SPH

Hydroforming simulation in Abaqus

Notice: This package will be available one week after purchase.

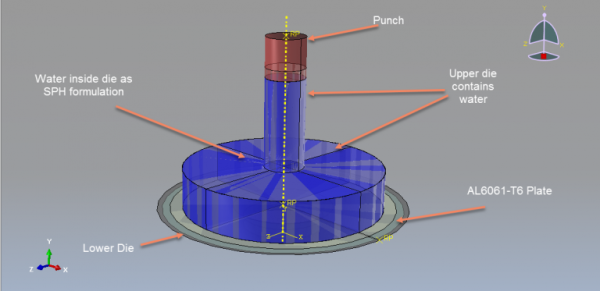

Hydroforming is a metal forming process that allows the shaping of various metals, such as steel, stainless steel, copper, aluminum, and brass. It is a cost-effective and specialized form of die molding that utilizes highly pressurized fluid to shape the metal. Hydroforming can be classified into two main categories: sheet hydroforming and tube hydroforming. Sheet hydroforming uses a single die and a sheet of metal, while tube hydroforming involves expanding metal tubes using two die halves. Hydroforming simulation in Abaqus is a valuable tool for optimizing the hydroforming process. It enables engineers to predict and analyze important factors such as material flow, stress distribution, thinning, and wrinkling during the forming process. By accurately simulating the hydroforming process, engineers can optimize key parameters like fluid pressure, die design, and material properties to achieve the desired shape with minimal defects. In this package, you will learn hydroforming process simulation with the SPH method and using time-pressure curve.

Friction Stir Welding (FSW) Simulation in Abaqus

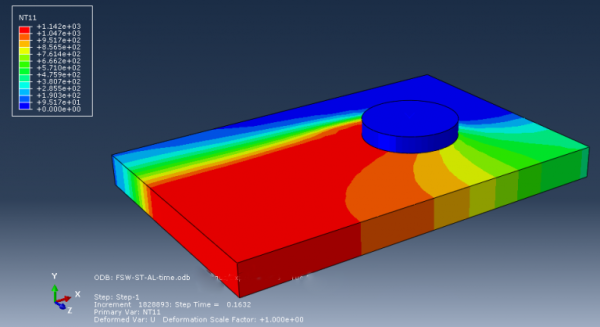

Friction stir welding (FSW) is a solid-state joining process that utilizes a rotating tool to generate frictional heat, enabling the consolidation of materials without melting. FSW offers numerous benefits and is particularly valuable for welding challenging materials like aluminum alloys. It finds widespread applications in industries such as automotive, aerospace, shipbuilding, and construction, providing enhanced strength, weight reduction, and structural integrity. FSW minimizes distortion, reduces the need for post-weld machining, and eliminates issues related to solidification and cooling. Simulations using Abaqus, a popular finite element analysis software, play a crucial role in optimizing FSW processes. Engineers can investigate process parameters, evaluate weld quality, predict residual stresses and distortions, and optimize weld designs through Abaqus simulations. These simulations enable cost-effective development, improved weld quality, reduced material waste, and enhanced productivity in industrial applications. In this package, you will learn how to simulate FSW simulations in a variety of examples with different methods.

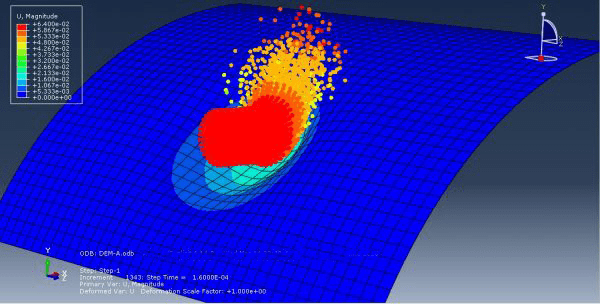

Soil Impact Analysis in Abaqus

Soil impact refers to the interaction between a solid object and the soil, wherein the object collides with or penetrates into the soil. This issue holds great importance across various industries, including civil engineering, geotechnical engineering, construction, and transportation. Understanding soil impact behavior is crucial for designing and assessing the safety and performance of structures and systems subjected to dynamic loads, such as vehicle collisions, pile driving, and projectile impacts. Simulation plays a vital role in studying soil impact. By employing advanced numerical methods and software tools like Abaqus, researchers and engineers can accurately model and analyze the complex interactions between objects and soil. Simulation allows for the investigation of various parameters, such as impact velocity, soil properties, object geometry, and boundary conditions, to assess their influence on the response and behavior of the system. In this package, you will learn how to do soil impact simulations in several practical examples.

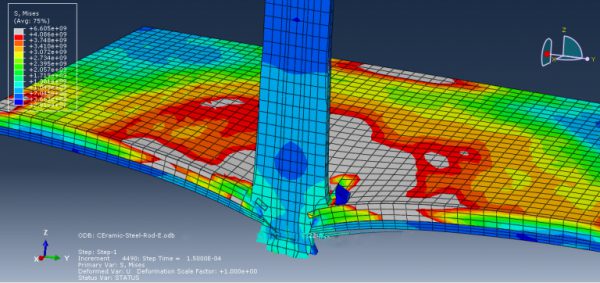

High-Velocity Impact Simulation in Abaqus

High-velocity impact refers to the collision between two bodies at extremely high speeds, typically involving projectiles and targets. It is a phenomenon of great interest in various fields, including defense, aerospace, and automotive industries. High-velocity impact simulation in Abaqus is a computational approach used to analyze and predict the behavior of materials and structures subjected to such impacts. Abaqus, a powerful finite element analysis software, enables engineers and researchers to model and simulate the complex interactions between impacting bodies, accurately predicting factors like stress, strain, deformation, and damage. By simulating high-velocity impacts in Abaqus, engineers can gain valuable insights into the performance and integrity of materials and structures, ultimately aiding in the design of safer and more resilient systems. In this package, you will learn how to do these simulations in many practical examples.

9 Practical Workshops for SPH in Abaqus💡 | Abaqus SPH Tutorial

Smoothed Particle Hydrodynamics Tutorial: Abaqus SPH (Smoothed Particle Hydrodynamics) is a numerical method used in this software to model fluid-structure interaction problems. SPH in Abaqus is a meshless approach that uses a set of particles to discretize the fluid domain. The Abaqus SPH modeling tutorial is particularly useful for problems with large deformations, fragmentation, and free surface effects.

It can be used in combination with other Abaqus features, such as finite element analysis, to model coupled fluid-structure systems. This Abaqus SPH tutorial, created by CAE Assistant group, can help you understand and apply this method through practical examples, some of which include projectile impact simulation on a cementitious material, TNT explosion simulation inside a rock using the SPH method, bullet movement through a water pipe in Abaqus, and bird strike simulation in Abaqus.