A common technique for numerically resolving differential equations that appear in engineering and mathematical modeling is the Finite Element Method (FEM). The conventional topics of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential are typical issue areas of interest. We can say FEM engineering is a numerical approach for solving physics and engineering problems. Be with us till the end of this post to understand the FEM and finite element analysis (FEA analysis), see some of its applications and learn how to work with it.

Contents

Finite Element Method

3. General Finite Element Method steps

3.1. Step 1: Discretize and Select the Element Types

3.1.1. Element shape function

3.1.2. Linear and Higher-Order Elements

3.2. Step 2: Select U Function (degrees of freedom)

3.3. Step 3: Determination of stress/displacement and stress/strain relationships

3.4. Step 4: Derive the Element Stiffness Matrix and Equations

3.4.1. Direct equilibrium Method

3.4.2. Work or energy Method

3.4.3. Weighted residuals Method

3.4.4. Derivation of the Stiffness Matrix for a Spring element

3.5. Step 5: Assemble the Element Equations to get the Global or Total Equations, and then add Boundary Conditions

3.6. Step 6: Determine the Unknown Degrees of Freedom

3.7. Step 7: Solve for the Element Strains and Stresses

3.8. Step8: Analyze the Result

4.1. Aerospace & FEA analysis

4.2. Naval & FEA analysis

4.3. Sports & FEA analysis

5. Benefits of Using the Finite Element Method

6. Limitation of Finite Element Method

9. Example of process FEM to FEA

9.1. Step 1: Modeling

9.2. Step 2: Choose the material of the structure

9.3. Step 3: Assemble the structure

9.4. Step 4: Choose the solution method

9.5. Step 5: Create boundary condition

9.6. Step 6: Choose the element type

9.7. Step 7: result

Read More: abaqus units system / abaqus consistent units

1. Introduction to finite element analysis

Science can amuse and fascinate us all, but engineering changes the world, and the Finite Element Method (FEM) is a kind of science world changer.

FEM is not only limited to engineering and scientific fields but can make it easier for us to solve all life issues. Here are some interesting applications of FEM:

[Ref] [Ref] |

|

|

|

|

|

We can say FEM engineering is a numerical approach for solving physics and engineering problems. The finite element approach can solve problems in various engineering and mathematical physics fields, such as structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. It is typically impossible to find analytical mathematical solutions to model the behavior of physical systems with complex geometries, loadings, and material properties. These differential equations typically cannot be solved because of the complex geometries, loadings, and material properties.

We must rely on numerical techniques to estimate these equations’ solutions, such as the finite element approach. Instead of needing the solution of differential equations, the problem’s finite element formulation provides a system of multiple simultaneous algebraic equations. These numerical techniques approximate the unknown values at discrete numbers of locations along the continuum. FEA analysis differs from FEM; keep reading this post to get more information.

Read More: All about Composite analysis | Abaqus composite

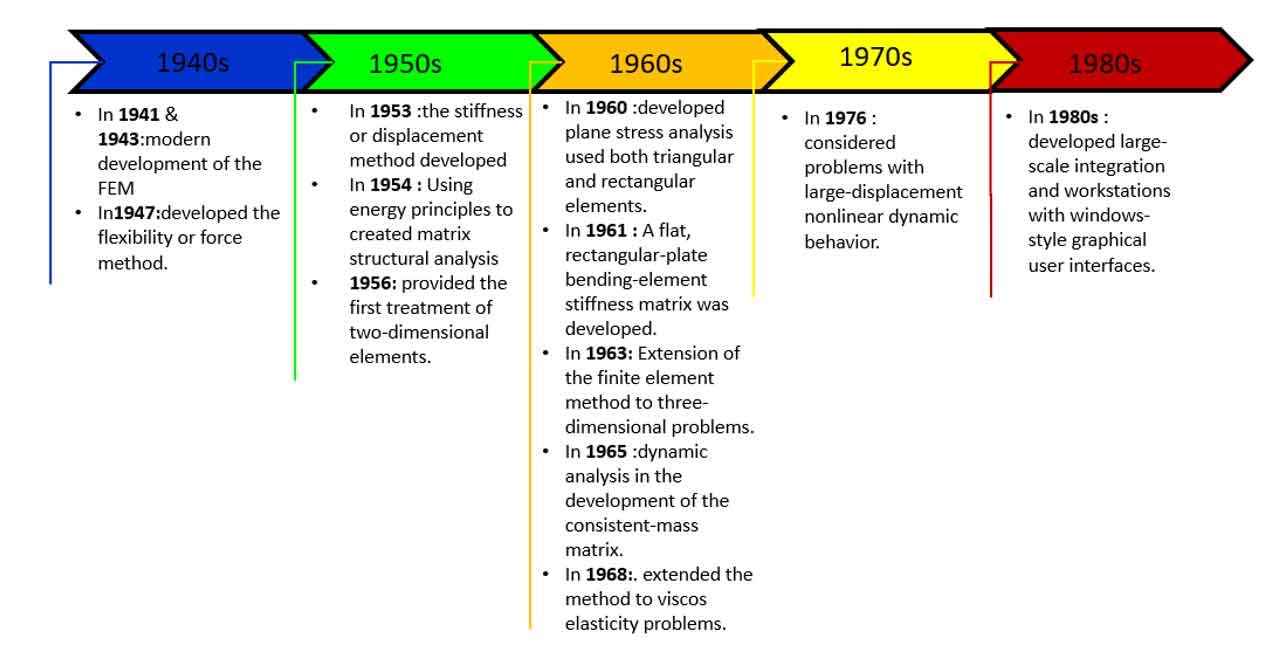

2. Brief history

- 1941 & 1943, With the work of Hrennikoff and McHenry in the field of structural engineering, the modern development of the finite element method started in the 1940s.

- In 1947, Levy developed the flexibility or force method, and his study recommended that a different approach should be used in 1953.

- In 1954, Using energy principles, Argyris and Kelsey created matrix structural analysis techniques.

- In 1956 Turner et al. provided the first treatment of two-dimensional elements. They created stiffness matrices for two-dimensional triangular and rectangular elements, beam elements, and truss elements in plane stress.

- In 1960 Clough developed the term “finite element” when plane stress analysis used both triangular and rectangular elements.

- In 1961, A flat, rectangular-plate bending-element stiffness matrix was developed by Melosh.

- In 1963 Extension of the finite element method to three-dimensional problems with the development of a tetrahedral stiffness matrix was done by Melosh.

- In 1963 Melosh’s realization that the finite element method could be set up in terms of a variational formulation, it began to be used to solve nonstructural applications.

- In 1965 Archer considered dynamic analysis in the development of the consistent-mass matrix.

- In 1968, Zienkiewicz et al. extended the method to visco elasticity problems.

- In 1969, using weighted residual techniques, first by Szabo and Lee to obtain the elasticity equations previously employed in structural analysis.

- In 1976, Belytschko considered problems associated with large-displacement nonlinear dynamic behavior and improved numerical techniques for solving the resulting systems of equations.

- In the late 1970s and early 1980s, Large-scale integration and workstations with windows-style graphical user interfaces were first developed, along with the computer mouse.

3. General Finite Element Method steps

Now we want to know how to solve a problem with FEM step by step, so follow me to learn it. This section describes the fundamental stages of developing and solving an engineering problem using the finite element method(FEM Engineering). We will follow these steps as a guide to creating solutions for structural and nonstructural challenges.

We will only consider the structural issue to simplify the presentation of the subsequent steps. The nonstructural heat transfer, fluid mechanics, and electrostatics issues, as well as the analogies between them and the structural issue, are regarded as the same. The engineer typically tries to figure out the displacements and stresses throughout the structure when it is in equilibrium and under applied loads for the structural stress-analysis problem. The finite element method must be used because conventional methods make it difficult to determine the distribution of deformation for many structures.

The finite element equations of a physical system can be obtained in three primary ways. For structural analysis problems, there are the direct method or direct equilibrium method, variation methods based on the principle of virtual work and subset energy methods, and weighted residual methods. The following briefly describes these three primary approaches; step 4 of this section will provide additional information on each.

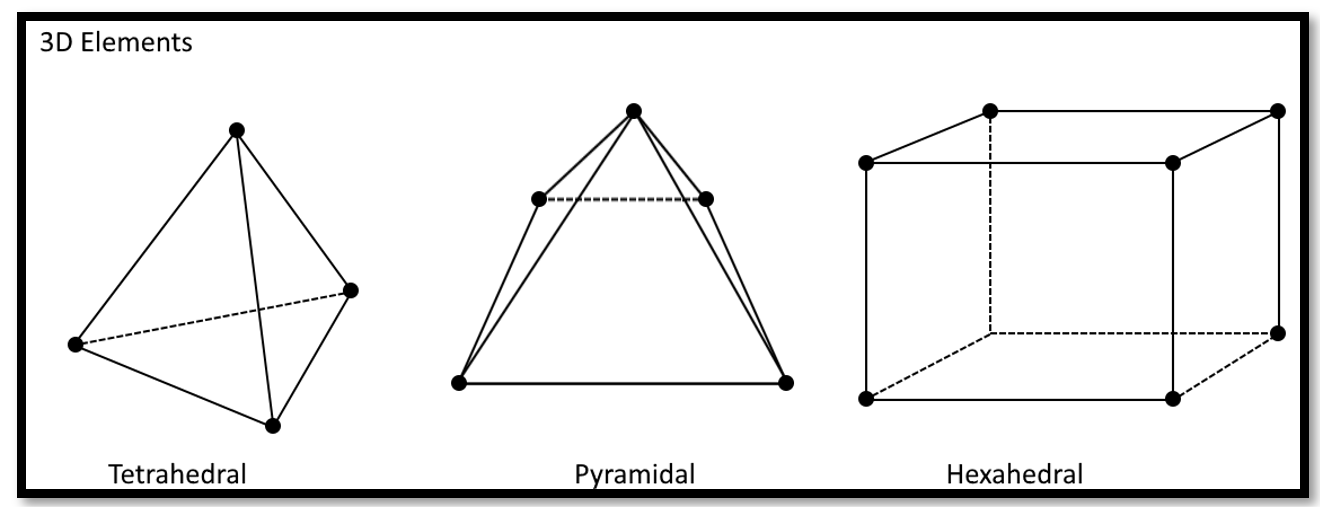

3.1. Step 1: Discretize and Select the Element Types

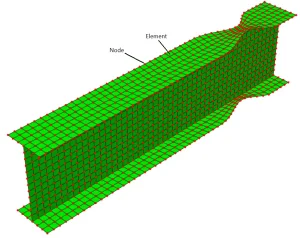

First, what’s the meaning of “Discretize” at FEM? The process of dividing a structure into smaller parts, called elements, is called the discretization of a structure in the finite element method. A node is a point in space where coordinates are used to define degrees of freedom (DOFs). The DOFs for this point show the potential movement of this point as a result of the structure’s loading. Additionally, the DOFs depict the forces and moments that are transferred from one element to the following. You can see an example in figure 1.

