatigue crack growth and factors like loading conditions and material properties.

Discover how XFEM Abaqus simplifies crack and fracture simulations! Our latest blog covers key concepts like enrichment functions and cohesive crack modeling, plus step-by-step guides for 2D and 3D simulations. Solve complex engineering challenges with precision.

Discover how DLOAD and VDLOAD subroutines in Abaqus let you define complex, custom loads for precise simulations. From wind pressures to wave loads, our guide covers it all!

Discover the power of Additive manufacturing simulation—essential for tackling challenges like warping, optimizing designs, and achieving precision in 3D printing. Our blog covers key parameters and highlights three top software tools to help you master simulation and improve your prints.

Looking to improve the efficiency of your designs? Our article on structural optimization in Abaqus dives into the essentials of topology and shape optimization techniques.

Ready to take your metal 3D printing simulations to the next level? Our article covers the Inherent Strain Method in Abaqus, showing you how to effectively simulate residual stresses and distortions in additive manufacturing.

Looking to customize your heat fluxes and thermal distributions in Abaqus? Our guide on the DFLUX and VDFLUX subroutines walks you through the process of applying custom thermal loads to your simulations.

Want to finally understand shear force and how it affects structural elements? This blog breaks it all down in a simple way, with clear explanations about bending moment and their diagrams as well.

Struggling to understand moment of inertia and moment of area? This simple, beginner-friendly guide breaks down everything you need to know — with clear examples and visuals. Whether you’re a student or a working engineer, this is the only blog you need to finally get these essential concepts.

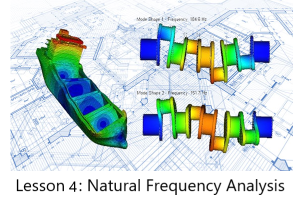

If you’re looking to understand how structures vibrate and how to prevent resonance issues, our latest blog post on modal analysis in Abaqus is a must-read. It breaks down the essentials of modal analysis in a clear and approachable way, helping you grasp how to identify natural frequencies and mode shapes.

Dive into the world of steel structure analysis with our blog, where we break down the importance of analyzing steel beams and joints, understanding structural models, and designing efficient steel structures. Learn the best techniques, compare Abaqus FEM with traditional methods, and explore practical tips for mastering structural steel design.

| ✅ Subscribed students | +80,000 |

| ✅ Upcoming courses | +300 |

| ✅ Tutorial hours | +300 |

| ✅ Tutorial packages | +100 |