What is welding?

Using heat to bond materials together is the main purpose of the crucial construction-related activity of welding. It is a fabrication technique in which two components are fused together using heat, pressure, or both.

Welding categorization

Generally, we have two methods for welding: Fusion welding and non-fusion welding.

Fusion welding uses heat to melt two or more materials to join them. This process may or may not need to use a filler material.

Non-fusion welding uses high pressure or, in some cases, heat to join materials. In this process, materials won’t melt, but they may be heated to an elevated temperature. Also, no filler is usually used in this process.

Fusion welding is done in three ways: Electron Beam welding (EBW). This method is based on the electron’s kinetic energy and is suitable for any material with any thickness. Laser Beam Welding (LBW). It uses a laser beam and is proper for narrow and deep welds. This method does not use any filler. Arc welding (AW). It is the most important and widely used method. It uses the electric arc to create enough heat to melt the parts and bond them. The arc welding can be done in seven ways according to the electrode used: Shielded metal arc welding (SMAW), Submerged arc welding, Flux-cored arc welding (FCAW or FCA), Carbon arc welding (CAW), Tungsten inert gas (TIG) welding, Gas metal arc welding (GMAW), Plasma arc welding (PAW).

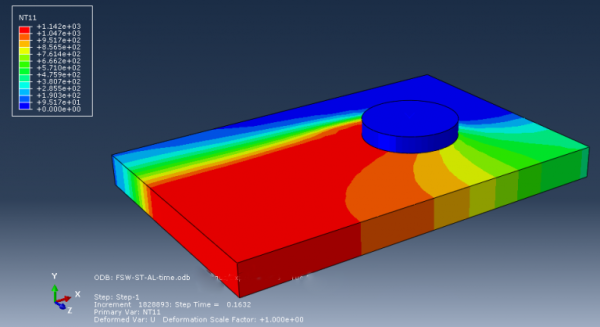

The non-fusion welding categorized in five methods. First, Friction stir welding (FSW). This method is a solid-state joining process. The heat will be generated by friction between a non-consumable rotating tool and the workpiece to create a softened region and bond the pieces. The second method is Explosive welding (EW). Like the FSW method, this one is also a solid-state welding process. It uses high energy rate deformation to join metal plates. The pressure caused by the explosion will bond the plates. The third method is Ultrasonic welding (UW). It is an industrial process that uses high-frequency ultrasonic acoustic vibrations to create a solid-state weld to join the workpieces being held together under pressure. The next method is Rolling welding. This one is used to connect metal sheets. In this method, we need to first clean the surface of two or more sheets. Then, pile the sheets together and pass them through the rolls until sufficient deformation occurs to weld the sheets. The fifth method is Resistance welding (RW), and it is the most widely used. This method uses heat caused by the application of electric current and mechanical pressure at the same time to form a great bond.

