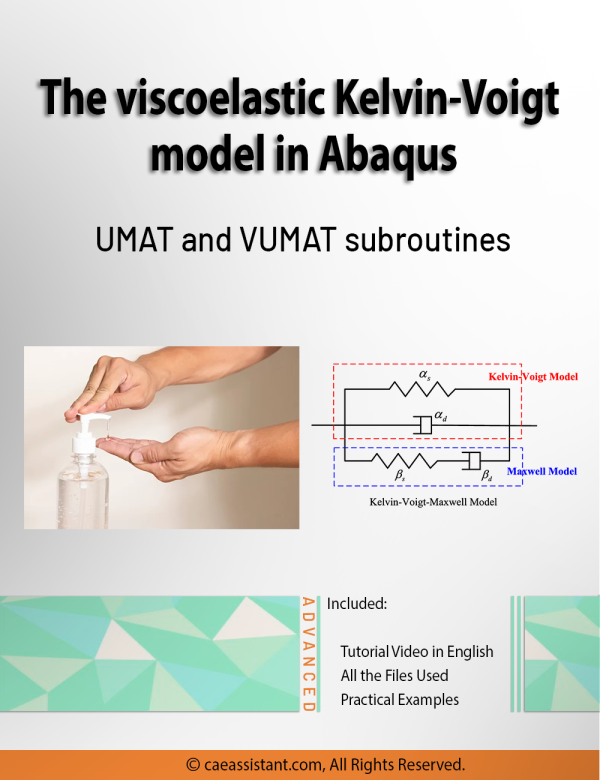

Abaqus Kelvin Voigt Model (Viscoelastic) Simulation Using UMAT and VUMAT Subroutines

This research presents a precise three-dimensional mechanical response of viscoelastic materials using Abaqus kelvin voigt viscoelastic model. We performed this kelvin voigt model Abaqus simulation using both UMAT and VUMAT subroutines for standard and explicit solvers.

The behavior of viscoelastic materials is a state between the behavior of a liquid and a solid. In other words, they behave both like liquids and solids. That is to say, there are many natural and synthetic materials that are classified as viscoelastic materials; From the biological structures of the body such as skin, cartilage and tissue to concrete, foams, rubbers, and synthetic polymers. Due to these unique properties, viscoelastic materials have many applications.

In this regard, the primary goals of this study include the development and implementation of an accurate three-dimensional Abaqus kelvin voigt viscoelastic model, and the integration of viscoelastic properties into the analysis, which can improve the prediction of viscoelastic materials response under different boundary and loading conditions.

This tutorial, by customizing the UMAT and VUMAT subroutines to simulate flexible samples behavior, contributes to the advancement of viscoelastic materials design and analysis.

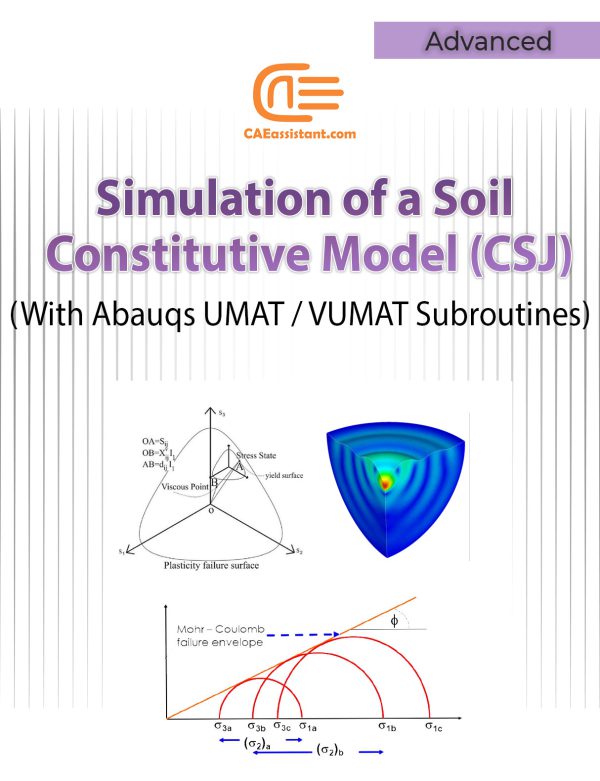

Implementation of Soil Constitutive Models in Abaqus | With a Special Focus on CSJ Models

Constitutive model implemented in calculation code, play an important role in the material behaviors prediction. In the field of geotechnical engineering there are numerous soil constitutive models. By installing these models in a finite element code such as Abaqus, their development, efficiency and advancement can be increased. Also, more and more complex engineering problems can be solved by this method. But to do this, you need a proper understanding of the mathematical and programming basics of these models. This tutorial focuses on implementing advanced constitutive models in Abaqus, particularly for simulating soil behavior. Focusing on the CJS model, this tutorial tries to teach how to work and how to program these models in Abaqus code. It includes detailed explanations of VUMAT and UMAT subroutines and practical examples of implementing the CJS model.

