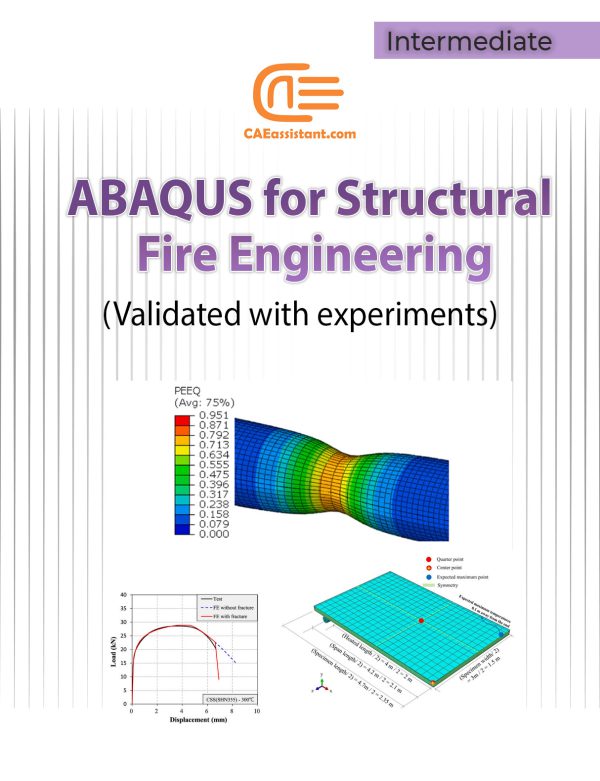

Structural Fire Engineering Simulation Using Ductile Damage Model | Validated with Experiments

This tutorial package on Structural Fire Engineering provides a detailed guide for simulating fire effects on structural elements using ABAQUS. It focuses on ductile damage modeling, enabling engineers to simulate material behavior under elevated temperatures accurately. The tutorial covers techniques such as applying boundary condition applications, while also validating the simulation results with experimental fire test data. By following the steps outlined, engineers can confidently design fire-resistant structures using accurate, data-validated models.

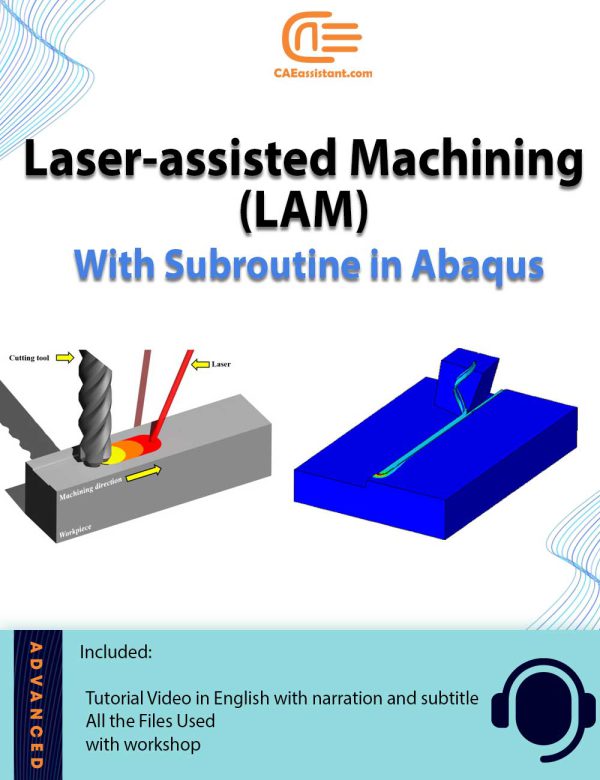

Laser Assisted Machining (LAM): Modeling and Simulation in Abaqus/CAE

In this tutorial, a comprehensive discussion on modeling and simulation of laser assisted machining is presented. It includes building FEM-based models of machining, laser heating, and laser-assisted machining models in Abaqus/CAE. The finite element method (FEM) simulation is based on the coupled thermo-mechanical behavior. The package walks learners through building models that simulate the impact of laser heating on the workpiece. Detailed lessons cover constructing basic machining and laser heating models, setting boundary conditions like cutting speed and laser power, and writing subroutines such as DFLUX and VDFLUX to simulate laser heat sources. Additionally, learners will perform analyses to study temperature distribution, and stress-strain behavior. Through parametric analysis and comprehensive result evaluation, learners will gain a deep understanding of temperature distribution, stress behavior, and how laser heating can improve the machining process.

