Introduction to Hygrothermal effects on composite materials

Aerospace, marine, automotive, and civil engineering industries widely use fiber-reinforced composites (FRCs) because of their high strength-to-weight ratio and adaptability. These composites often operate in environments with varying moisture and temperature, such as marine and aerospace applications. Over time, exposure to such conditions can lead to significant changes in their mechanical properties due to hygrothermal effects on composite materials. Therefore, hygrothermal analysis is essential to ensure the performance and longevity of these materials. From aircraft components to wind turbine blades and automotive structures, understanding how composites degrade under these conditions is key to enhancing durability and preventing premature failure.

Hygrothermal degradation refers to the deterioration of a material’s elastic properties when exposed to combined moisture and temperature variations over time. FRCs, particularly those with polymeric matrices, are susceptible to this degradation, which can significantly alter their mechanical behavior. Moisture absorption leads to swelling and softening of the matrix, reducing stiffness and strength, while temperature changes can affect the glass transition temperature of the polymer, causing further mechanical property loss.

Parallel Finite Element Analysis with Abaqus

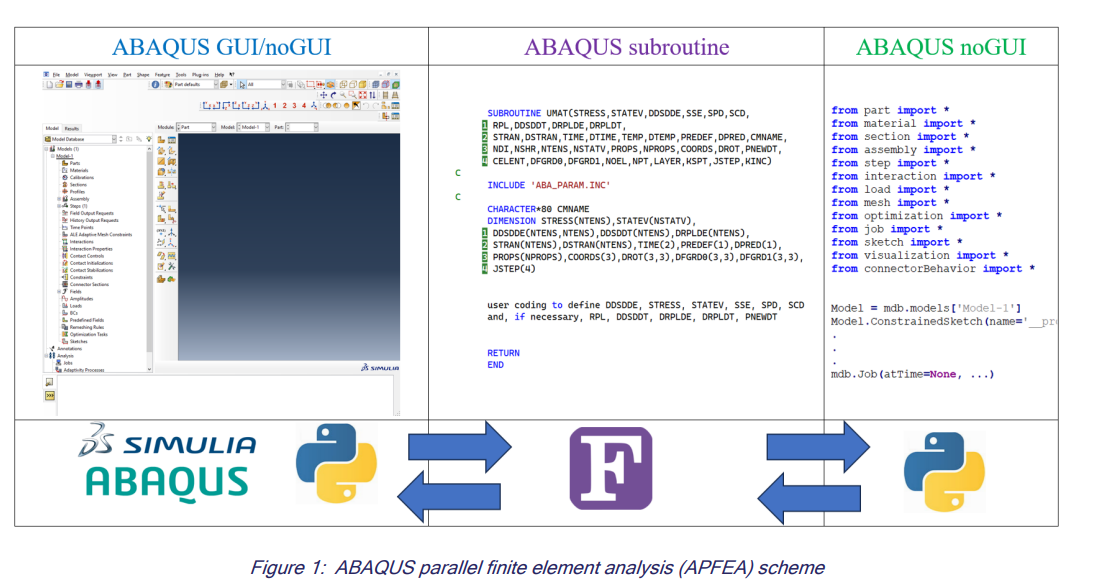

When tackling complex problems that require simultaneous finite element analysis (FEA), Abaqus is one of the most reliable and accurate tools in the field. To carry out such tasks, coding in different environments of Abaqus is essential. This includes Python scripting in the noGUI environment and Fortran coding within the subroutine environment.

In this Abaqus tutorial for parallel finite element analysis, we cover all the necessary skills to perform parallel FEA, such as micro-macro scale analysis. You’ll learn how to write Python scripting code for the noGUI environment and Fortran code for the UMAT subroutine environment, enabling efficient parallel finite element analysis in Abaqus.

One critical application of parallel finite element analysis is studying the hygrothermal effects on composite materials. In this tutorial, we explore how environmental factors like moisture and temperature influence the degradation of elastic properties in fiber-reinforced composites. Using parallel FEA, we can better simulate and analyze these complex interactions.

