Computational Predictions for Predicting the Performance of Structure

This package focuses on developing and applying predictive models for the structural analysis of steel and concrete components subjected to fire and subsequent earthquake loading. To accurately simulate the complex behavior of these structures, finite element analysis (FEA) using ABAQUS is employed. The Taguchi method optimizes the number of samples needed for FE analysis, and this method is used with SPSS after explanation its concept. However, due to the computational demands of FEA, various machine learning techniques, including regression models, Gene Expression Programming (GEP), Adaptive Network-Based Fuzzy Inference Systems (ANFIS), and ensemble methods, are explored as surrogate models. These models are trained on large datasets of FEA results to predict structural responses efficiently. The performance of these models is evaluated using statistical metrics such as RMSE, NMSE, and coefficient of determination.

Damage Prediction in Reinforced Concrete Tunnels under Internal Water Pressure

This tutorial package equips you with the knowledge and tools to simulate the behavior of reinforced concrete tunnels (RCTs) subjected to internal water pressure. It combines the power of finite element (FE) modeling with artificial intelligence (AI) for efficient and accurate analysis. The Taguchi method optimizes the number of samples needed for FE analysis, and this method is used with SPSS after explanation its concept.

By leveraging Artificial Intelligence (AI) techniques such as regression, GEP, ML, DL, hybrid, and ensemble models, we significantly reduce computational costs and time while achieving high accuracy in predicting structural responses and optimizing designs.

Computational Modeling of Steel Plate Shear Wall (SPSW) Behavior

This course equips engineers with the tools to design and analyze Steel Plate Shear Walls (SPSW) and Reinforced Concrete Shear Walls (RCSW) subjected to explosive loads. Traditional Finite Element (FE) simulation is time-consuming and requires numerous samples for accurate results. This package offers a more efficient approach using Artificial Intelligence (AI) models trained on FEA data. You'll learn to develop FE models of SPSW and RCSW in ABAQUS software, considering material properties, interactions, and boundary conditions. The Taguchi method optimizes the number of samples needed for FE analysis, and this method is used with SPSS after explanation its concept.

We then delve into AI modeling using MATLAB. Explore various methods like regression, Machine Learning (ML), Deep Learning (DL), and ensemble models to predict the behavior of SPSW and RCSW under blast loads. Statistical analysis helps compare model accuracy. By combining FE analysis with AI models, you'll gain a powerful tool for designing blast-resistant structures while saving time and resources.

In this package, the dynamic behavior of a developed bypass viscous damper is evaluated. The developed bypass viscous damper is an advanced seismic protection device that features a flexible, high-pressure hose as an external orifice, which acts as a thermal compensator to reduce viscous heating during dynamic events. This damper's performance can be adjusted by modifying the hose's dimensions, enabling precise control over its damping properties. The package includes comprehensive simulations and experimental validations using CFD models in ABAQUS and structural analysis in SAP2000. A simplified design procedure for incorporating these dampers into structures is also provided, demonstrated through the case study of an 8-story hospital, showing reduced structural demands and improved performance of nonstructural elements during seismic events.

Abaqus basic tutorials on concrete beams and columns

Welcome to the “Abaqus Basic Tutorials on Concrete Members,” a comprehensive course tailored for civil and structural engineers seeking to master finite element modeling (FEM) of concrete structures. This tutorial covers key concepts such as plain concrete beam and column modeling, reinforced concrete members, and fiber-reinforced polymer (FRP) composites. The course guides learners through the application of boundary conditions, material properties, and various loading conditions in Abaqus. Key topics include plain concrete beam and column modeling, reinforcement modeling with steel bars and stirrups, and fiber-reinforced polymer (FRP) reinforcement techniques. Participants will also explore comparing simulation results with experimental data, as well as interpreting critical outcomes such as stress distribution and failure modes. Through hands-on workshops, learners will simulate structural behaviors under axial, lateral, and compression loads, ensuring a practical understanding of FEM for concrete members. By the end of this course, participants will be proficient in using Abaqus to model and analyze concrete structures, reinforced elements, and advanced composites, providing them with a strong foundation for structural analysis and design.