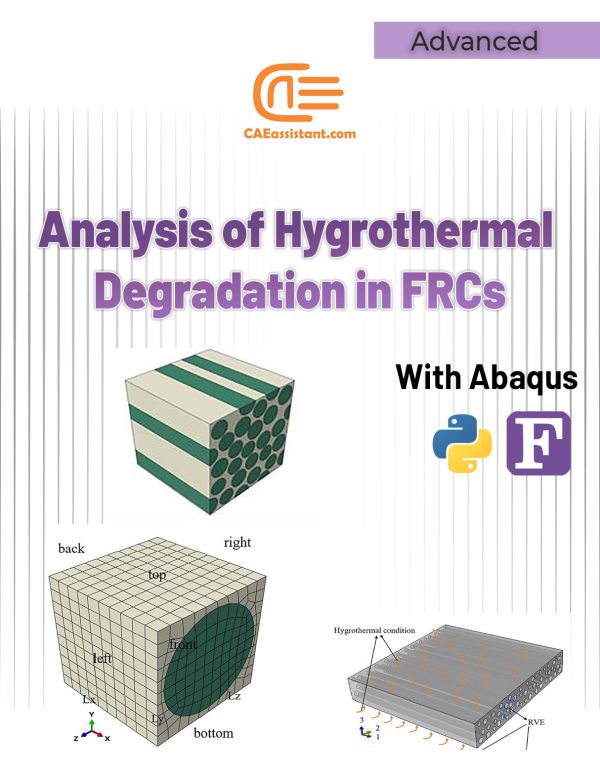

In this tutorial, we explore the hygrothermal degradation of fiber-reinforced composites using ABAQUS, a powerful tool for parallel finite element analysis. Industries like aerospace, marine, and automotive heavily rely on these composites due to their high strength-to-weight ratio and versatility. However, long-term exposure to moisture and temperature can degrade their mechanical properties, making hygrothermal analysis essential for ensuring durability. ABAQUS enables precise modeling of these conditions through Python scripts and Fortran subroutines. This combination allows for efficient simulations across multiple processors, offering insights into the material's elastic properties, such as Young’s and shear modulus, under varying environmental conditions. By leveraging the ABAQUS Python Scripting Micro Modeling (APSMM) algorithm and custom subroutines, engineers can predict how fiber-reinforced composites will perform over time, optimizing design and enhancing performance across critical sectors like aerospace and marine.

In the present Abaqus tutorial for parallel finite element analysis, we have presented the software skills that a person needs when he wants to perform a parallel finite element analysis such as a micro-macro scale analysis. The Abaqus tutorial for parallel finite element analysis covers all you need to write a python scripting code for noGUI environment and also Fortran code for the subroutine environment of Abaqus to execute a parallel finite element analysis via Abaqus software. You can download the syllabus of this package here.

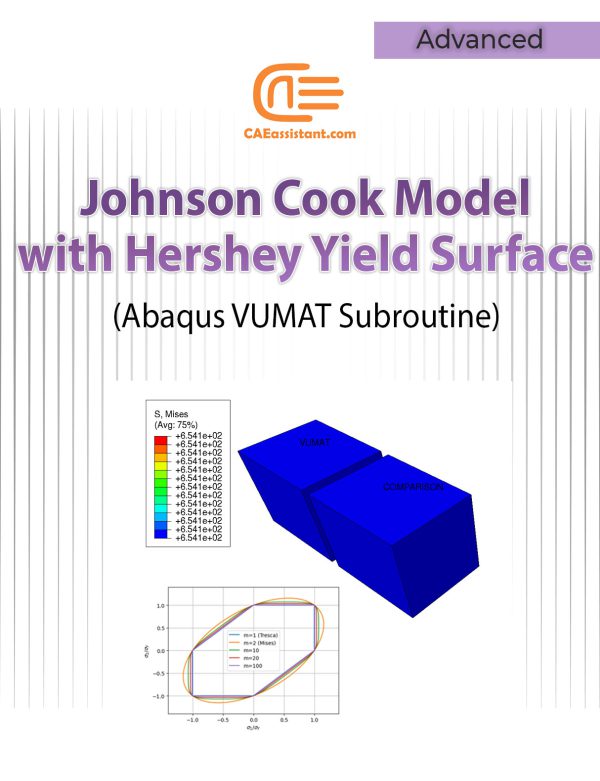

This project offers a set of Abaqus models for 3D continuum elements, integrating a VUMAT subroutine that implements the Modified Johnson Cook (MJC) viscoplastic model and the Hershey yield surface. The MJC model simulates material behavior under varying strain rates and temperatures, while the Hershey yield surface predicts complex yielding behavior. Together, they provide highly accurate simulations of materials under extreme conditions such as impacts and high temperatures. Ideal for industries like automotive, aerospace, and defense, this package supports critical applications like crash testing, metal forming, and ballistic analysis. The model has been implemented for 3D continuum elements.

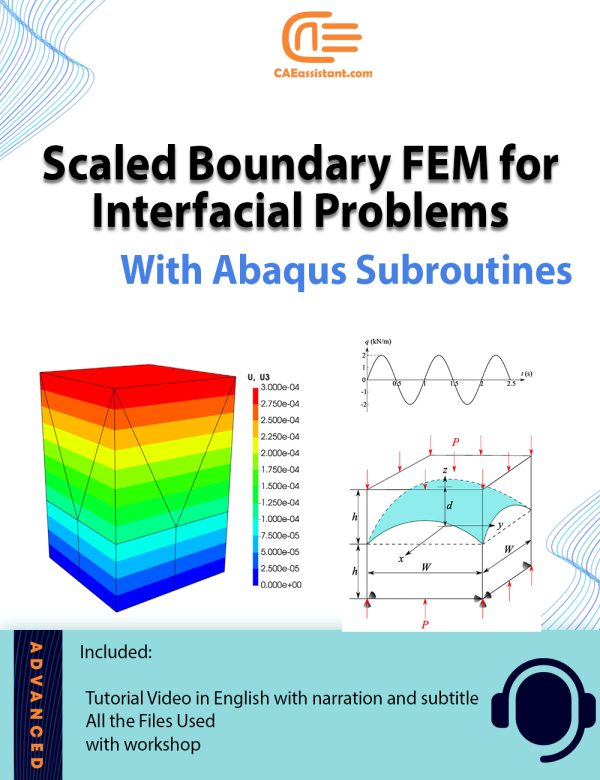

Note: The inp and Fortran files are only applicable in Linux.Scaled Boundary Finite Element Method (SBFEM) Modeling Files for ABAQUS

