Machining Simulation Abaqus: Tools, Techniques & Laser Assisted Machining Method

Machining is a complex process that involves extreme stresses, high temperatures, rapid tool wear, and intricate chip formation. Accurately predicting what happens during cutting is not easy—but FEA-based machining simulation offers a powerful solution.

Let’s start with a few important questions:

-

How can we predict chip shape and material deformation during cutting?

-

Can we estimate the temperature rise in both the tool and the workpiece?

-

What’s the best way to optimize cutting parameters without trial-and-error on real machines?

-

How do we reduce tool wear when working with hard-to-machine materials?

-

Can we somehow minimize cutting forces and improve surface finish in tough machining scenarios?

Now, here’s the twist:

The last two challenges—reducing cutting forces and improving machinability of hard materials—can be significantly improved using Laser Assisted Machining (LAM).

So what is LAM, simply put?

Laser-Assisted Machining is a technique where a focused laser beam preheats the material just ahead of the cutting tool. This softens the material slightly, making it easier to cut and reducing tool stress.

🧠 What You’ll Discover in This Blog

In this post, we’ll walk through:

-

How machining simulation Abaqus helps engineers simulate and analyze the cutting process

-

How to implement a moving laser heat source using subroutines

-

The advantages of LAM, as revealed through simulation

-

Tips for setting up your own laser assisted machining model in Abaqus

Let’s dive in!

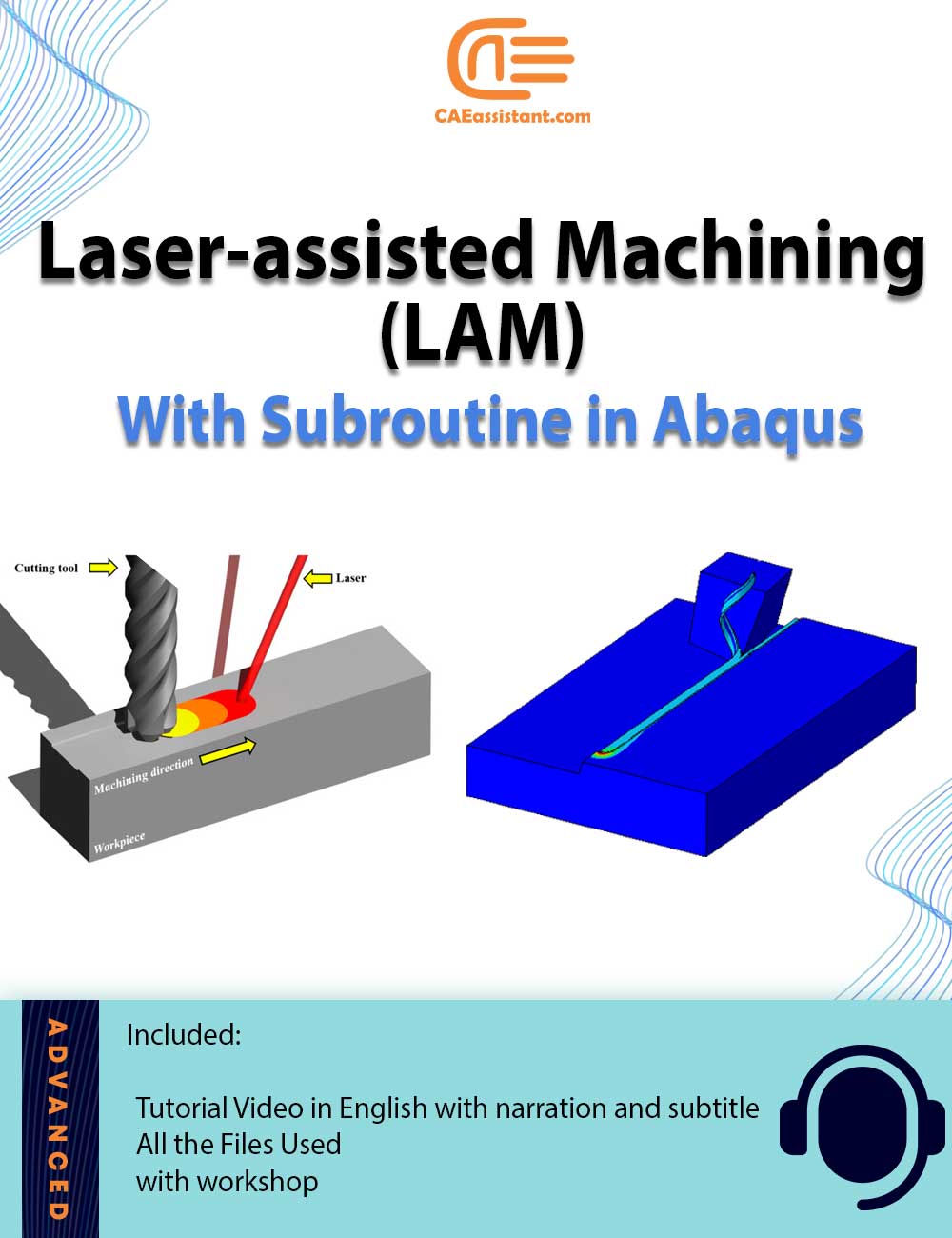

Abaqus simplifies the simulation of Laser Assisted Machining (LAM) by integrating coupled thermo-mechanical modeling. This tutorial covers machining and laser heating models, boundary condition setup, and subroutines like DFLUX and VDFLUX for accurate heat source simulation. Engineers can analyze temperature distribution, stress-strain behavior, and optimize machining performance with parametric studies. Abaqus’ robust FEM capabilities make it easy to evaluate how laser heating enhances cutting efficiency and material properties.