This tutorial also introduces two powerful algorithms: the Abaqus Python Scripting Micro Modeling (APSMM) and the Abaqus Parallel Finite Element Analysis (APFEA). Both are highly effective for tackling intricate problems, including the study of hygrothermal effects on composite materials, which is essential in evaluating long-term material performance.

With these tools, you’ll gain deeper insights into composite material behavior under environmental stress, making this tutorial an essential resource for engineers working in FEA and materials science.

Importance of Analyzing Hygrothermal Degradation Composites

Analyzing hygrothermal effects on composite materials is essential for predicting how fiber-reinforced composites (FRCs) will perform in real-world conditions. Industries such as aerospace and marine often use these composites in environments where long-term exposure to humidity and temperature can lead to premature failure.

For instance, in marine environments, continuous exposure to water and fluctuating temperatures can significantly weaken the composite structure. Similarly, in aerospace, the failure of composite parts due to environmental degradation can result in catastrophic outcomes. Understanding the hygrothermal degradation composites allows engineers to accurately predict the extent of damage and design more durable composites.

By analyzing these effects, we can ensure greater safety and longevity in applications where environmental stress is a critical factor.

Predicting Hygrothermal Degradation: Numerical vs. Experimental Methods

You can predict hygrothermal degradation composites using two primary approaches: experimental testing and numerical analysis.

Experimental Methods

This approach involves physically testing composite samples under controlled environmental conditions. While experimental methods provide accurate and real-time data, they are time-consuming, expensive, and often impractical for complex or large structures.

Numerical Methods

Numerical simulations, such as Finite Element Analysis (FEA), offer a cost-effective and efficient alternative to experimental testing. These methods use mathematical models to predict how materials will behave under different environmental conditions, reducing the need for extensive physical testing. They also allow for the simulation of various scenarios that might not be easily replicated in a laboratory.

Concluding Remarks

Numerical methods have gained popularity due to their ability to model complex geometries and environmental conditions. However, they still require validation against experimental data to ensure accuracy.

Using ABAQUS for the Simulation of Hygrothermal Degradation

Engineers widely use ABAQUS, a leading software tool, to conduct finite element analysis (FEA) and simulate the mechanical behavior of materials under various conditions. In the context of hygrothermal degradation composites, ABAQUS allows for detailed modeling of the composite’s response to moisture and temperature changes. The software can simulate both transient and steady-state conditions, making it an ideal choice for studying time-dependent hygrothermal degradation effects.

