When it comes to solving engineering problems, there are three main approaches: experimental methods, analytical solutions, and simulation and modeling.

All engineering and science students regardless of their specific major have heard about simulation and modeling during their education, however, in the following, its advantages are explained.

1. Advantages of simulation

These days, simulation as an economical, efficient method is one of the most, if not the most, considerable methods of solving engineering problems. Both engineers in industry and students in universities take advantage of simulation to obtain the behavior of the system without needing to go to the lab or involve complex mathematical equations.

2. Numerical methods

Numerical methods are developed as a powerful tool for solving the system of the ordinary differential equation (ODE) and partial differential equation (PDE). With the advancement of computers, numerical methods have become very popular among engineers and researchers. There are a number of approaches such as the finite element method (FEM), finite difference method (FDM), finite volume method (FVM), and Lattice Boltzmann method (LBM) to name but a few.

3. Finite element method

Partial differential equations (PDEs) are governing equations of many time and space-depending problems. In a plethora of problems and geometries, it is not possible to solve these PDEs analytically. In this regard, an approximation form of these equations, based on various discretization methods is replaced, which becomes solvable by taking advantage of numerical methods.

Nowadays, the finite element method (FEM) as one of the first numerical approaches is widely used in academic and industrial problems.

4. What is COMSOL?

COMSOL Multiphysics as a finite element-based software plays an important role in simulating scientific phenomena and engineering problems. It is really user-friendly software, which provides a proper graphical environment for the user. In the following paragraphs, this practical software is explained briefly.

4.1 History

It dates back to FEMLAB, which was a package written based on MATLAB. After that time several versions of this were released, and in each version, some new packages were added. The latest version is COMSOL 6.1, in which some packages were updated and some features in several modules were added.

4.2 Multiphysics

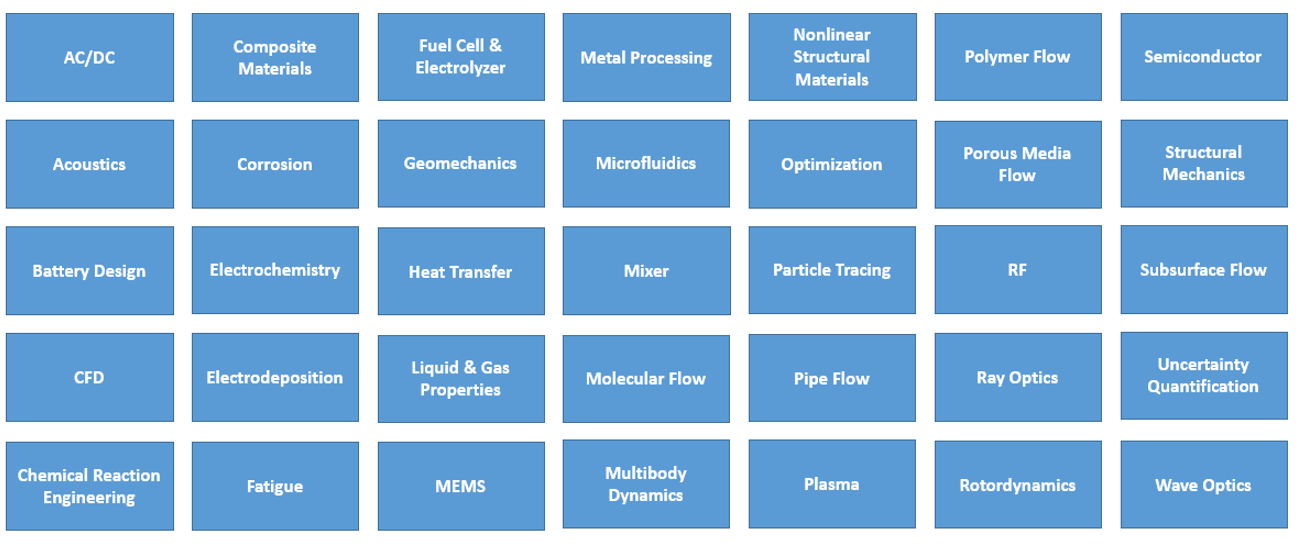

COMSOL is a Multiphysics simulation and application design environment where all steps of a simulation are integrated into a single user interface. In addition, COMSOL allows you to couple together physical effects the way they would be in the real world which is referred to as Multiphysics. It means 3 or 4 physical effects may interact with each other without any limitation on the number of involved physics. Fluid Flow, Heat Transfer, Structural Mechanics, Acoustics, Electromagnetic Fields, Chemical Reactors, User-Defined Equations, etc. are different physics that might be included in a single model, and they could be coupled together in the software.

