Imagine a car built from the same materials as your wooden furniture or a skyscraper incorporating fibers from plants. This isn’t science fiction but a reality thanks to natural fiber composites (NFCs). These innovative materials are transforming various industries by combining natural fibers with polymers to create strong and sustainable products.

Natural fiber composites utilize fibers like wood, bamboo, flax, and hemp to produce materials that are both eco-friendly and cost-effective. Their unique hierarchical structures give them impressive mechanical properties, making them suitable alternatives to traditional synthetic composites. Challenges like fiber-matrix compatibility are being addressed through advanced techniques, including molecular dynamics simulations and nanoscale modifications.

In this course, we’ll explore the world of NFCs in depth. We’ll discuss their structures, the challenges they face, and the cutting-edge methods used to enhance their performance. You’ll learn about their diverse applications in construction, automotive, and aerospace industries, and how machine learning is shaping their future development. Real-world case studies will showcase their practicality, and we’ll look ahead to emerging trends and research directions in this exciting field.

1. Introduction to Natural Fiber Composites (NFCs)

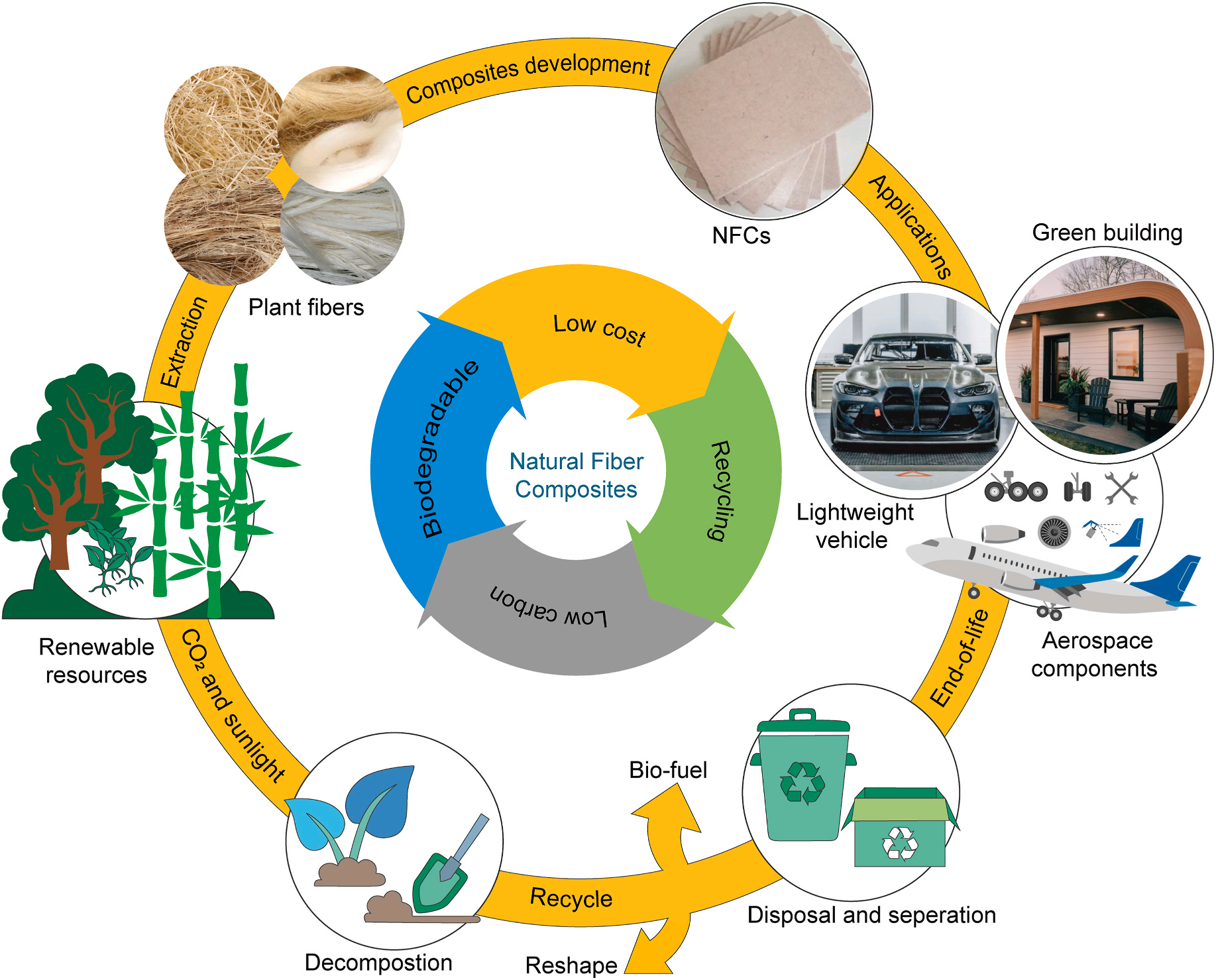

Natural fiber composites (NFCs) represent a significant advancement in sustainable material development. These composites utilize fibers derived from renewable sources, such as wood, bamboo, and other plant materials, offering an eco-friendly alternative to traditional synthetic fiber composites like those made from glass or carbon fibers. The environmental benefits of NFCs include reduced carbon footprint, lower energy consumption during production, and biodegradability, making them vital for sustainable development. Economically, NFCs are advantageous due to the abundance and low cost of natural fibers, which can significantly reduce material costs in various industries. Unlike synthetic composites, NFCs contribute to a circular economy by being recyclable and having minimal environmental impact.

Figure 1: the life cycle of natural fiber composites (NFCs) [Ref]

