Thermal mechanical Analysis

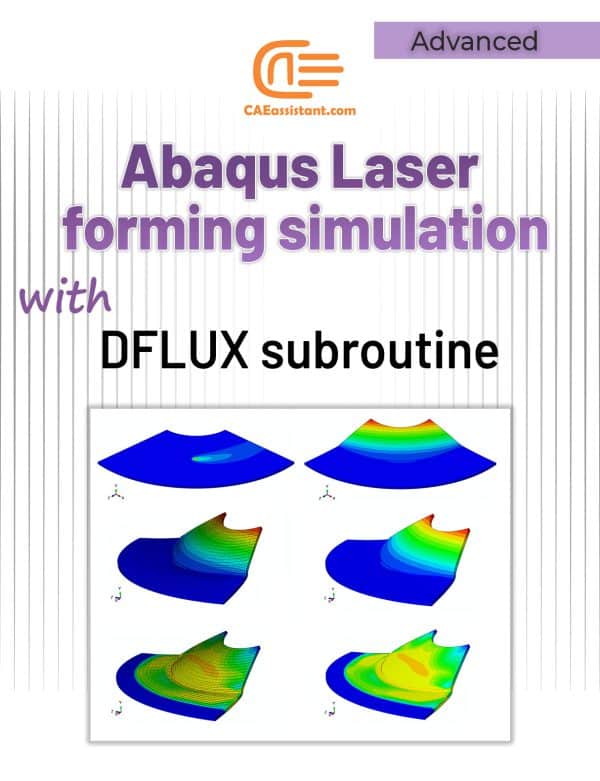

Laser forming simulation tutorial in Abaqus

The laser forming process is performed by applying thermal stresses to the workpiece surface by heating the surface with a laser beam. These internal stresses induce plastic strains in the part resulting in local elastic-plastic deformation (Laser-induced plastic deformation). In this laser forming simulation tutorial the DFLUX subroutine is used to apply heat flux (Gaussian heat distribution) dependent on location and time in finite element simulation. For example, the linear heating processes of laser forming and welding (with a slight simplification) can be simulated by this subroutine. In the linear heating process, by applying heat flux to the surface of a sheet, a thermal gradient is created in its thickness. This thermal gradient causes permanent deformation of the sheet. To simulate the laser forming process, it is necessary to apply a time and location-dependent heat flux to the sheet. In this type of loading, a heat flux is applied on the plate, which is defined using the DFLUX subroutine, including the laser power, movement speed, beam diameter, absorption coefficient, and laser movement path according to the designed experiments (Laser forming process parameters). To verify this Abaqus laser forming simulation, the simulation results and experimental results of sheet deformation (U) are compared. The displacement of the sheet in the simulation is in good agreement with the experimental results.