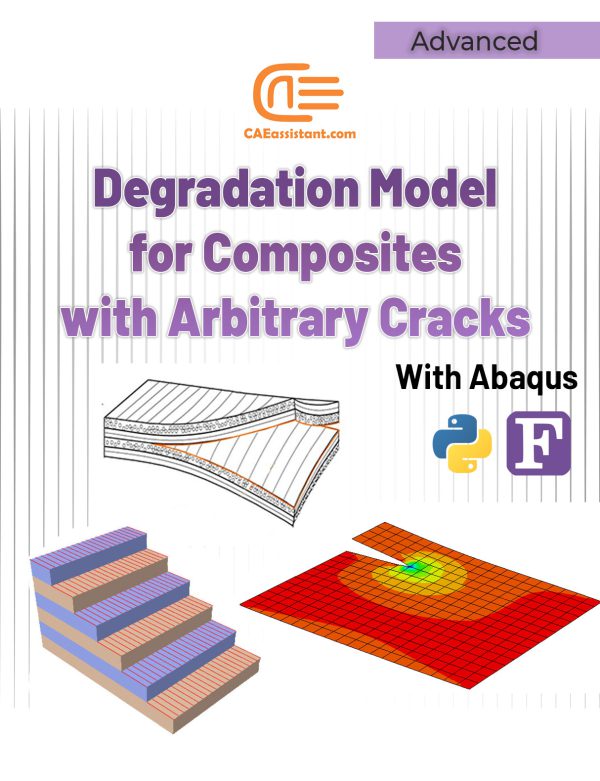

An Efficient Stiffness Degradation Composites Model with Arbitrary Cracks | An Abaqus Simulation