2. Hierarchical Structure of Natural Fibers

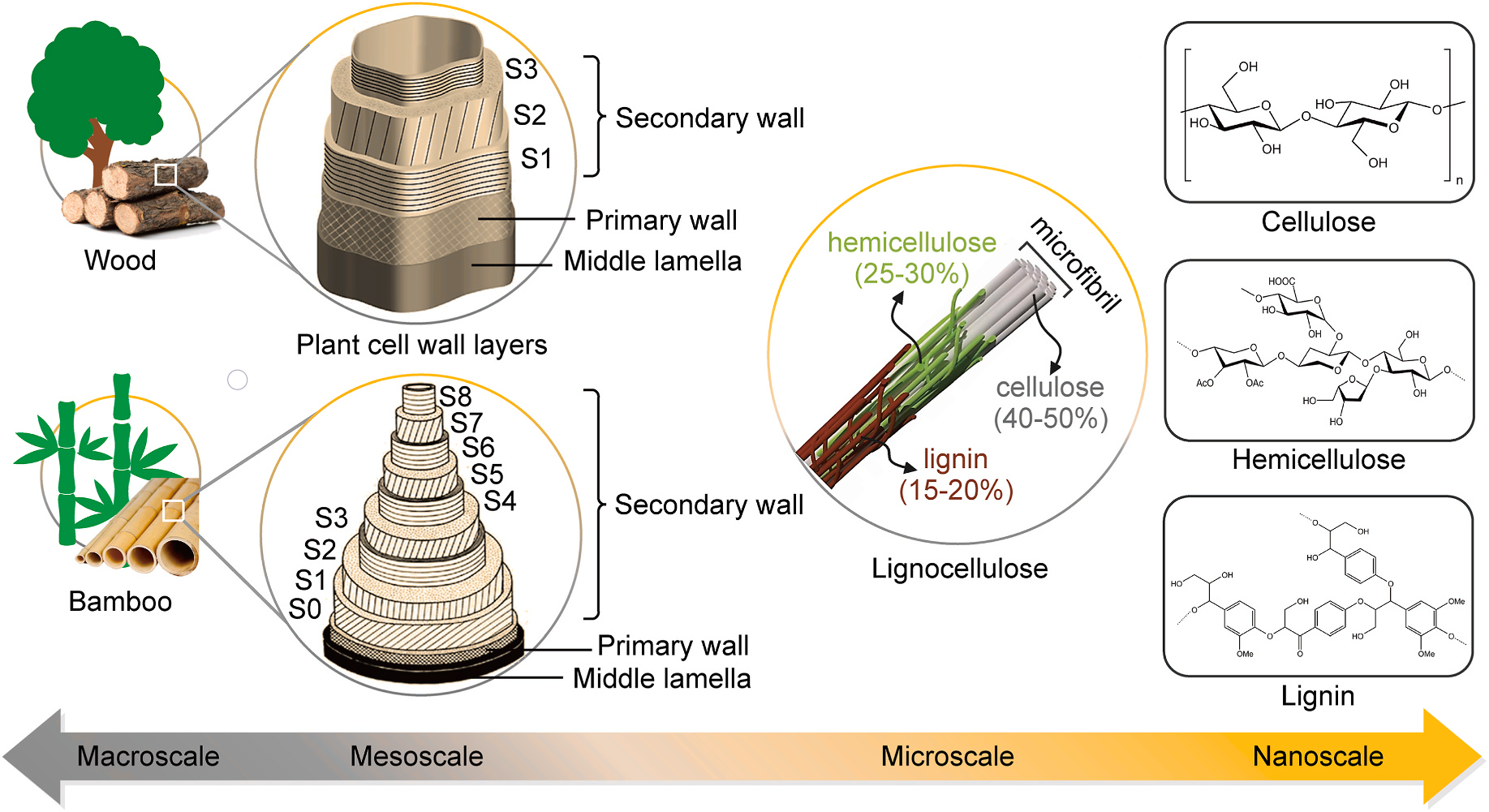

Natural fibers, particularly wood and bamboo, exhibit a complex hierarchical structure that directly influences their mechanical properties. These fibers consist of multiple layers, with cellulose, hemicellulose, and lignin as the primary components. The secondary cell wall, especially in bamboo, features several layers with varying microfibril angles, which contribute to the fiber’s strength and flexibility. The crystalline cellulose provides high tensile strength, while the amorphous regions offer flexibility. Thermal stability in natural fibers is closely tied to their nanostructure; cellulose and hemicellulose degrade at different temperatures, impacting the overall stability of the composite material.

3. Challenges in Natural Fiber Composite Materials

Natural Fiber Composite Materials face several challenges, primarily related to the compatibility between hydrophilic natural fibers and hydrophobic polymer matrices. This incompatibility often results in weak interfacial bonding, which can limit the mechanical performance of the composites. Additionally, the variability in natural fiber properties, influenced by factors such as growth conditions and plant species, presents challenges in achieving consistent composite quality. Strategies to address these issues include surface treatments of fibers, chemical modifications, and the use of coupling agents to enhance fiber-matrix adhesion and improve the overall performance of NFCs.

4. Molecular Dynamics (MD) Simulations in NFCs

Molecular dynamics (MD) simulations offer valuable insights into the behavior of natural fiber composites at the molecular level. These simulations allow researchers to study the interactions between fibers and matrices, providing detailed information on mechanical properties, thermal stability, and interfacial interactions. For instance, MD simulations can reveal the bonding mechanisms within the composite, such as hydrogen bonding and van der Waals forces, which are crucial for enhancing fiber-matrix compatibility. By simulating various environmental conditions, MD simulations help in optimizing the design and processing of NFCs, contributing to the development of more durable and high-performance materials.

5. Nanoscale Modifications of Natural Fibers

Nanoscale modifications of natural fibers involve techniques such as surface treatment, incorporation of nanoparticles, and altering the nanostructure of cellulose. These modifications can significantly enhance the performance of NFCs by improving mechanical properties, thermal stability, and moisture resistance. For example, the addition of nanoparticles like titanium dioxide (TiO2) or zinc oxide (ZnO) can improve the thermal stability and UV resistance of the composites. Moreover, functionalized properties such as antimicrobial resistance or electromagnetic shielding can be achieved, broadening the application scope of NFCs.