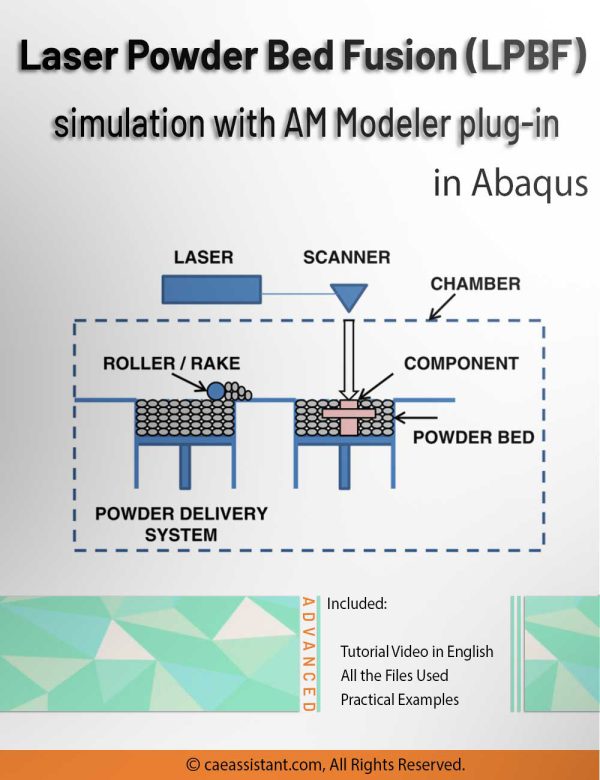

3D printing simulation with Laser Powder Bed Fusion (LPBF) method in Abaqus

3D printing is a process of creating three-dimensional objects by layering materials, such as plastic or metal, based on a digital design. 3D printing simulation involves using software to predict and optimize the printing process, allowing for more efficient and accurate production. This educational package includes two 3D printing modeling methods. The first method is based on the use of subroutines and Python scripting. After an introduction to the 3D printing process, the first method with all of its detail is explained; then, there would be two workshops for this method; the first workshop is for the 3D printing simulation of a gear with uniform cross-section and the second one is for a shaft with non-uniform cross-section. The second method uses a plug-in called AM Modeler. With this plug-in, the type of 3D printing can be selected, and after inserting the required inputs and applying some settings, the 3D printing simulation is done without any need for coding. Two main workshops will be taught to learn how to use this plug-in: "Sequential thermomechanical analysis of simple cube one-direction with LPBF 3D printing method using the trajectory-based method with AM plug-in" and "3D printing simulation with Fusion deposition modeling and Laser direct energy deposition method with AM plug-in".

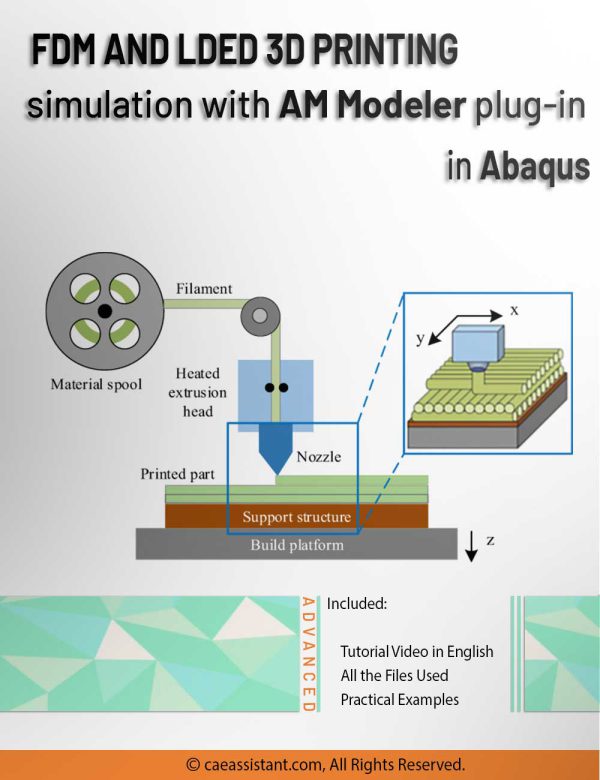

3D printing simulation with Fused Deposition Modeling (FDM) in Abaqus

3D printing is the process of fabricating objects in three dimensions by adding layers of materials, such as plastic or metal, based on a digital design. Simulation for 3D printing involves the use of software to predict and optimize the printing process, enabling more efficient and precise production. This educational package includes a simulation specifically for 3D printing using Fused Deposition Modeling (FDM). The simulation employs a plug-in known as AM Modeler, which allows users to select the desired 3D printing method. By inputting the necessary parameters and adjusting settings, the 3D printing simulation can be performed without requiring any coding. A workshop will be conducted to teach participants how to utilize this plug-in effectively, focusing on "3D printing simulation with Fused Deposition Modeling and Laser Direct Energy Deposition method using the AM plug-in."