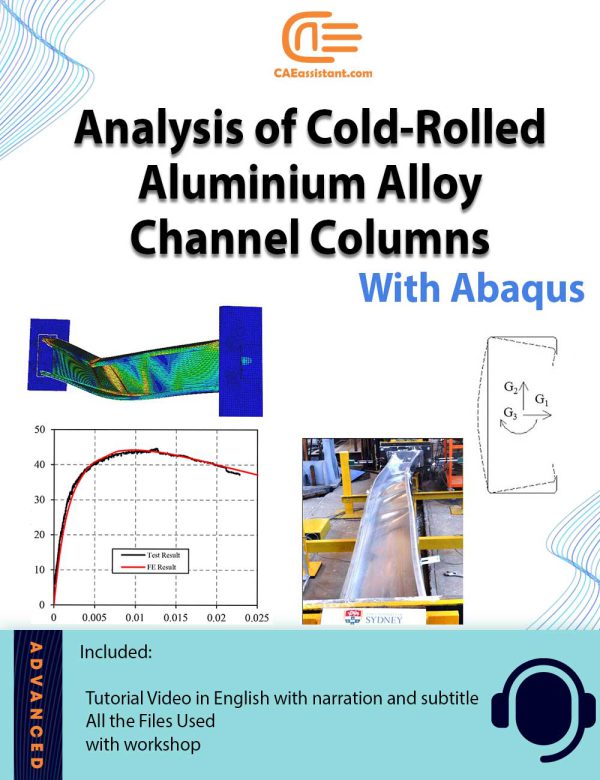

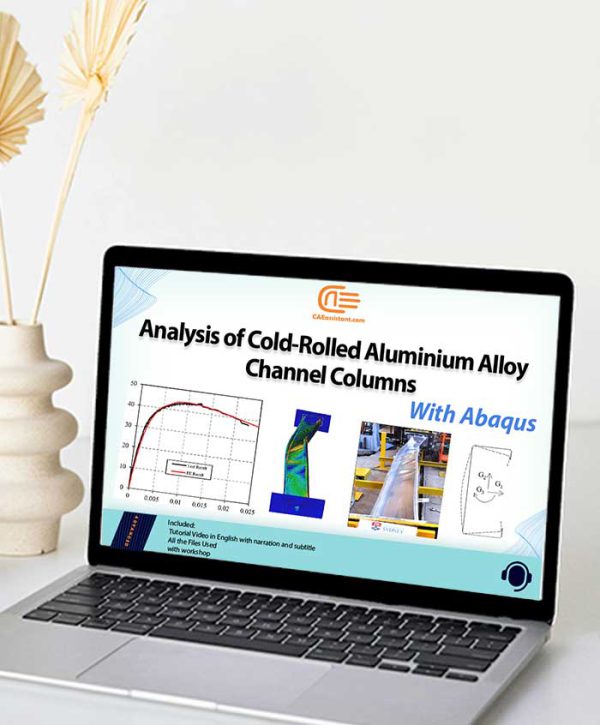

Analysis of Cold Rolled Aluminium Alloy Channel Columns With Abaqus CAE

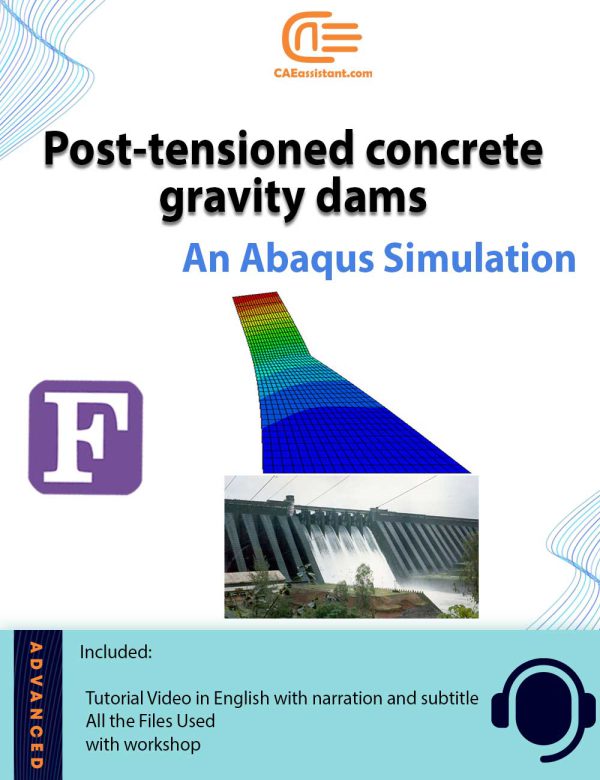

Seismic Analysis in Post-Tensioned Concrete Gravity Dam Design Using Abaqus Subroutines