Figure 2: Bamboo and Wood Structures from Macro to Nano [Ref]

6. Improving Fiber-Matrix Compatibility

To enhance the compatibility between natural fibers and polymer matrices, various chemical and physical treatments are employed. Chemical treatments, including alkali treatment, silane coupling, and grafting with maleic anhydride, modify the fiber surface to improve adhesion with the matrix. Physical treatments, such as plasma or corona discharge, increase surface roughness and energy, facilitating better bonding. Case studies have shown that these treatments can significantly enhance the mechanical properties of NFCs, making them more suitable for structural applications in industries like construction and automotive.

7. Applications of Natural Fiber Composites

Natural fiber composites are increasingly used in various industries due to their sustainability and performance characteristics. In construction, NFCs are employed in building materials such as panels, roofing, and cladding, where they offer benefits like lightweight and thermal insulation. In the automotive and aerospace sectors, NFCs are used in interior components, structural parts, and even in the development of lightweight electric vehicles. Beyond structural applications, NFCs are also explored for their functional roles, such as in energy-efficient buildings with transparent wood technology and in smart materials for environmental sensing.

8. Machine Learning in NFC Design

The integration of machine learning (ML) with molecular dynamics (MD) simulations is revolutionizing the design of natural fiber composites. ML algorithms can analyze vast amounts of data from MD simulations to predict material properties, optimize processing conditions, and even discover new composite formulations. This data-driven approach enables faster and more efficient development of NFCs with tailored properties. Future trends in AI-driven NFC design include the creation of more complex and multifunctional composites that can meet specific industry demands, such as higher strength, improved durability, and enhanced sustainability.

9. Case Studies and Practical Implementations

Several real-world examples highlight the successful implementation of natural fiber composites. In construction, projects like the BioHome3D—a 3D-printed house made from wood fiber composites—demonstrate the practical use of NFCs in sustainable building. The automotive industry also showcases the benefits of NFCs, with vehicles like the BMW M4 GT4 incorporating high-performance natural fiber components. These case studies underscore the versatility and effectiveness of NFCs in various applications, supporting industry standards and guidelines that promote the adoption of these eco-friendly materials.