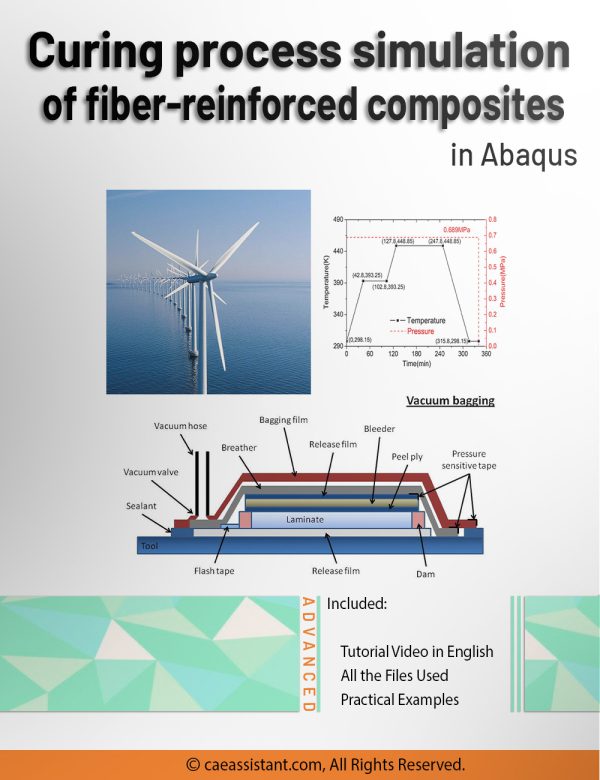

Curing process simulation in Abaqus

Fiber-reinforced composites have found widespread use across various fields due to their remarkable properties. This necessitates a careful design of their manufacturing processes to attain industrial application quality. The critical factor influencing their quality is the curing process, wherein the resin transforms into a solid state under temperature cycles. However, the challenge lies in achieving optimal curing quality while maintaining production efficiency. To overcome this challenge, an effective approach involves utilizing numerical simulations to optimize temperature cycles during curing. Nonetheless, creating such a model is complex as it must consider multiple factors concurrently, including temperature release from chemical reactions, shrinkage strains, and stress resulting from temperature variations, topics covered in this package. The package begins with an introduction to fiber-reinforced composites, exploring their advantages, applications, and categorization. It guides you through the fabrication process, detailing curing techniques and associated challenges. Furthermore, the package introduces constitutive equations for simulating the curing process and the necessary Abaqus subroutines for implementation. Additionally, two practical workshops are included to offer experience in modeling the curing process with Abaqus. These workshops enable you to evaluate internal heat generation and analyze strain and stress distributions. They not only provide guidance on simulation and subroutine implementation but also are provided for verification purposes.

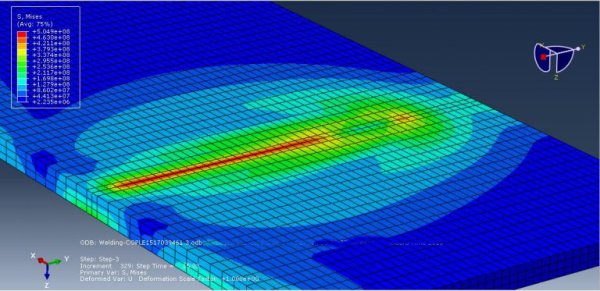

Arc welding simulation in Abaqus

Notice: This package will be available one week after purchase.

Arc welding is a fusion process that involves joining metals by applying intense heat, causing them to melt and mix. The resulting metallurgical bond provides strength and integrity to the welded joint. Arc welding is widely used in various industries for fabricating structures and components. Arc welding simulation in Abaqus is essential for optimizing the welding process and ensuring high-quality welds. It allows engineers to predict and analyze factors such as temperature distribution, residual stresses, distortion, and microstructure evolution during welding. By accurately simulating the welding process, parameters like welding speed, heat input, and electrode positioning can be optimized to achieve desired weld characteristics and minimize defects.

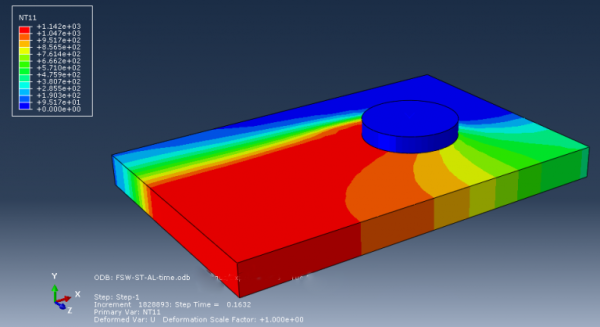

Friction Stir Welding (FSW) Simulation in Abaqus

Friction stir welding (FSW) is a solid-state joining process that utilizes a rotating tool to generate frictional heat, enabling the consolidation of materials without melting. FSW offers numerous benefits and is particularly valuable for welding challenging materials like aluminum alloys. It finds widespread applications in industries such as automotive, aerospace, shipbuilding, and construction, providing enhanced strength, weight reduction, and structural integrity. FSW minimizes distortion, reduces the need for post-weld machining, and eliminates issues related to solidification and cooling. Simulations using Abaqus, a popular finite element analysis software, play a crucial role in optimizing FSW processes. Engineers can investigate process parameters, evaluate weld quality, predict residual stresses and distortions, and optimize weld designs through Abaqus simulations. These simulations enable cost-effective development, improved weld quality, reduced material waste, and enhanced productivity in industrial applications. In this package, you will learn how to simulate FSW simulations in a variety of examples with different methods.

