welding

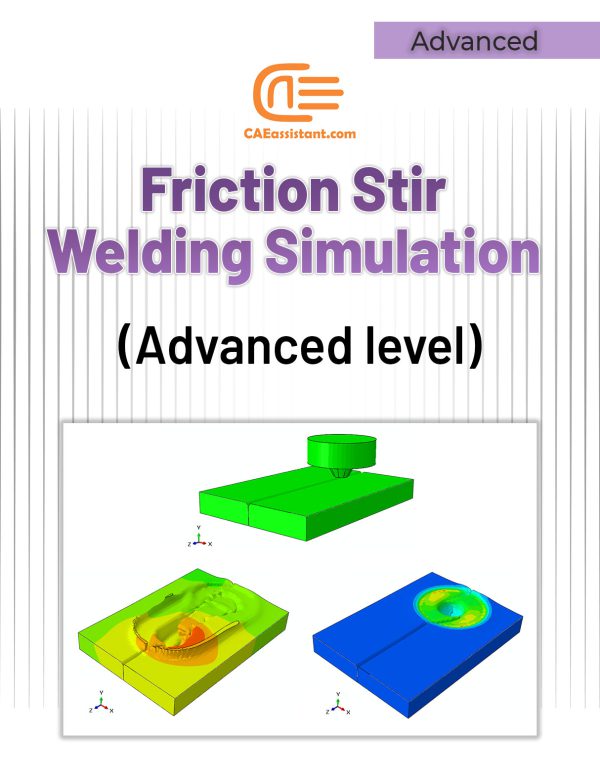

Friction Stir Welding simulation Tutorial | FSW Advanced level

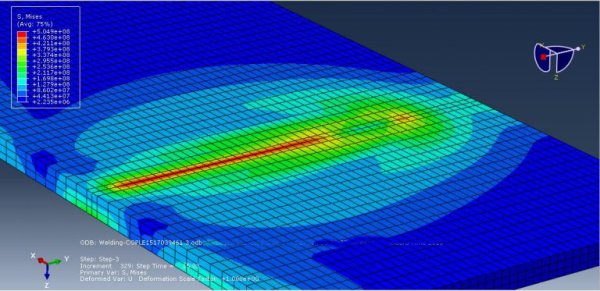

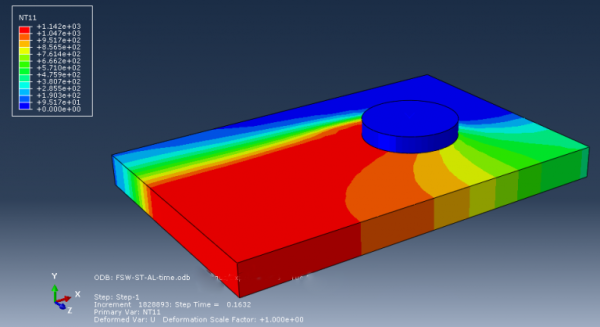

Friction stir welding (FSW) involves complex material flow and plastic deformation. Welding parameters, tool geometry, etc., have important effects on the material flow pattern, heat distribution, and eventually on the structural evolution of the material. In an Abaqus friction stir welding example, the rotational movement of the tool and its friction in contact with the workpiece causes heat generation, loss of strength, and an increase in material ductility around the tool. The feeding movement of the tool causes the material to transfer from the front of the tool to the back of it, and eventually leads to a join. Therefore, heat plays an important role in this process, and parameters such as rotational speed, tool feeding speed, tool geometry, and others, all somehow have a significant impact on controlling the amount of incoming heat, the disturbance and flow pattern of the material, the evolution of the microstructure, and the quality of the resulted weld. This friction stir welding example simulation tutorial shows you how to simulate the Abaqus FSW simulation process in such a way that you can accurately predict the effect of all relevant parameters on the process. In most of the implemented projects, welding mud, and welding defects (welding overfills and overlaps, weld gaps) are not visible and predictable; however, in this simulation, these cases are visible. This project is designed to enhance participants' understanding of how to accurately simulate the FSW process to see the weld's general appearance.

Arc welding simulation in Abaqus

Notice: This package will be available one week after purchase.

Arc welding is a fusion process that involves joining metals by applying intense heat, causing them to melt and mix. The resulting metallurgical bond provides strength and integrity to the welded joint. Arc welding is widely used in various industries for fabricating structures and components. Arc welding simulation in Abaqus is essential for optimizing the welding process and ensuring high-quality welds. It allows engineers to predict and analyze factors such as temperature distribution, residual stresses, distortion, and microstructure evolution during welding. By accurately simulating the welding process, parameters like welding speed, heat input, and electrode positioning can be optimized to achieve desired weld characteristics and minimize defects.

Friction Stir Welding (FSW) Simulation in Abaqus

Friction stir welding (FSW) is a solid-state joining process that utilizes a rotating tool to generate frictional heat, enabling the consolidation of materials without melting. FSW offers numerous benefits and is particularly valuable for welding challenging materials like aluminum alloys. It finds widespread applications in industries such as automotive, aerospace, shipbuilding, and construction, providing enhanced strength, weight reduction, and structural integrity. FSW minimizes distortion, reduces the need for post-weld machining, and eliminates issues related to solidification and cooling. Simulations using Abaqus, a popular finite element analysis software, play a crucial role in optimizing FSW processes. Engineers can investigate process parameters, evaluate weld quality, predict residual stresses and distortions, and optimize weld designs through Abaqus simulations. These simulations enable cost-effective development, improved weld quality, reduced material waste, and enhanced productivity in industrial applications. In this package, you will learn how to simulate FSW simulations in a variety of examples with different methods.

DFLUX Subroutine (VDFLUX Subroutine) in ABAQUS

DFLUX subroutine (VDFLUX Subroutine) is used for thermal loading in various body flux and surface flux states in heat transfer and temperature displacement solvers when flux load is a function of time, place, or other parameters. In this package, you will learn “when do you need to use this subroutine?”, “how to use the DFLUX subroutine”, “what is the difference between DFLUX & VDFLUX?”, “how to convert DFLUX to VDFLUX and vice versa?”, and “How to use it in an example?”. Three workshops are presented so you can learn all these stuff in action: Simulation of welding between two plate with DFLUX subroutine, Simulation of Arc welding between two tube with DFLUX, and Simulation of different types of functional heat flux(Body-surface-Element) in plate with Johnson-cook plasticity with VDFLUX subroutine(Thermomechanical Analysis).

This training package fully covers the various possible methods for welding simulation. First, an introduction to welding and two basic categories of welding, fusion and non-fusion welding. Next, the theories and the elements used to simulate the welding will be explained. These theories are Lagrangian, Eulerian, ALE, and SPH. After that, you will learn how to apply these theories with different methods, such as the death and birth of an element, DFLUX subroutine, etc. Finally, you will learn how to simulate welding with the help of five workshops: Friction Stir Welding (FSW) simulation with the Eulerian element, Explosive welding simulation, simulation of FSW with the SPH method, Butt welding with death and birth of an element method, and Simulation of Arc welding between two tubes with DFLUX subroutine (Thermomechanical Analysis).