Figure 1: Dividing structure into elements

3.1.1. Element shape function

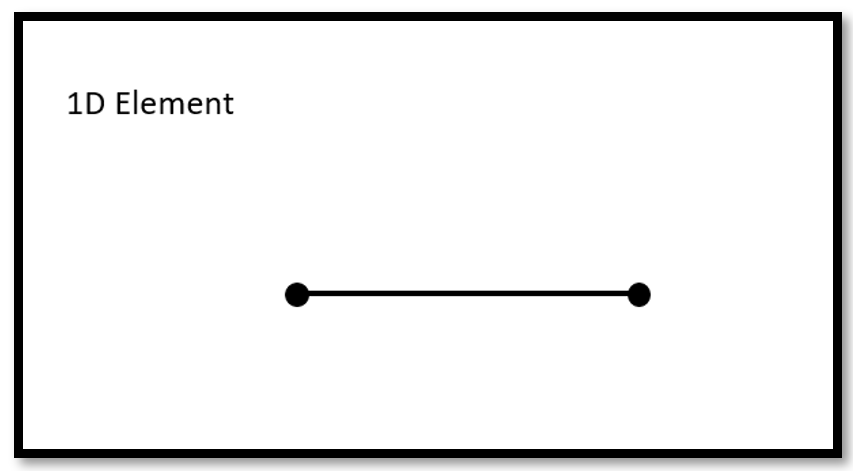

In the FEM engineering, continuous models are estimated using the data from a finite number of discrete locations. Discretization is the process of breaking the structure down into discrete parts. The function that interpolates the solution between the discrete values obtained at the element nodes is known as the shape function. We can choose different element shape functions:

- Line element(1D)

A linear shape function describes a linear element or a lower-order element.

- surface element(2D)

Three or four corner nodes and a part’s mid-surface make up a surface element. The surface thickness must be assigned once it has been developed for the FEA software.

- Solid element(3D)

Since they can be applied to any CAD solid model, solid elements are the most common element type employed by automatic mesh generators in FEA software.

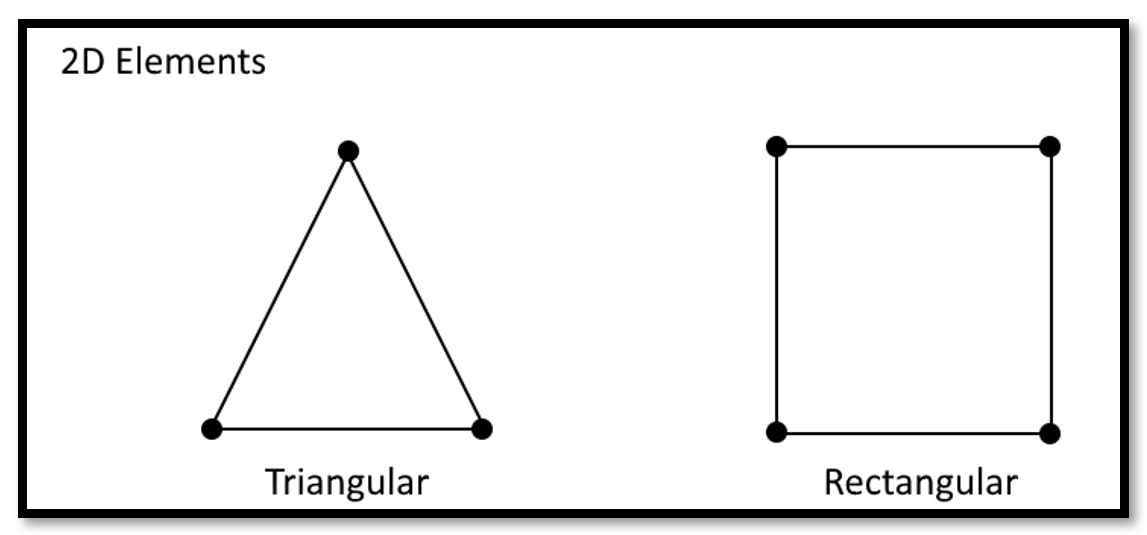

3.1.2. Linear and Higher-Order Elements

The most typical element types were already covered, so I’ll just conclude here. I simply want to make a few things clear in FEM engineering because, regrettably, the names can be a little confusing.

People commonly refer to the “first-order” elements—those that only have Nodes in “corners”—by this name (Shown on the left side of figure 2). And there is another type, typically referred to as quadratic. These components would be considered second-order because in the midst of each of those are extra nodes (Shown on the right side of figure 2).

Figure 2: First-order and second-order elements [Ref]

Now that you have learned some stuff about the elements and FEM engineering, you can find more info about the elements and simulation FEA in lesson 2 of the FEM simulation tutorial. You will learn about the nodes, elements, how FEM works, etc.

3.2. Step 2: Select U Function (degrees of freedom)

Degree of Freedom (DoF) refers to the “ability” to move in a specific direction. In 3D space, there are 6 degrees of freedom (DoF): you can move or rotate along axis x, y, or z. These elements, when combined, describe a 3D motion. DoF in finite element analysis (FEA) also controls boundary conditions, provide information about stresses, and more!

The term degree of freedom is most commonly used in statistics, machine tools, mechanisms, vibration, FEM, and other fields. Whatever the field, the number of degrees of freedom can be defined as the minimum number of independent coordinates that can completely specify the system’s position.

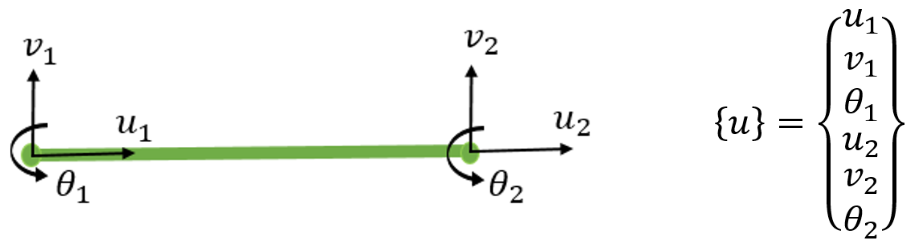

As we said in this post, we want to show you how FEM and simulation FEA can solve a structural problem; so, in this step, the U function is displacement. For each element, we can define a vector {u} that contains all of the possible displacements for the nodes of the element, including rotations. Suppose we are analyzing a two-dimensional case with beam elements. In that case, each node can translate along the X and Y axes and rotate about the Z axis. As we said, each of these displacements is called a degree of freedom. For example, for the beam element, we have 3 degrees of freedom per node, or 6 in total, in the 2D case.

Figure 3: Degrees of freedom for 2D beam element

Now for our problem, we should select a displacement function for each element in step 2. The element’s nodal values are used to specify the function inside the element. Each element can use the same general displacement function repeatedly. The finite element method uses a discrete model created by a number of piecewise-continuous functions, which are defined within each finite domain or finite element to approximate a continuous quantity like the body displacement.

3.3. Step 3: Determination of strain/displacement and stress/strain relationships

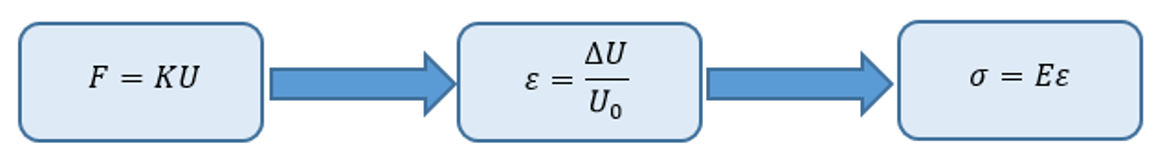

The relationship between strain, stress, and displacement is required to derive the equations for each finite element. For example, for one-dimensional deformation in the x direction, the strain “εx” is associated with the displacement u by εx=du/dx if the strain is small. Furthermore, stress must be related to strain by the stress-strain law, commonly known as the law of materials. The ability to accurately define material behavior is paramount to achieving acceptable results. Hooke’s law is the simplest of the stress/strain laws and is commonly used in stress analysis.

- F: External force

- K: stiffness matrix of element

- U: displacement of each element

- ε: strain of each element

- σ: stress of each element

- E: Young modulus of material

As we said, the example we are considering for this article is about a structural type, and therefore all the written equations are related to the calculation of the stress and strain of the structure. If we want to start our simulation FEA on another subject, we must write the governing equations specific to the new subject. For example, for heat transfer, we have:

Q = CT

Q is proportional to the temperature difference between the objects and the heat capacity C of the object.