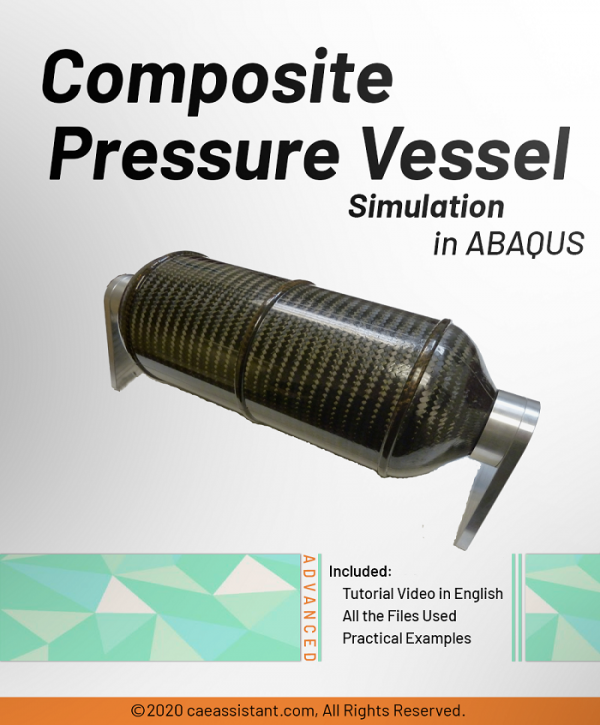

Composite Pressure Vessel simulation in ABAQUS

Pressure vessels are made using different methods today, and one of them is filament winding. This package shows the simulation of composite pressure vessels made using the filament winding method.

In this training package, three winding methods, planar, geodesic, and isotensoid, have been taught for filament winding pressure vessels. In this tutorial, two general methods also have been presented for simulating filament wound pressure vessels. One uses the Abaqus graphical user interface(GUI), and the other uses the Python script. On the other hand, two criteria, Tsai-Hill and Puck, have been used to model damage in the composite. A UMAT subroutine has been used to use the Puck criterion.

Car part industrial simulation

Car industrial parts are complex and critical components that play a vital role in the operation of a car. Two such parts are the exhaust manifold and the internal combustion engine (IC engine). The exhaust manifold directs hot exhaust gases from the engine's cylinders into the exhaust system and is typically made of cast iron or stainless steel. The IC engine converts fuel into mechanical energy by burning fuel in a controlled explosion within the engine cylinder. High temperatures and pressures must be considered in the design, and the components must be made of durable materials that can withstand the stresses of constant combustion. Therefore, it is important to know how these parts respond under different loading conditions to have the best design possible. In this package, there are two workshops to help you with this job: Heat transfer analysis in an exhaust manifold and Thermomechanical analysis of an exhaust manifold.

Rock simulation is essential for evaluating the behaviour of rock masses under various loading conditions, such as earthquakes, landslides, and blasting. It enables engineers and geologists to assess the stability and integrity of rock structures, predicts potential failure modes, and develop effective mitigation strategies. Rock simulation is crucial in the design and planning of mining operations, tunnels, and underground constructions to ensure the safety and longevity of the structures. It also plays a vital role in assessing the seismic hazard of an area and evaluating the potential impact of earthquakes on the built environment. In this package, you will learn how to do an impact simulation on a granite stone using the JH-2 model; also an explosion simulation inside a rock for excavation purposes. You can learn more detail in the description of the workshops.

The aim of fire analysis is to evaluate the performance of structures in real fire scenarios and to develop strategies to improve their fire resistance and safety. Fire analysis is commonly used in the design and evaluation of buildings, bridges, and other structures. Fire analysis is the process of simulating the behavior of structures under fire conditions. Fire analysis typically involves two main steps: (i) heat transfer analysis to estimate the propagation of heat in the structure and (ii) structural analysis taking into account the effects of heat and mechanical loads. In this package, you will learn how to do a fire simulation on some structures and parts like concrete beams. You can find more details about how to do this simulation in the description of the workshops.

