Abaqus shaft slip ring simulation | Using Python scripts for parametric analysis

Creep is one of the most significant failure modes in many components where the working temperature and stresses are high for a prolonged period of time. Existing creep models in commercial analysis software like Abaqus are not adequate to model all stages of creep namely – primary, secondary, and tertiary stages. Theta projection method is a convenient method proven to predict all stages of creep, especially the tertiary stage where strain rates are high leading to internal damage and fracture. The aim of the project is to develop a user subroutine for Abaqus to model creep in components using the Theta projection method. The constitutive model for the Theta projection method based on the accumulation of internal state variables such as hardening, recovery, and damage developed by (R.W.Evans, 1984) is adopted to compile a Fortran code for the user subroutine. The user subroutine is validated through test cases and comparing the results with experimental creep data. Creep analysis of a sample gas turbine blade (Turbine Blade Creep) is then performed in Abaqus through the user subroutine and the results are interpreted.

Results of test cases validate the accuracy of the Theta Projection Method in predicting all primary, secondary, and tertiary stages of creep than existing creep models in Abaqus (Creep Failure in Turbine Blades). Results at interpolated & extrapolated stress & temperature conditions with robust weighted least square regression material constants show the convenience in creep modeling with less input data than existing models. The results of creep analysis not only predicted the creep life but also indicated the internal damage accumulation. Thus, creep modeling of components through the user subroutine at different load conditions could lead us to more reliable creep life predictions and also indicate the regions of high creep strain for improvements in the early stages of design.

Simulation of pitting corrosion with scripting in Abaqus

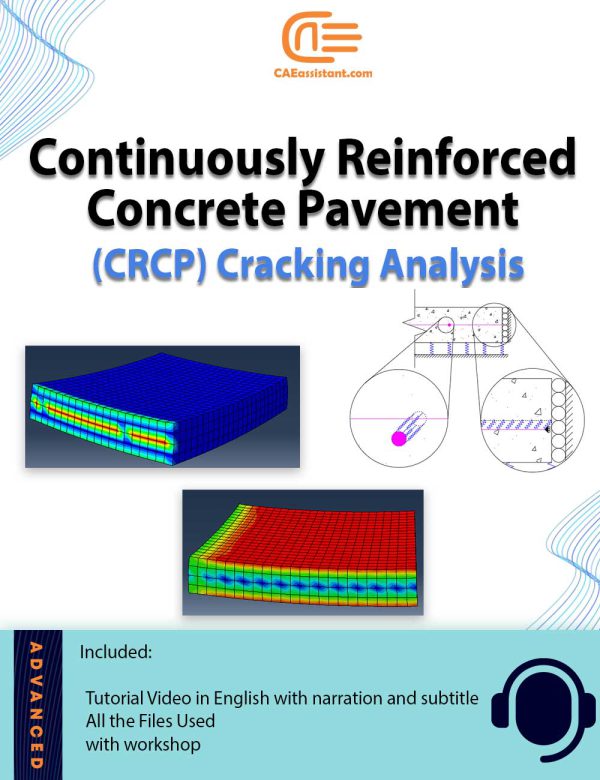

Continuously Reinforced Concrete Pavement (CRCP) Cracking Analysis

|

The increasing adoption of continuously reinforced concrete pavement (CRCP) in highway pavement design is driven by its demonstrated superior performance. Critical to evaluating the long-term effectiveness of CRCP is the understanding of early-age cracks (CRCP crack analysis), which has garnered significant interest from highway departments. This Abaqus Continuously reinforced concrete pavement modeling project aims to establish precise design parameters for CRCP and analyze the formation of crack patterns. By accounting for stress factors such as environmental conditions and CRCP shrinkage modeling, the project offers valuable insights into predicting the likelihood of crack initiation and propagation within the concrete slab. These insights are instrumental in enhancing the durability and performance of CRCP structures, thus advancing the efficiency and effectiveness of highway infrastructure. |

Script to transfer load from CFD to structural model in Abaqus

Python Scripting in Abaqus Full Tutorial

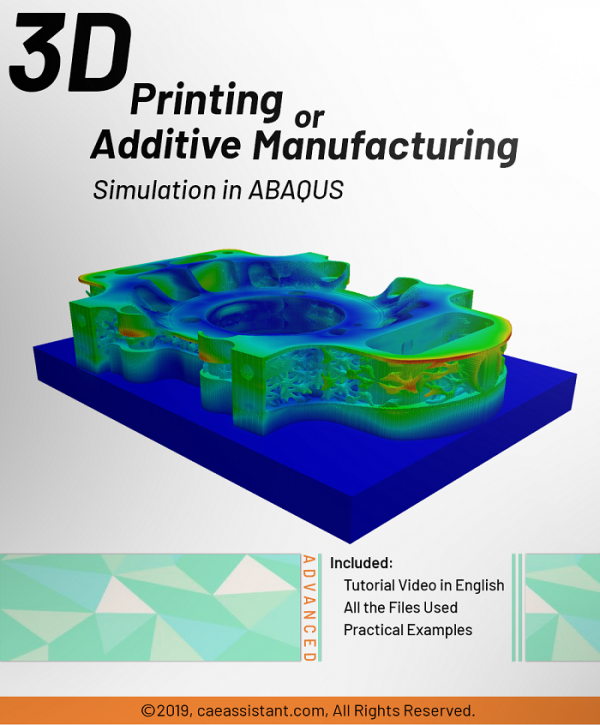

Additive manufacturing simulation with Abaqus subroutine & python | 3D printing Python

Python scripting in ABAQUS Part 2

Python scripting in ABAQUS-(FREE Version)

Python scripting in ABAQUS Part1

Additive Manufacturing or 3D Printing Abaqus simulation