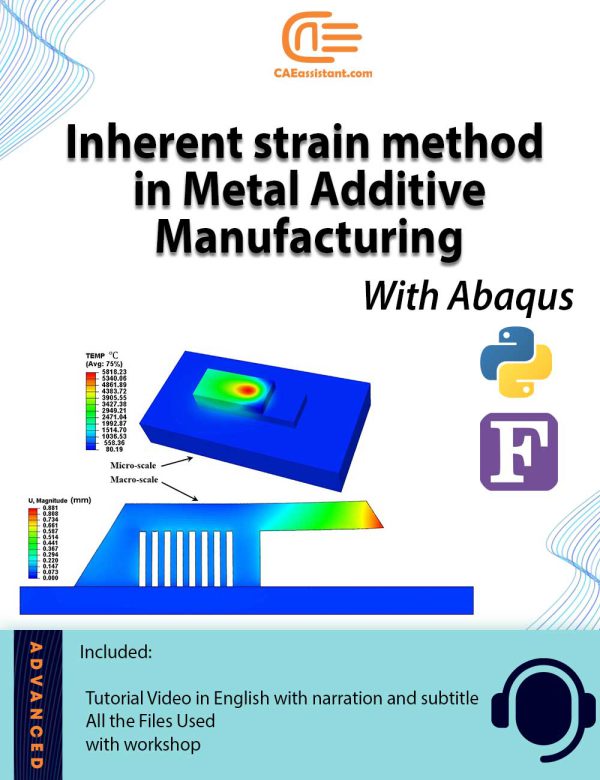

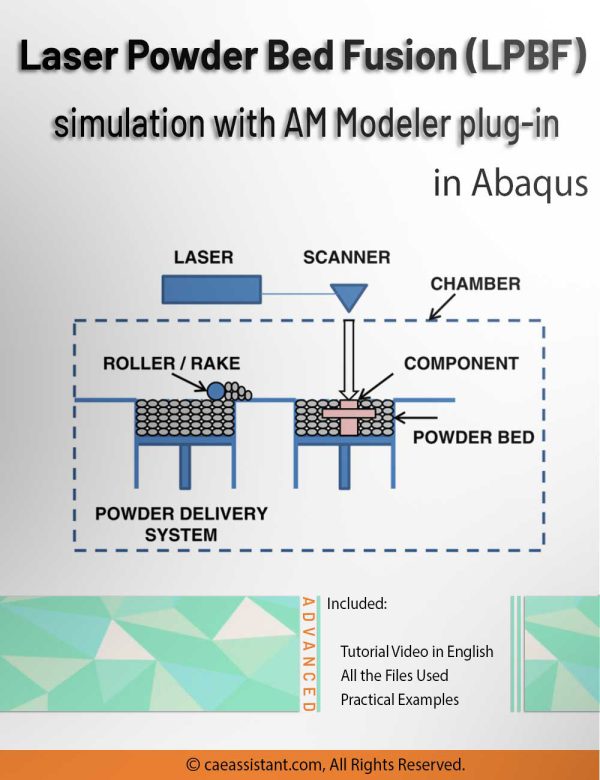

Additive Manufacturing (AM), a revolutionary layer-by-layer fabrication technology, is transforming how products are designed and manufactured. This comprehensive tutorial package focuses on the Inherent Strain (IS) method, a highly efficient numerical approach for simulating the Laser Powder Bed Fusion (LPBF) process in metal additive manufacturing. The detailed thermo-mechanical simulation of the Laser Powder Bed Fusion (LPBF) for complex geometric parts requires a large number of time steps to estimate residual stress and distortion, which is not computationally cost-effective. Furthermore, based on the large thermal gradient near the heat source, the mesh size must be sufficiently small to accurately predict the induced residual stress and distortion of the deposited layers in the heat-affected zone. Therefore, applying a coupled thermo-mechanical analysis for multiple laser scans with a fine mesh model to macro-scale simulation would incur excessively large computational costs.

