Short fiber Composite materials, short fiber reinforced composites, discontinuous fiber composites, or whatever you like to call them are soaring in popularity by the day, yet with their rise come inevitable challenges, none more insidious than fatigue analysis—the silent saboteur threatening material integrity. But you may say “How in heaven’s name I can predict the short fiber composite fatigue life or analyze the fatigue behavior in them?”

Understanding and predicting short fiber composite fatigue behavior is paramount for engineers seeking to design reliable and long-lasting products. This blog post dives deep into the world of short fiber reinforced composite fatigue analysis using the Abaqus software and UMAT subroutine. Whether you’re an expert in discontinuous fiber composites or just starting your journey, this post is for you. We’ll explore the key factors influencing short fiber composite fatigue, and equip you with the knowledge to confidently simulate fatigue in your next composite design.

1. Intro: Short fiber composite fatigue analysis in Abaqus

To solve the Short fiber composite fatigue analysis problems, we need to better understand different types of composite materials, and analyze their behavior under different loadings and phenomena, such as fatigue. Simulating composite materials in powerful software like Abaqus provides us with the advantage of analyzing their behavior at minimal cost. Now, in this article, we intend to familiarize you with the world of short fiber composites and study short fiber composite fatigue. To do this, we will first introduce you to the fatigue concept, and different types of composites, such as short fiber composites, and in the next step, we will explore methods for short fiber composite fatigue analysis. Finally, we will review the short fiber composite fatigue simulation in Abaqus and offer you a special recommendation. So, stay with us until the end of this article.

Figure 1: composites material applications in various industries

Fact: Did you know that car manufacturers are increasingly using short fiber composites in car parts like hoods and fenders? This is because these materials can be colored throughout, meaning no more pesky paint jobs!

2. What is fatigue damage?

Fatigue refers to the initiation and propagation of cracks in a material due to cyclic loading. When a fatigue crack starts, it grows incrementally with each loading cycle. The crack continues to grow until it reaches a critical size. Finally, the crack propagates sufficiently within the structure, which leads to complete failure of the structure.

Figure 2: Failure of a crank arm due to fatigue

In the fatigue phenomenon, various factors affect the rate and growth of cracks, such as the average stress applied to the structure, the temperature, the environment, and the surface finish of the structure. While studying these factors provides us with a good understanding of fatigue, structural failure usually occurs suddenly due to fatigue, making it a dangerous phenomenon. Therefore, examining and analyzing fatigue in materials is of great importance. Since fatigue is a destructive phenomenon, one of the approaches to investigate structural fatigue is the Finite Element Method, which will be discussed further in this article. Now, let’s review together the important factors and parameters in the study of the fatigue phenomenon.

2.1. Five types of fatigue loading

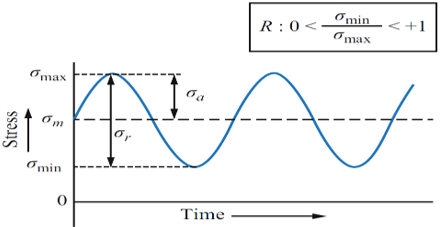

As mentioned, cyclic loading is one of the factors contributing to the fatigue phenomenon. Understanding and examining the type of loading is important due to its influence on the mean stress. Generally, there are five types of cyclic loading that can lead to fatigue:

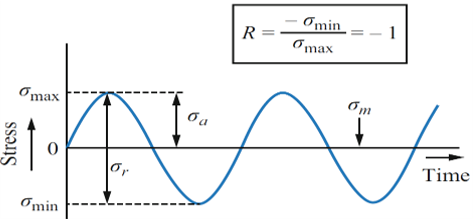

The magnitude of tension and compression is equal. Here is stress-time diagram:

Figure 3: first fatigue loading type’s stress-time curve

To calculate the mean stress, stress amplitude, and stress range, the following equations, respectively labeled as 1 to 3, are used:

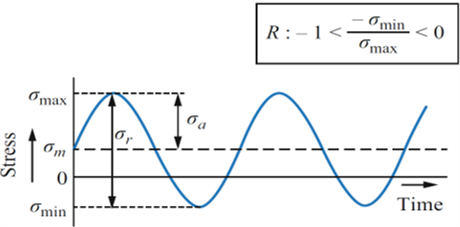

In this case, the loading is asymmetric, with unequal tension and compression. In this case, the magnitude of tensile stress is greater than the compressive stress:

Figure 4: Second fatigue loading type’s stress-time curve

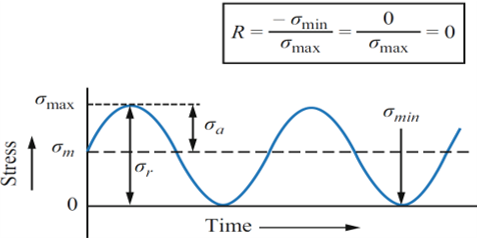

In this case, the minimum stress level is zero so loading is purely tensile:

Figure 5: Third fatigue loading type’s stress-time curve

In this case, loading is purely tensile and the minimum stress level is greater than zero.

Figure 6: Fourth fatigue loading type’s stress-time curve

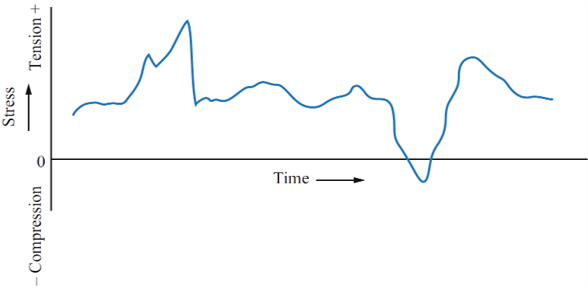

The last type of loading is irregular loading, which is the repetition of tension and compression without a specific pattern.

Figure 7: Fifth fatigue loading type’s stress-time curve

2.2. Fatigue cycle number

To study fatigue, including short fiber composite fatigue, attention should be paid to the number of fatigue cycles. Fatigue is generally divided into two main categories:

- Low-cycle fatigue

- High-cycle fatigue

If the applied stress exceeds the yield stress, it results in low-cycle fatigue. On the other hand, if the stress is below the yield stress, it leads to high-cycle fatigue.

Did you know that a car’s bumper, despite its tough exterior, can be susceptible to fatigue over time? This is because they’re often made from short fiber composites, which are strong but can weaken under repeated stress. So, the next time you see a car enduring a bumpy road, imagine its bumper quietly undergoing a fatigue test! Speaking of fatigue test; how to do short fiber composite fatigue analysis? check out this link: “Short fiber composite fatigue analysis“.

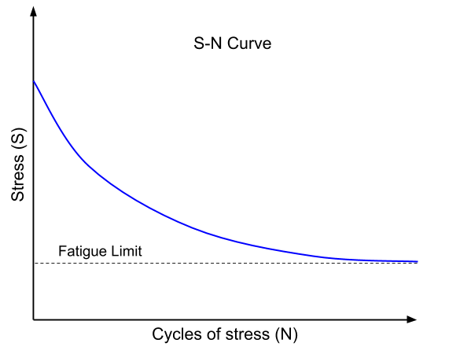

2.3. Fatigue life

Fatigue life is another important parameter in the fatigue analysis of a structure. Fatigue life refers to the number of cycles that a specimen undergoes during testing until fatigue occurs. In the stress-cycle number diagram, there is a theoretical value where the component never experiences fatigue for stresses less than this value. This value is referred to as the fatigue limit.

Figure 8: Fatigue life curve(S-N curve)

3. Four categories of Fiber reinforced composites

Fiber reinforced composites are a type of composites that are made by combining fibers with a matrix, such as resin or polymer. The presence of fibers in the composite can greatly enhance its strength, as the tensile load is borne by the fibers, which have much higher tensile strength than the matrix. The mechanical properties of fiber-reinforced composites are strongly influenced by the type, volume fraction, length, and orientation of the fibers. Generally, fiber-reinforced composites can be classified into four categories:

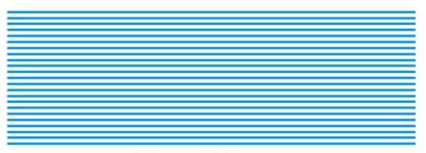

Continuous aligned fiber composites

Figure 9: Continuous aligned fiber composites schematic

Discontinuous aligned fiber composites

Figure 10: Discontinuous aligned fiber composites schematic

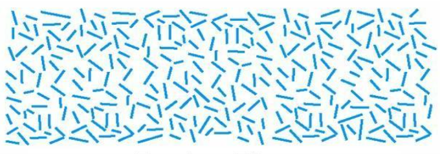

short random fiber composites

Figure 11: Short random fiber composites schematic

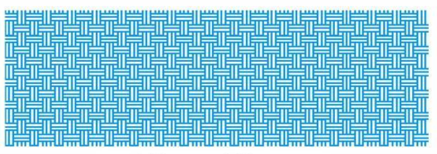

Woven composites

Figure 12: Woven composites schematic

4. Short fiber reinforced composite fatigue

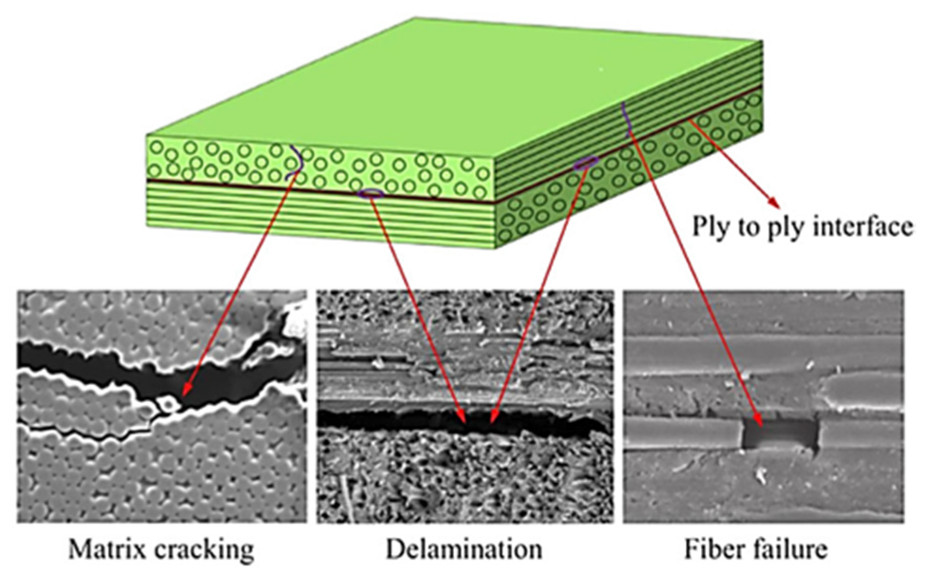

Generally, when damage occurs in composites, such as short fiber composite fatigue damage, these damages can be categorized into three groups:

- Fiber damage: Tensile loading in composites is borne by the fibers. When the loading exceeds the fiber’s tolerance limit, the fibers become damaged, resulting in damage to the composite.

- Matrix damage: In fiber reinforced composites, compression is usually tolerated by the matrix. When the compression exceeds the matrix’s tolerance limit, the matrix fractures and becomes damaged.

- Delamination: Delamination is one of the mechanisms of damage in composites. In this case, the layers of the composite separate, leading to damage to the composite structure.

In the short fiber reinforced composite fatigue process, similar to other composites, various factors such as fiber material, fiber volume fraction, temperature, and creep strain have an impact. However, one of the most important factors in short fiber composite fatigue is the fiber distribution within the matrix. If the fiber distribution is random, the behavior of the composite material is homogeneous and isotropic. Otherwise, the composite will be anisotropic.

Figure 13: Damage modes in composites

5. Short fiber composite fatigue behavior

As mentioned, the short fiber composite fatigue behavior depends on various factors, including fiber length, fiber distribution within the matrix, etc. Most studies have shown that longer fiber length leads to higher composite strength, and the strength directly affects the fatigue life of the composite. If the fiber distribution in the composite is not random, the composite is orthotropic, meaning it behaves differently from a composite with a random fiber distribution. There are various models available to simulate the short fiber composite fatigue behavior, and two of the most well-known models for short fiber composite fatigue damage are:

- The Nori damage model for short fiber composite fatigue.