The Scaled Boundary Finite Element Method (SBFEM) enhances traditional Finite Element Analysis (FEA). It provides flexibility in handling complex geometries and interfaces. Integrated into ABAQUS, SBFEM allows for the creation of polyhedral elements, reducing meshing challenges. It effectively manages non-matching meshes and complex boundary conditions, particularly in interfacial problems like contact mechanics and fracture analysis. ABAQUS supports custom user elements (UEL), enabling direct integration of SBFEM with advanced solvers, improving efficiency and expanding its applicability to complex engineering problems. The open-source implementation allows for customization, making SBFEM in ABAQUS a powerful tool for precise and efficient simulations. This is particularly beneficial in scenarios requiring advanced FEA.

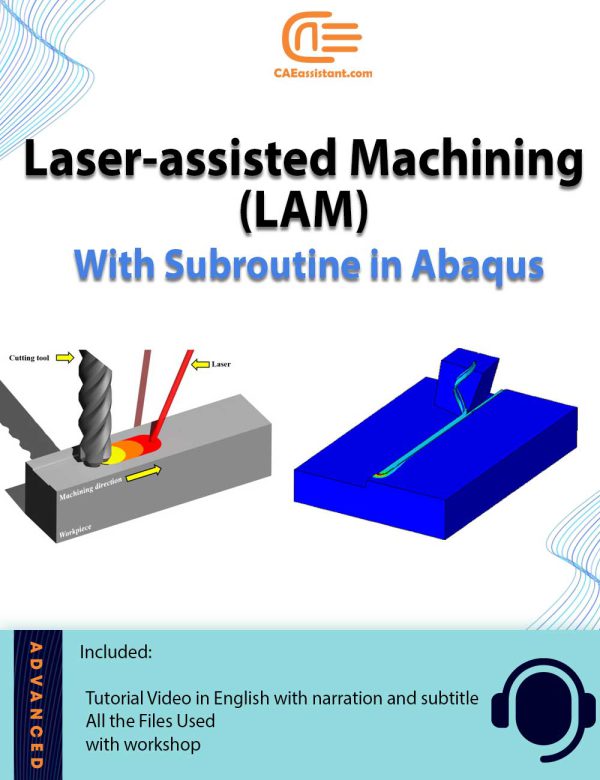

Laser Assisted Machining (LAM): Modeling and Simulation in Abaqus/CAE

In this tutorial, a comprehensive discussion on modeling and simulation of laser assisted machining is presented. It includes building FEM-based models of machining, laser heating, and laser-assisted machining models in Abaqus/CAE. The finite element method (FEM) simulation is based on the coupled thermo-mechanical behavior. The package walks learners through building models that simulate the impact of laser heating on the workpiece. Detailed lessons cover constructing basic machining and laser heating models, setting boundary conditions like cutting speed and laser power, and writing subroutines such as DFLUX and VDFLUX to simulate laser heat sources. Additionally, learners will perform analyses to study temperature distribution, and stress-strain behavior. Through parametric analysis and comprehensive result evaluation, learners will gain a deep understanding of temperature distribution, stress behavior, and how laser heating can improve the machining process.

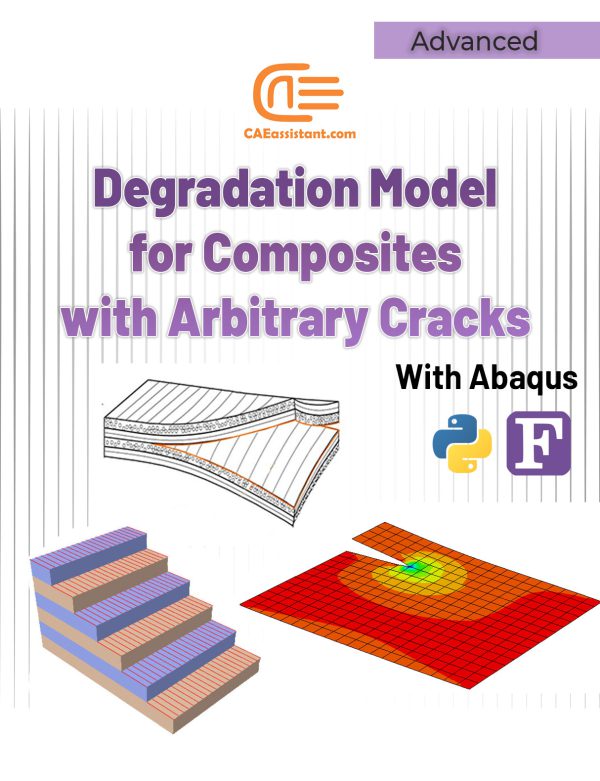

An Efficient Stiffness Degradation Composites Model with Arbitrary Cracks | An Abaqus Simulation

Advanced Finite Element Analysis of Off-Axis Tunnel Cracking Laminates

Additive Manufacturing (AM), a revolutionary layer-by-layer fabrication technology, is transforming how products are designed and manufactured. This comprehensive tutorial package focuses on the Inherent Strain (IS) method, a highly efficient numerical approach for simulating the Laser Powder Bed Fusion (LPBF) process in metal additive manufacturing. The detailed thermo-mechanical simulation of the Laser Powder Bed Fusion (LPBF) for complex geometric parts requires a large number of time steps to estimate residual stress and distortion, which is not computationally cost-effective. Furthermore, based on the large thermal gradient near the heat source, the mesh size must be sufficiently small to accurately predict the induced residual stress and distortion of the deposited layers in the heat-affected zone. Therefore, applying a coupled thermo-mechanical analysis for multiple laser scans with a fine mesh model to macro-scale simulation would incur excessively large computational costs.