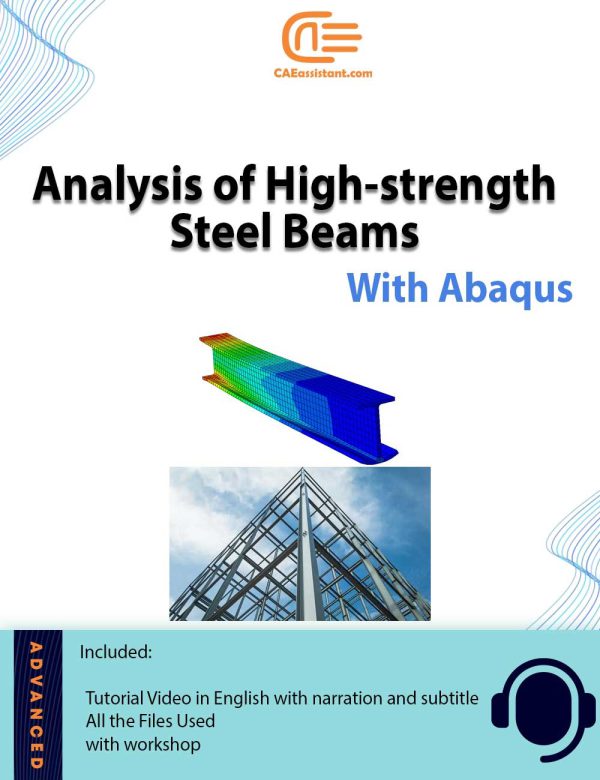

Fiber-based Model for High-Strength Steel Beam Analysis with Abaqus

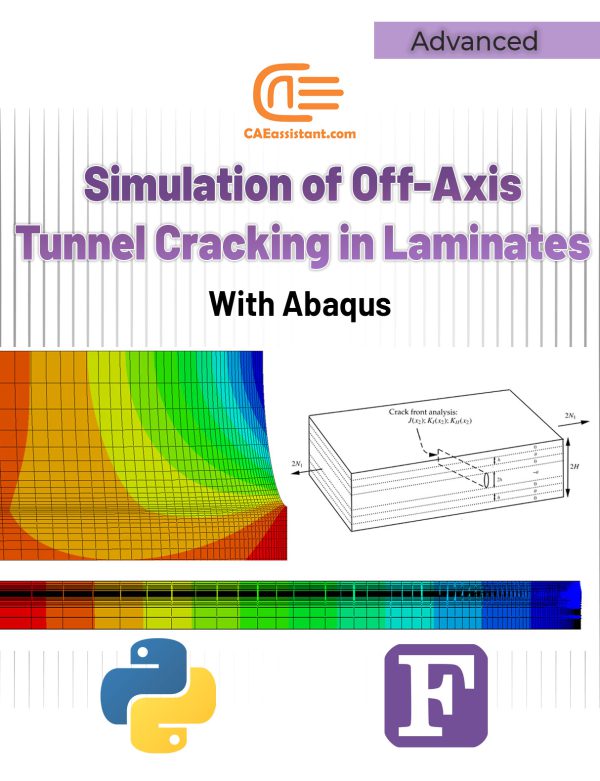

Advanced Finite Element Analysis of Off-Axis Tunnel Cracking Laminates

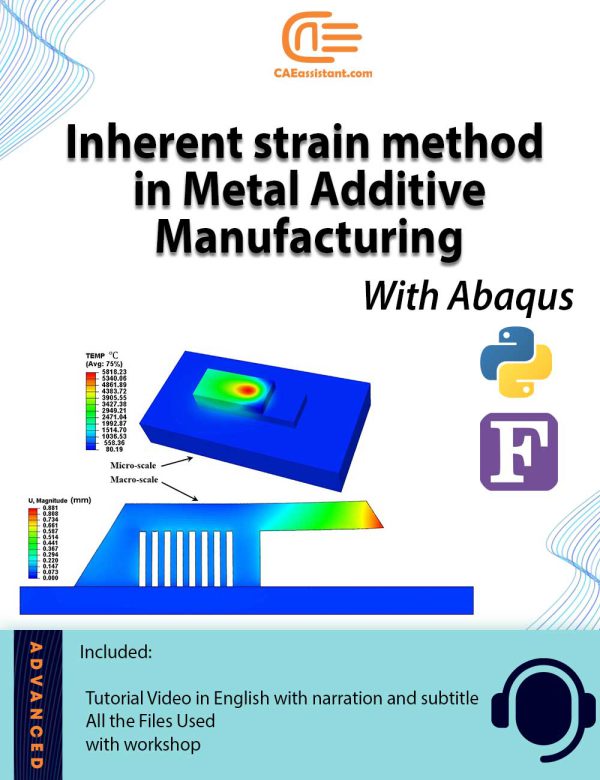

Additive Manufacturing (AM), a revolutionary layer-by-layer fabrication technology, is transforming how products are designed and manufactured. This comprehensive tutorial package focuses on the Inherent Strain (IS) method, a highly efficient numerical approach for simulating the Laser Powder Bed Fusion (LPBF) process in metal additive manufacturing. The detailed thermo-mechanical simulation of the Laser Powder Bed Fusion (LPBF) for complex geometric parts requires a large number of time steps to estimate residual stress and distortion, which is not computationally cost-effective. Furthermore, based on the large thermal gradient near the heat source, the mesh size must be sufficiently small to accurately predict the induced residual stress and distortion of the deposited layers in the heat-affected zone. Therefore, applying a coupled thermo-mechanical analysis for multiple laser scans with a fine mesh model to macro-scale simulation would incur excessively large computational costs.

Additionally, the large number of degrees of freedom for each element in the mechanical analysis leads to higher complexity as well as a longer amount of processing time. Detailed thermo-mechanical analysis for an industrial component is almost impractical since it would demand hundreds of terabytes of memory and years to calculate. Therefore, to overcome the huge computational burden associated with the numerical simulation of the LPBF caused by the infinitesimal laser spot size and thousands of thin layers with a thickness at the micron level, the Inherent Strain Method in additive manufacturing has been widely used in research and commercial software.

In this tutorial, the Inherent Strain Method additive manufacturing approach is presented both theoretically and practically in Abaqus. An agglomeration approach will be considered to transfer an equivalent inherent strain from both micro-scale and macro-scale modeling strategies. The implementation of this approach is explained step by step, accompanied by various workshops in micro-scale and macro-scale models for different geometries. This training package enables you to write your subroutine codes and Python scripting, as well as have more control over the LPBF process simulation.