4.3 Modules

Different modules are available in COMSOL Multiphysics to define and compute a great number of problems such as acoustic modules, heat transfer modules, fatigue modules, and such like.

4.3.1 Geometry

It is often argued that COMSOL Multiphysics is a proper tool for solving small to medium size problems. Moreover, COMSOL is a powerful software for building the geometry of the model as it is using live communication modules for example Livelink, which is available for CAD packages. There is a plenty of ways for defining the geometry such as using CAD toolbar (for instance, SolidWorks, Inventor, SpaceClaim) as well as MATLAB and Excel, and the generating tools in the graphical software environment.

4.3.2 Material

COMSOL Multiphysics has a great deal of materials data (about 12,763). Users can have access to their properties by adding the Material Library. In addition, users can control all of the definitions and properties of their models. For each material up to 42 key property functions are defined, which depend on temperature most of the time or other variables in some cases. These properties and functions can be changed and plotted. Also, references to all material properties data are available.

4.3.3 Equations

All governing equations and variables are accessible in COMSOL so that the user enable to know the method of calculating variables, know their names and the quantities of them, access the variables in the formula form, have easy access to variables and definitions, and use Multiphysics coupling.

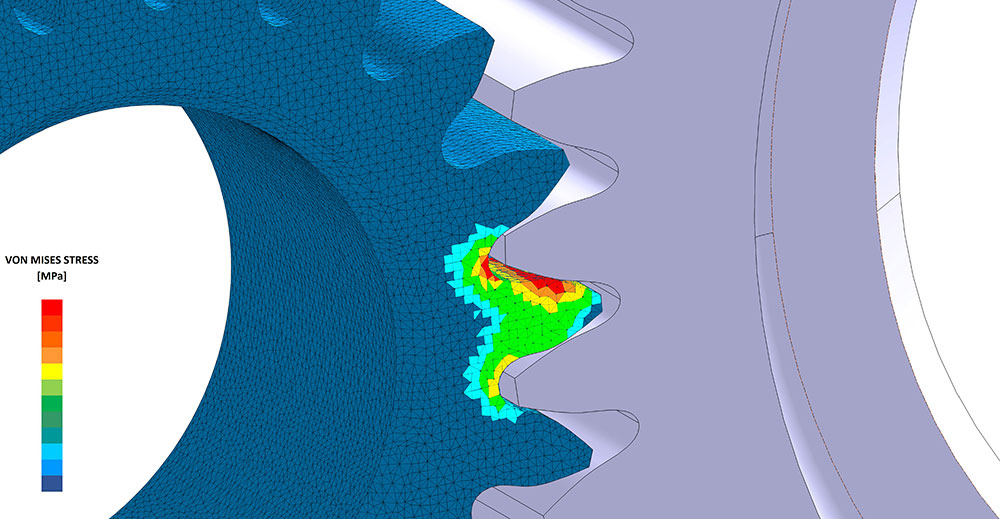

4.3.4 Meshing

The next essential step, after building the geometry, is creating the mesh. The way the geometry is divided, the shape of the dividing elements, the number, size, and density of elements in the generating mesh, and the quality of elements are determining factors in computing the problem. As they affect the run time of the problem, the amount of memory required, the interpolation between nodes, the accuracy, and the convergence of the solution. Therefore, generating a high-quality mesh is one of the most significant steps in solving a problem in the simulation process.

COMSOL allows the user to provide the mesh both automatically and manually by choosing the physics-controlled and user-controlled mesh type, respectively. Irrespective of what type of mesh is chosen, the optimum mesh could be considered by taking advantage of several meshing options and tools.

