AI in mechanical engineering is no longer a futuristic concept; it’s actively making waves in various mechanical engineering domains. This roadmap will explore the current and future applications of AI in mechanical engineering, providing insights on how to leverage this technology effectively. Key areas of focus include design optimization, predictive maintenance, advanced robotics, additive manufacturing, material science, complex CAD, computational fluid dynamics (CFD), and finite element analysis (FEA). Additionally, we’ll delve into the essential skills and collaborative efforts needed to harness the power of AI in this field.

The Intersection of AI and Mechanical Engineering

AI and mechanical engineering intersect at the convergence of traditional engineering principles and cutting-edge technology. This synergy is transforming the way engineers approach design, analysis, and manufacturing processes. Mechanical engineering, a discipline rooted in physics and materials science, now leverages AI’s capabilities in data analysis, machine learning, and predictive modeling to push the boundaries of innovation.

The integration of AI in mechanical engineering enhances precision, efficiency, and creativity, enabling engineers to solve complex problems and develop advanced systems. From optimizing design parameters to predicting maintenance needs and creating autonomous machines, the intersection of AI and mechanical engineering is reshaping industries and driving progress.

1. Understanding AI and Its Applications in Mechanical Engineering

1.1 What is AI?

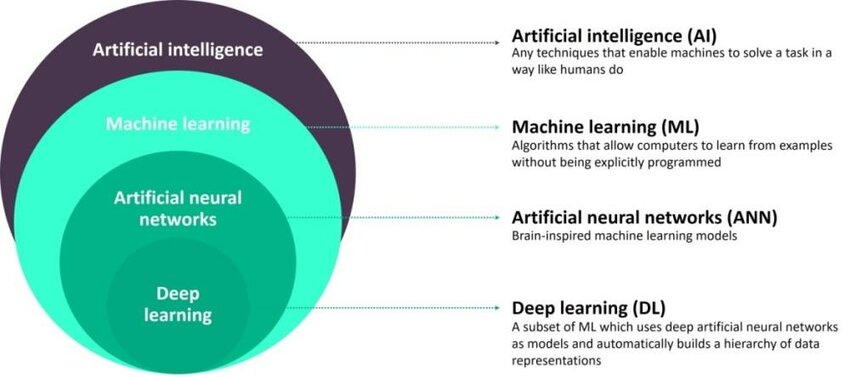

Artificial Intelligence (AI) refers to the simulation of human intelligence in machines designed to think and learn like humans. It encompasses various technologies, including machine learning (ML), neural networks, and natural language processing (NLP). In mechanical engineering, AI is used to process large amounts of data, identify patterns, and make predictions, which significantly enhances the decision-making process.

Fig1: AI and related keywords Ref

1.2 Key AI Applications in Mechanical Engineering

Design Optimization

Traditionally, design refinement relied on trial and error. AI algorithms can now analyze countless design parameters, materials, and operating conditions. This allows for rapid exploration of design possibilities, leading to lighter, stronger, and more efficient products. AI-driven generative design tools, like Autodesk’s Dreamcatcher, take design requirements as inputs and generate numerous feasible designs, helping engineers select the optimal solution by evaluating trade-offs.

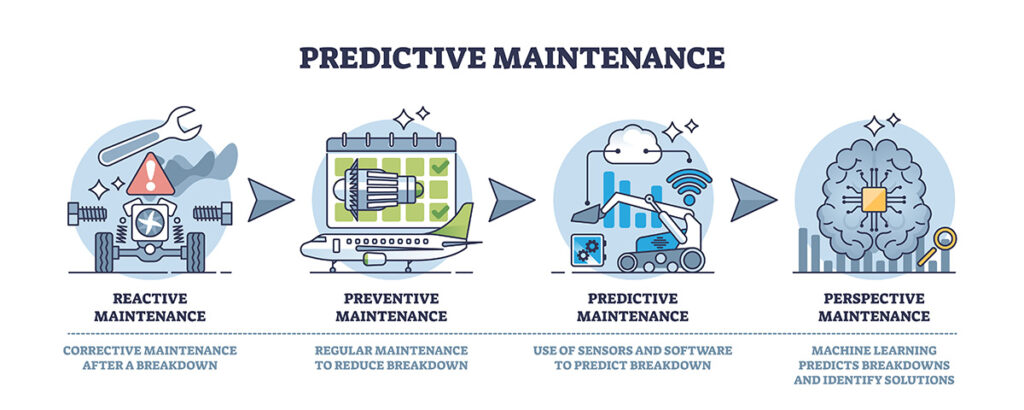

Predictive Maintenance

Imagine a world where machines predict their own maintenance needs! AI, combined with sensor data analysis, can identify anomalies and predict potential failures before they occur. This empowers engineers to implement preventive maintenance, minimizing downtime and maximizing productivity. For instance, AI systems can monitor the health of machinery in real-time, analyzing vibration data, temperature changes, and operational patterns to forecast maintenance requirements.