Additionally, the large number of degrees of freedom for each element in the mechanical analysis leads to higher complexity as well as a longer amount of processing time. Detailed thermo-mechanical analysis for an industrial component is almost impractical since it would demand hundreds of terabytes of memory and years to calculate. Therefore, to overcome the huge computational burden associated with the numerical simulation of the LPBF caused by the infinitesimal laser spot size and thousands of thin layers with a thickness at the micron level, the Inherent Strain Method in additive manufacturing has been widely used in research and commercial software.

In this tutorial, the Inherent Strain Method additive manufacturing approach is presented both theoretically and practically in Abaqus. An agglomeration approach will be considered to transfer an equivalent inherent strain from both micro-scale and macro-scale modeling strategies. The implementation of this approach is explained step by step, accompanied by various workshops in micro-scale and macro-scale models for different geometries. This training package enables you to write your subroutine codes and Python scripting, as well as have more control over the LPBF process simulation.

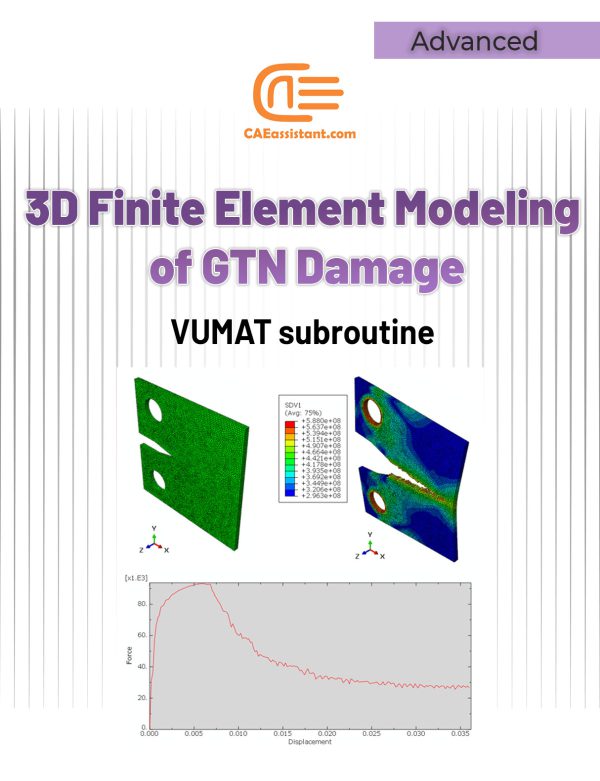

3D Simulation of Gurson-Tvergaard-Needleman (GTN) Damage Model

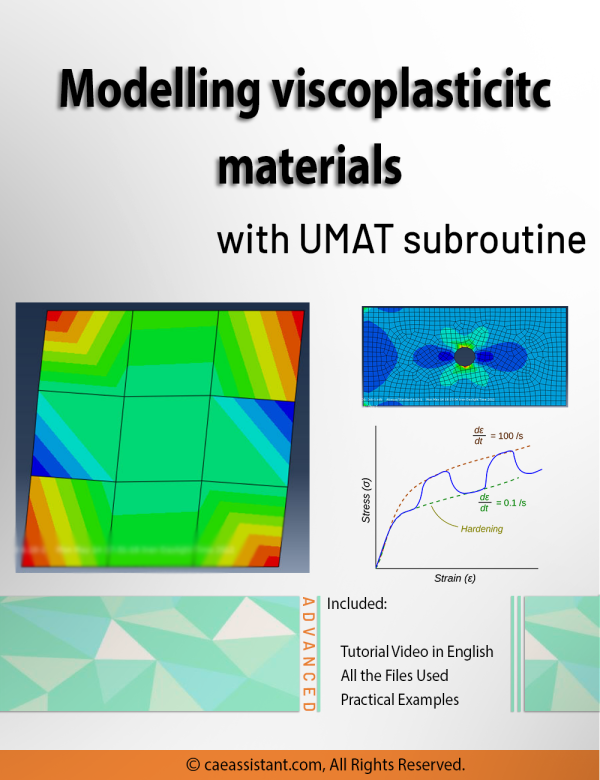

Viscoplasticity Abaqus Simulation Using UMAT Subroutine | Perzyna Viscoplastic Model

Viscoplasticity describes the rate-dependent inelastic behavior of materials, where deformation depends on both stress magnitude and application speed. This concept is crucial in many engineering applications, such as designing structures under dynamic loads, modeling soil behavior during earthquakes, and developing materials with specific mechanical properties. Viscoplasticity Abaqus simulation, especially using Abaqus with UMAT subroutines, are vital for understanding, predicting, and optimizing the behavior of viscoplastic materials. This tutorial focuses on implementing the Perzyna viscoplasticity model in Abaqus. The Perzyna viscoplastic model, a strain rate-dependent viscoplasticity model, relates stress to strain through specific constitutive relations. This involves defining plastic strain rate based on stress state, internal variables, and relaxation time. The tutorial provides general UMAT codes for viscoplastic analysis, yielding results like stress fields essential for various engineering applications. These simulations help in predicting permanent deformations, assessing structural failure points, and analyzing stability under different loads, benefiting fields such as aerospace, automotive, civil engineering, and energy.