You can see the general usage of the FEM and the equation “F=KU” in lesson 2 of the Abaqus course for beginners package. Just go to the “General Usage of FEM” section of this lesson to learn more.

3.4. Step 4: Derive the Element Stiffness Matrix and Equations

The development of the element stiffness matrix and element equations is initially based on the concept of factors affecting stiffness, which requires a background in statics. We present an alternative method.

3.4.1. Direct equilibrium Method

According to this method, the stiffness matrix and element equations, which relate nodal forces to nodal displacements, are attained using force equilibrium conditions and force/deformation connections for a basic element. This method is most easily adaptable to line or one-dimensional elements.

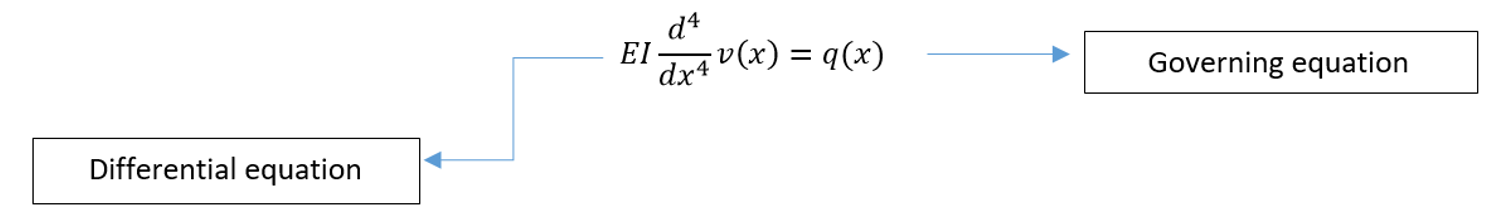

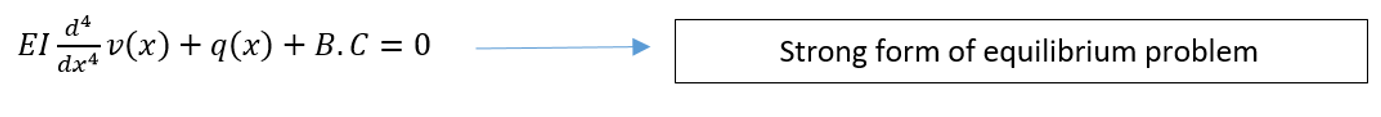

For example, to calculate the horizontal displacement of the beam, the following equation can be written:

Now, if these equations are placed next to the boundary conditions, they get a strong form. The strong mode can be used to solve simple elements.

3.4.2. Work or energy Methods

It is much easier to use a work or energy method to develop the stiffness matrix and equations for two- and three-dimensional elements. The principle of virtual work (using virtual displacements), the principle of minimum potential energy, and Castigliano’s theorem are frequently used to derive element equations.

Furthermore, the virtual work principle can be applied even when a potential function does not exist.

Following that, the principle is commonly used to derive all other stress-analysis stiffness matrices and element equations.

A functional similar to the one used with the principle of minimum potential energy is quite useful in deriving the element stiffness matrix and equations to extend the finite element method for the structural stress analysis field.

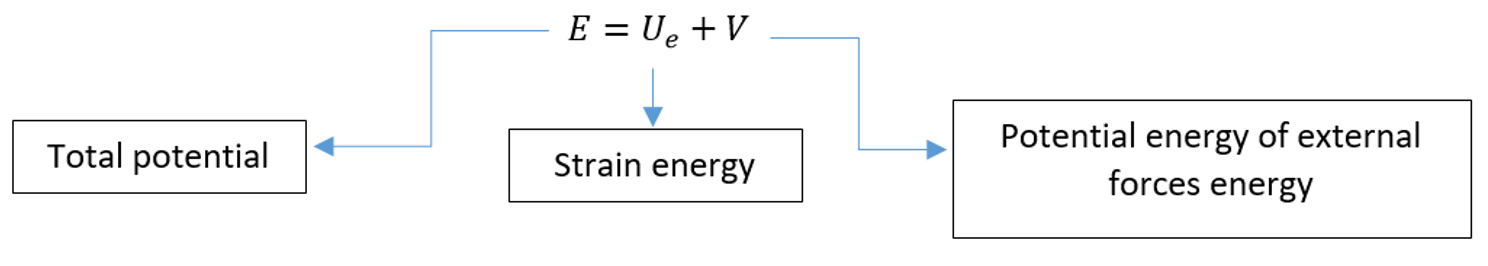

A functional is an integral expression that implicitly contains differential equations that describe the problem. A typical functional is of the form where u(x).x and F are real so that I(u) is also a real number. Here

.

We can write this equation for structural analysis:

3.4.3. Weighted residuals Methods

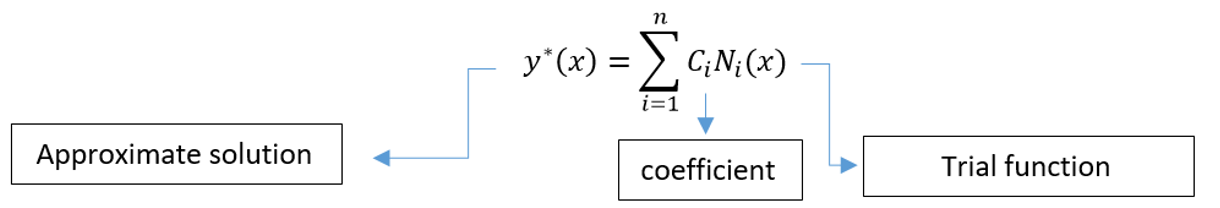

Weighted residual methods, particularly Galerkin’s method, are useful for developing element equations. Wherever energy methods are applicable, these methods produce the same results as energy methods. They are especially useful when a function, such as potential energy, is not readily available. The weighted residual methods allow applying the finite element method directly to any differential equation. In this method, the function that satisfies the differential equation is approximated as the sum of several assumed trial functions that each have unknown coefficients.

This approximate solution is substituted into the differential equation. In differential equation mode, we can write:

And an equation for the error, called the residual, is an error function, and we can write it like this:

If the value of y*(x) is an exact value, the error function is equal to zero.

If we multiply each trial function by the residual and set the integral of this product to zero, we can calculate the unknown coefficients that minimize the residual. This gives us an approximate solution to the differential equation. Now, any unknown coefficient can be calculated using the error function:

Each element must have its own displacement function. This is a more widely applicable approach than the principle of minimum potential energy. To solve the singularity problem, we must use boundary conditions. We need boundary condition to keep the structure in place rather than moving as a rigid body, so “a” and “b” is the boundary condition of our problem.

|

⭐⭐⭐ Abaqus Course | ⏰10 hours Video 👩🎓+1000 Students ♾️ Lifetime Access

✅ Module by Module Training ✅ Standard/Explicit Analyses Tutorial ✅ Subroutines (UMAT) Training … ✅ Python Scripting Lesson & Examples |

You’re bored, right?! Let’s solve an example to understand it better.

3.4.4. Derivation of the Stiffness Matrix for a Spring element

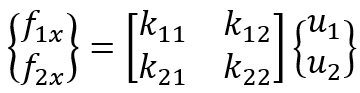

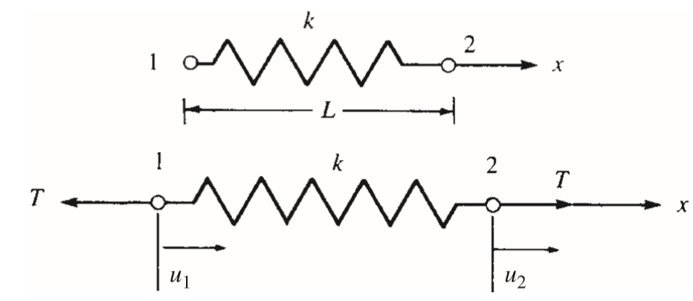

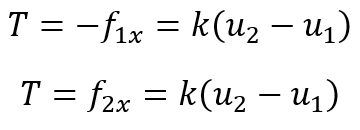

We will now derive the stiffness matrix for a one-dimensional linear spring using the direct equilibrium approach. This spring obeys Hooke’s law and resists forces only in the direction of the spring.

We now want to develop a relationship between nodal forces and nodal displacements for a spring element. The stiffness matrix will be based on this relationship. As a result, we propose the following relationship between the nodal force matrix and the nodal displacement matrix:

Consider the linear spring element subjected to the resulting nodal tensile forces T directed along the spring axial direction x, as shown in Figur3, to be in equilibrium.

Figure 4: Spring subjected to tensile forces and in the equilibrium state

The Strain/Displacement and Stress/Strain Relationships must be defined. The difference in nodal displacements represents the total deformation of the spring as follows:

Instead of the stress/strain relationship, consider the force/deformation relationship:

Now we can write:

We can rewrite the equation by substituting the force components as follows:

Now expressing the equations above in a single matrix equation:

Then, for structures composed of more than one element

t, we must assemble the element equations to obtain the global equations and introduce boundary conditions.

where and

are now element stiffness and force matrices expressed in a global reference frame.

The displacements are then calculated by imposing boundary conditions, such as support conditions, and simultaneously solving a system of equations as:

Finally, the element forces are determined by back-substitution.

3.5. Step 5: Assemble the Element Equations to get the Global or Total Equations, and then add Boundary Conditions

The individual element nodal equilibrium equations generated in step 4 are assembled into global nodal equilibrium equations in this step. Another more direct method of superposition (known as the direct stiffness method) based on nodal force equilibrium can be used to obtain global equations for the entire structure. The concept of continuity, or compatibility, is implicit in the direct stiffness method, which requires that the structure remain together and that no tears occur anywhere within the structure. The final assembled or global equation in matrix form is as follows:

As we said before, {F} is the vector of global nodal forces, [K] is the structure global or total stiffness matrix (for most problems, the global stiffness matrix is square and symmetric), and {u} is the vector of known and unknown nodal degrees of freedom or generalized displacements of the structure.

