Glass Fracture Analysis + Post Fracture + Abaqus Glass Fracture Simulation

Glass is a widely used material in construction and engineering due to its transparency and strength. However, its brittle nature makes it prone to fractures, necessitating a thorough analysis of its behavior post-breakage. Professor Chiara Bedon, a leading researcher in this field, has made significant contributions to understanding glass fracture analysis. This article delves into key theoretical and simulation-based insights into glass post-fracture behavior, focusing on structural integrity and safety.

Understanding glass fracture mechanics is essential for designing safer buildings, vehicles, and industrial applications. When glass breaks, it exhibits different fracture patterns depending on factors such as impact force, temperature fluctuations, and structural constraints. By studying these aspects, engineers can develop solutions to improve post-fracture performance and enhance structural resilience.

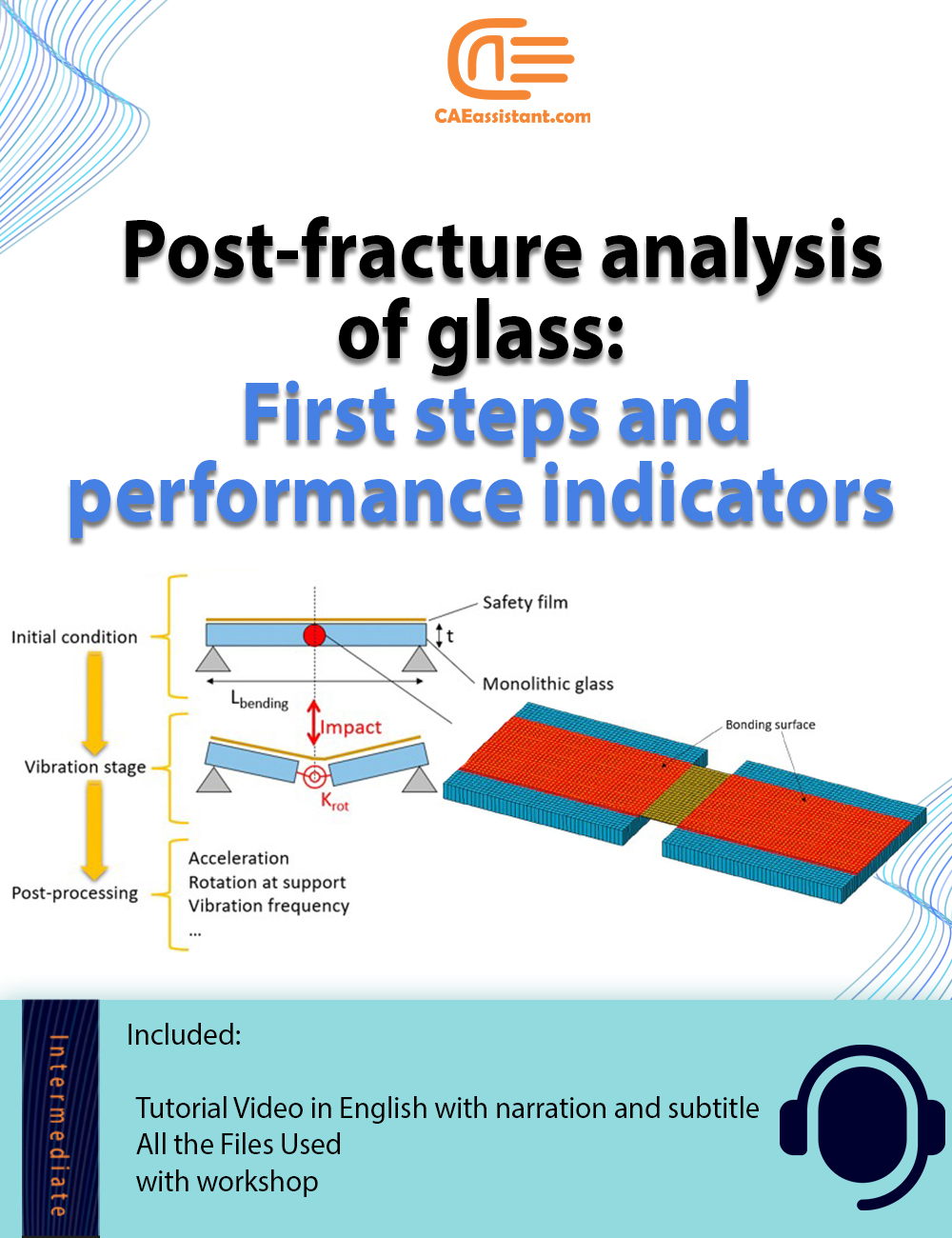

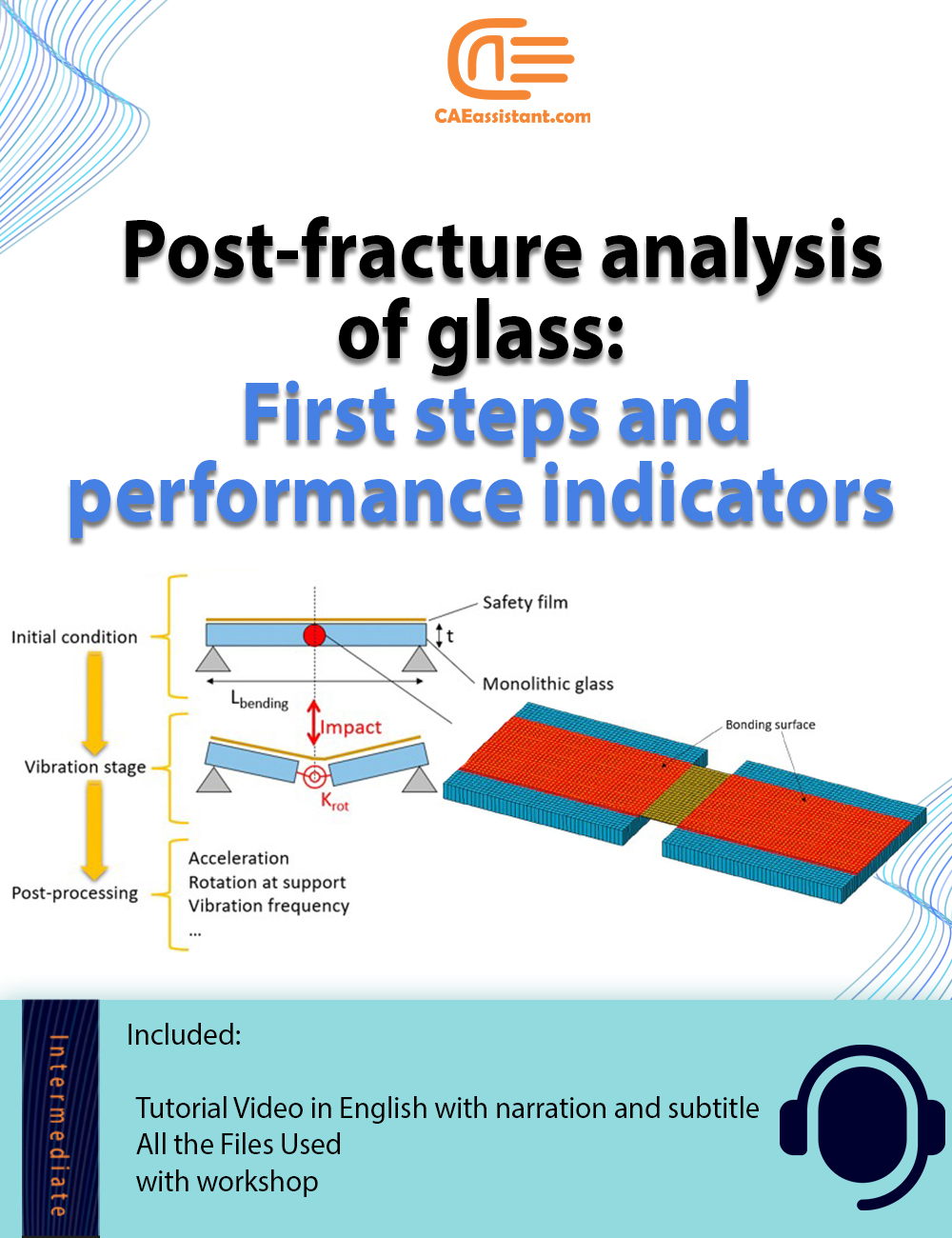

Working with glass structures and safety retrofits? Dive into this advanced Abaqus tutorial on glass fracture and post-fracture analysis, perfect for engineers tackling real-world structural glass behavior under impact and temperature variations. This package guides you through simulating cracked glass members retrofitted with safety films, focusing on vibration response and residual strength evaluation. With practical modeling techniques, dynamic identification concepts, and performance assessment, it’s a must-have for those working with glass retrofit technologies. Ready to explore? Discover the full package here:

|

1. The Fundamentals: What Are the Basics of Glass Fracture Mechanics & Glass Fracture Analysis?

- Overview of Glass Fracture Mechanics

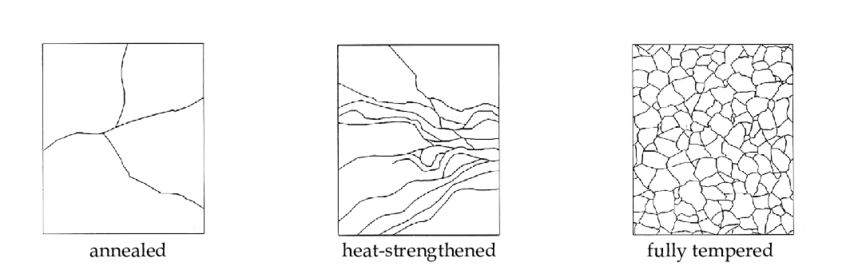

Understanding glass fracture mechanics requires a detailed analysis of stress distribution, fracture patterns, and the material’s behavior under different loading conditions. Glass fractures in unique patterns due to its brittle failure mode, which can be influenced by factors such as impact force, temperature variations, and structural constraints. The study of these factors is crucial in predicting and mitigating failures in engineering applications.

Figure 1: types of glass fracture patterns

- The Role of Stress Distribution and Pre-Existing Flaws

Stress distribution in glass plays a crucial role in determining its fracture behavior. When subjected to external forces, glass experiences tensile and compressive stresses. The weakest points, often originating from micro-cracks or imperfections, dictate where and how fractures initiate. Research indicates that pre-existing flaws significantly affect the failure mechanism, necessitating advanced modeling techniques to predict fracture propagation accurately.

- Effects of Static vs. Dynamic Loading Conditions