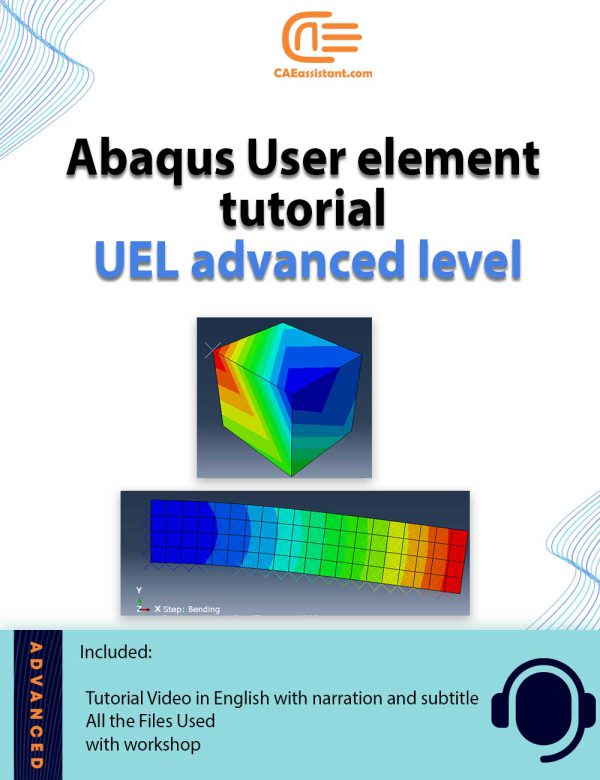

Abaqus User element tutorial | UEL advanced level

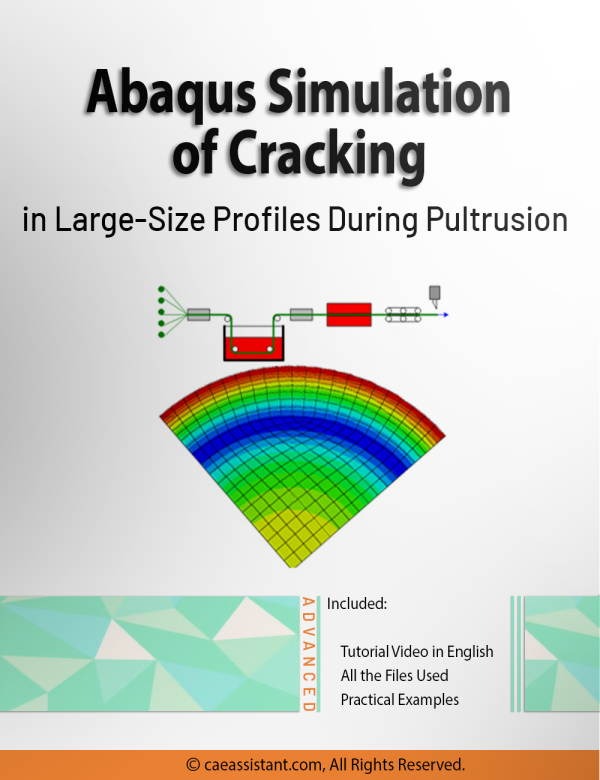

Pultrusion Crack Simulation in Large-Size Profiles | Pultrusion Abaqus

Pultrusion is a crucial task for producing constant-profile composites by pulling fibers through a resin bath and heated die. Simulations play a vital role in optimizing parameters like pulling speed and die temperature to enhance product quality and efficiency. They predict material property changes and aid in process control, reducing reliance on extensive experimental trials. However, simulations face challenges such as accurately modeling complex material behaviors and requiring significant computational resources. These challenges underscore the need for precise simulation methods to improve Pultrusion processes. This study employs ABAQUS with user subroutines for detailed mechanical behavior simulations, including curing kinetics and resin properties. Key findings include insights into crack formation (pultrusion crack simulation), material property changes, and optimization strategies for enhancing manufacturing efficiency and product quality. This research (pultrusion Abaqus) provides practical knowledge for implementing findings in real-world applications, advancing composite material production.

