What is piezoelectric?

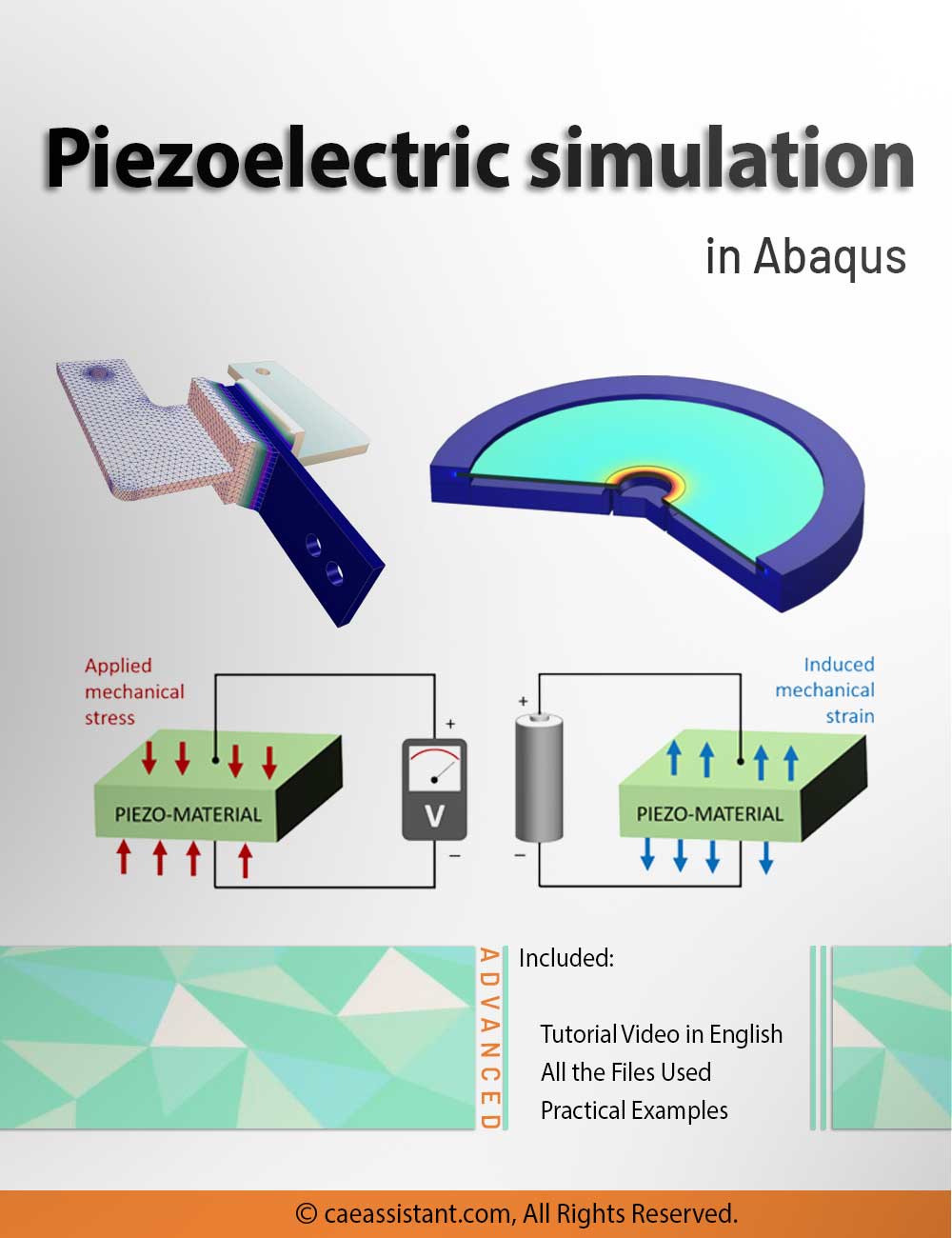

Piezoelectricity is a phenomenon exhibited by certain materials wherein they generate an electric charge in response to applied mechanical stress or deformation. Conversely, these materials can also deform or change shape when an electric field is applied to them. This unique property arises from the crystal structure of piezoelectric materials and their ability to convert mechanical energy into electrical energy and vice versa. The word “piezoelectric” is derived from the Greek words “piezo,” meaning “to press” or “to squeeze,” and “electric.” When a piezoelectric material is subjected to mechanical stress or pressure, such as compression, bending, or vibration, it causes the displacement of positive and negative electric charges within the material. This charge separation creates an electric potential difference across the material, resulting in the generation of an electric field.

Piezoelectric materials can be naturally occurring, such as quartz, topaz, and tourmaline, or they can be artificially engineered, like lead zirconate titanate (PZT) ceramics and certain polymers. These materials possess a non-centrosymmetric crystal structure, meaning that their crystal lattice lacks a center of symmetry. This unique crystal structure allows them to exhibit the piezoelectric effect.

The piezoelectric effect has numerous practical applications across various industries. Piezoelectric sensors are commonly used for measuring pressure, force, acceleration, and strain. They are employed in applications like automotive engine management systems, touchscreens, and medical devices. Piezoelectric actuators are utilized for precise positioning, micro-actuation, and vibration control in applications such as robotics, inkjet printers, and optical devices. Additionally, piezoelectric materials find use in ultrasonic transducers for medical imaging, energy harvesting systems, and acoustic wave devices.

