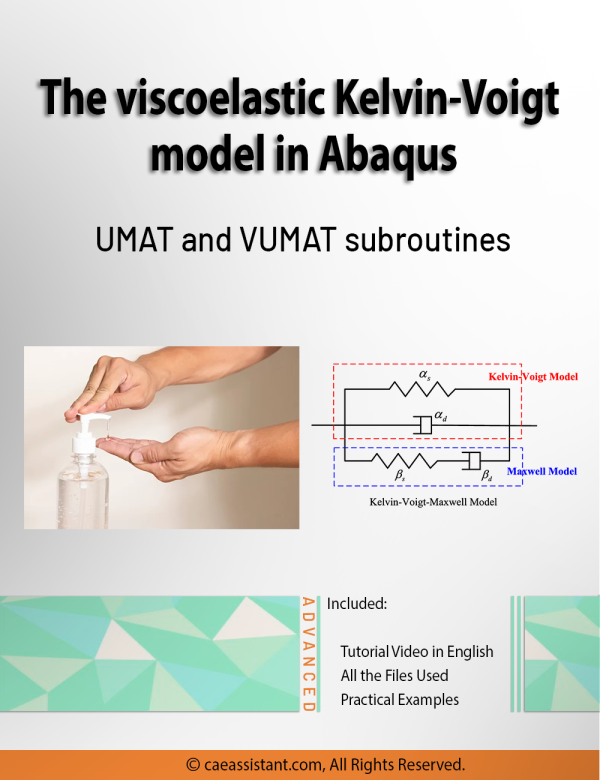

Abaqus Kelvin Voigt Model (Viscoelastic) Simulation Using UMAT and VUMAT Subroutines

This research presents a precise three-dimensional mechanical response of viscoelastic materials using Abaqus kelvin voigt viscoelastic model. We performed this kelvin voigt model Abaqus simulation using both UMAT and VUMAT subroutines for standard and explicit solvers.

The behavior of viscoelastic materials is a state between the behavior of a liquid and a solid. In other words, they behave both like liquids and solids. That is to say, there are many natural and synthetic materials that are classified as viscoelastic materials; From the biological structures of the body such as skin, cartilage and tissue to concrete, foams, rubbers, and synthetic polymers. Due to these unique properties, viscoelastic materials have many applications.

In this regard, the primary goals of this study include the development and implementation of an accurate three-dimensional Abaqus kelvin voigt viscoelastic model, and the integration of viscoelastic properties into the analysis, which can improve the prediction of viscoelastic materials response under different boundary and loading conditions.

This tutorial, by customizing the UMAT and VUMAT subroutines to simulate flexible samples behavior, contributes to the advancement of viscoelastic materials design and analysis.

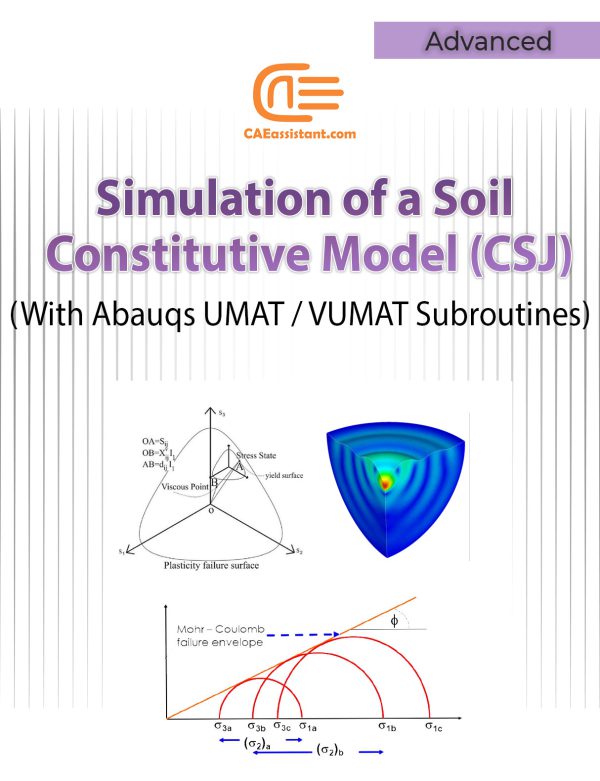

Implementation of Soil Constitutive Models in Abaqus | With a Special Focus on CSJ Models