Parallel ABAQUS Modeling and Scripting

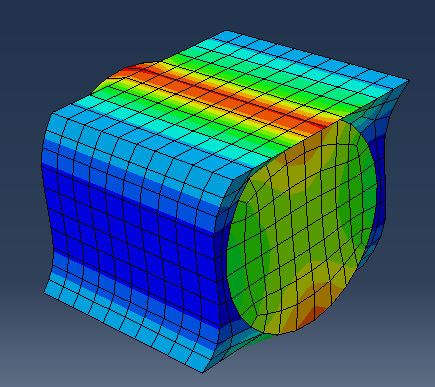

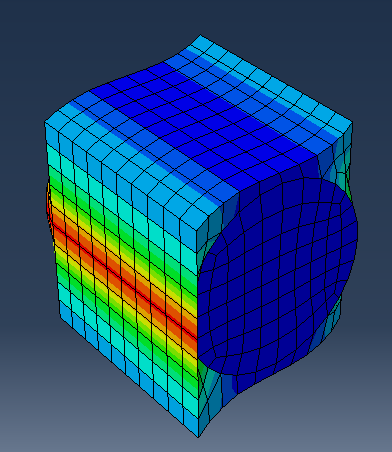

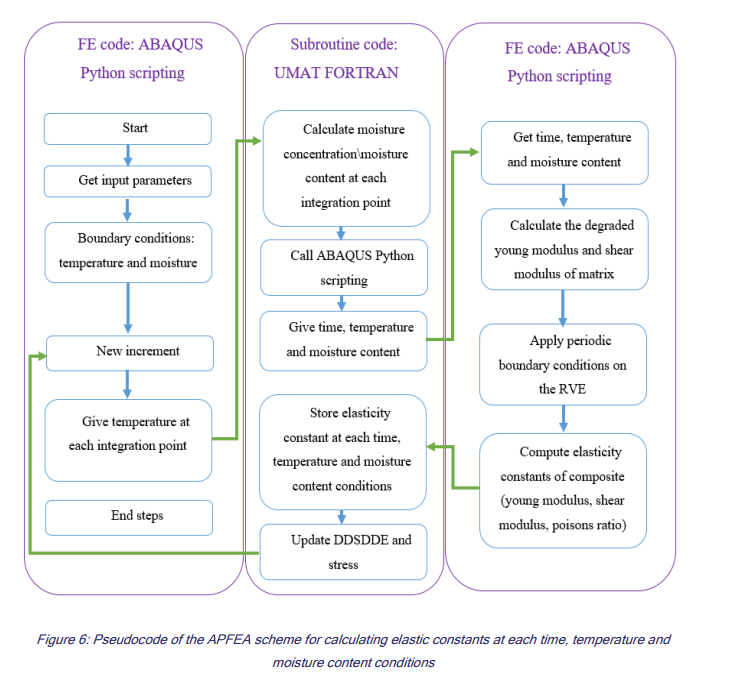

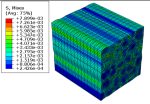

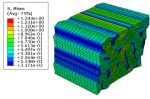

In the study of hygrothermal effects on composite materials, a parallel ABAQUS model was employed to leverage the software’s capability for large-scale simulations across multiple processors. This significantly enhances computational efficiency, particularly when conducting time-dependent, transient simulations that involve numerous iterations.

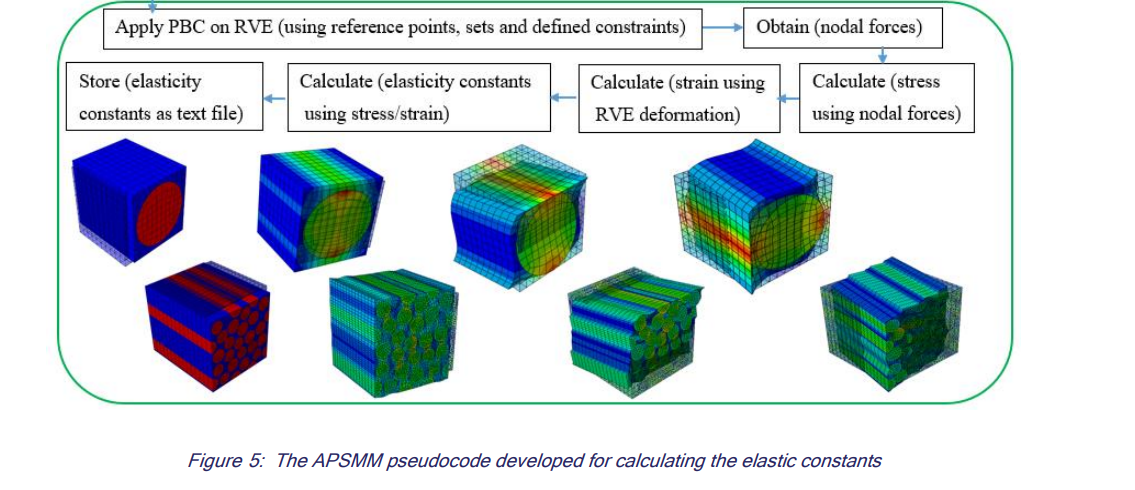

The modeling process also utilized the ABAQUS Python Scripting Micro Modeling (APSMM) algorithm. This allows for the automatic calculation of degraded elastic constants under various environmental conditions. By integrating APSMM with a custom UMAT subroutine written in FORTRAN, the model effectively handles position and time-dependent variations in moisture and temperature. This hybrid approach provides a robust framework for predicting material behavior across a broad spectrum of environmental scenarios, offering a deeper understanding of how composites degrade under hygrothermal conditions.