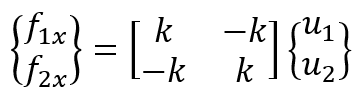

The element stiffness matrix defines how much each node in the element will displace when a set of forces and moments is applied to the nodes. Moreover, it is the key to solving the displacements at every node. Figure 5 shows just one element, but our overall mesh will be made up of many more elements.

Figure 5: Stiffness matrix for one element

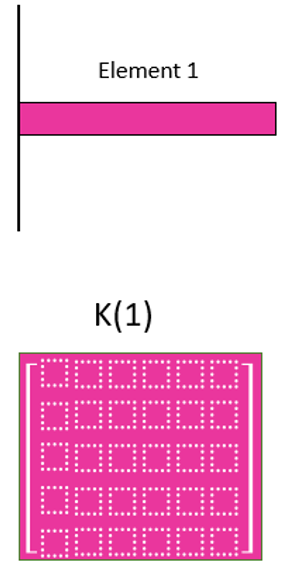

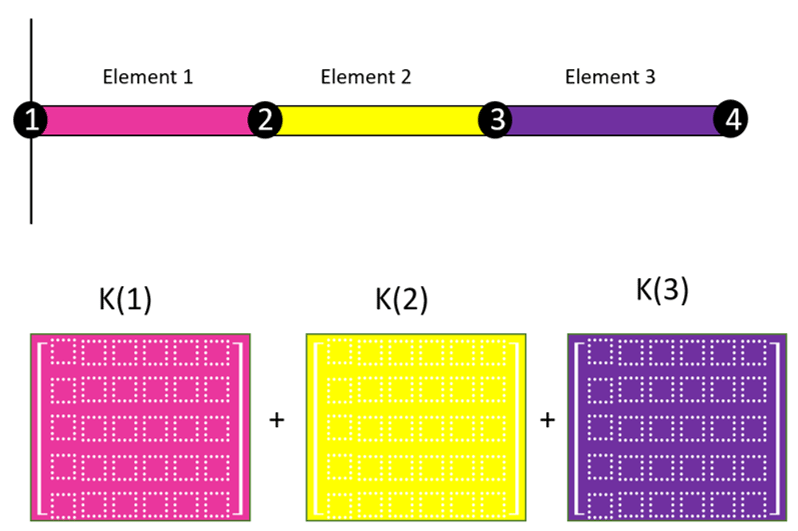

For example, in a 2D beam, we can assemble the individual stiffness matrices of all the elements (figure 6) into a huge global stiffness matrix that defines how the entire structure will displace when loads are applied to it.

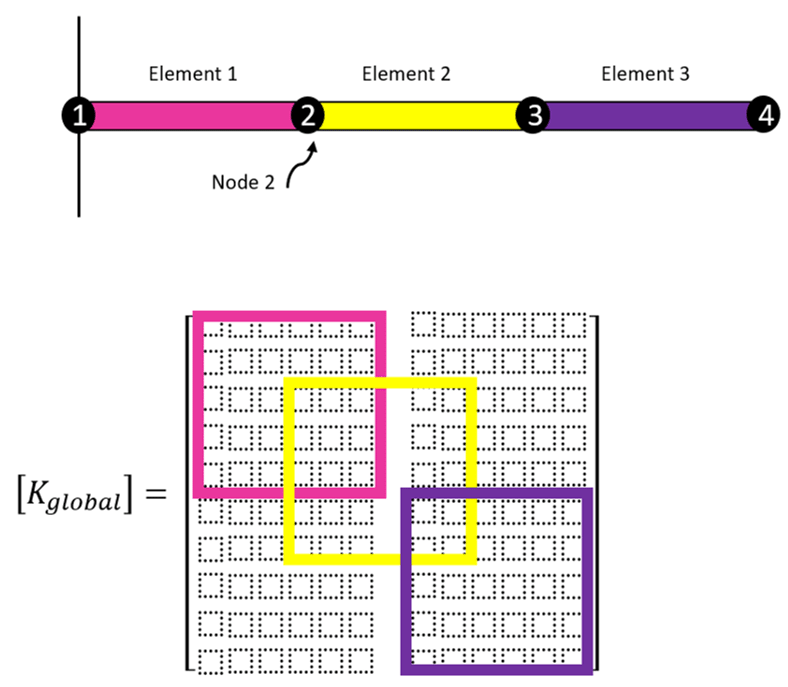

Figure 6: Stiffness matrices for each element of the 2D beam

Like the element stiffness matrix, the global stiffness matrix is a square matrix, and the number of rows and columns is equal to the total number of degrees of freedom in the model. The element stiffness matrices are assembled together to form the global stiffness matrix based on how the elements are connected together. Figure 7 shows that elements 1 and 2 are connected at node 2, and it tells us that since these two elements are connected at the same node, the displacement for both elements must be the same at the common node.

Figure 7: Global stiffness matrix of a 2D beam element

So when we assemble the global stiffness matrix, the terms in the element stiffness matrices corresponding to node 2 should be summed for each degree of freedom. Figure 7 shows that element 3 is not connected to node 2, so this element’s stiffness matrix should not affect the displacements at node 2. Figure 7 shows the actual global stiffness matrix for this model.

3.6. Step 6: Determine the Unknown Degrees of Freedom

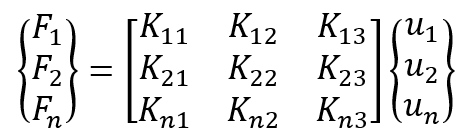

You are doing great! Keep going. The above equation, with the boundary conditions taken into account, is a set of simultaneous algebraic equations that can be written in expanded matrix form as:

n is the structure’s total number of unknown nodal degrees of freedom.

For the du, these equations can be solved using either an iterative or elimination approach (such as the Gauss-Seidel approach). The stiffness (or displacement) finite element method first determines the du, which are referred to as the primary unknowns.

3.7. Step 7: Solution for the Element Strains and Stresses

Because stress and strain can be directly expressed in terms of the displacements determined in step 6, important secondary quantities of strain and stress (or moment and shear force) can be obtained for the structural stress-analysis problem.

3.8. Step 8: Analyze the Result of finite element analysis

The final objective is to use the results in the design/analysis process by interpreting and analyzing them. When making decisions for design or analysis, it is usually important to find the places in the structure where there are a lot of stresses and big deformations. Postprocessor computer programs aid in their interpretation by providing the user with a graphical representation of the results.

In this post, we have briefly introduced finite element analysis or engineering FEA fundamentals, and you may need more references for your future works; I recommend checking our Free Abaqus course. In this course, you will learn all you need from A to Z about finite element analysis (FEA analysis) in Abaqus.

4. Application of FEM (finite element analysis)

Now we come to the exciting part of the story. Before we start, close your eyes and relax for 10 seconds!

Both structural and nonstructural issues can be examined using the finite element method.

The most typical structural areas are:

- Stress analysis, including truss and frame analysis

- Buckling, such as in columns, frames, and vessels

- Vibration analysis, such as in vibratory equipment

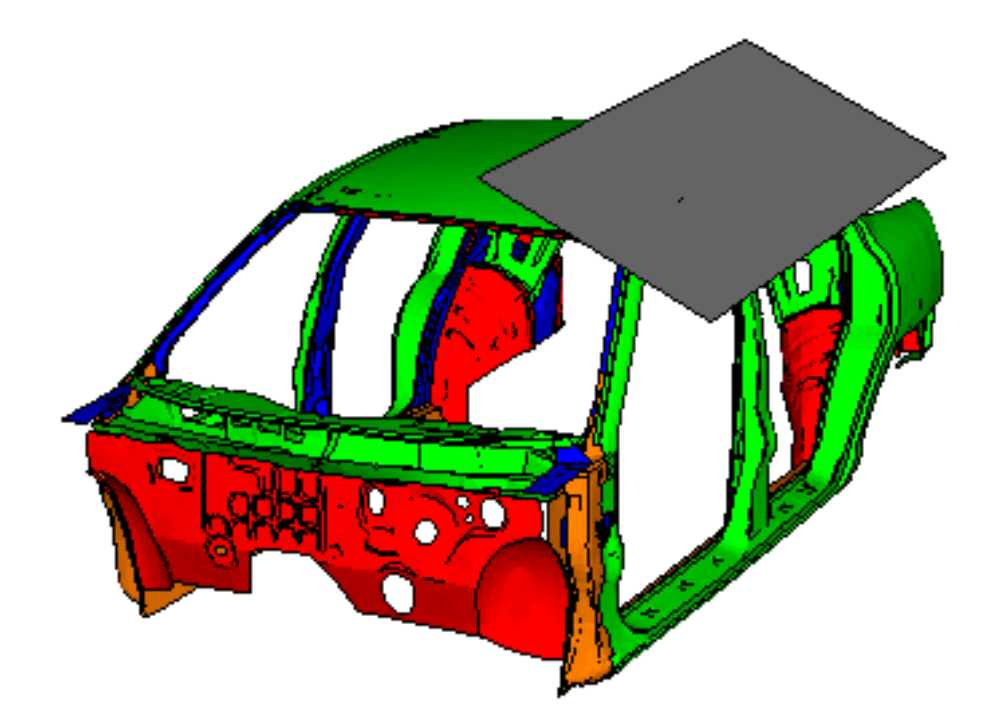

- Impact problems, including crash analysis of vehicles

And nonstructural problems include:

- Heat transfer, such as in electronic devices emitting heat as in a personal computer microprocessor chip