Constitutive model implemented in calculation code, play an important role in the material behaviors prediction. In the field of geotechnical engineering there are numerous soil constitutive models. By installing these models in a finite element code such as Abaqus, their development, efficiency and advancement can be increased. Also, more and more complex engineering problems can be solved by this method. But to do this, you need a proper understanding of the mathematical and programming basics of these models. This tutorial focuses on implementing advanced constitutive models in Abaqus, particularly for simulating soil behavior. Focusing on the CJS model, this tutorial tries to teach how to work and how to program these models in Abaqus code. It includes detailed explanations of VUMAT and UMAT subroutines and practical examples of implementing the CJS model.

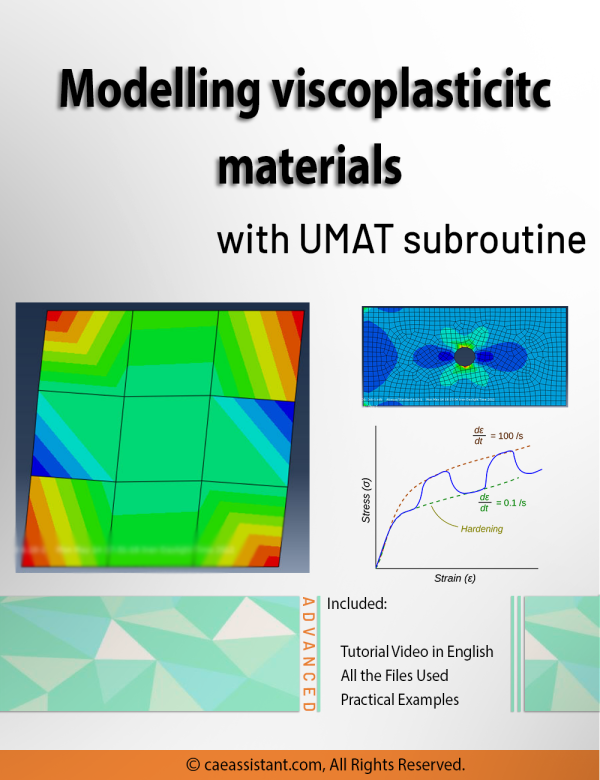

Viscoplasticity Abaqus Simulation Using UMAT Subroutine | Perzyna Viscoplastic Model

Viscoplasticity describes the rate-dependent inelastic behavior of materials, where deformation depends on both stress magnitude and application speed. This concept is crucial in many engineering applications, such as designing structures under dynamic loads, modeling soil behavior during earthquakes, and developing materials with specific mechanical properties. Viscoplasticity Abaqus simulation, especially using Abaqus with UMAT subroutines, are vital for understanding, predicting, and optimizing the behavior of viscoplastic materials. This tutorial focuses on implementing the Perzyna viscoplasticity model in Abaqus. The Perzyna viscoplastic model, a strain rate-dependent viscoplasticity model, relates stress to strain through specific constitutive relations. This involves defining plastic strain rate based on stress state, internal variables, and relaxation time. The tutorial provides general UMAT codes for viscoplastic analysis, yielding results like stress fields essential for various engineering applications. These simulations help in predicting permanent deformations, assessing structural failure points, and analyzing stability under different loads, benefiting fields such as aerospace, automotive, civil engineering, and energy.