The ability of piezoelectric materials to convert mechanical energy into electrical energy and vice versa makes them valuable in a wide range of technologies. Their sensitivity, fast response, compact size, and versatility make them indispensable in numerous fields, including engineering, electronics, medical imaging, energy harvesting, and more.

Piezoelectric applications and simulation

Piezoelectricity is a unique property exhibited by certain materials that can convert mechanical energy into electrical energy and vice versa. These materials are called piezoelectric materials and are widely used in various applications due to their remarkable properties. The piezoelectric effect arises from the crystal structure of these materials, which causes the generation of electric charges when subjected to mechanical stress or deformation.

Benefits of Piezoelectric Materials:

- Sensitivity and Precision: Piezoelectric materials possess high sensitivity, enabling them to detect even subtle changes in pressure, force, or acceleration. This makes them ideal for precise measurements and sensing applications.

- Fast Response: Piezoelectric materials can rapidly respond to changes in the applied electric field or mechanical stress, making them suitable for applications that require quick and accurate actuation.

- Wide Frequency Range: Piezoelectric materials can operate across a broad range of frequencies, from DC (direct current) to ultrasonic frequencies. This versatility allows their use in diverse applications, including medical imaging, sonar systems, and vibration control.

- Compact Size: Piezoelectric devices can be designed to be compact and lightweight, making them suitable for integration into miniaturized systems and portable devices.

Applications of Piezoelectric Materials:

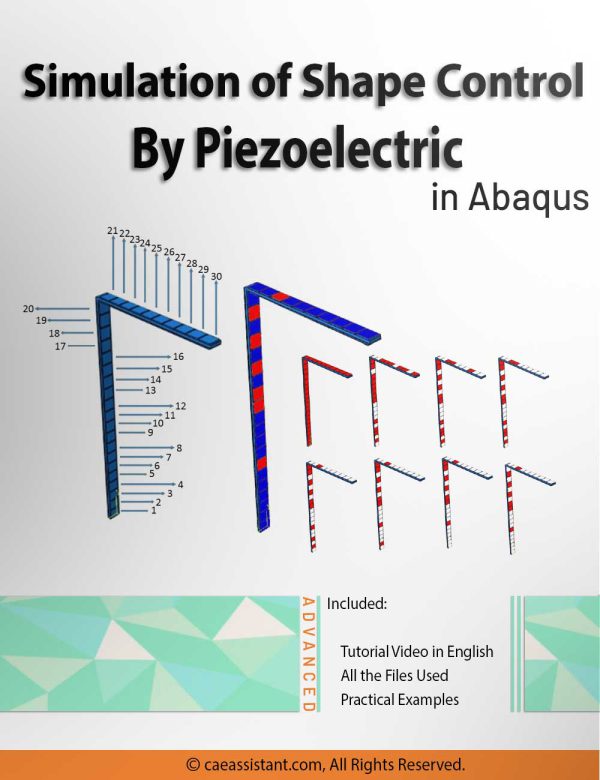

- Sensors and Actuators: Piezoelectric materials are extensively used in sensors for pressure, force, acceleration, and strain measurements. They are also employed as actuators to generate precise and controlled mechanical displacements, enabling applications such as inkjet printers, robotic systems, and micro-positioning devices.

- Energy Harvesting: Piezoelectric materials can convert mechanical vibrations or ambient vibrations into electrical energy. This ability is harnessed in energy harvesting systems to power small-scale devices and wireless sensors.

- Ultrasonic Transducers: Ultrasonic transducers based on piezoelectric materials are used in medical imaging (ultrasound), non-destructive testing, and cleaning applications. They emit and receive high-frequency sound waves for imaging and inspection purposes.

- Piezoelectric Motors: These motors utilize the piezoelectric effect to generate precise motion without the need for traditional electromagnetic components. They find applications in optics, robotics, and microelectronics.

Simulating piezoelectric materials using software tools like Abaqus is crucial for several reasons:

- Design Optimization: Simulation allows engineers to optimize the design and placement of piezoelectric components in devices or structures, ensuring maximum performance and efficiency. It enables virtual testing of different configurations, saving time and resources in the prototyping phase.

- Performance Prediction: Simulations provide valuable insights into the behavior of piezoelectric materials under specific operating conditions. Engineers can analyze factors like stress distribution, deformation, and electrical response, aiding in the prediction of material performance and failure analysis.

- Parameter Sensitivity Analysis: Software simulations enable the study of how changes in various parameters, such as material properties or applied voltage, affect the behavior of piezoelectric devices. This analysis helps in identifying critical factors that impact device performance and assists in making informed design decisions.

- Cost and Time Efficiency: Virtual simulations significantly reduce the need for physical prototypes and testing, saving both time and costs associated with experimental setups. Engineers can iterate through different design concepts and evaluate their viability quickly and efficiently.

- Complex System Integration: Simulating piezoelectric materials in software allows for the integration of piezoelectric components into larger systems or structures. Engineers can assess the interactions between piezoelectric elements and other components, ensuring seamless integration and avoiding potential issues.

It would be helpful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial. Moreover, if you need to get some info about the FEM, visit this article: “Introduction to Finite Element Method | Finite Element Analysis”. You don’t know which Abaqus software editions are suitable for you, Do not worry! This article would give you info about Abaqus editions: “How to download Abaqus? | Abaqus student & commercial edition” .

Enrique –

In piezoelectric simulation in Abaqus, how can the effect of electrical distribution on material deformation be investigated?