Welding simulation in Abaqus

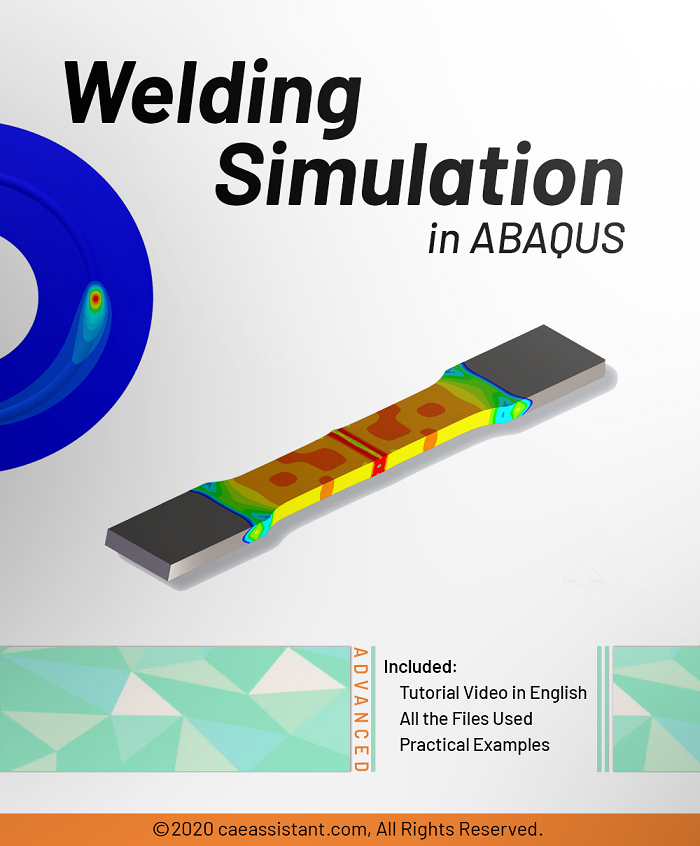

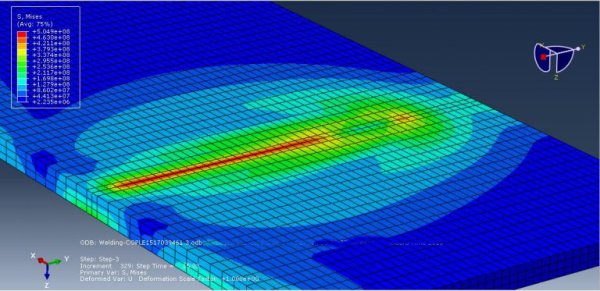

This training package fully covers the various possible methods for Abaqus welding simulation. Various methods in welding simulation include the Lagrangian method, The Eulerian method, ALE, and SPH methods.

In the Lagrangian method, nodes move exactly with material points, it is easy to track free surfaces and apply boundary conditions, and the mesh will become distorted with high strain gradients. In the Eulerian theory, nodes stay fixed while material flows through the mesh, it is more difficult to track free surfaces, and we have no mesh distortion because the mesh is fixed. The ALE is a combination of the two previous theories. In this method: the mesh motion is constrained to the material motion only where necessary (at free boundaries); otherwise, material motion and mesh motion are independent. The last method is smoothed-particle hydrodynamics (SPH). In this method, there are no elements, only a collection of nodes. This is one of the meshless (or mesh-free) methods in the ABAQUS.

In the process of welding, the base metal is melted, and generally, a filler material is added to create a pool of molten metal, which fuses the two components together. In creating a simulation model, there are two major issues when simulating the welding process to evaluate the structural behavior of a welded joint:

- The thermal and structural behavior of the model needs to be coupled with each other.

- Material needs to be added during the welding process. This also changes the boundaries and the location of the boundary conditions.

Here in this package, some technics to overcome these issues in Abaqus welding problems are presented.

It would be useful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial.

The Abaqus user subroutine allows the program to be customized for particular applications unavailable through the main Abaqus facilities. You should write a user subroutine if you could not run your analysis by ABAQUS built-in models for materials, loads, properties, elements, etc., for example, if you need to model a user-defined nonlinear stress-strain relation, which is not provided by Abaqus, then look for UMAT user subroutine. A more advanced subroutine is DFLUX, which allows the creation of user-defined load flux. If it is your first time writing a subroutine like DFLUX, please read the Start Writing an Abaqus Subroutine: Basics & Recommendations article. After reading this post and watching this tutorial’s demo video, you will definitely decide to save time in Abaqus modelling and get this Abaqus Welding manual package. If you have questions, ask here on our live chat on the left side of this page.

Users ask these questions

In social media, users ask questions regarding welding simulation in Abaqus, friction stir welding, resistance welding, types of welding, and other sorts of stuff about welding simulation in Abaqus. therefore, we decided to answer some of them, which you can see them below.

I. Resistance welding

Q: In Abaqus, my simulation topic is resistance welding. I finished the portion about Coulpled thermal-electrical-structural, and now I want to simulate a melt pool, such as a solid changing to a liquid, but I don’t know where to begin, and I can’t find any information about it online…

A: Hi,

In this case, you must use the heat transfer step as well. watch this video: https://www.youtube.com/watch?v=IqDGbYCQLMs

Also, you can find more information about the welding process, types of welding, methods of welding simulation, and theories behind them in the link below. I think it could be a great help in welding analysis.

Also, we have another tutorial that is about the friction stir welding in case you needed: “Friction Stir Welding simulation Tutorial | FSW Advanced level“.

Karan –

The quality of the instructional videos in this package was very good, and I was able to easily follow the different simulation steps.