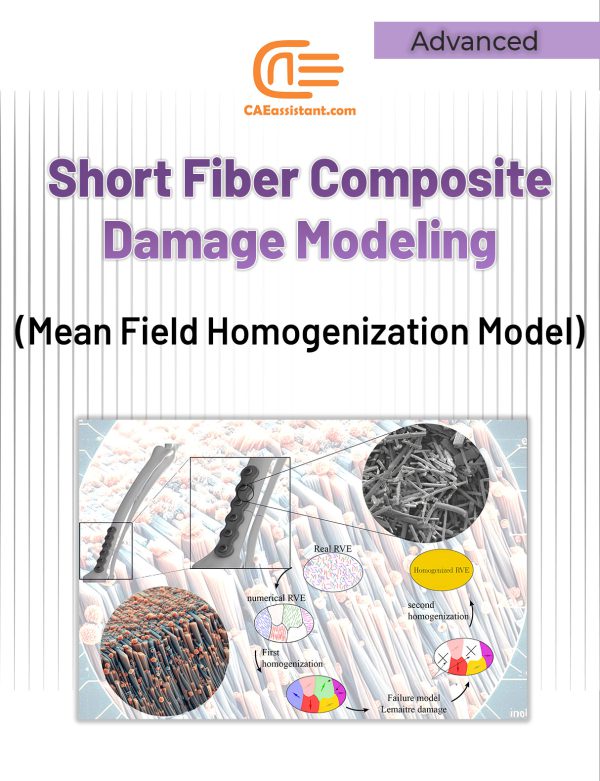

Short fiber composite damage (Mean Field Homogenization Model)