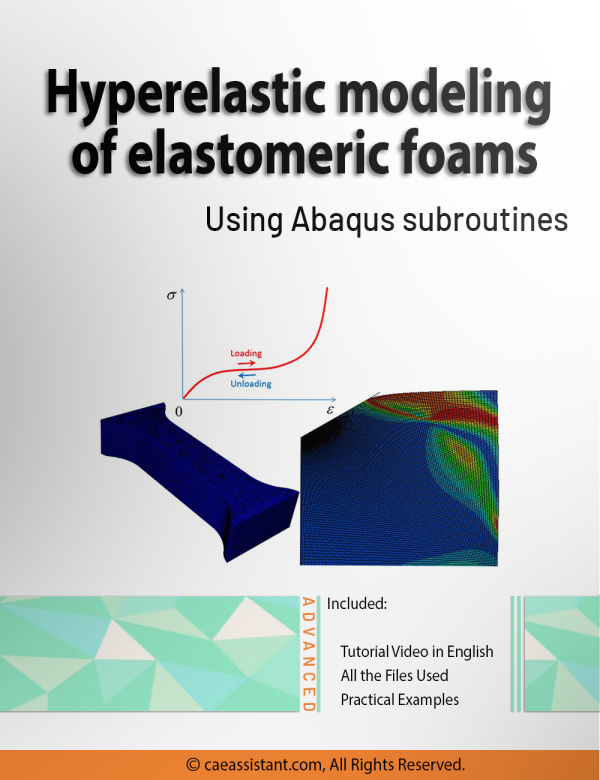

Elastomeric Foam Simulation Using Abaqus Subroutines

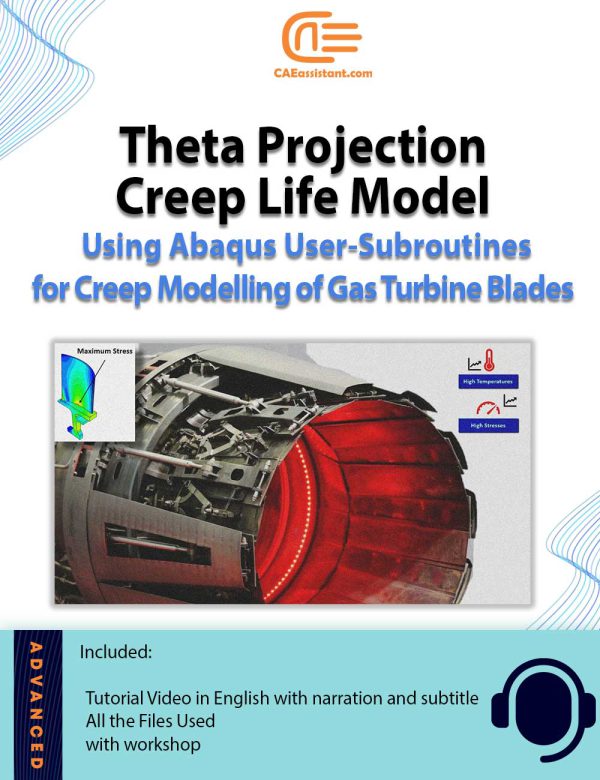

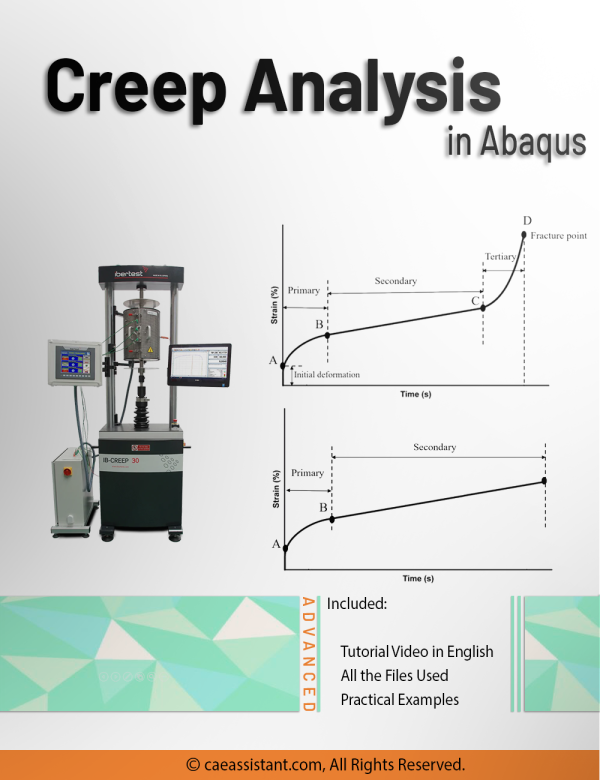

Creep is one of the most significant failure modes in many components where the working temperature and stresses are high for a prolonged period of time. Existing creep models in commercial analysis software like Abaqus are not adequate to model all stages of creep namely – primary, secondary, and tertiary stages. Theta projection method is a convenient method proven to predict all stages of creep, especially the tertiary stage where strain rates are high leading to internal damage and fracture. The aim of the project is to develop a user subroutine for Abaqus to model creep in components using the Theta projection method. The constitutive model for the Theta projection method based on the accumulation of internal state variables such as hardening, recovery, and damage developed by (R.W.Evans, 1984) is adopted to compile a Fortran code for the user subroutine. The user subroutine is validated through test cases and comparing the results with experimental creep data. Creep analysis of a sample gas turbine blade (Turbine Blade Creep) is then performed in Abaqus through the user subroutine and the results are interpreted.

Results of test cases validate the accuracy of the Theta Projection Method in predicting all primary, secondary, and tertiary stages of creep than existing creep models in Abaqus (Creep Failure in Turbine Blades). Results at interpolated & extrapolated stress & temperature conditions with robust weighted least square regression material constants show the convenience in creep modeling with less input data than existing models. The results of creep analysis not only predicted the creep life but also indicated the internal damage accumulation. Thus, creep modeling of components through the user subroutine at different load conditions could lead us to more reliable creep life predictions and also indicate the regions of high creep strain for improvements in the early stages of design.