10. Future Trends and Research Directions in NFCs

The future of natural fiber composites lies in advancing material modifications and expanding their applications across industries. Emerging technologies such as advanced nano-engineering, machine learning integration, and 3D printing are expected to drive innovations in NFCs. These advancements will likely lead to composites with superior mechanical properties, multifunctionality, and greater environmental sustainability. As industries continue to prioritize green materials, NFCs are poised to play a crucial role in achieving carbon neutrality and supporting sustainable development worldwide.

– Overview of NFCs and their role in sustainable development.

– Comparison between natural fiber composites and traditional synthetic fiber composites.

– Environmental and economic benefits of using natural fibers.

– Detailed exploration of the structure of natural fibers, focusing on wood and bamboo.

– Relationship between fiber structure and mechanical properties.

– Thermal stability and its dependence on the fiber’s nanostructure.

– Compatibility issues between natural fibers and the polymer matrix.

– Factors limiting the performance and development of NFCs.

– Strategies for addressing these challenges.

– Introduction to molecular dynamics simulations.

– Application of MD simulations in studying NFCs.

– Insights provided by MD simulations on mechanical properties, thermal stability, and interfacial interactions.

– Techniques for modifying natural fibers at the nanoscale.

– Impact of nanoscale modifications on the performance of NFCs.

– Functionalized properties resulting from these modifications.

– Chemical and physical treatments to enhance fiber-matrix bonding.

– Surface modification techniques for natural fibers.

– Case studies showcasing improved NFC performance through enhanced compatibility.

– Use of NFCs in construction materials.

– Applications in the automotive and aerospace industries.

– Functional roles of NFCs beyond structural applications.

– Integration of machine learning with MD simulations.

– Data-driven approaches to optimize the design of NFCs.

– Future trends in using AI to enhance NFC performance.

– Real-world examples of NFC applications.

– Hands-on projects involving the design and analysis of NFCs.

– Exploration of industry standards and guidelines for NFC use.

– Emerging technologies in natural fiber modification and composite design.

– Potential advancements in NFC applications.

– Sustainability and the future of natural fiber composites in various industries.

Our team of CAE Assistant instructors, renowned experts in their respective domains, will deliver each section of the course, providing you with unparalleled knowledge and insights.

Currently, the course instructor is being finalized, but we are committed to bringing you one of the leading experts in the field. We’re working diligently to ensure that a top researcher will be selected to develop and deliver this course soon.

Our courses are designed for a diverse audience that includes graduate and PhD students, R&D professionals in industry, and university faculty members. Each course is meticulously crafted based on the latest ISI papers and cutting-edge research to ensure that participants receive the most current and relevant knowledge in emerging technology topics.

Graduate and PhD Students: These courses provide advanced insights and practical applications of recent research, equipping students with the latest knowledge and methodologies to enhance their academic work and research capabilities.

R&D Employees: For professionals working in industrial research and development, our courses offer valuable updates on new trends and technologies, fostering innovation and enhancing their ability to address complex challenges in their projects.

University Faculty Members: Academics seeking to stay abreast of the latest developments will benefit from our courses by gaining access to cutting-edge research and emerging technologies, which can be integrated into their teaching and research activities.

By participating in our courses, all these groups will gain a competitive edge through up-to-date knowledge, practical skills, and insights directly derived from the forefront of scientific and technological advancements.

Finite Element Analysis course Certificate

Upon successful completion of this course, you will receive a course completion certificate. This certificate guarantees your skills with the amount of time spent, skills trained, and can be verified online.

Taking this course on “Advanced Materials Engineering: Design, Simulation, and Applications of Natural Fiber Composites” opens up several specialized job opportunities, including:

- Materials Engineer/Scientist: Focus on the development and testing of sustainable natural fiber composites for various industries, including construction, automotive, and aerospace.

- R&D Engineer: Work in research and development to innovate and improve natural fiber composites, addressing challenges like fiber-matrix compatibility and enhancing material properties.

- Simulation and Modeling Engineer: Utilize molecular dynamics simulations and machine learning to predict and optimize the performance of natural fiber composites in real-world applications.

- Sustainability Consultant: Advise companies on integrating natural fiber composites into their products and processes, emphasizing eco-friendly and sustainable practices.

- Product Development Engineer: Design and develop new products using natural fiber composites, focusing on applications that benefit from their lightweight, sustainable properties.

First Session for Free!