Additionally, the large number of degrees of freedom for each element in the mechanical analysis leads to higher complexity as well as a longer amount of processing time. Detailed thermo-mechanical analysis for an industrial component is almost impractical since it would demand hundreds of terabytes of memory and years to calculate. Therefore, to overcome the huge computational burden associated with the numerical simulation of the LPBF caused by the infinitesimal laser spot size and thousands of thin layers with a thickness at the micron level, the Inherent Strain Method in additive manufacturing has been widely used in research and commercial software.

In this tutorial, the Inherent Strain Method additive manufacturing approach is presented both theoretically and practically in Abaqus. An agglomeration approach will be considered to transfer an equivalent inherent strain from both micro-scale and macro-scale modeling strategies. The implementation of this approach is explained step by step, accompanied by various workshops in micro-scale and macro-scale models for different geometries. This training package enables you to write your subroutine codes and Python scripting, as well as have more control over the LPBF process simulation.

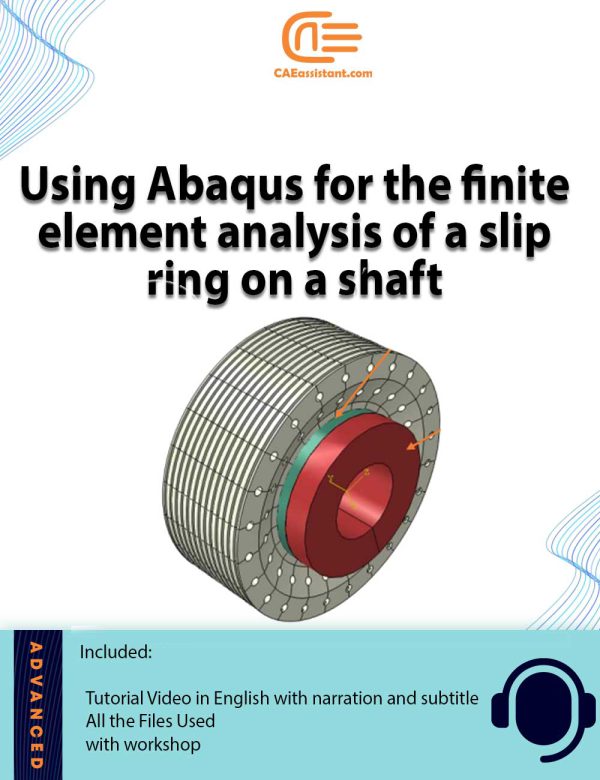

Abaqus shaft slip ring simulation | Using Python scripts for parametric analysis

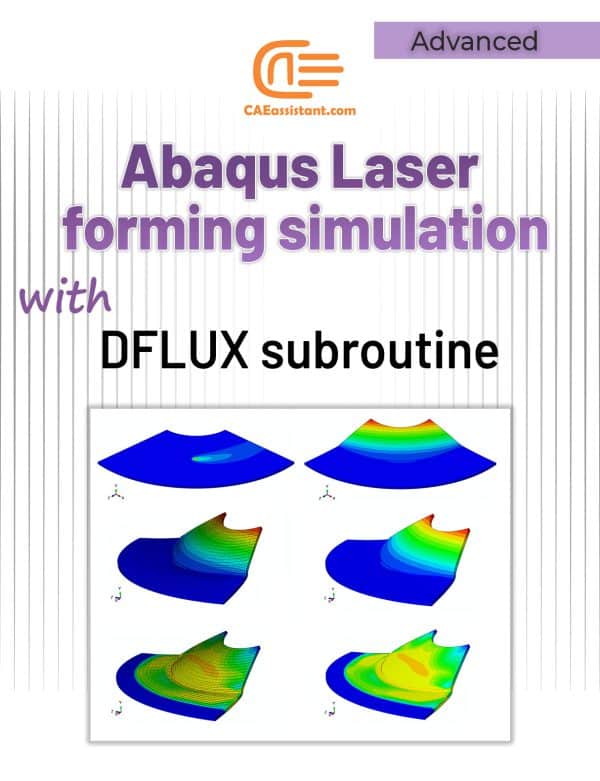

Laser Forming Process Tutorial in Abaqus

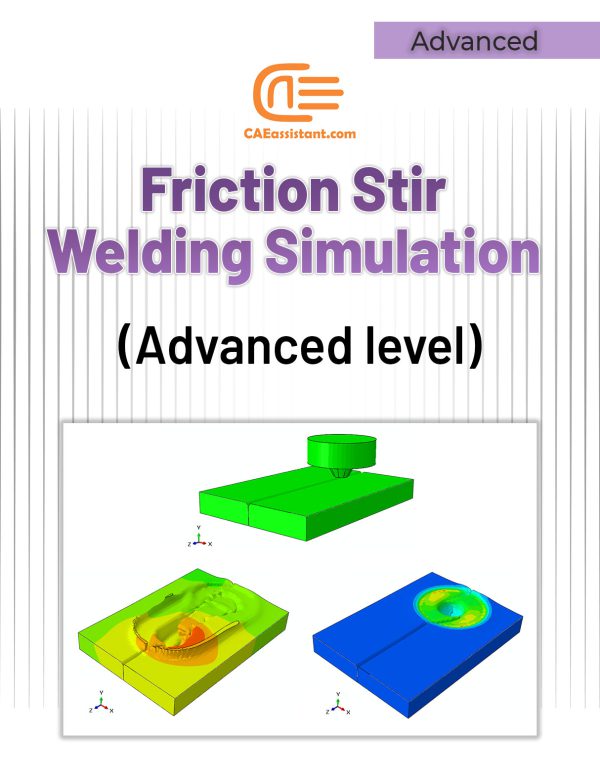

Friction Stir Welding simulation Tutorial | FSW Advanced level

LPBF Printing Simulation in Abaqus | 3D Printing with Laser Powder Bed Fusion Process (LPBF) Method