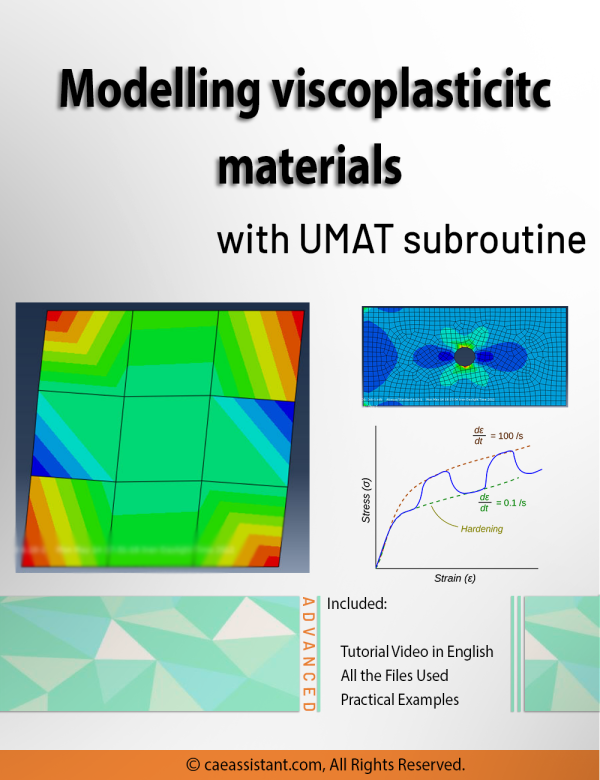

Viscoplasticity Abaqus Simulation Using UMAT Subroutine | Perzyna Viscoplastic Model

Viscoplasticity describes the rate-dependent inelastic behavior of materials, where deformation depends on both stress magnitude and application speed. This concept is crucial in many engineering applications, such as designing structures under dynamic loads, modeling soil behavior during earthquakes, and developing materials with specific mechanical properties. Viscoplasticity Abaqus simulation, especially using Abaqus with UMAT subroutines, are vital for understanding, predicting, and optimizing the behavior of viscoplastic materials. This tutorial focuses on implementing the Perzyna viscoplasticity model in Abaqus. The Perzyna viscoplastic model, a strain rate-dependent viscoplasticity model, relates stress to strain through specific constitutive relations. This involves defining plastic strain rate based on stress state, internal variables, and relaxation time. The tutorial provides general UMAT codes for viscoplastic analysis, yielding results like stress fields essential for various engineering applications. These simulations help in predicting permanent deformations, assessing structural failure points, and analyzing stability under different loads, benefiting fields such as aerospace, automotive, civil engineering, and energy.

Pultrusion Crack Simulation in Large-Size Profiles | Pultrusion Abaqus

Pultrusion is a crucial task for producing constant-profile composites by pulling fibers through a resin bath and heated die. Simulations play a vital role in optimizing parameters like pulling speed and die temperature to enhance product quality and efficiency. They predict material property changes and aid in process control, reducing reliance on extensive experimental trials. However, simulations face challenges such as accurately modeling complex material behaviors and requiring significant computational resources. These challenges underscore the need for precise simulation methods to improve Pultrusion processes. This study employs ABAQUS with user subroutines for detailed mechanical behavior simulations, including curing kinetics and resin properties. Key findings include insights into crack formation (pultrusion crack simulation), material property changes, and optimization strategies for enhancing manufacturing efficiency and product quality. This research (pultrusion Abaqus) provides practical knowledge for implementing findings in real-world applications, advancing composite material production.

Elastomeric Foam Simulation Using Abaqus Subroutines

Techniques of simulating Large and Complex models in Abaqus

Piezoelectric simulation in Abaqus

Full Composite fatigue Add-on (Academic and industrial usage)

Full Composite damage Add-on (Academic and industrial usage)

How to use ABAQUS Documentation

This package teach you how to simulate your customized problem by using help to find similar problems and execute them, theories, using scripts and subroutines and etc.

This tutorial teach how to define incremental thermal strains as functions of temperature, predefined field variables, and state variables loads. UEXPAN and VUEXPAN subroutines are used for implicit and explicit solvers respectively.

This tutorial is given the shear and bending forces as the output of the subroutine where the shell mechanical behavior is nonlinear and can only be presented on the basis of general terms of the shell matrix and such behavior is not present in the ABAQUS graphical environment.