Fig2: Level of Maintenance Ref

Advanced Robotics

The rise of collaborative robots (cobots) working alongside humans is fueled by AI and ML in mechanical engineering. AI algorithms enable cobots to learn from their environment and adapt to changing tasks, making them valuable partners in manufacturing. These robots can assist in assembly lines, handle complex tasks, and ensure precision, significantly enhancing productivity and safety in industrial settings.

Additive Manufacturing (3D Printing)

AI applications in mechanical engineering are optimizing 3D printing processes by suggesting optimal printing parameters, material usage, and support structures. This leads to shorter printing times, reduced material waste, and higher quality printed parts. By analyzing vast amounts of data from previous prints, AI can predict and correct potential issues, ensuring consistent and reliable production. To explore these advancements further and enhance your projects, consider 3D printing simulation in Abaqus, which offers comprehensive tools for optimizing additive manufacturing processes.

3d Printing in Medicine Ref: Copilot AI

Material Science

The vast universe of potential materials can be overwhelming. AI algorithms can analyze extensive databases of material properties, helping engineers discover novel materials with specific characteristics for groundbreaking applications. This accelerates the development of new materials that are lighter, stronger, and more durable, driving innovation across various industries.

2. AI in Simulation and Analysis Tools

2.1 AI Helping in Complex CAD

AI used in Computer-Aided Design (CAD) generally works on knowledge-based systems. Design artifacts, rules, and problems in CAD are stored, which later assist CAD designers. The merging of AI and CAD is done through Model-Based Reasoning (MBR). Many new releases of software packages are using knowledge-based systems. A major field for the application of AI is Generative Design. Generative design tools take design requirements as input and give possible designs as output. For example, SolidWorks introduced topology optimization in its 2018 version, using algorithms based on generative design principles.

2.2 Artificial Neural Networks in CFD

Computational Fluid Dynamics (CFD) has been of great interest among scientists, engineers, and mathematicians. The turbulence and chaos associated with fluid mechanics have made it difficult to solve with Direct Numerical Simulation (DNS). AI, particularly Artificial Neural Networks (ANN), is gaining traction for its potential to approximate flow behavior with less computing power and time. ANN models can provide good agreement with traditional CFD models, though they require extensive training with example simulations. While ANNs offer efficient flow predictions, they currently lack the ability to provide detailed insights into flow mechanisms.

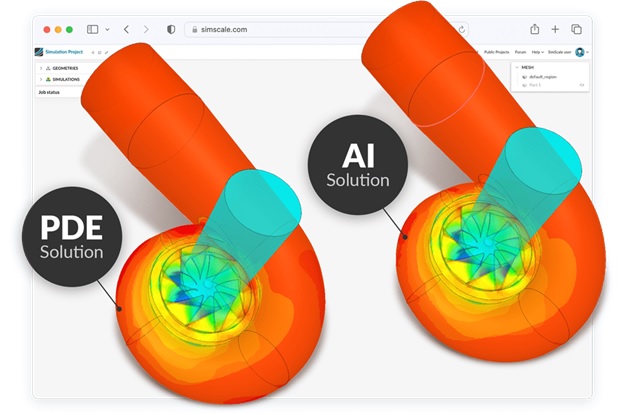

2.3 Finite Element Analysis (FEA)

Finite Element Analysis (FEA) is crucial for predicting how products react to real-world forces, vibration, heat, and other physical effects. AI enhances FEA by optimizing meshing processes, identifying potential failure points, and reducing computational times. Machine learning models can predict stress distribution and deformation patterns, enabling more accurate and efficient simulations. AI-driven FEA tools help engineers quickly iterate designs and make data-driven decisions to improve product performance.

AI applications in FEA : A case – SimScale GmbH announced fully integrated and cloud-native A.I. based physics predictions coming to its simulation software. SimScale has partnered with the leading A.I. for accelerated engineering developer, NAVASTO to integrate their solutions into the SimScale platform which will enable engineers to design in real-time using side-by-side physics and A.I. generated analysis results. Ref

3. Emerging Trends and Technologies

The integration of AI into mechanical engineering is not static; it is continually evolving with new trends and technologies that promise to revolutionize the field further. Some of the most exciting emerging trends include:

3.1 Digital Twins

Digital twins are virtual replicas of physical assets, systems, or processes that use real-time data to simulate their performance. AI enhances digital twins by providing predictive analytics, allowing engineers to test scenarios and optimize performance without physical trials. This technology is particularly beneficial in complex systems like aerospace, automotive, and industrial manufacturing.