- Fluid flow, including seepage through porous media

- Distribution of electric or magnetic potential

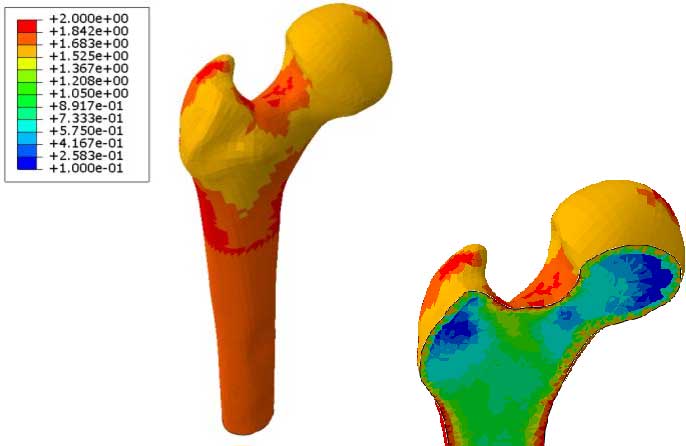

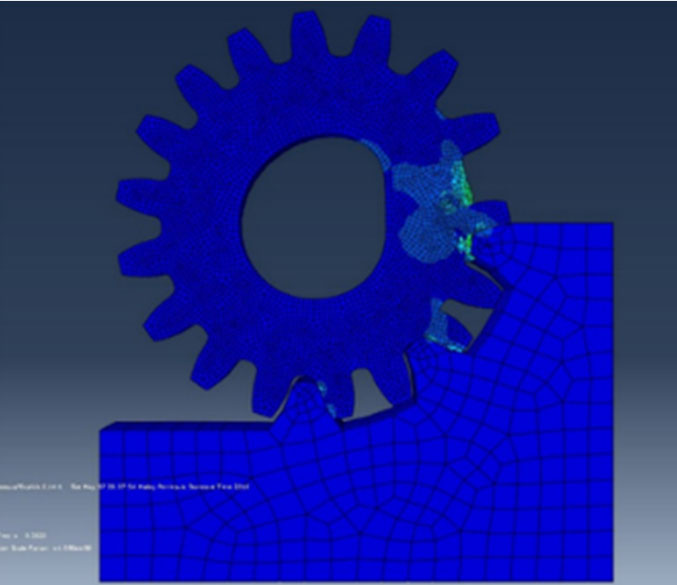

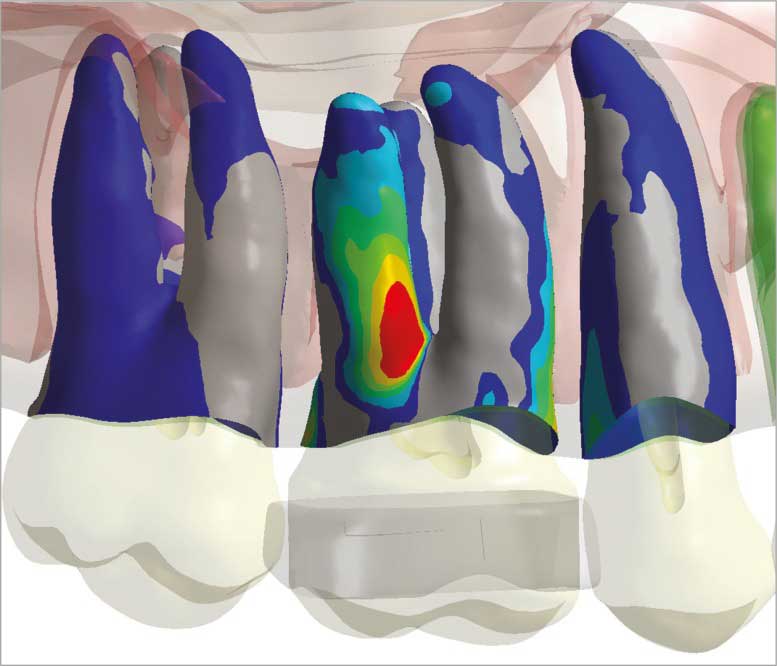

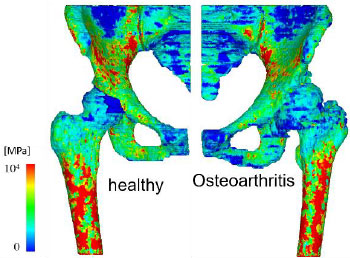

Finally, the human spine, skull, hip joints, jaw/gum tooth implants, heart, and eye analysis are typical of some biomechanical engineering problems that may include stress analysis.

|

|

You know that the implants and bones are basically composite materials, right?! Well, aren’t you interested to know how to model composites in a finite element software like Abaqus? You can learn it via these packages:

Simulation of Unidirectional Composite Damage in ABAQUS and Abaqus composite modeling

IF you are interested in biomechanical structures and want to see some practical examples in Abaqus, I think this package can help you a lot:

Bio-Mechanical Abaqus simulation Full package

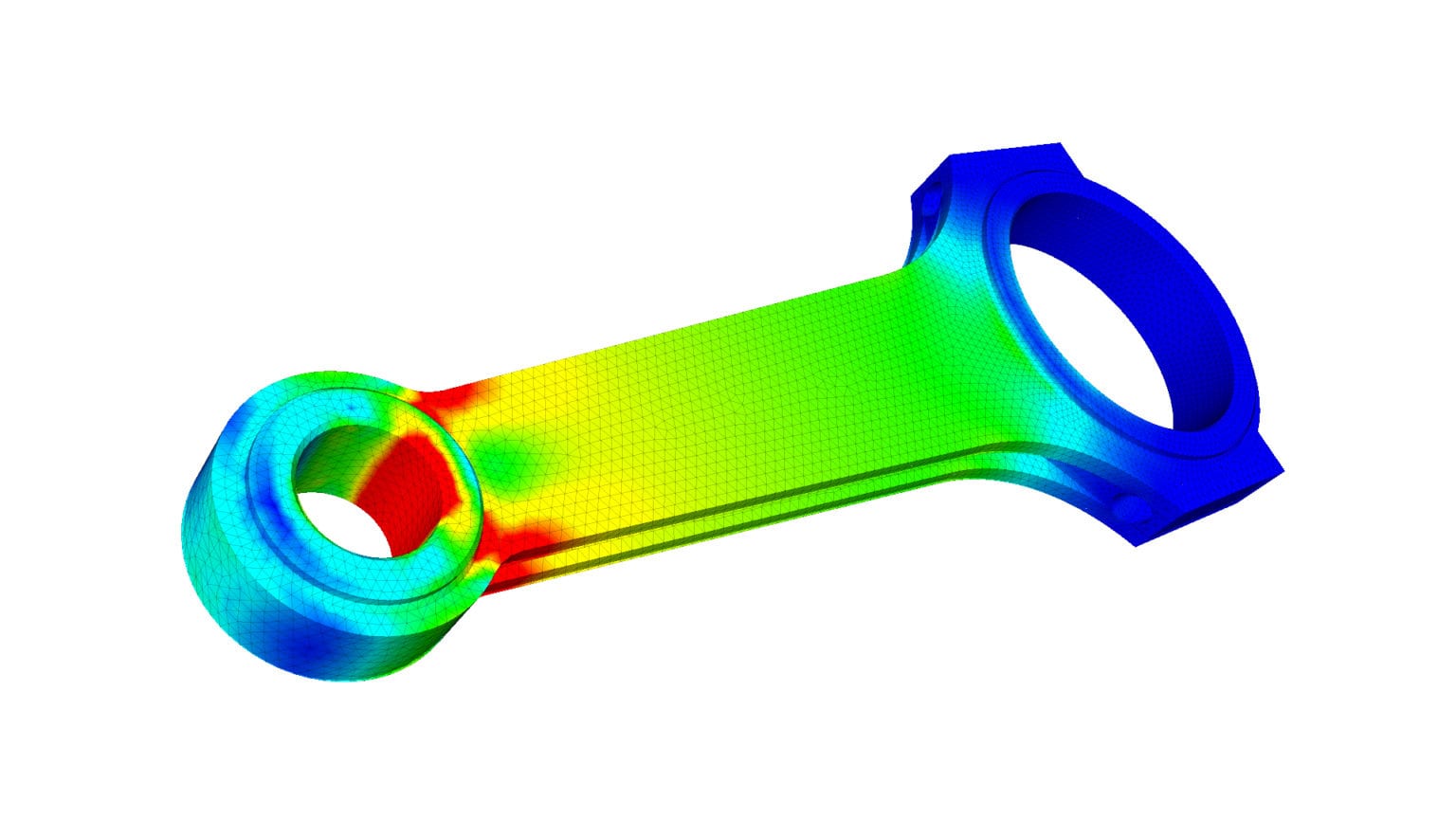

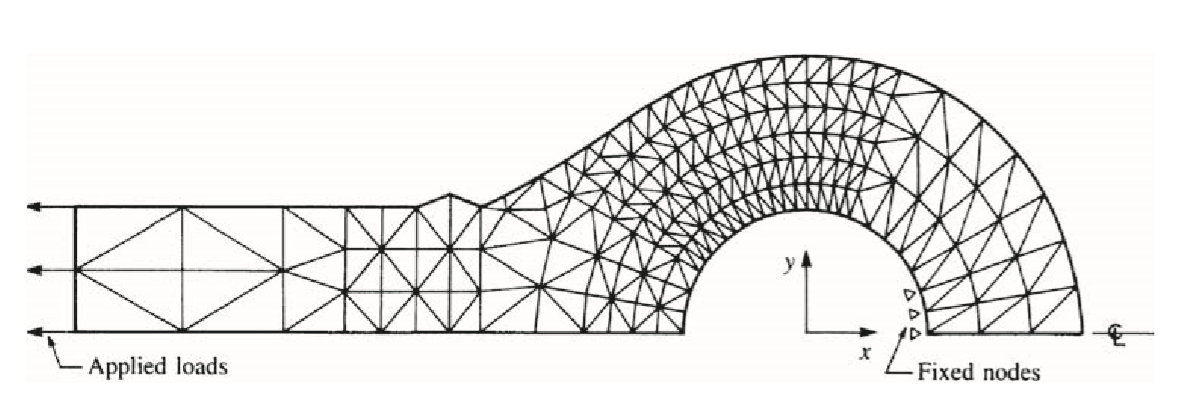

Now, we’ll talk about some common uses for the finite element method or engineering FEA. These applications will demonstrate the variety, size, and complexity of the problems that can be solved using the FEM method, as well as the typical discretization process and types of elements used. For example, 120 nodes and 297 plane strain triangular elements were used to model the hydraulic cylinder rod end in figure 4. In addition, symmetry was applied to the entire rod end so that only half of it needed to be analyzed, as depicted. This analysis aimed to find places in the rod end where there was a lot of stress. This is a simple kind of finite element analysis (FEA analysis) in industrial applications.

