Impact

Soil Impact Analysis in Abaqus

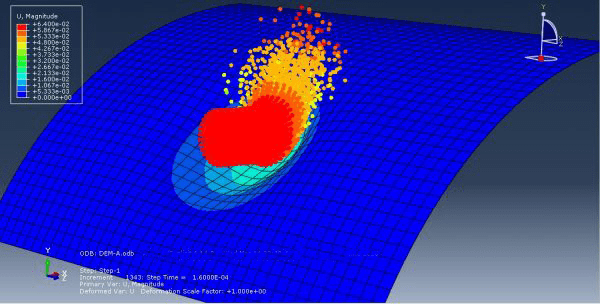

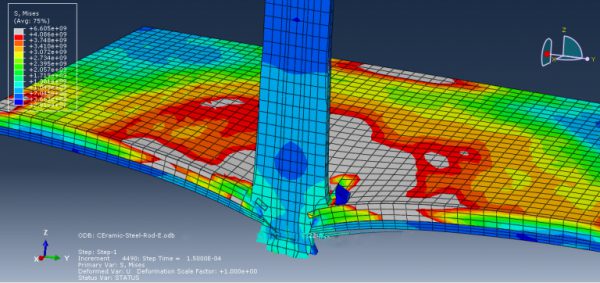

Soil impact refers to the interaction between a solid object and the soil, wherein the object collides with or penetrates into the soil. This issue holds great importance across various industries, including civil engineering, geotechnical engineering, construction, and transportation. Understanding soil impact behavior is crucial for designing and assessing the safety and performance of structures and systems subjected to dynamic loads, such as vehicle collisions, pile driving, and projectile impacts. Simulation plays a vital role in studying soil impact. By employing advanced numerical methods and software tools like Abaqus, researchers and engineers can accurately model and analyze the complex interactions between objects and soil. Simulation allows for the investigation of various parameters, such as impact velocity, soil properties, object geometry, and boundary conditions, to assess their influence on the response and behavior of the system. In this package, you will learn how to do soil impact simulations in several practical examples.

Low-Velocity Impact simulation in Abaqus

Low-velocity impact refers to the collision between objects at relatively low speeds. While the impact energy may be lower compared to high-speed impacts, low-velocity impacts can still cause significant damage and deformation. Assessing the effects of low-velocity impact is crucial for various industries to ensure the structural integrity, safety, and performance of their products. For example, in the automotive industry, understanding the response of vehicles to low-velocity impacts is essential for designing crashworthy structures and improving occupant safety. In aerospace, assessing the impact resistance of aircraft components, such as fuselage panels or wings, helps ensure their ability to withstand ground handling incidents or bird strikes. In this package, you will learn how to do low-velocity impact simulations with several practical examples.

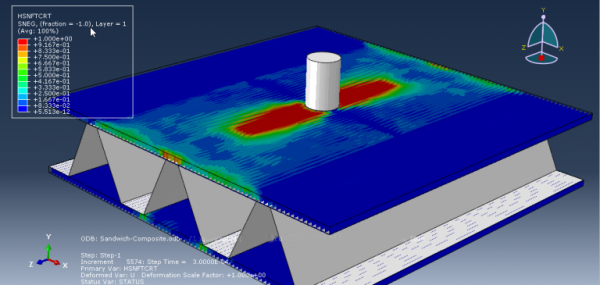

High-Velocity Impact Simulation in Abaqus

High-velocity impact refers to the collision between two bodies at extremely high speeds, typically involving projectiles and targets. It is a phenomenon of great interest in various fields, including defense, aerospace, and automotive industries. High-velocity impact simulation in Abaqus is a computational approach used to analyze and predict the behavior of materials and structures subjected to such impacts. Abaqus, a powerful finite element analysis software, enables engineers and researchers to model and simulate the complex interactions between impacting bodies, accurately predicting factors like stress, strain, deformation, and damage. By simulating high-velocity impacts in Abaqus, engineers can gain valuable insights into the performance and integrity of materials and structures, ultimately aiding in the design of safer and more resilient systems. In this package, you will learn how to do these simulations in many practical examples.

Rock simulation is essential for evaluating the behaviour of rock masses under various loading conditions, such as earthquakes, landslides, and blasting. It enables engineers and geologists to assess the stability and integrity of rock structures, predicts potential failure modes, and develop effective mitigation strategies. Rock simulation is crucial in the design and planning of mining operations, tunnels, and underground constructions to ensure the safety and longevity of the structures. It also plays a vital role in assessing the seismic hazard of an area and evaluating the potential impact of earthquakes on the built environment. In this package, you will learn how to do an impact simulation on a granite stone using the JH-2 model; also an explosion simulation inside a rock for excavation purposes. You can learn more detail in the description of the workshops.

Cold spray & Shot peening simulation in Abaqus

Cold spray is a process used to deposit materials onto a substrate by accelerating fine powder particles to high velocities using compressed gas. Upon impact with the substrate, the particles undergo rapid plastic deformation, disrupting surface oxide films and promoting bonding between metal surfaces. Unlike thermal spray processes, cold spray avoids thermal degradation and partial oxidation of the coating material, resulting in coatings with low porosity and oxygen content. The process is highly efficient, with deposition efficiencies often exceeding 90%. Shot peening is a metal treatment process that involves bombarding a surface with small, round metallic (usually steel), ceramic, or glass beads at high velocity. This process creates small indentations on the surface, which in turn introduces compressive residual stress into the material. These two processes are different and use for separate purposes but their simulations are the same.

Cold spray is particularly important in applications where thermal degradation or oxidation of the coating material is a concern or where the coating is required to be thick and free from defects. In this package, you will learn how to simulate this process with different methods, such as ALE and SPH, with different materials. For example, Cold spray simulation of steel particles impacts on the Inconel target using ALE method.

The study of mechanical waves in gases, liquids, and solids, including issues like vibration, sound, ultrasound, and infrasound, is the focus of the physics subfield of acoustics. A shock wave is a sort of disturbance that propagates across a medium faster than the local speed of sound. In industry, we use acoustic loading in cases such as hydraulic forming, SONAR, seismology, acoustic emission, vibration analysis, engine testing, etc. In this package, you will learn how to model acoustic loadings and shock loadings in four workshops: Deformation behavior of a stiffened panel subjected to underwater shock loading, Acoustic method-based numerical simulation of the electro-hydraulic forming process, Failure modes of concrete gravity dams simulation exposed to an underwater explosion, and Simulation of hull Coupled acoustic-structural response subjected to an underwater explosion.

Simulation of impact in ABAQUS

Impact in Abaqus is one of the most important mechanical tests used to check safety before construction. Due to the expansion of the use of this test in the industry, including the automotive industry, the importance of the issue has increased. In this package, by presenting 7 workshops, we try to teach you most of the capabilities of Abaqus software for this widely used topic.

ABAQUS course for beginners | FEM simulation tutorial

In this Abaqus course for beginners, which is designed for FEM Simulation students in mechanical engineering, various examples in the most widely used fields are presented. These examples are provided with the necessary points and theories for simulation. With this training package, you will be able to get acquainted with different ABAQUS modules in the form of various examples in modeling, how to get the output and the necessary results for reporting. You can download the syllabus of this package here.

Watch Demo