4.3.5 Post processing

The postprocessing tools in the COMSOL Multiphysics are proper services for understanding results, comprehending physical phenomena, and explaining the problems to the audience.

The postprocessing packages are powerful tools for verifying the intended design by making the user sure that the model setup represents their intended design correctly and checking out the model’s accuracy. Moreover, a good understanding is provided for the user to comprehend how the design works by reducing the prototyping and increasing the speed of development.

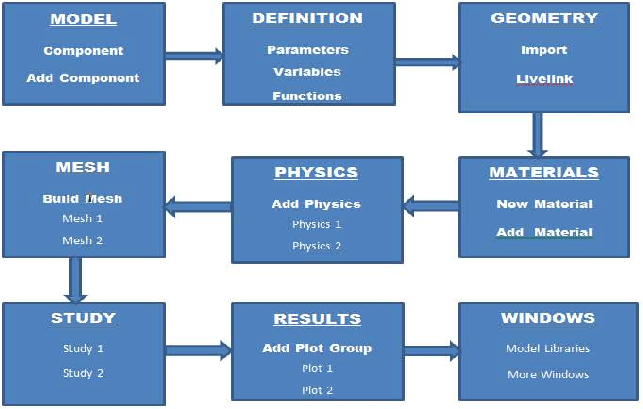

4.4 Simulation workflow

To explain how to simulate a problem in COMSOL Multiphysics briefly, the following steps could be pursued:

- Setup model environment

- Create geometric objects

- Specify materials’ properties

- Define physics boundary conditions

- Create the mesh

- Run simulation

- Postprocess results

Ref. 1

5. Comparison between COMSOL, ANSYS, and ABAQUS

When it comes to comparison between up-to-date and currently used software, we must remember that all of them have advantages and disadvantages, otherwise, they become out-of-date. In this regard, for comparison between this three powerful software, the goals and configuration of the project should be considered, however, in the following paragraphs we compare both Abaqus and Ansys with COMSOL Multiphysics concisely.

5.1 ANSYS & COMSOL:

If one wants to build a general case and save time, it would be better for them to use Ansys, however, if one want to access physics and equations, and become able to change them easily regardless of the time it takes it would be better for them to take advantage of COMSOL Multiphysics. Furthermore, COMSOL as a multiphysics software is able to couple different phenomena and solve multi-physical problems, which can compute a wide range of problems. In addition, COMSOL is considered the most user-friendly software.

In the field of CFD and solid mechanics, although Ansys is more powerful, COMSOL does its best to upgrade and improve its solver to enhance its speed and efficiency.

5.2 COMSOL & ABAQUS:

Despite the fact that Abaqus is examined as an incredibly accurate software for solving non-linear solid mechanics problems, it is unable to couple different physics.

In the end, it should be mentioned that for users, who know MATLAB, COMSOL is a proper, decent tool as it could be linked with MATLAB, thus providing more efficient results.

6. Applications of using COMSOL Multiphysics in industry

Nowadays, highly valued companies around the world take advantage of COMSOL Multiphysics for improving and enhancing the quality of their products. Companies such as BOEING, intel, HUAWEI, NASA, and TOYOTA to name but a few, use COMSOL Multiphysics as a proper, descent simulation software.

For instance, BOEING used COMSOL Multiphysics for simulating thermal expansion in aircraft composites. They take advantage of COMSOL in order to evaluate the thermal stress and displacement in each layer of the composite structure layup.

Another example of using COMSOL Multiphysics in the high technology industry is modeling the chamber gas dynamics and the internal acoustics of rocket systems by NASA.

In addition, a group of engineers at NASA developed a water-saving system, which is called Isothermal Bulk Desiccant (IBD). It is used to absorb water from the atmosphere and recycle it. The team used COMSOL Multiphysics in order to simulate the gas flow and heat transfer in the IBD. COMSOL Multiphysics made them able to track flow rates, water concentration, and pressure conditions. They use COMSOL for the optimization of their model, by doing so, they hope to become able to design systems for traveling longer distances than ever before.