More details here: LAM Abaqus Tutorial

|

|

1. Machining Simulation Abaqus | How FEA Helps Machining Process?

Machining, at its core, is the process of removing material from a workpiece using a cutting tool. It typically involves methods such as milling, turning, and drilling, where the material is shaped and refined to meet strict tolerances. The cutting tool interacts with the workpiece, generating heat and forces, often leading to tool wear and surface finish concerns. These operations are critical in industries ranging from aerospace to automotive, where precision and efficiency are vital.

In the past, engineers would rely on trial and error to determine the best machining parameters, wasting valuable time and resources. Today, machining simulation provides the ability to model and simulate these processes digitally. By integrating finite element analysis (FEA) with thermal simulations and machining simulation Abaqus, engineers can predict how tools will perform under different conditions, optimizing cutting speeds, tool paths, and material removal rates.

The primary reason machining simulation is so valuable is that it offers the ability to:

- Optimize machining parameters like feed rates and cutting speeds without physical testing.

- Predict tool wear and failure, allowing for proactive maintenance and reducing downtime.

- Improve surface finish quality by adjusting cutting tool geometry and motion.

- Integrate laser assistance to reduce cutting forces and improve tool life.

Machining simulations are not just about visualizing tool movement—they’re a form of physics-based modeling that predicts how the material behaves under extreme thermal and mechanical loads. FEA tools like Abaqus help simulate these interactions at a microstructural level.

Machining Simulation Abaqus enables detailed cutting process simulations, including chip formation, plastic deformation, and heat generation—critical elements for predicting machining outcomes accurately.

By integrating simulation into the workflow, manufacturers can not only save costs but also increase throughput and quality—without the risks associated with untested setups.

🚀A BIG Challenge🚀

Despite all the advances in simulation and tooling, machining hard or heat-resistant materials still presents serious challenges. Engineers often face excessive tool wear, high cutting forces, and poor surface finish—especially when working with materials like titanium alloys, hardened steels, or ceramics.

These issues don’t just drive up manufacturing costs; they can cause delays, rework, and even complete process failures. The question is:

How can we make these materials more machinable—without sacrificing part quality or tool life?

This is where Laser Assisted Machining (LAM) comes into play, offering a practical and simulation-friendly solution to one of modern manufacturing’s toughest problems.

2. What is Laser Assisted Machining Method?

Laser Assisted Machining (LAM) introduces a unique approach to the machining process, using high-powered lasers to heat the workpiece before cutting. This softens the material, allowing for easier machining, reduced forces, and improved surface finish. However, simulating LAM is a complex task, as it requires the integration of thermal effects with the mechanical forces at play during the cutting operation.

In practical terms, when building a LAM simulation model, it’s essential to address how the laser’s thermal influence will alter material properties like hardness and ductility during machining. This necessitates the coupling of thermal modeling with mechanical machining processes within the simulation environment, such as Abaqus or other advanced CAE software. The integration ensures that the simulation reflects both the laser heating and the cutting mechanics in a unified model.

3. Laser Assisted Machining Essentials

Key considerations when integrating laser heating with machining models include:

- Laser-Tool Interaction: The positioning of the laser in relation to the cutting tool is crucial. The laser must heat the workpiece surface evenly to achieve optimal thermal softening. The gap between the laser and cutting tool should be minimized to ensure efficient heat conduction without compromising tool engagement.

- Thermo-Mechanical Coupling: Simulating the interaction between thermal softening and cutting forces requires a coupled thermo-mechanical simulation. In this model, the laser heat flux interacts with the cutting tool’s force distribution and material flow. The coupling must be carefully calibrated to ensure that the thermal effects on material properties are accurately represented and that the mechanical effects of the cutting process are not overlooked.

- Advanced Material Modeling: Unlike traditional machining, LAM requires precise modeling of temperature-dependent material properties. This includes factors such as thermal conductivity, specific heat, and elastoplastic behavior. These properties change with temperature, and accurate modeling of these variables is critical for simulating real-world performance.

- Laser Parameters Optimization: Adjusting laser power, beam diameter, and scanning velocity in the simulation allows engineers to identify the best conditions for reducing cutting forces while maintaining part quality. Parametric studies should be conducted to determine how varying these parameters affects both thermal distribution and cutting performance.