A tunnel is an underground or underwater passage for transportation, utility lines, or water pipelines. Tunnels are critical infrastructure, and their safety and reliability are essential for ensuring public safety and the smooth functioning of society. Tunnel simulation involves using computer models to predict the behaviour of tunnels under different types of loading conditions, such as earthquakes, floods, or explosions. These simulations can help engineers and policymakers assess the safety and reliability of tunnels, identify potential failure modes, and develop strategies to mitigate risks. By using advanced simulation techniques, engineers can better understand the complex behavior of tunnels and design more effective and durable structures. Tunnel simulation is an essential tool for ensuring the safety and resilience of tunnels and the infrastructure they support. Some workshops are presented in this package to teach you how to simulate and analyze tunnels in Abaqus; two of these workshops are Damage analysis of an underground box tunnel subjected to surface explosion and Tunnel dynamic analysis subjected to internal blast loading using CEL method.

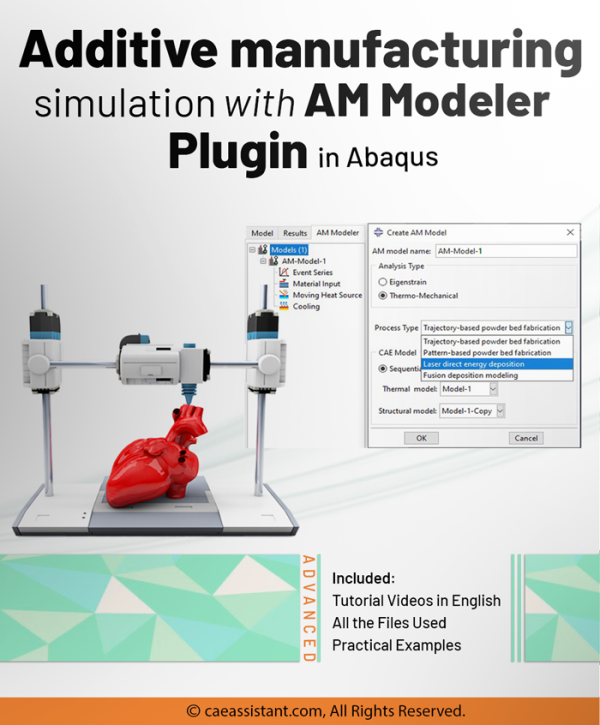

Additive manufacturing simulation with Abaqus AM modeler plugin

3D printing is the layer-by-layer creation of three-dimensional objects using materials such as plastic or metal, based on a digital design. Simulation of the 3D printing process involves software that predicts and enhances the printing process for efficient and accurate production. This training package includes the use of the AM Modeler plug-in, which allows for selecting the type of 3D printing and conducting the simulation without coding. Two workshops will be taught to master the use of this plug-in: "Sequential Thermomechanical Analysis of Simple Cube One-Direction with LPBF 3D Printing Method Using the Trajectory-Based Method with AM Plug-In" and "3D Printing Simulation with Fusion Deposition Modeling and Laser Direct Energy Deposition Method with AM Plug-In".

Water is the primary component of the Earth's hydrosphere and the fluids of all known living things. Therefore, we build dams to store the water and transfer it through piping systems to use it for daily activities and produce energy. In industries, we use it as a cooler, solvent, hydroforming, cutting, etc. In this package, there are nine practical examples, such as the ones mentioned to teach you how to simulate water in Abaqus. These examples are explosions in the depth of the water, gravity dam simulation subjected to the underwater explosion, ball impact to the water, water jet cutting, etc.

Additive manufacturing simulation with Abaqus subroutine & python | 3D printing Python

3D printing is a technique for creating three-dimensional objects by layering materials such as plastic or metal based on a digital design. 3D printing simulation involves the use of software to predict and enhance the printing process, resulting in more efficient and precise production. This training package is based on the use of subroutines and Python scripting. Following an introduction to the 3D printing process, this method with all its details is explained. Two workshops are then conducted for this method. The first workshop covers 3D printing simulation of a gear with a uniform cross-section, while the second workshop covers a shaft with a non-uniform cross-section.