3.2 Edge Computing

Edge computing brings computation and data storage closer to the location where it is needed, improving response times and saving bandwidth. In mechanical engineering, edge computing combined with AI enables real-time monitoring and control of machinery and processes, enhancing efficiency and reducing latency.

3.3 Augmented Reality (AR) and Virtual Reality (VR)

AR and VR, powered by AI, are transforming how engineers design, test, and maintain equipment. These technologies offer immersive experiences for training, prototyping, and troubleshooting, reducing the need for physical models and enabling remote collaboration.

3.4 Blockchain for Supply Chain Management

Blockchain technology, integrated with AI, enhances transparency and traceability in supply chains. This ensures the authenticity of materials and parts, reduces fraud, and improves efficiency in logistics and procurement processes.

3.5 Quantum Computing

Although still in its early stages, quantum computing holds immense potential for solving complex mechanical engineering problems that are beyond the reach of classical computers. AI algorithms running on quantum computers could revolutionize materials science, optimization problems, and simulation tasks.

4. A Glimpse into the Crystal Ball: The Future of AI in Mechanical Engineering

As AI continues to evolve, we can expect even more transformative applications of AI in mechanical engineering:

4.1 Autonomous Machines

Imagine self-driving cars that not only navigate roads but also adapt to unforeseen situations. AI will play a crucial role in developing autonomous machines capable of independent decision-making in complex environments. These machines will revolutionize industries such as automotive, aerospace, and manufacturing by enhancing efficiency and safety.

4.2 Generative Design

AI algorithms will take design optimization to a whole new level. By understanding the desired function and performance parameters, AI can autonomously generate innovative design solutions, pushing the boundaries of what’s possible. This will lead to the creation of more sophisticated, efficient, and sustainable products.

4.3 Human-Machine Collaboration

The future of work in mechanical engineering will see seamless collaboration between humans and AI. Engineers will leverage AI’s analytical prowess to focus on creative problem-solving and strategic decision-making. This symbiotic relationship will enhance productivity and innovation, allowing engineers to tackle more complex challenges.

5. Equipping Yourself for the Journey: How to Use AI in Mechanical Engineering

The world of AI in mechanical engineering is no longer exclusive to a select few. Here’s how to use AI in mechanical engineering effectively:

5.1 Embrace Continuous Learning

AI is a rapidly evolving field. Stay updated on the latest advancements in AI and ML algorithms relevant to mechanical engineering. Consider online courses, workshops, or even pursuing certifications in AI for engineers. This will ensure you remain at the forefront of technological advancements and can effectively integrate AI into your projects.

5.2 Data is King

AI thrives on data. Familiarize yourself with data collection techniques from sensors, simulations, and past projects. Develop a strong understanding of data analysis tools and techniques to extract valuable insights for AI algorithms. Proper data management and analysis will significantly enhance the accuracy and efficiency of AI applications.

5.3 Learn to Code

While you don’t need to be a full-fledged programmer, basic coding skills in languages like Python will empower you to interact with AI tools and tailor them to your specific engineering needs. Understanding coding principles will also help you collaborate more effectively with software developers and data scientists.

5.4 Collaboration is Key

The use of AI in mechanical engineering requires a collaborative approach. Work with data scientists, AI specialists, and fellow engineers to bridge the gap between technical expertise and AI implementation. By fostering a collaborative environment, you can leverage diverse skill sets and perspectives to develop innovative solutions.

By developing the right skillset and fostering a collaborative spirit, you can become a valuable asset in the world of AI-powered mechanical engineering. The integration of AI into mechanical engineering is not just a trend; it’s a paradigm shift that will redefine the industry. Embrace this transformation, equip yourself with the necessary skills, and be prepared to contribute to the future of AI in mechanical engineering projects.

6. Conclusion

The integration of AI in mechanical engineering is reshaping the industry, driving innovation, and enhancing efficiency across various domains. From design optimization to predictive maintenance, advanced robotics, and additive manufacturing, the applications of AI in mechanical engineering are vast and transformative. As AI continues to evolve, its impact on mechanical engineering will only grow, offering new opportunities for innovation, collaboration, and improved performance. Embracing AI technologies and developing the necessary skills will be crucial for engineers to stay ahead in this rapidly advancing field. The future of AI in mechanical engineering is bright, promising smarter, more efficient, and groundbreaking advancements that will redefine the industry.

References: https://ahmadwriter.medium.com/ai-in-mechanical-engineering-a-complete-guide-cb867df0b01

| ✅ Subscribed students | +80,000 |

| ✅ Upcoming courses | +300 |

| ✅ Tutorial hours | +300 |

| ✅ Tutorial packages | +100 |

Thank you for being with us in this article. In order to always provide you with up-to-date and engaging content, we need to be familiar with your educational and professional experiences so that we can offer articles and lessons that are most useful to you.