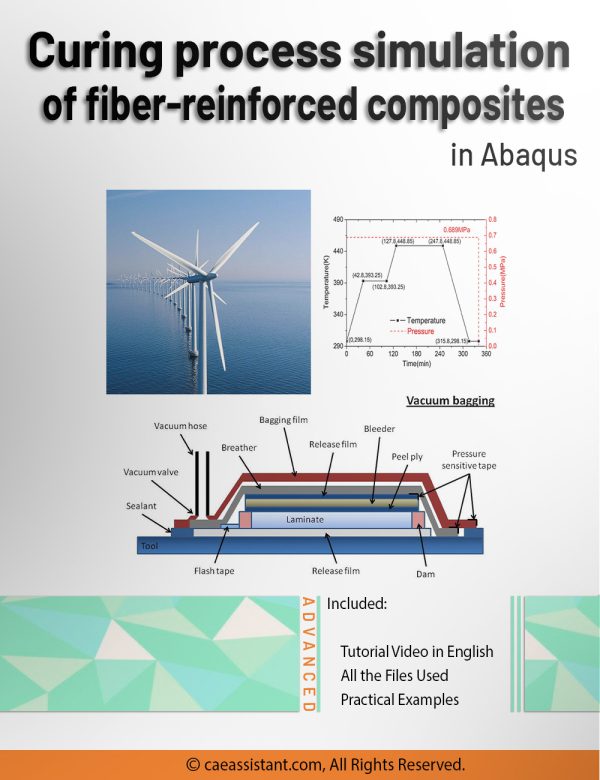

Curing process simulation in Abaqus

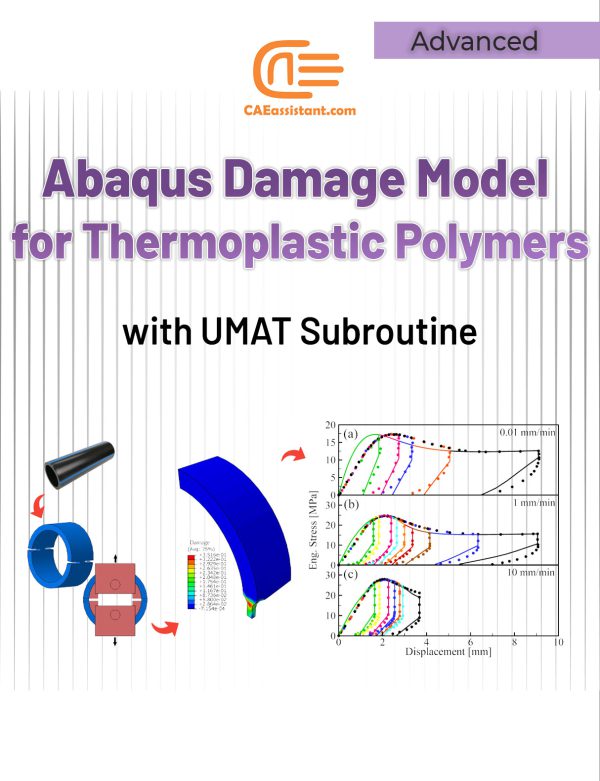

Damage Properties of Thermoplastic Polymers with UMAT Subroutine

Composite Pressure Vessel simulation in ABAQUS

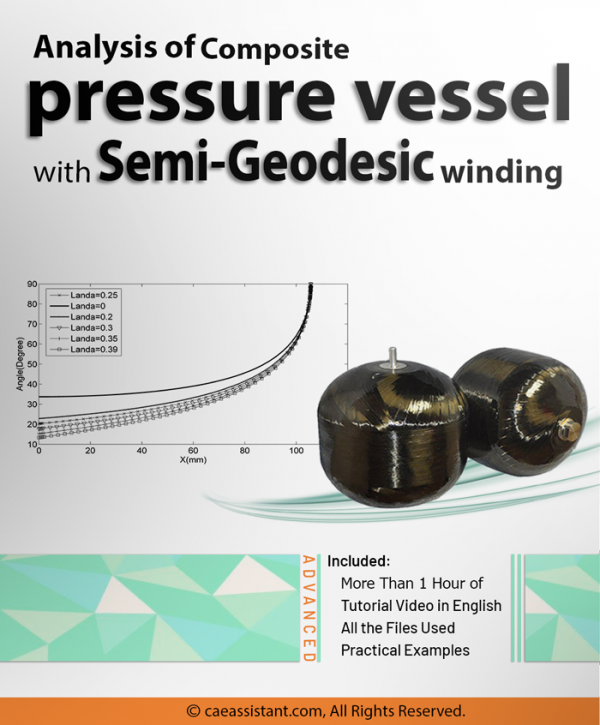

Composite pressure vessel analysis with Semi-Geodesic winding

Composite simulation for experts-Part-3

Pay attention to the syllabus and availability file details. some of the packages are fully available and some of them are partially available. If this is partially available it takes at least two months to be completely available.

If you are a graduate or Ph.D. student, if you are a university professor or an expert engineer in the industry who deals with simulation software, you are definitely familiar with the limitations of this software in defining the material properties, loading or meshing, interaction properties, and etc. You have certainly tried to define the properties of materials based on advanced fracture theories in finite element software and are familiar with their limitations and problems. Now, here is your solution. Start writing subroutines in finite element software and overcome the limitations. With the tutorials in the Golden Package, you will learn how to write 8 subroutines in Abaqus software professionally.Composite simulation for experts-Part-2