Foam is a type of expanded plastic and rubber produced by forcing gas bubbles into a polymer material. It is a permeating, lightweight material. Along with corrugated packaging, foam fabric can protect goods during transportation. Foams, a novel family of ultra-light materials, have the capacity to undergo significant deformation at practically constant plateau stress, which allows them to absorb a significant amount of kinetic energy. In this tutorial package, you will learn how to analyze sandwich panels with an interior layer of foam, Foam-Filled Aluminum Tubes subjected to compressive loads, simulation of a reinforced foamed concrete beam, concrete-titanium foam panel explosion, etc. All of these cool practical examples with their complete tutorial videos are in this package which you can read their description below.

Earthquake simulation in Abaqus

It is known that an earthquake is a disastrous event that can cause great damage to buildings, structures, and even people. So it's essential to know how a structure will behave when subjected to an earthquake. Therefore engineers must take into account the possibility of an earthquake when designing a structure. With finite element analyses, engineers can predict the behaviour of structures under earthquake loading. With this method, they can determine the best way to design a structure to withstand an earthquake. In this package, you can learn how to do earthquake simulation in Abaqus to have the best design for your structure to save human lives. Three practical examples are presented to you to start simulating earthquakes: “simulating an earthquake over a gravity dam in contact with water and soil”, “simulating an earthquake load over a water-filled tank”, “Abaqus-Micro model simulation of seismic load over masonry wall (concrete brick)”.

Fluid-Structure Interaction also known as FSI is a multiphysics problem where the fluid and structure are coupled. The fluid flow can cause the structure to deform, and the deformation of the structure can affect the flow. So when you want to design something, you need to know how the structure will deform and how that deformation affects the flow. Common examples of FSI analysis are airplanes, cars, spacecrafts, and buildings. Other examples like junctions in piping systems, or the human circulatory system. CFD is a branch of research that uses numerical methods to solve the mathematical equations governing fluid flow, heat transfer, mass transfer, chemical reactions, and related phenomena. In Abaqus, you can model both methods. In this package, we present to you three workshops to get you started with CFD and FSI: “Using CFD methods in Abaqus, examining heat mixing and reverse flow characteristics in a T-junction”, “impact of air velocity over the short column”, “simulate fluid structure interaction on an aluminum body with a flexible tail in Abaqus”.

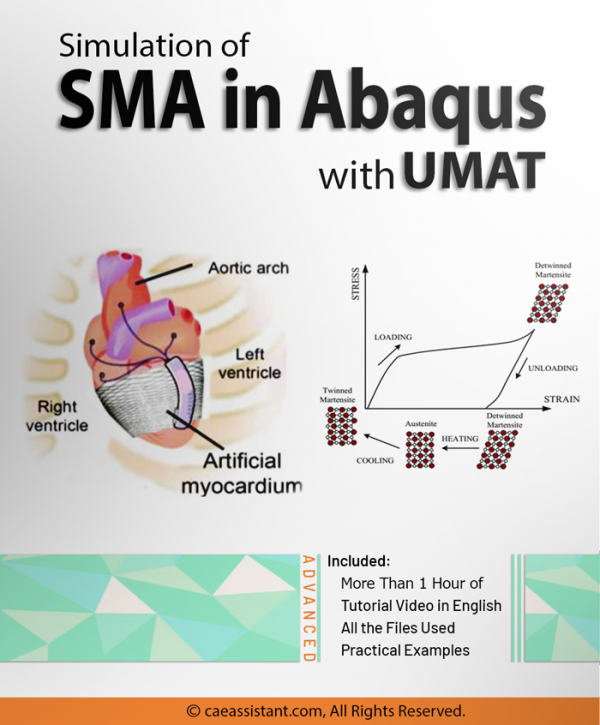

Simulation of SMA in Abaqus with UMAT

Shape-memory alloys (SMAs) have the ability to recover their original shape, thanks to the shape-memory effect and superelasticity. These unique characteristics have led to the broad usage of SMAs in engineering and medical applications. Simulations offer cost-effective methods for analyzing SMAs’ behavior, ultimately enhancing their reliability and performance. Consequently, researchers frequently employ simulations to investigate SMA-based systems. This educational package begins by exploring the fundamentals of SMA wires, presenting their various types and specific capabilities. It then provides the necessary constitutive equations to describe the behavior of SMAs in simulation. The package includes a flowchart and a step-by-step guide for writing a subroutine to model SMAs in Abaqus. Users will also discover a workshop that uses Abaqus to simulate the superelasticity effect in SMA wires. This workshop not only offers guidance on the simulation and the implementation of the subroutine, but also compares the result with an analytical solution for verification.