- The Avanzi damage model for short fiber composite fatigue.

In the next section, we will examine the Avanzi model.

But if you need to learn these models with examples, I suggest to visit this link: “Short fiber composite fatigue“.

6. Discontinuous fiber composite fatigue analysis by Avanzini’s model

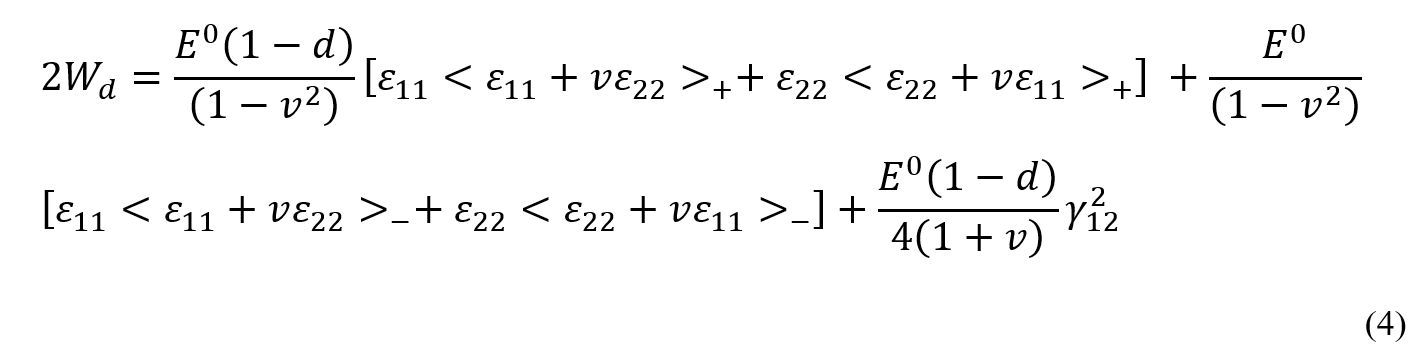

The Avanzini model for discontinuous fiber composite fatigue analysis has emerged from the development and modification of the Nori model. In this model, the fiber distribution is considered random, assuming a homogeneous and isotropic composite. In this model, the strain energy is calculated using equation 4:

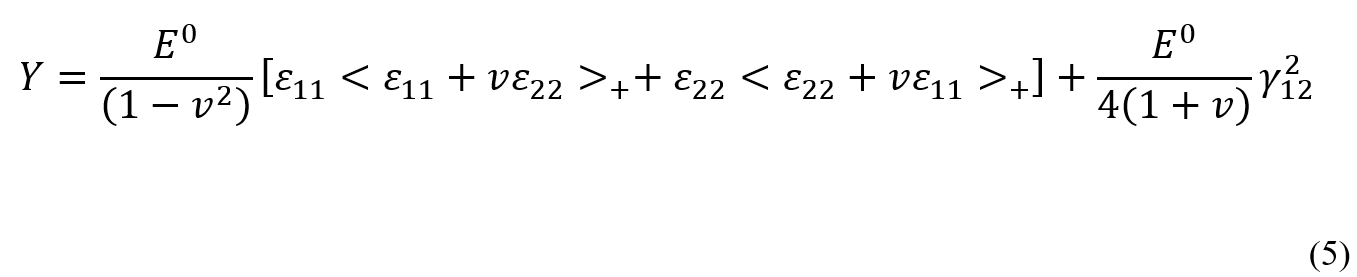

By integrating equation 4, the thermodynamic force is obtained from equation 5:

In the above equations, γ represents the damage constant, and d is the damage variable. The damage variable d can be calculated using equation 6:

We can use the Avanzini model to analyze the short fiber composite fatigue in Abaqus software.

7. Abaqus short fiber composite fatigue simulation using UMAT subroutine

As mentioned earlier, with the increased use of composites, it is necessary to simulate composites under various loading conditions and working conditions, including short fiber composite fatigue. Abaqus software is a powerful tool that allows us to perform simulations of short fiber composite fatigue. However, Abaqus short fiber composite fatigue simulation is complex and challenging because Abaqus does not have a default material called “short fiber composite.” Therefore, to simulate short fiber composite fatigue, the user material subroutine (UMAT) needs to be utilized. Another challenge in this simulation is fatigue cycle simulation. However, there is a solution to these challenges.