Figure 8: Two-dimensional analysis of a hydraulic cylinder rod end (120 nodes, 297 plane strain triangular elements)

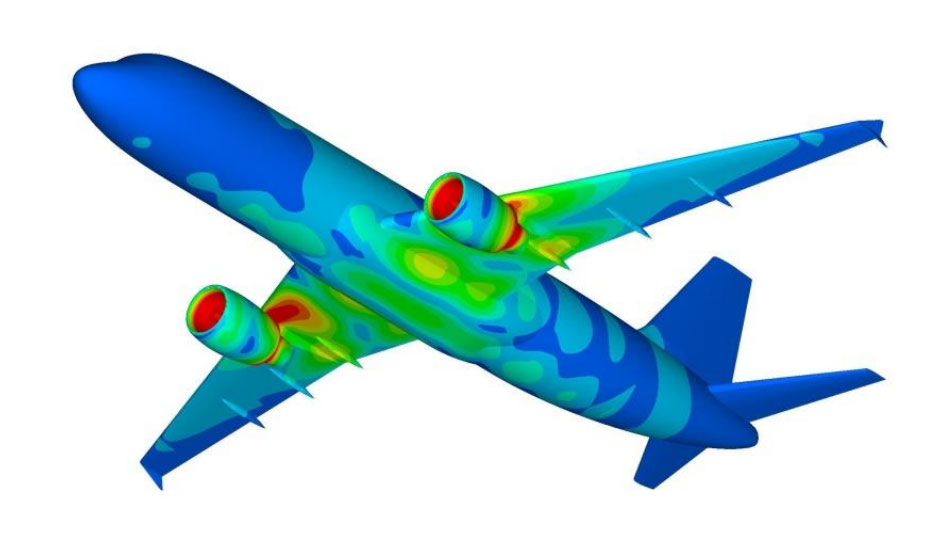

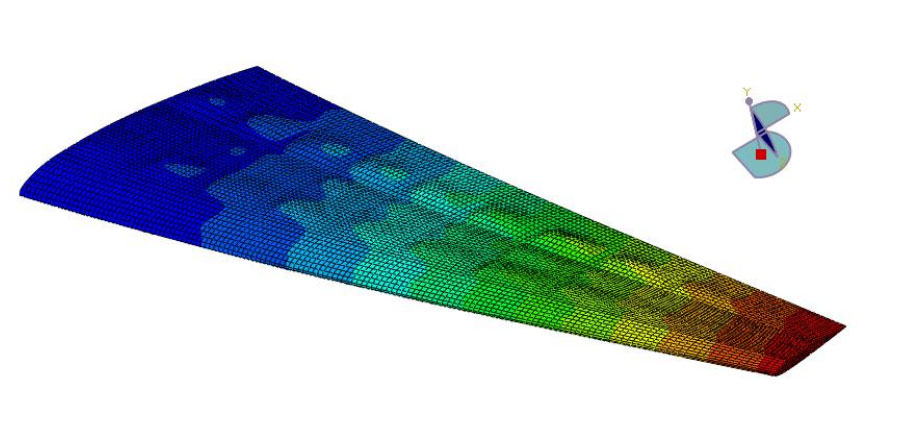

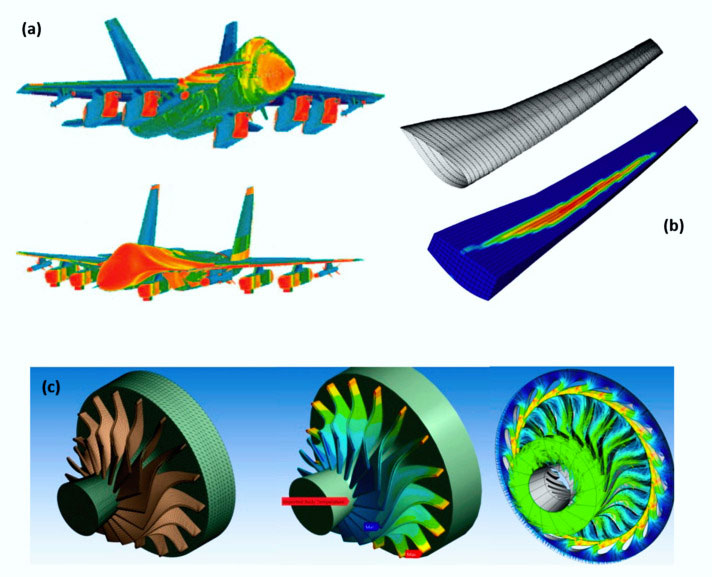

4.1. Aerospace & FEA analysis

Automotive and aerospace are two of the many sectors where the use of composite materials has grown in recent years. However, they present challenging research gaps because of their high prices, specific qualities, and implications related to heterogeneity. Consequently, engineering FEA using the finite element method has been used to investigate composite materials subjected to the most unusual conditions.

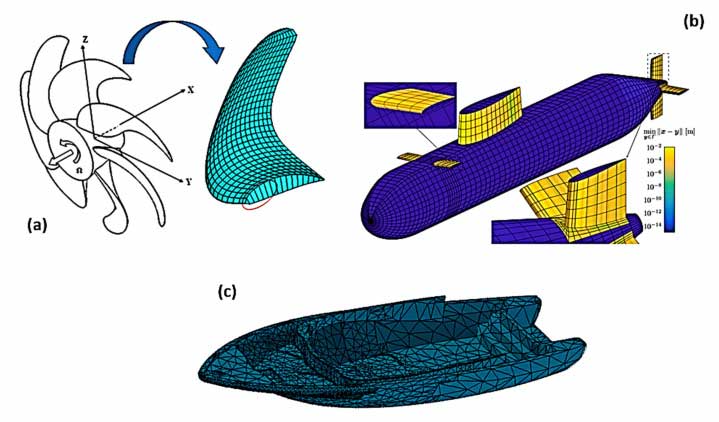

4.2. Naval & FEA analysis

The use of composite materials in the naval industry has increased due to the application of engineering FEA using FEM. Marine propellers, ships, and submarines are the primary areas of research. FEM is used in this study field to predict vessel vibrations and determine their mechanical properties, in addition to maximizing structural weight.

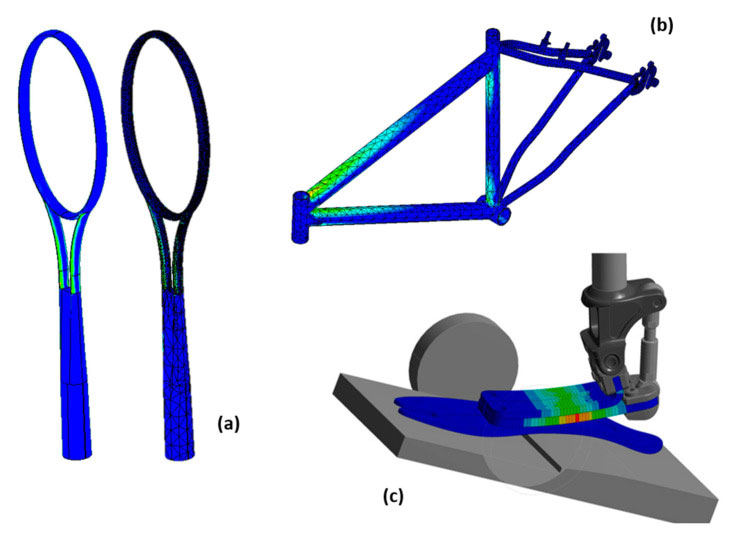

4.3. Sports & FEA analysis

In addition to gaining ground in the major industrial sectors, composite materials have also gained popularity in the sports industry, particularly in high-performance or professional sports. This field has been utilizing composite materials to lighten equipment. These materials can be further optimized by utilizing engineering FEA with FEM to select geometries with high resistance and low weight to enhance athletes’ performances.

|

⭐⭐⭐ Abaqus Course | ⏰10 hours Video 👩🎓+1000 Students ♾️ Lifetime Access

✅ Module by Module Training ✅ Standard/Explicit Analyses Tutorial ✅ Subroutines (UMAT) Training … ✅ Python Scripting Lesson & Examples |

5. Benefits of Using the Finite Element Method

As previously mentioned, the finite element method (finite element analysis) has been used to solve numerous structural and nonstructural issues. This method has several advantages over conventional approximate methods for modeling and determining physical quantities like displacements, stresses, temperatures, pressures, and electric currents. Conventional methods such as those were taught in traditional courses in material mechanics and heat transfer. These advantages are:

- Designing bodies with irregular shapes is simple.