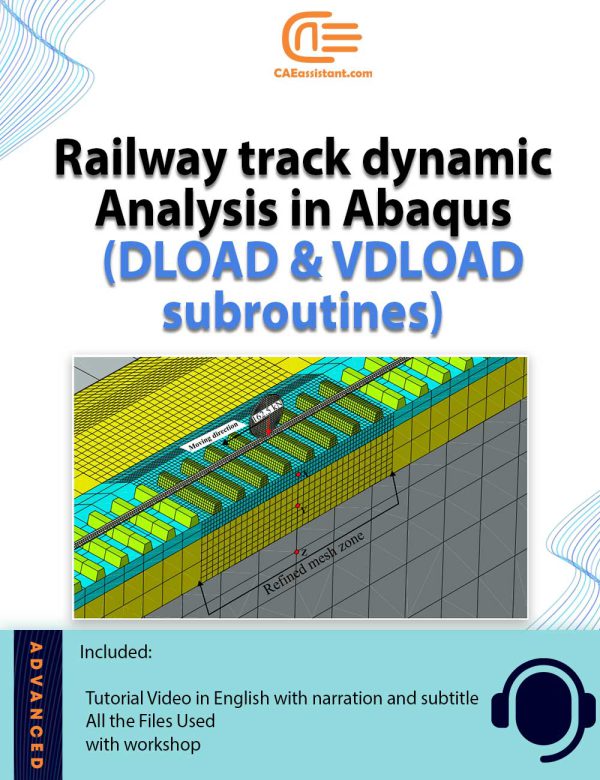

Dynamic Response of Rail Track Analysis Under a Moving Load

Railway tracks are subjected to moving loads of trains and this causes vibration and degradation of the track. The judgment of these vibrations is important to design the railway tracks. Therefore, the rail track analysis become important. The design involves the permissible speed of trains and the maximum axle load of the train. The model given here creates a 3D geometry of a railway track and applies a moving load in the form of a wheel. A user can change the speeds and the properties of the material including geometry as per their needs.

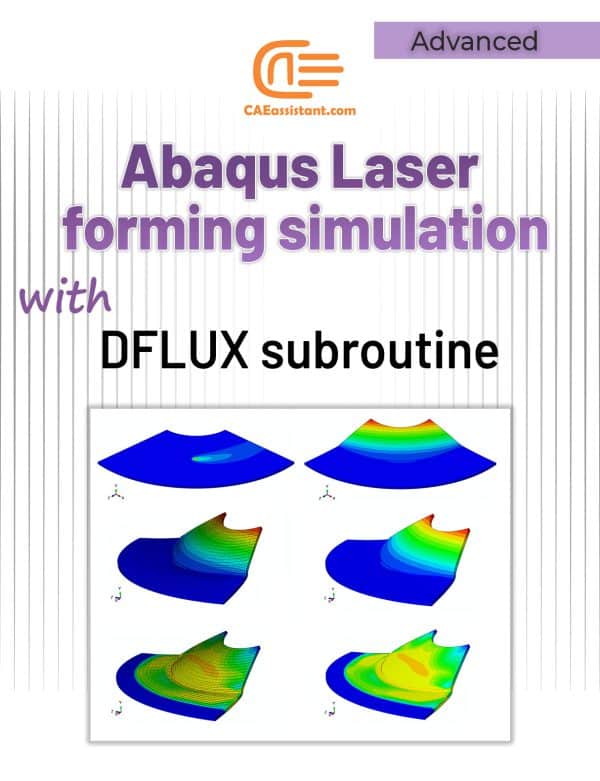

Laser Forming Process Tutorial in Abaqus

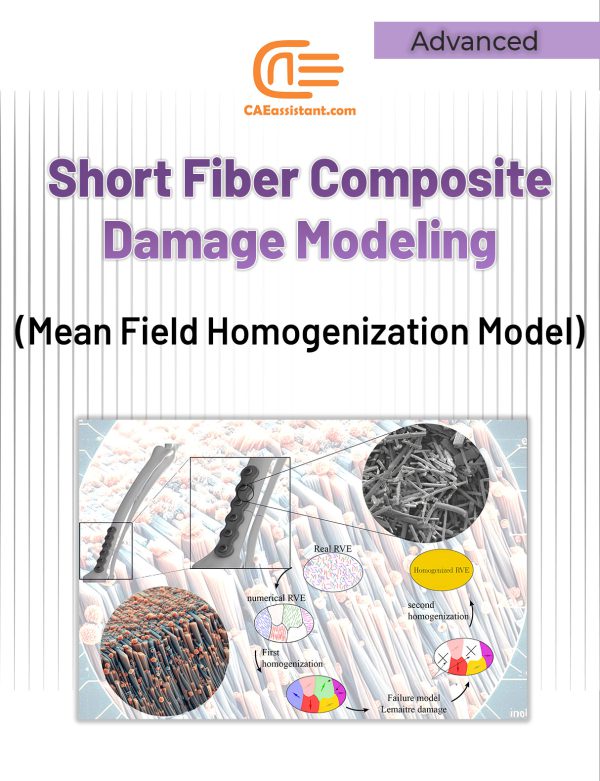

Short fiber composite damage (Mean Field Homogenization Model)