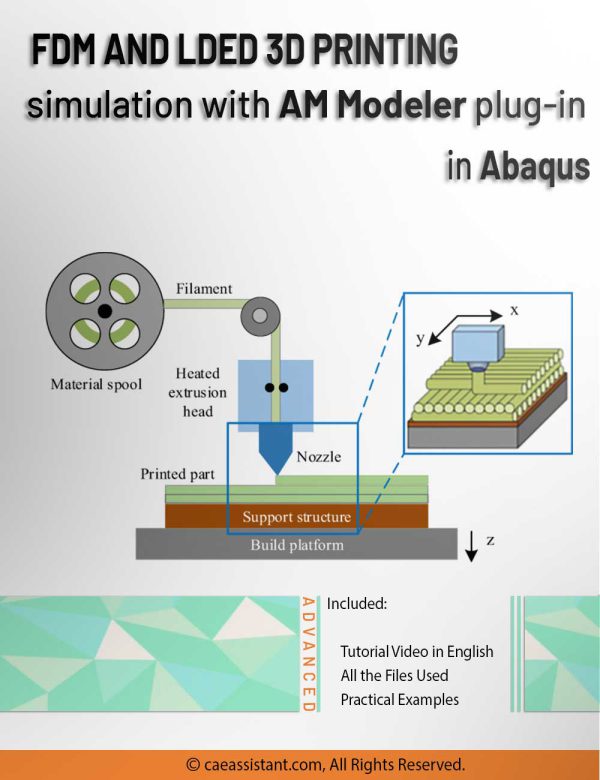

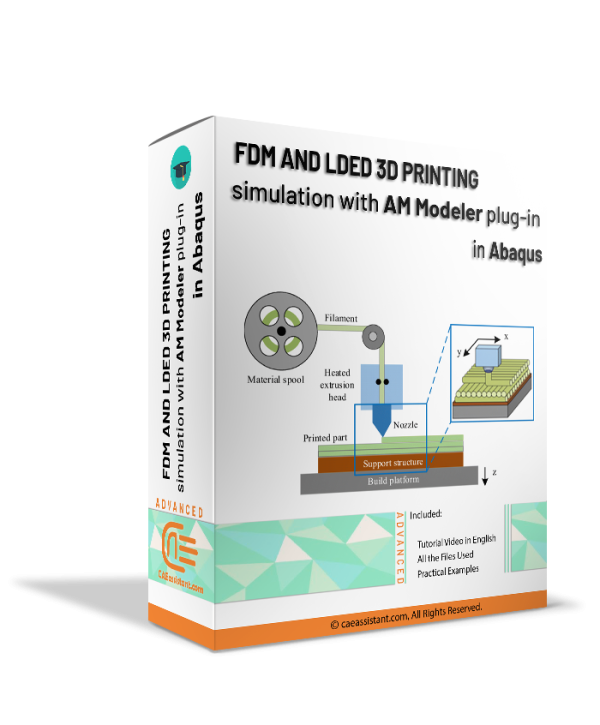

FDM Simulation in Abaqus | Simulating 3D Printing with Fused Deposition Modeling

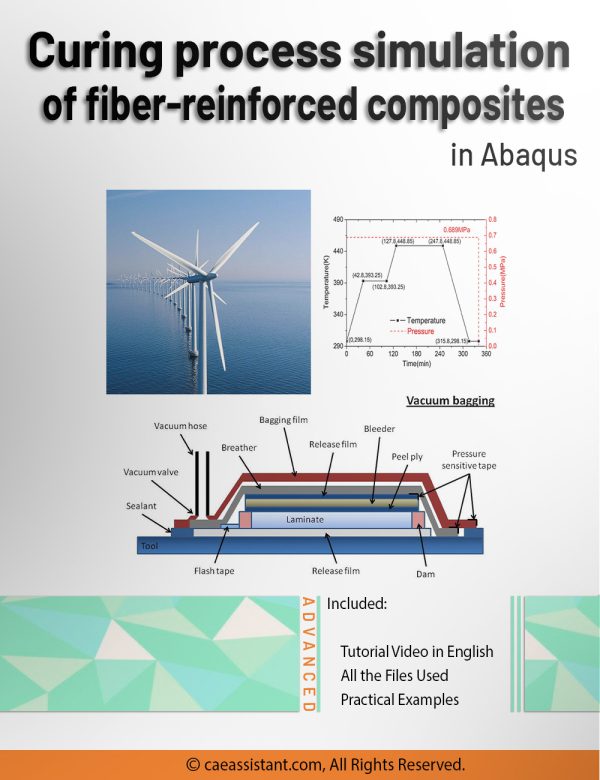

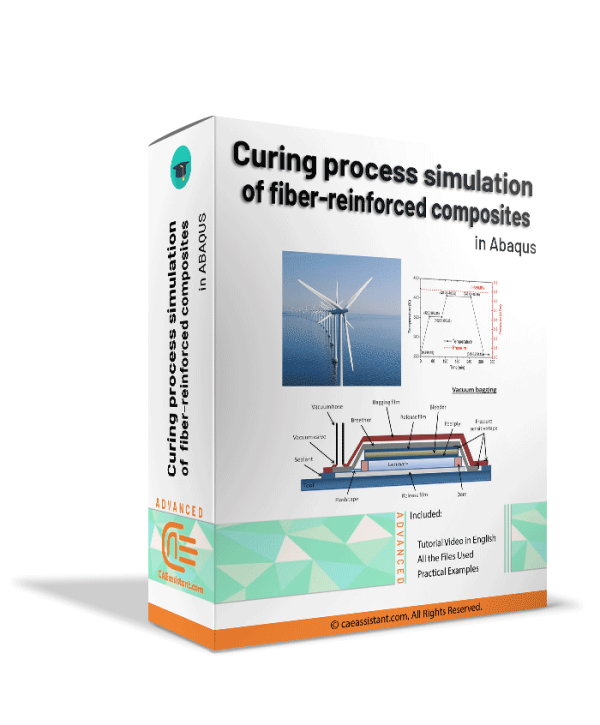

Curing process simulation in Abaqus

Arc welding simulation in Abaqus

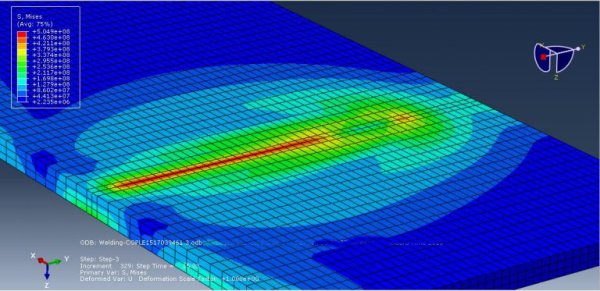

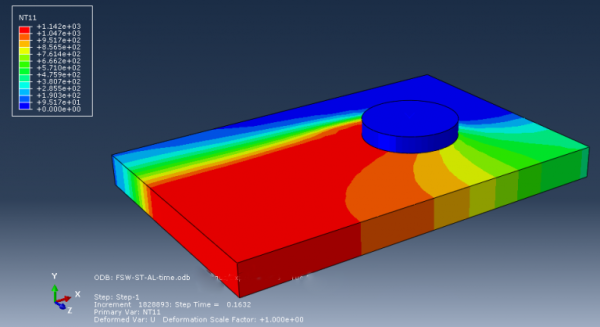

Friction Stir Welding (FSW) Simulation in Abaqus

Car part industrial simulation

Additive manufacturing simulation with Abaqus subroutine & python | 3D printing Python

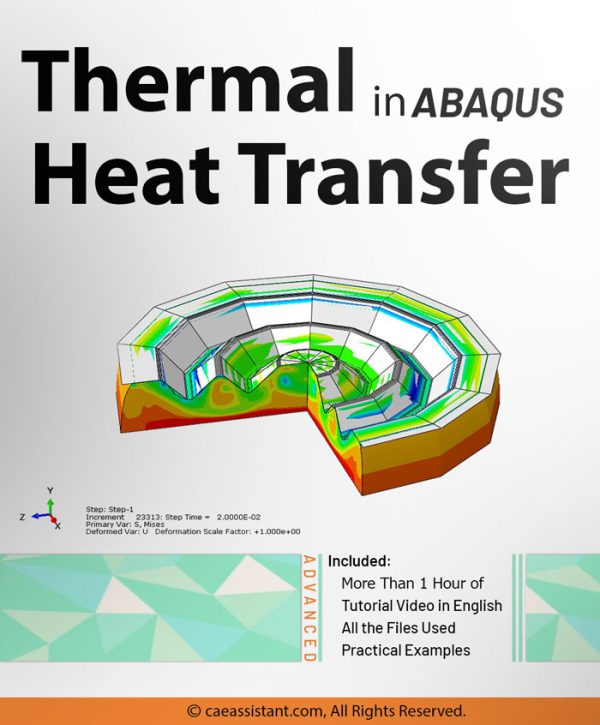

Thermal Heat Transfer in Abaqus

- Uncoupled heat transfer analysis

- Sequentially coupled thermal-stress analysis

- Fully coupled thermal-stress analysis

- Adiabatic analysis

Analysis of Heat Transfer in Abaqus

- Duration: 12 months

- Cost: €789 per 12 months

- Packages Included: 5 packages

- Packages Paid For: 4 packages

- Discount: More than 55%

- Access to 5 ABAQUS training packages

- Pay for only 4 packages, but receive 5 packages

- Significant discount of more than 55% off the regular package pricing

- Duration: 24 months

- Cost: €2,489 per 24 months

- Packages Included: 20 packages

- Packages Paid For: 13 packages

- Discount: More than 65%

- Access to 20 ABAQUS software packages

- Pay for only 13 packages, but receive 20 packages

- Significant discount of more than 65% off the regular package pricing