7. Summary

In the past, engineers and scientists had to make assumptions when designing their projects. However, as time goes on, these assumptions are becoming more accurate and being eliminated, enabling more precise results. Multiphysics is a key factor in this process, as it couples related physical applications together to form complete models that include all necessary factors. COMSOL Multiphysics is a simulation software designed to provide the most accurate results by minimizing the assumptions that its users must make.

COMSOL Multiphysics allows its users to have complete control over their models, unlike other simulation software that can be restrictive. Users can couple any number of physics together and input user-defined physics and expressions directly into a model, allowing for creative possibilities that may not be possible or more difficult to achieve with other simulation software.

COMSOL Multiphysics is a software package used for finite element analysis, simulation, and solving of physics and engineering problems, particularly involving multiphysics and coupled phenomena. The software includes user interfaces for various physics-based systems and partial differential equations. It has a unified workflow for different applications in mechanical, electrical, fluid, acoustics, and chemical domains. The software also provides an API for Java and LiveLink for MATLAB, and external control of the software can be done using LiveLink for major CAD software. The Application Builder allows creation of custom simulation apps, using drag-and-drop tools or programming. COMSOL Server is a separate software that manages COMSOL simulation applications in companies. The modules in COMSOL are categorized based on different application areas, including Electrical, Mechanical, Fluid, Acoustic, Chemical, Multipurpose, and Interfacing.

COMSOL is a simulation environment that aims to replicate real-world scenarios as closely as possible. This is achieved through the use of multiphysics, which involves multiple scientific models such as acoustics, electromagnetics, chemical reactions, mechanics, fluid flow, and heat transfer. By including all these effects in the simulation environment, COMSOL ensures that it can model a wide range of scenarios encountered by scientists and engineers in their work. The user interface is designed to be user-friendly and geared towards enhancing productivity. The software is used by engineers to design better products, scientists to make new discoveries, physicians to research medical treatments, and educators to connect with students. The simulations produced using COMSOL multiphysics have a significant impact on the real world.

Here’s an example of how COMSOL Multiphysics can be used in a real-world scenario:

In the field of biomedical engineering, COMSOL Multiphysics has been used to simulate the performance of medical devices such as stents. Stents are small tubes that are inserted into blood vessels to treat blockages. In order to ensure the safety and efficacy of stents, engineers need to understand how they interact with the human body. COMSOL Multiphysics can be used to simulate the blood flow and mechanical stresses within the stent and surrounding tissues, helping engineers to optimize the design and minimize the risk of complications.

By using COMSOL Multiphysics, engineers can model the fluid dynamics of blood flow, the mechanical stresses on the stent, and the biological responses of the surrounding tissues. This allows them to predict how the stent will perform inside the body and make design adjustments to optimize its performance and minimize the risk of complications.

COMSOL Multiphysics is a software package that uses the finite element method to solve complex physics-based problems. Here’s how it works:

- Problem Definition: The user defines the problem they want to solve, including the geometry, physics, and boundary conditions.

- Meshing: The software automatically generates a mesh, which is a set of discrete points and elements that represent the geometry of the problem.

- Physics-Based Modules: The user selects the physics-based modules that are relevant to the problem they want to solve. These modules represent different physical phenomena, such as electromagnetics, fluid dynamics, heat transfer, and structural mechanics.

- Coupling: The user can couple multiple physics-based modules together to solve multiphysics problems. This allows them to model the interactions between different physical phenomena.

- Solver: The software uses numerical methods to solve the system of equations that describe the problem. The solution is represented as a set of variables at each point in the mesh.

- Post-Processing: The user can visualize and analyze the results of the simulation using a variety of post-processing tools, such as plots, animations, and tables.

COMSOL Multiphysics allows users to solve complex physics-based problems across multiple domains using a unified software environment. The software provides a range of physics-based modules that can be coupled together to solve multiphysics problems, and it uses numerical methods to solve the system of equations that describe the problem. The results of the simulation can be visualized and analyzed using a range of post-processing tools.