ABAQUS Scripting and Subroutines

To better analyze hygrothermal effects on composite materials, we developed custom subroutines that extend the functionality of ABAQUS. The ABAQUS Python Scripting Micro Modeling (APSMM) algorithm, written in Python, enables detailed modeling of fiber-reinforced composites at the microscale. This algorithm processes input data, including temperature, time, and moisture content, to calculate the resulting degradation in elastic properties.

Additionally, the UMAT subroutine enhances the model by accounting for moisture concentration and temperature gradients within the composite. Together, these custom subroutines provide a more accurate prediction of how composite materials degrade under environmental stresses like moisture and heat.

These subroutines make it possible to simulate complex hygrothermal conditions that may vary both spatially and temporally. So, they give a detailed insight into how different parts of the composite degrade over time.

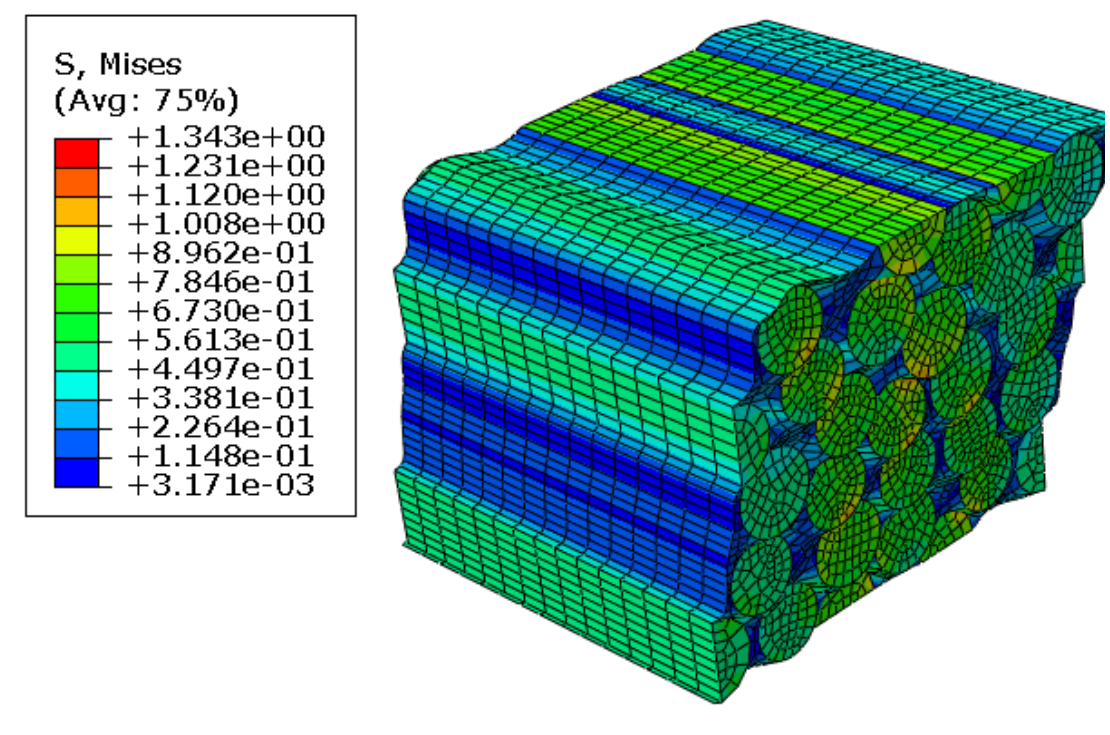

Key Results that Can be Extracted from the ABAQUS Model

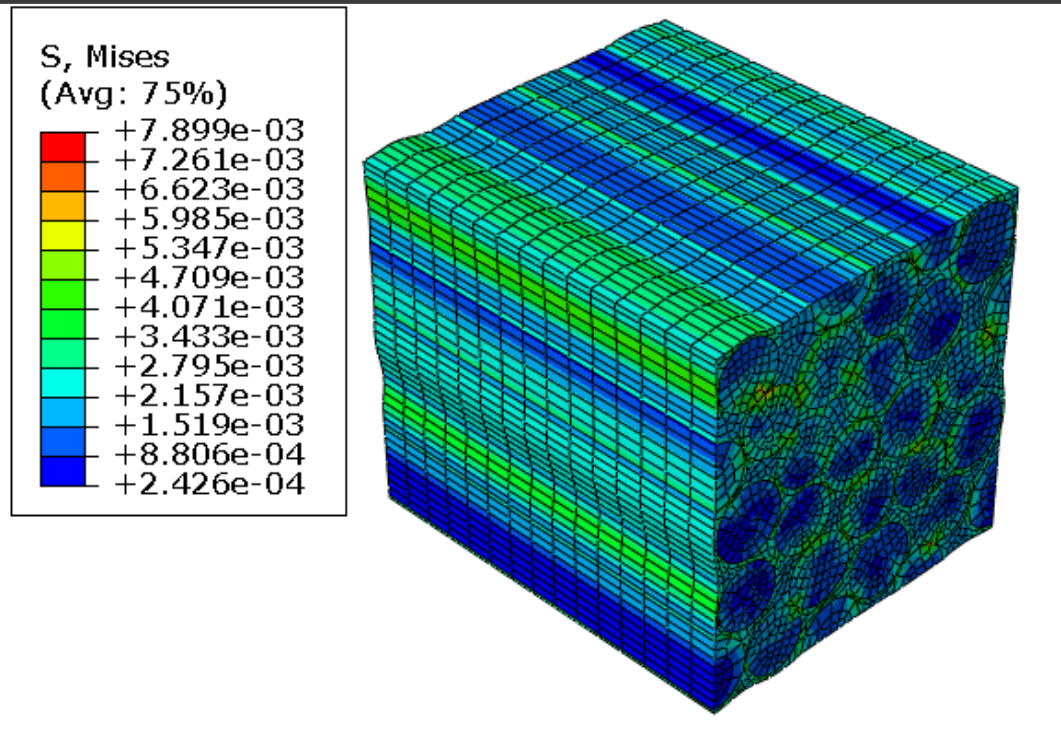

The ABAQUS simulation provided valuable insights into how the elastic properties of fiber-reinforced composites degrade under specific hygrothermal effects on composite materials. Key results extracted from the simulation include:

- Degradation of Young’s Modulus: As moisture content increases, Young’s modulus decreases, especially at higher temperatures. This is crucial for predicting the lifespan of structural components.

- Shear Modulus Variation: The shear modulus is also significantly impacted by moisture absorption, with a sharp decline observed under elevated temperature and humidity.

- Time-Dependent Moisture Absorption: The model accurately predicts the time required for the material to reach moisture saturation, providing insights into the long-term durability of the composite.