Academic or Business Membership

Payment Yearly

Why should you choose this Membership?

This Abaqus course package contains more than 10000 minutes of video training files, including 150 packages, 500 workshops, and 300 videos,1000 simulation files, and 50 subroutines.

This Abaqus course package contains more than 10000 minutes of video training files, including 150 packages, 500 workshops, and 300 videos,1000 simulation files, and 50 subroutines.

It will guide you going from the basics up to complex simulation techniques, and it is very fluid and comprehensive, and every single detail is explained.

It will guide you going from the basics up to complex simulation techniques, and it is very fluid and comprehensive, and every single detail is explained.

Every lesson goes straight to the point, without any worthless piece of content. You will learn what you need at every stage, and you will be putting it into practice from the very first day.

Every lesson goes straight to the point, without any worthless piece of content. You will learn what you need at every stage, and you will be putting it into practice from the very first day.

HETVAL is a user subroutine specifically developed to address the limitations of Abaqus in accurately handling volumetric heat flux resulting from internal heat generation within materials. The subroutine’s functionality depends on factors such as time, temperature, or evolving state variables, stored as solution-dependent variables. Accordingly, it can tackle scenarios involving phase changes during simulations. Moreover, the subroutine allows the integration of kinetic theory to account for phase changes associated with internal heat release, such as predicting crystallization in polymer casting processes. Such a multi-functional subroutine finds applications in heat transfer analyses, coupled thermal-electric studies, or temperature-displacement analyses. In this package, our primary goal is to provide valuable insights into the HETVAL subroutine and its diverse applications. Afterward, through a series of comprehensive workshops, we will guide participants in utilizing HETVAL under various conditions. In the final workshop, a problem will be presented, allowing you to explore a realistic example and gain hands-on experience in simulating the curing process within fiber-reinforced composites using HETVAL. Furthermore, to assist those unfamiliar with fiber-reinforced composites, we have included an introductory lesson covering their applications, significance, and an explanation of the importance of accurately simulating the curing process. By completing this package, you will have gained a comprehensive understanding of utilizing HETVAL across various conditions and scenarios. Moreover, you will have acquired the ability to simulate the heat generated during the curing process of fiber-reinforced composites, demonstrating a real-world application of HETVAL.

DFLUX Subroutine (VDFLUX Subroutine) in ABAQUS

DFLUX subroutine (VDFLUX Subroutine) is used for thermal loading in various body flux and surface flux states in heat transfer and temperature displacement solvers when flux load is a function of time, place, or other parameters. In this package, you will learn “when do you need to use this subroutine?”, “how to use the DFLUX subroutine”, “what is the difference between DFLUX & VDFLUX?”, “how to convert DFLUX to VDFLUX and vice versa?”, and “How to use it in an example?”. Three workshops are presented so you can learn all these stuff in action: Simulation of welding between two plate with DFLUX subroutine, Simulation of Arc welding between two tube with DFLUX, and Simulation of different types of functional heat flux(Body-surface-Element) in plate with Johnson-cook plasticity with VDFLUX subroutine(Thermomechanical Analysis).

In this training package, different types of forming simulations are presented along with different tips. These points include increasing the solution speed, different types of plasticity and damage models, different solvers, Lagrangian, CEL, and SPH methods and etc.

Select options

Coming soon...

This training package fully covers the various possible methods for welding simulation. First, an introduction to welding and two basic categories of welding, fusion and non-fusion welding. Next, the theories and the elements used to simulate the welding will be explained. These theories are Lagrangian, Eulerian, ALE, and SPH. After that, you will learn how to apply these theories with different methods, such as the death and birth of an element, DFLUX subroutine, etc. Finally, you will learn how to simulate welding with the help of five workshops: Friction Stir Welding (FSW) simulation with the Eulerian element, Explosive welding simulation, simulation of FSW with the SPH method, Butt welding with death and birth of an element method, and Simulation of Arc welding between two tubes with DFLUX subroutine (Thermomechanical Analysis).