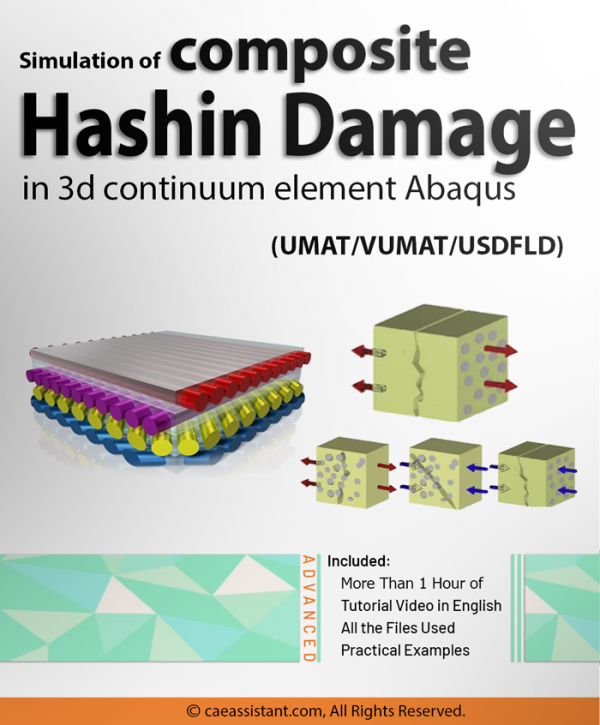

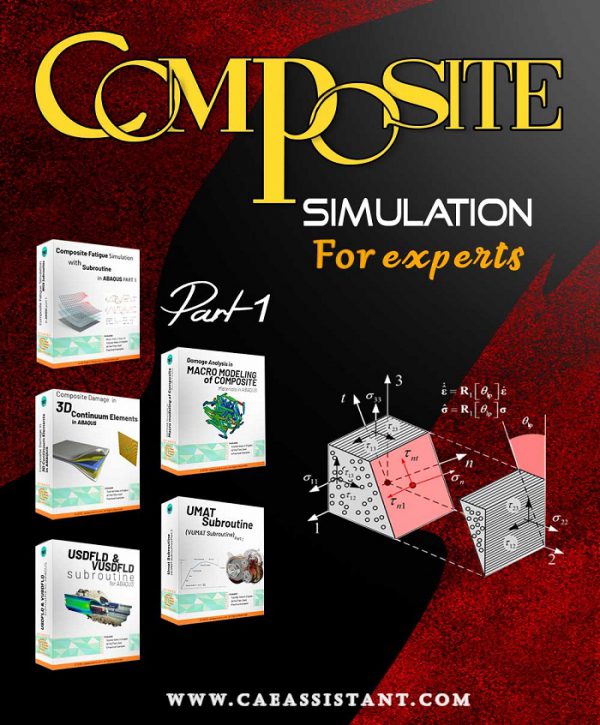

If you are a researcher, student, university professor, or Engineer in the company in the field of composite materials, this training package in simulating these materials in Abaqus software is the best selection. This training package is the second part of the composite for expert package and is focusing on the Simulation of woven composite damage in Abaqus, Composite Fatigue Simulation, Analysis of Composite pressure vessel with Semi-Geodesic winding, Simulation of composite Hashin damage in 3d continuum element (UMAT-VUMAT-USDFLD), and Abaqus composite modeling of Woven & Unidirectional + RVE method.

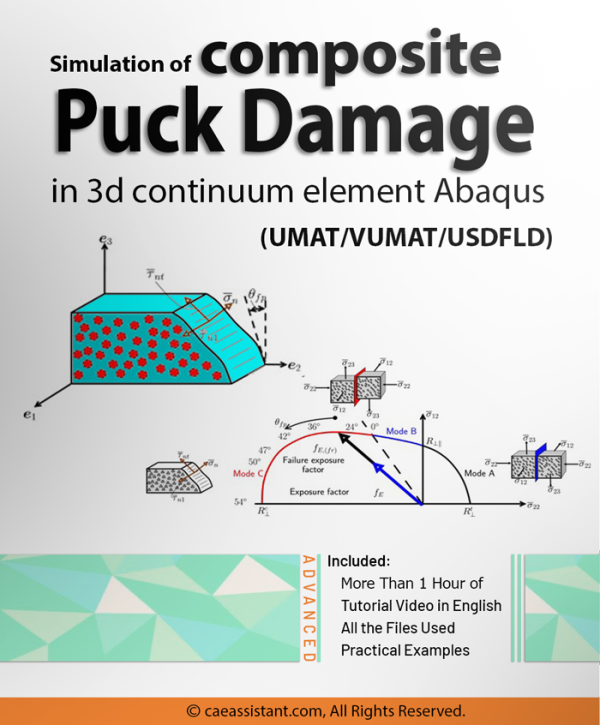

Simulation of composite Puck damage in 3d continuum element in Abaqus (UMAT-USDFLD-VUMAT)

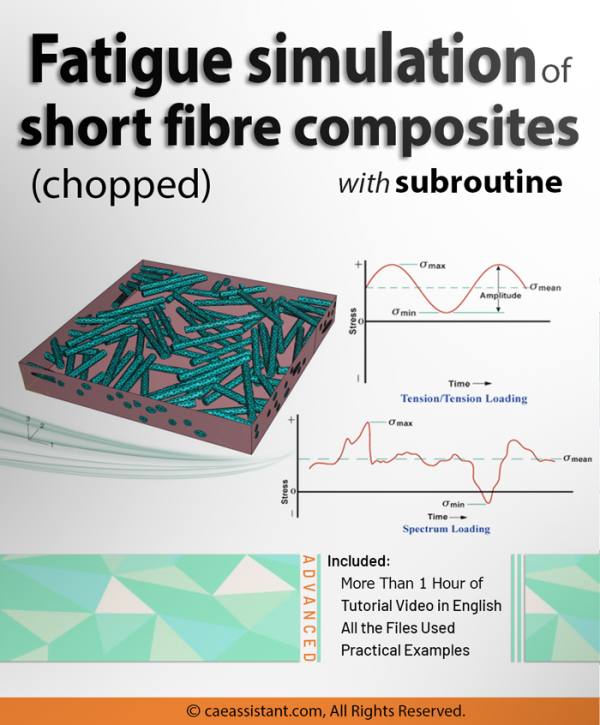

Fatigue damage simulation of short fibre composites with subroutine

UMAT Subroutine (VUMAT Subroutine) in ABAQUS-Free Version- UMAT Abaqus example

"UMAT Subroutine (VUMAT Subroutine) introduction" is used when the material model is not available in ABAQUS software. If you follow this tutorial package, including standard and explicit solver, you will have the ability to write, debug and verify your subroutine based on customized material to use this in complex structures. These lectures are the introduction to writing advanced UMAT and VUMAT subroutines in hyperelastic Martials, Composites, and Metal, and so on. Watch Demo