- Handle stress/strain cases without trouble

- Because each element equation is assessed separately, model bodies are made of various materials.

- Manage an infinite variety of boundary conditions

- Changing the size of the components to enable the usage of small components as necessary and implementing higher-order elements in the finite element model is possible.

- Simulating many kinds of material qualities from element to element or even within an element is simple.

- FEM is popular among the engineering community since it is easy to use, small, and focused on results.

- Take care of any nonlinear behavior resulting from significant deformations and materials by incorporating a finite element model.

- A variety of computer software programs and books are readily available, making FEM a flexible and effective numerical method.

6. Limitation of Finite Element Method

Some limitations of FEM:

- The mesh used for nodal analysis requires a significant amount of data as input.

- Idealization of real-life objects can’t be exact for complex shapes.

- It is extremely involved and requires just a computer.

- The time needed for solving the problems increases with the degree of fineness of the mesh.

- The output results will vary considerably. FEM yields an approximate solution. It is tried to minimize the error over the whole domain; as a result, we get the exact solution at nodes only.

But the list of advantages of FEM is very large in comparison to its disadvantages.

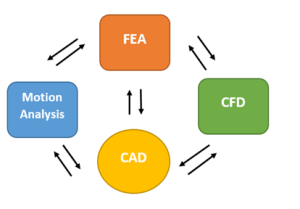

What Is the Place of FEA among Other Tools of Computer-Aided Engineering?

FEA is one of many computer-aided engineering (CAE) tools used in the mechanical design process. Other CAE tools include fluid analysis and mechanical analysis, commonly referred to as computational fluid dynamics (CFD). These three major CAE tools, FEA, CFD, and motion analysis, are integrated into Computer Aided Design (CAD), which is the hub of all his CAE applications. Geometry, material properties, and certain boundary conditions can be exchanged between CAD and add-ins and among add-ins themselves. FEA, CFD, and mechanistic analysis were developed independently and are based on different numerical methods. CAE tools are standalone programs and are not add-ins to CAD, but they can be connected to CAD.

Figure – CAE applications such as FEA, CFD, and Motion Analysis are add-ins to CAD,They can exchange data with CAD and among themselves

7. FEM & FEA (Finite Element Analysis)

The finite element method (FEM) is the most popular numerical method, and the applications for this method are linear, non-linear, buckling, thermal, dynamic, and fatigue analysis. Now the question is FEA and FEM different or not?

Well, FEM and FEA are both one and the same. The term FEA is most popular in industries and FEM at universities. Also, FEA has a wide area of problems related to heat transfer, vibrations, the strength of materials, acoustics, and various other domains. And FEM includes the Galerkin method, the weighted residual method, and various numerical integration methods to solve problems related to FEA domains and its totally mathematical approach. The term “Finite Element Method” (FEM) mostly refers to sophisticated mathematical techniques employed in your preferred solver. Consider it to be a theory guidebook with a ton of equations and algebra. The term Finite Element Analysis (FEA) typically refers to the process of using Finite Element Method (FEM) and a finite element model to address actual engineering issues.

First, I want to tell you why finite element analysis (FEA analysis) has become so popular. Here are some reasons:

- In reality, it is quite complicated if you look at the theoretical aspects of the Finite Element Method (FEM) and the creation of a Finite Element Model. Even if you understand the theoretical aspect and modeling process, getting things to work with a computer code is challenging. But these days, the mathematics is hidden deep behind pretty interfaces, and the only things an engineer sees are a CAD model and the contour plots. The major FE software vendors are making theory software more user-friendly. These days, even SolidWorks has an FE solver (I think that’s a joke). So bottom line, using FE software just as a black box is easier than ever, which is why they are popular.

- It’s a competitive market out there, and FE provides the cheapest way to optimize your products.

- Our problems are getting more and more complicated, and there doesn’t really exist a closed-form solution. In such situations, FE provides a fast method to reach an approximate and reliable answer.

- (Maybe) People are becoming lazy to solve problems the old way, and they just want to build finite element models and let the solver deal with the headaches that come with dealing with difficult situations.

I think FE has matured a lot but keep an eye on Meshless methods. It is not in its mature state yet but is following in FE’s footsteps. As the shape of the finite element model become more organic, the FE meshing becomes more difficult. To capture the geometry, we must reduce the mesh size and sacrifice computation time. Meshless methods don’t exactly mesh and use elements to solve a problem and are very useful in such cases.

8. FEM Software

Before purchasing any software, a user interested in supporting finite element programs and designing finite element model should carefully consult the vendor. However, to give you an idea of the various commercial, and personal computer programs currently available for problem-solving using the finite element method, we provide a partial list of the currently available programs.

- Autodesk Simulation Multiphysics

- Abaqus

- ANSYS

- COSMOS/M

- GT-STRUDL

- LS-DYNA

- MARC

- MSC/NASTRAN

- NISA

- Pro/MECHANICA

- SAP2000

- STARDYNE

8.1 Verification and Validation of FEA Results

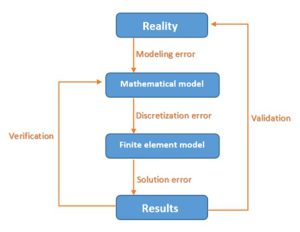

Verification and validation as applied to design analysis with FEA are defined as follows:

- Verification checks whether the mathematical model has been discretized and solved correctly.

- Validation determines if the solution correctly represents the reality from the perspective of the intended use of the results. It checks if the results correctly describe the real-life behavior of the analyzed system.

It checks whether the results accurately describe the actual behavior of the system under analysis.

A model with mesh errors will fail the verification test. For example, using elements that are too large will result in an incorrect solution. The check fails if discretization errors or solution errors invalidate the results. Convergent analysis will uncover issues that cause testing to fail.

A model with an incorrect load definition will fail the verification test because verification is only concerned with the correctness of the mathematical model solution and not whether the mathematical model itself is correct. Establishing the correctness of a mathematical model as well as the correctness of its solution is the process of validation. Validation will fail if there is a conceptual error in the definition of the mathematical model. Concept errors are much more dangerous than discrete errors.

They can escape the attention of the modeler, especially because there is no clearly defined process for detecting conceptual errors. The only protection against validation errors is a precise definition of the problem being analyzed. Verification checks the numerical solution of a mathematical model. Validation checks how well the results apply to reality. The flowchart also shows errors introduced at each step of the FEA project.

Figure – Verification and validation of FEA results and the errors introduced at each step of the FEA project

9. Example of process FEM to FEA

After you have a cup of coffee, let’s solve this example together! Here you can see FEA analysis in a simple example.

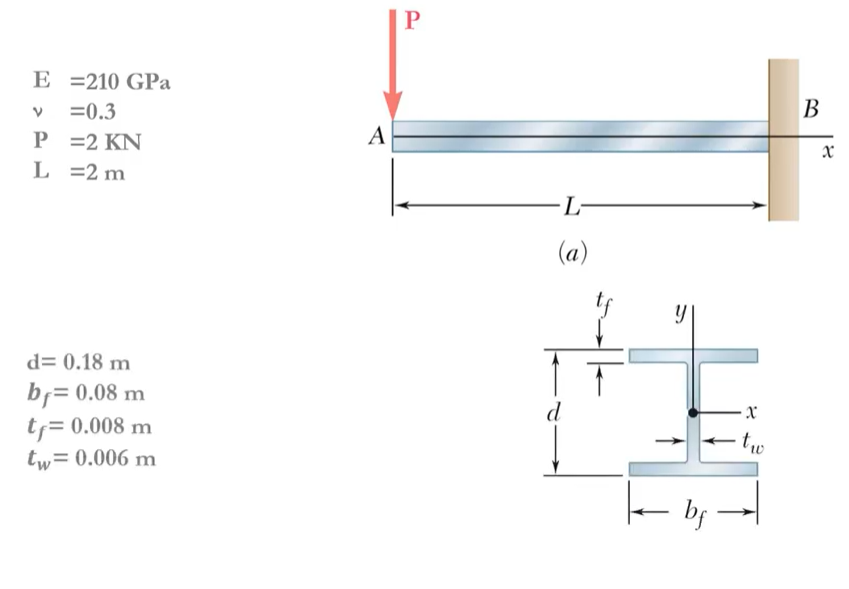

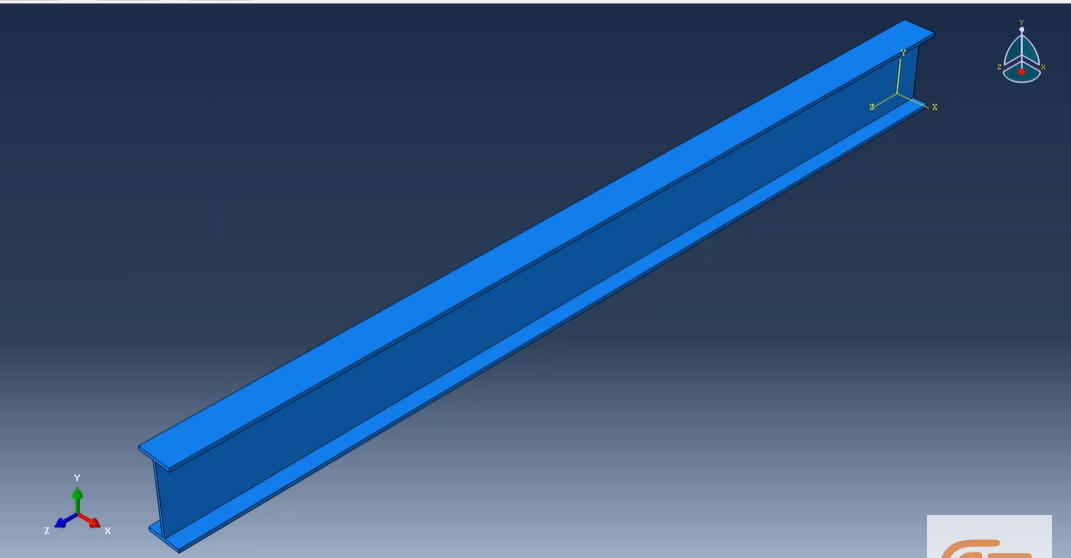

The modern form of the finite element method can routinely solve many industrial problems. They enable fundamental understanding and allow predictive analysis for product design. We want to simulate an I-shaped beam under the constricted transfer loading P.