Incorporating these elements into a simulation allows manufacturers to explore how different laser settings influence cutting efficiency, tool wear, and final part quality. The integration of laser heating with traditional machining processes in the virtual environment allows for a comprehensive optimization of the overall machining process.

The simulation requires a fine mesh in areas of high thermal gradients or where cutting forces are most concentrated. These areas need to be modeled with higher resolution to capture the nuances of thermal softening and mechanical interactions. In contrast, areas away from the cutting zone can be modeled with coarser meshes to save on computational resources.

Once the simulation is set up, a parametric analysis is essential to optimize the process. By varying key laser parameters—such as power, beam diameter, and scanning velocity—along with cutting speeds and feed rates, engineers can identify the best combinations for reducing forces, improving surface quality, and optimizing overall machining performance.

Finally, analyzing the simulation results involves examining the temperature distribution and its effect on material softening and mechanical stresses. A comparison with traditional machining methods helps highlight the benefits of Laser-Assisted Machining, showing how it reduces cutting forces, minimizes tool wear, and improves surface finishes.

By integrating these complex variables, the simulation provides manufacturers with critical insights into how to improve machining processes and achieve optimal results.

4. Advantages of Laser Assisted Machining (LAM)

-

✔️ Lower cutting forces: Abaqus can show how pre-heating with a laser reduces material hardness and results in lower reaction forces on the cutting tool.

-

✔️ Improved surface finish: With the help of thermal-mechanical coupling in Abaqus, users can analyze how smoother chip flow and less vibration lead to better surface quality.

-

✔️ Extended tool life: FEA allows you to simulate temperature and stress fields in the tool, helping predict areas of wear and fatigue.

-

✔️ Machining hard materials: Abaqus makes it possible to virtually test how laser preheating can make hard-to-machine alloys more compliant during cutting.

By simulating laser-assisted machining in Abaqus, engineers can optimize these advantages before physical implementation, saving both time and cost in tool development.

5. An Overview of Abaqus Machining

To implement Abaqus machining such as LAM, engineers use subroutines such as DFLUX, which define the heat flux across the material. DFLUX applies the laser’s energy in the form of a heat source at the workpiece surface. The heat flux distribution can be adjusted based on the laser parameters like power, velocity, and beam diameter to simulate various operational scenarios.

A significant challenge is simulating the moving heat source. Since the laser beam moves over the workpiece during machining, it’s crucial to account for the continuous shift in the heat source’s position. The simulation uses time-stepping methods to update the position of the laser beam, allowing the material to absorb the laser energy in real time. This movement affects the thermal profile of the material, which in turn influences the thermal softening of the material. For detailed guidance on Heat Transfer and Thermal Stress Analysis in Abaqus, check out our blog post Heat Transfer and Thermal Stress Analysis with Abaqus.

The laser heat source is then integrated with the mechanical model of machining. The simulation combines the thermal effects of the laser with the mechanical interaction of the cutting tool. This coupling is essential, as it accounts for how the thermal softening from the laser reduces cutting forces, enabling higher cutting speeds and better surface finishes.

Why Laser Assisted Machining (LAM) 🤔? > Start by modeling simple machining model ⚙️ > Continue with building simple laser heating model ♨️ > Finally , building a laser assisted machining model 👍👍

Learn all in LAM tutorial full package + All simulation files

For detailed guidance on implementing this process in Abaqus, check out our Laser Forming Simulation Tutorial.

6. Building a Laser Heating Model

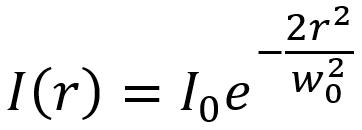

In Laser-Assisted Machining (LAM) simulations, the accurate modeling of the laser heat source is paramount. The process involves applying heat to the workpiece to reduce its hardness and facilitate easier material removal. Typically, the heat from the laser is modeled as a Gaussian distribution to represent the way the laser energy is concentrated on the workpiece surface. The distribution equation for the Gaussian beam is:

Where I(r) is the intensity at a radial distance r from the beam center, I0 is the peak intensity, and w0 is the beam waist (the point of minimum beam diameter). This equation allows the simulation to reflect how the laser intensity varies across the beam profile, with the maximum energy concentrated at the center.

Abaqus simplifies the simulation of Laser-Assisted Machining (LAM) by integrating coupled thermo-mechanical modeling. This tutorial covers machining and laser heating models, boundary condition setup, and subroutines like DFLUX and VDFLUX for accurate heat source simulation. Engineers can analyze temperature distribution, stress-strain behavior, and optimize machining performance with parametric studies. Abaqus’ robust FEM capabilities make it easy to evaluate how laser heating enhances cutting efficiency and material properties.

More details here: LAM Abaqus Tutorial

|

|

7. Conclusion

This resource walks you through setting up your own machining simulation Abaqus model, including laser heat input, cutting setup, material calibration, and all the subroutine coding you need.

Whether you’re a student, researcher, or simulation engineer, this is your guide to mastering LAM simulation in Abaqus.