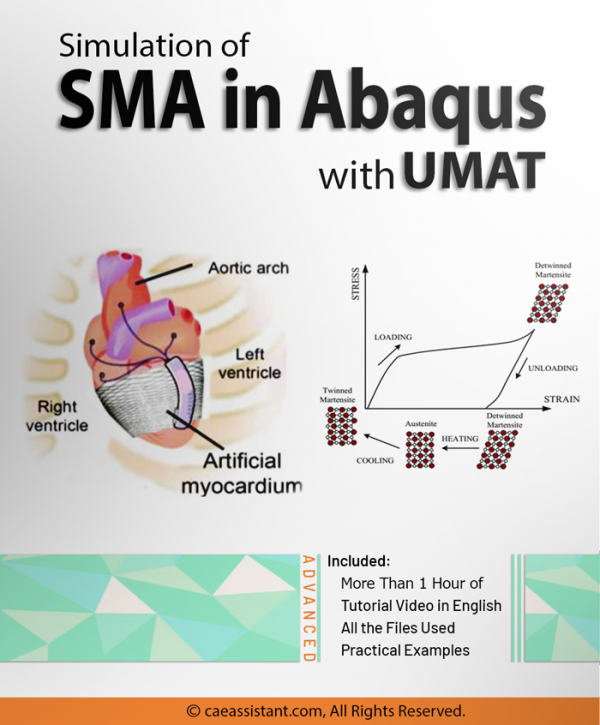

"Advanced UMAT Subroutine (VUMAT Subroutine)" training package helps Abaqus users to prepare complex UMAT and VUMAT subroutines. This training package is suitable for those who are familiar with subroutine or want to learn UMAT/VUMAT subroutine Professionally. Equations for computational plasticity based on kinematic stiffness are also discussed. In addition, metal damage has been implemented based on Johnson Cook's model. Watch DemoSimulation of SMA in Abaqus with UMAT

Simulation of composite Hashin damage in 3d continuum element in Abaqus (UMAT-VUMAT-USDFLD)

Composite simulation for experts-Part-1

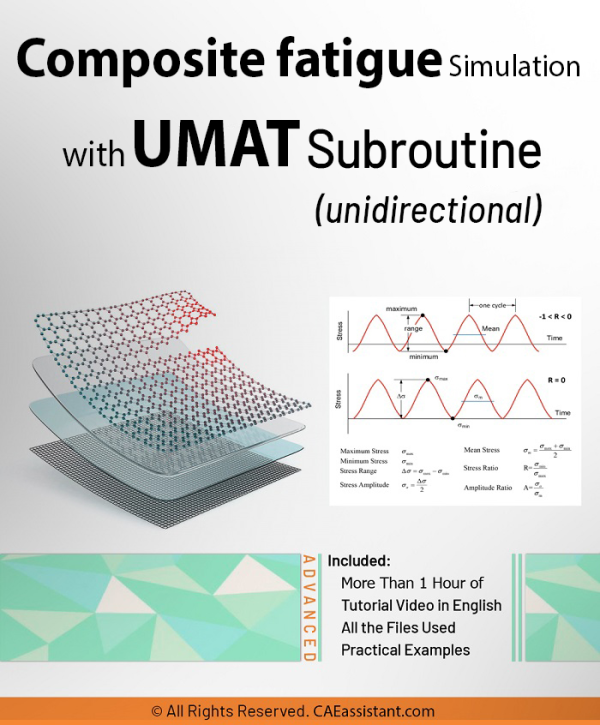

Composite Fatigue Simulation with UMAT Subroutine in ABAQUS (unidirectional)

Advanced UMAT Subroutine (VUMAT Subroutine) – Abaqus UMAT tutorial

UMAT Subroutine (VUMAT Subroutine) introduction

This package is usable when the material model is not available in ABAQUS software. If you follow this tutorial package, including standard and explicit solver, you will have the ability to write, debug and verify your subroutine based on customized material to use this in complex structures. These lectures are an introduction to write advanced UMAT and VUMAT subroutines in hyperelastic Martials, Composites and Metal and so on.

Watch Demo