These results are critical for assessing the performance and durability of composites under environmental stresses like moisture and heat.

Who Benefits from These Models?

The numerical models developed for predicting hygrothermal degradation of fiber-reinforced composites are beneficial to several stakeholders:

- Engineers and Designers: These models help in designing more durable composite materials that can withstand harsh environmental conditions.

- Aerospace and Marine Industries: These sectors heavily rely on FRCs for critical structural components. They can benefit from the predictive power of these models to enhance safety and performance.

- Researchers: The detailed numerical models provide a framework for further research into the degradation of other composite materials. So, they can be adapted to study different environmental effects.

- Manufacturers: By using numerical predictions, manufacturers can optimize their material selection and processing methods to produce composites with enhanced resistance to hygrothermal conditions.

Conclusion: The Value of ABAQUS Modeling for Fiber-Reinforced Composites

ABAQUS offers a powerful platform for analyzing hygrothermal degradation composites. By utilizing Python scripting and parallel processing, the model provides an efficient and accurate method to predict how fiber-reinforced composites behave under various environmental conditions. This enables engineers, researchers, and manufacturers to assess the hygrothermal effects on composite materials and predict their long-term performance.

With these insights, designers can create safer and more durable structures, ensuring that composite materials can withstand the challenges posed by moisture and temperature over time.

Reviews

Clear filtersThere are no reviews yet.