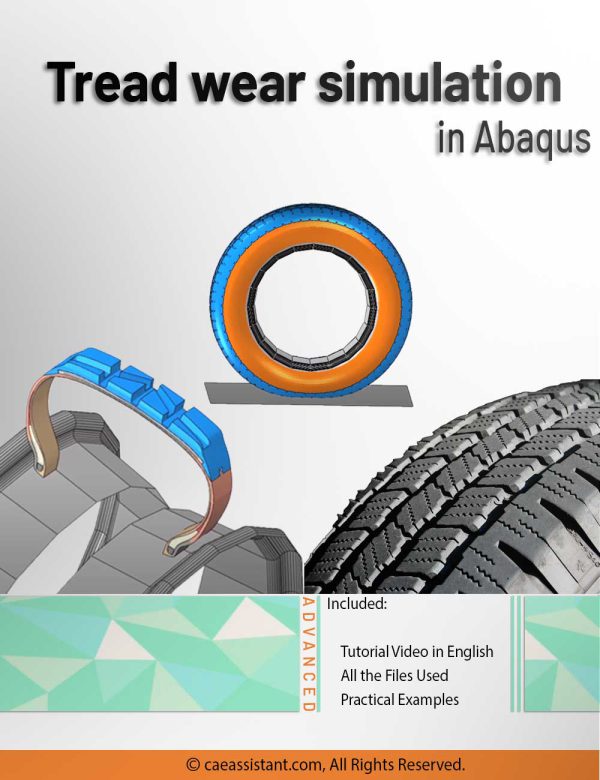

Tread wear simulation in Abaqus

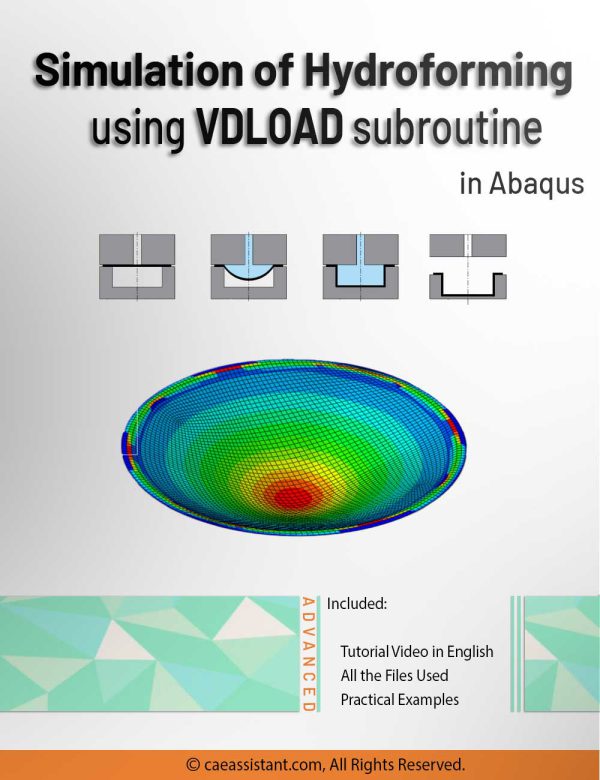

Hydroforming process simulation using VDLOAD subroutine in Abaqus

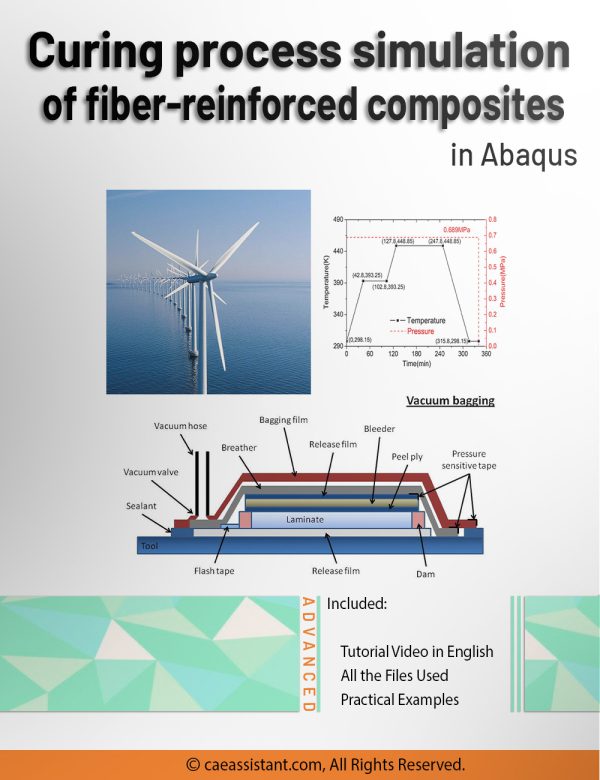

Curing process simulation in Abaqus

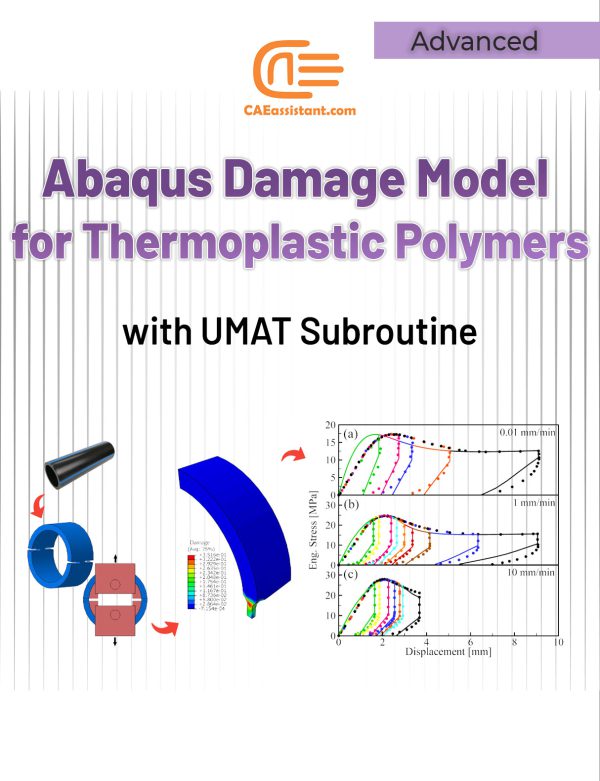

Damage Properties of Thermoplastic Polymers with UMAT Subroutine

Abaqus for Civil Engineering Part-1