Figure 9: Description of the problem (for FEA analysis)

In the remaining part of this post, I have explained the finite element analysis steps. If you are interested in FEA analysis learning or you are a student who needs to start finite element analysis for your project, I recommend checking the Abaqus tutorial page.

9.1. Step 1: Modeling

At first, we can model it in ABAQUS as a static model with the Part module. An ABAQUS/CAE model is built using parts as its foundation. Each part is created using the Part module, and instances of the parts are assembled using the Assembly module.

Figure 10: Creating the model in the Part module

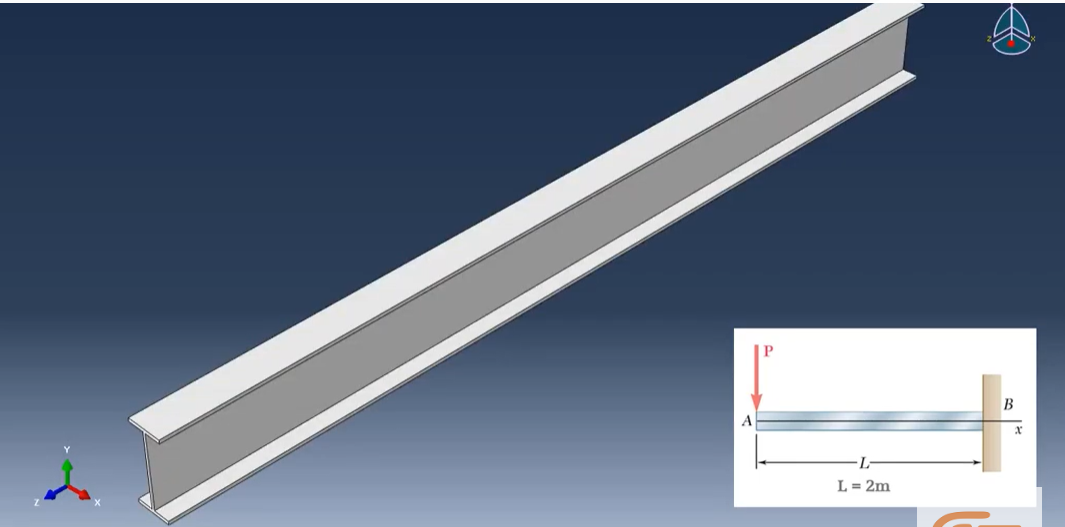

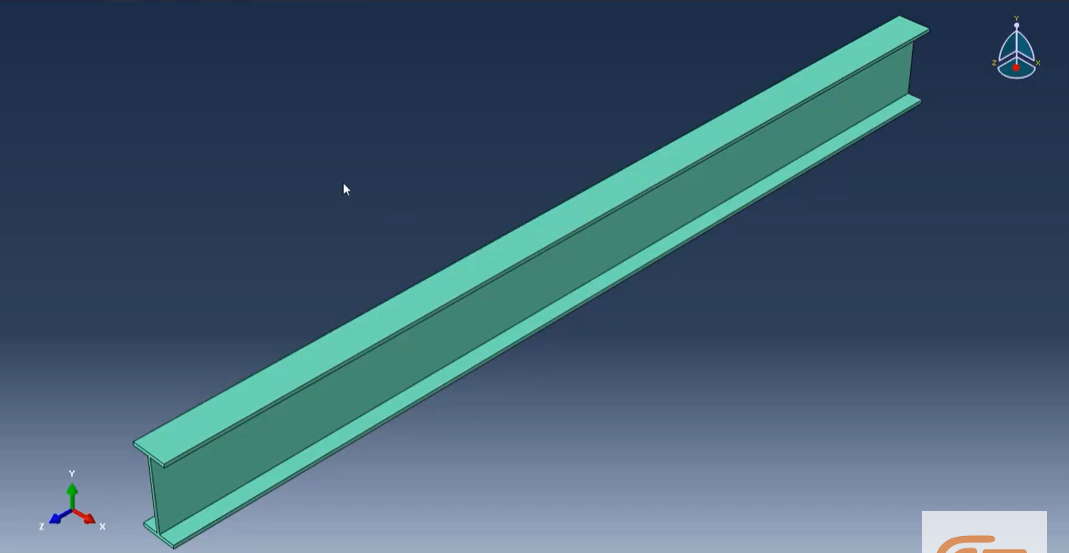

Figure 11: Created model in 3D shape

9.2. Step 2: Choose the material of the structure

The mechanical property of your material can be entered in ABAQUS using the Property module. By specifying them at a variety of temperatures, material properties become temperature-dependent. A material property can sometimes be defined as a function of ABAQUS-calculated variables; For instance, stress must be given as a function of equivalent plastic strain to define a work-hardening curve.

Figure 12: Assigned material properties on the model

9.3. Step 3: Assemble the structure

At the Assembly module, we can select any structure component to assemble. Using an organizational scheme that is analogous to the physical assembly, analysts can create a finite element mesh with the help of ABAQUS’s assembly interface. Part instances are the assemblies of individual components in ABAQUS.

Figure 13: model instance in the Assembly module

9.4. Step 4: Choose the solution method

In the Step module, we want to define the problem-solving approach. To solve this example, we can choose “Static, general.” Abaqus is based on the idea of breaking up the problem history into steps. An Abaqus step is any convenient loading history phase, such as a static, dynamic, or thermal transient. In its simplest form, a step can be nothing more than a static analysis of how a load changes from one magnitude to another.

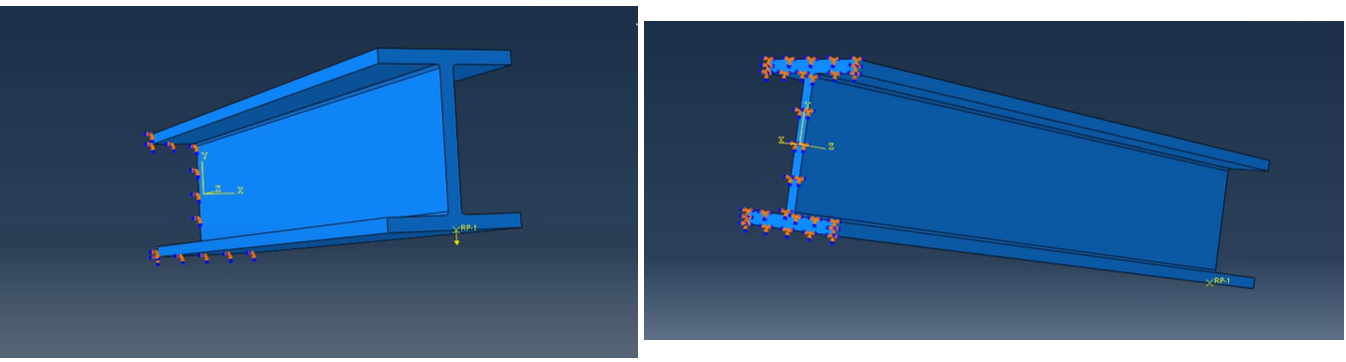

9.5. Step 5: Create boundary condition

We can use the Load module in ABAQUS to create boundary conditions and insert loading. The model’s boundary conditions and loading conditions can be defined and managed with the help of the Load module.

Figure 14: Loading and boundary conditions

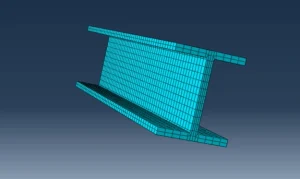

9.6. Step 6: Choose the element type

We should select the element type when meshing the model to achieve a satisfactory and sensible solution to the problem. An FEA model defines a mesh, which is an arrangement of finite elements. A mesh can be defined on a part or an assembly in Abaqus/CAE. The process of discretizing geometry into a finite element representation mesh is known as meshing.

Figure 15: Meshed part

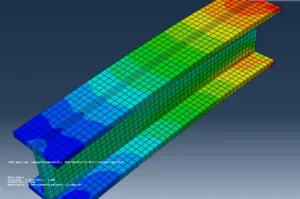

9.7. Step 7: result

In the Visualization module, you can select the results you want to display. For example, you can select stress or strain and see the results in all elements of the model. In this module, you can plot the results of any variable you want. FEA analysis results are the outcome of the FEA analysis process, and engineers use these results for their next calculations.

Figure 16: Results in the Visualization module in Abaqus (the outcome of FEA analysis)

See more examples in the workshops of these packages:

|

|

Get more practical knowledge about FEM simulation in a simple example in the below video:

What is FEM simulation?

A FEM simulation shows how a component or material reacts to certain influences. It is based on the finite element method (FEM). With this numerical calculation method, a component or an entire assembly is divided into a finite number of elements (sub-areas).

Thank you for being with us in this article. In order to always provide you with up-to-date and engaging content, we need to be familiar with your educational and professional experiences so that we can offer articles and lessons that are most useful to you.

| ✅ Subscribed students | +80,000 |

| ✅ Upcoming courses | +300 |

| ✅ Tutorial hours | +300 |

| ✅ Tutorial packages | +100 |

I am looking for a complete and detailed FEM. According to this article, it sounds like the one I need. thanks