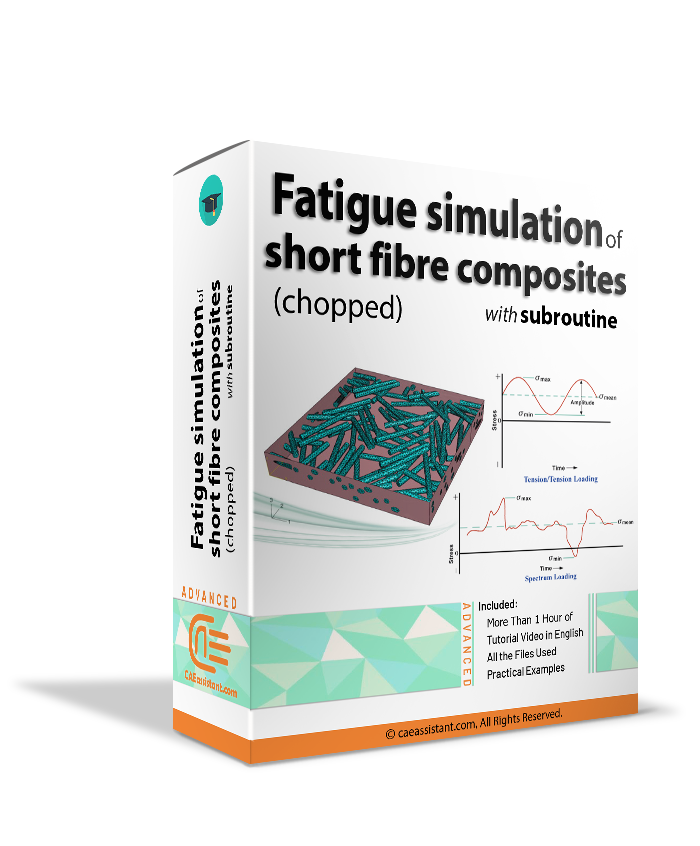

We introduce the ” Short fiber composite fatigue damage simulation in Abaqus with UMAT subroutine ” training package to you. This package provides answers to all your questions regarding simulating short fiber composite fatigue in Abaqus. In addition to comprehensive explanations about fatigue and composites, this package provides complete guidance on Abaqus short fiber composite fatigue simulation using the Avanzini model. Furthermore, all the necessary files, including Abaqus files and the umat subroutine, will be made available to you.

Fatigue failure in materials occurs when repetitive or fluctuating stresses, below the ultimate strength and often below the yield limit, lead to sudden and unpredictable failure, making it a significant concern in engineering due to its potential for catastrophic consequences. The reinforced part of the fiber-reinforced composites can be categorized as continuous or discontinuous, with the latter referred to as short fiber-reinforced composites. In this training package “Short fiber composite fatigue“, the fatigue of short (chopped) fiber composites is explained. Two fatigue damage models are presented for short fiber composites: Nouri fatigue damage model and Avanzini fatigue damage model. The Nouri’s model is applicable for composites with orthotropic behavior. But the Avanzini’s model has considered the fiber distribution in the matrix to be homogeneous and random. It has assumed the material behavior to be isotropic. Also, Nouri’s model was developed for strain-controlled test, but Avanzini’s model was developed for stress-controlled test. In this tutorial, we use the Avanzini’s model, which is base on this article: “Fatigue behavior and cyclic damage of peek short fiber reinforced composites”. This article has implemented the USDFLD subroutine, but we use the UMAT subroutine, which is more accurate than USDFLD since the material strength and properties reduction is smooth. A standard test specimen is used in this simulation to model such behavior. You will learn the details in the package.

It would be helpful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial.

One note, when you are simulating in Abaqus, be careful with the units of values you insert in Abaqus. Yes! Abaqus don’t have units but the values you enter must have consistent units. You can learn more about the system of units in Abaqus.