Composite types

The composites can be classified based on their matrix or reinforcement parts. Each of them has its own branches but this add-on consists of four types of composites: Unidirectional, Woven, short fiber composites (chopped), and wood.

Unidirectional composites are a type of composite material consisting of fibers that are aligned in a single direction, typically parallel to each other. These composites have high strength and stiffness in the fiber direction and are commonly used in aerospace and structural applications. Woven composites are a type of composite material consisting of interlacing fibers in a crisscross pattern. These composites have good mechanical properties in multiple directions and are commonly used in aerospace, automotive, and sporting goods applications. Short fiber composites are a type of composite material consisting of short fibers randomly dispersed in a matrix material. These composites have good toughness and are commonly used in automotive and consumer goods applications where impact resistance is important. Wood is a natural composite material consisting of cellulose fibers embedded in a lignin matrix. It has good mechanical properties and is commonly used in construction, furniture, and decorative applications. Wood composites, made by combining wood fibers or particles with a resin or adhesive, offer improved properties and versatility compared to natural wood.

Composite damage modeling in Abaqus

Composite damage modeling is used to predict the behavior of composite materials under various loading conditions. It involves modeling the damage progression in the composite material, such as cracking or delamination, and calculating the resulting changes in mechanical properties. Abaqus does this modeling in two ways: The Abaqus GUI itself and writing subroutines. The Abaqus GUI composite damage modeling has some limitations and most of the time a subroutine must be written. However, writing subroutine requires some skills and sometimes could be tricky even for the advanced users. Therefore, this add-on comes in and generates the subroutine for you. Just select the desired composite type, insert its material properties and generate the subroutine.

This add-on supports four types of composites: Unidirectional, Woven, short fiber composites (chopped), and wood.

Damage in unidirectional composites

Unidirectional composites are a type of composite material in which the fibers are oriented in a single direction. This provides excellent strength and stiffness in that direction, but makes the material weaker in other directions. Common types of damage in unidirectional composites include delamination, fiber breakage, matrix cracking, and inter-fiber debonding. These types of damage can occur due to overloading, impact, or fatigue, and can decrease the strength and durability of the material if not properly addressed.

When the Unidirectional type is selected, after the insertion of the material properties, the subroutine will be generated in the form of a VUSDFLD subroutine. The theory used for the damage analysis is the HASHIN criteria. The theory will be explained along with the VUSDFLD subroutine.

The Hashin criteria for all types of damage in this type of composite are as follows:

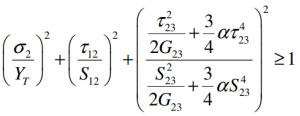

Matrix tensile failure, for :

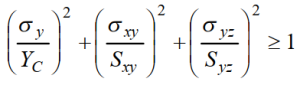

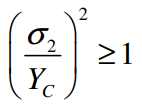

Matrix compressive failure, for :

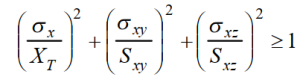

Fibre tensile failure, for :

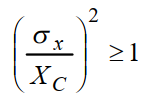

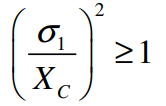

Fibre compressive failure, for :

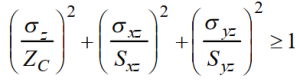

Delamination in tension, for :

Delamination in compression, for :

Fiber-matrix shear- out, for :

Where Sigma X, Y, and Z respectively are normal stress in directions one, two, and three; X(T), Y(T), and Z(T) respectively are tensile strength in directions 1, 2, 3 of; X(C), Y(C), Z(C) respectively are

compression strength in direction 1, 2, 3; Sxz, Syz, Szx are in-plane shear strength.

If a ply fails, its material properties are reduced by applying a sudden degradation rule.

Damage in woven composites

Woven composites are a type of composite material made up of interlaced fibers. This interlacing creates a crisscross pattern that provides strength and stiffness in multiple directions. However, the presence of interlacing also makes woven composites more susceptible to damage from delamination, fiber pullout, matrix cracking, and inter-fiber debonding. These types of damage can occur due to overloading, impact, or fatigue, and can weaken the material if not properly addressed.

The damage theory used for the woven type is the HASHIN criteria modified for the woven composites, which will be explained.

The Hashin criteria for damage in this type of composites are as follows:

Fiber failure criteria in warp direction (direction 1):

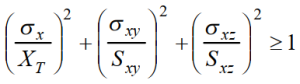

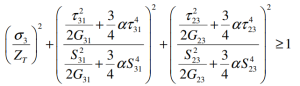

Tensile failure :

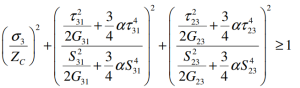

Compression failure :

Fibre failure criteria in weft direction (direction 2):

Tensile failure :

Compression failure :

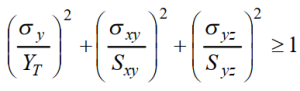

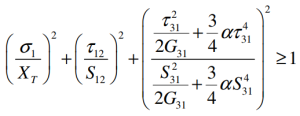

Delamination failure criteria in normal direction (direction 3):

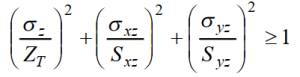

Tensile failure :

Compression failure :

Alpha, the material nonlinearity factor. Sigma one, two, and three respectively are normal stress in directions one, two, and three. are in plane shear stress; X(T), Y(T), and Z(T) respectively are tensile strength in directions 1, 2, 3 of woven ply; X(C), Y(C), Z(C) respectively are compression strength in direction 1, 2, 3 of woven ply; S12, S23, S31 are in-plane shear strength; and G12, G23, and G31 are in-plane shear modulus.

Damage in short fiber composites (chopped)

Short fiber composites are a type of composite material in which short fibers are mixed with a matrix material. This type of composite is known for its high toughness and impact resistance, making it a popular choice for applications that require durability and strength. However, short fiber composites are also susceptible to several types of damage, including fiber breakage, matrix cracking, fiber pullout, and interfacial debonding. These types of damage can occur due to overloading or fatigue, and can compromise the strength and integrity of the material. To prevent damage, short fiber composites are often designed with reinforcement structures and protective coatings.

Short-fiber thermoplastics were introduced in the 1960s, featuring fiberglass and carbon fiber as the most commonly used reinforcement fibers. The incorporation of short fibers into thermoplastic resins enhances the lightweight performance of the composite for various applications. Short-fiber thermoplastic composites are also less complex and costly to produce compared to continuous-fiber composites. This cost-effectiveness makes staple fiber thermoplastics a versatile choice for different applications.

The theory used for the short fiber composites (chopped) is the same one used and explained in the “Damage simulation of short fibre composites with subroutine” package.

Damage in wood

Wood is a natural composite material made up of cellulose fibers and a lignin matrix. It is known for its strength, durability, and versatility, making it a popular choice for construction, furniture, and other applications. However, wood is also susceptible to several types of damage, including decay, rot, termite infestation, and fire damage. These types of damage can weaken the material and compromise its structural integrity. To prevent damage, wood is often treated with preservatives and fire retardants. Regular maintenance and inspection can also help identify and address potential damage to ensure the longevity of the wood.

And finally, the theory of the damage analysis in wood is the Sandhas and Hashin failure criteria.

All theories, along with the VUSDFLD subroutine, will be explained in this tutorial package. Another advantage of this add-on is that it can be used for industrial purposes. A complex model like an airplane can be imported into the Abaqus; and by using this add-on, the composite materials can be created, and by use of the settings in the Property module, the composite materials can be assigned to each part and then generate the subroutine for damage analysis.

It would be helpful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial.

Read about Composites: All about Composite analysis | Abaqus composite

Diana –

The Full Composite damage Add-on from CAE Assistant is highly recommended for those looking to enhance their skills in composite damage modeling. It provides a comprehensive package that includes tutorials, video files, and other resources to help you learn and apply the concepts effectively. The Add-on is suitable for both academic and industrial usage, allowing you to gain practical knowledge that can be applied to real-world projects. I am extremely satisfied with this product and would encourage others to explore its capabilities.