Glass behaves differently under static and dynamic loading conditions. Under slow loading rates, cracks propagate gradually, allowing some time for stress redistribution. However, under high-speed impacts, fractures spread rapidly, leading to catastrophic failure. Engineers use numerical simulations in software like Abaqus to analyze these behaviors and design glass structures that can withstand various loading scenarios.

2. Evaluating Post-Fracture Performance: How Can Cracked Glass Still Carry a Load?

Post-fracture stiffness refers to the ability of a cracked glass structure to retain its mechanical integrity. Residual capacity assessment evaluates how much load a fractured glass component can still bear before complete failure. Various experimental and numerical methods, including finite element analysis (FEA), are employed to assess these parameters, providing valuable insights into structural resilience.

Post-fracture glass elements may still provide some load-bearing capacity due to interlocking shards and bonding layers, such as polymer films. Researchers assess this residual capacity through laboratory experiments and computational models, simulating real-world conditions. For example, studies have shown that laminated glass can retain significant structural performance even after initial fracture due to the adhesive properties of interlayers.

The effectiveness of safety films in improving post-fracture performance is another crucial aspect of the study. These films hold shattered glass pieces together, preventing dangerous shards from causing injuries. Their mechanical properties, such as adhesion strength and elasticity, play a pivotal role in maintaining residual capacity.

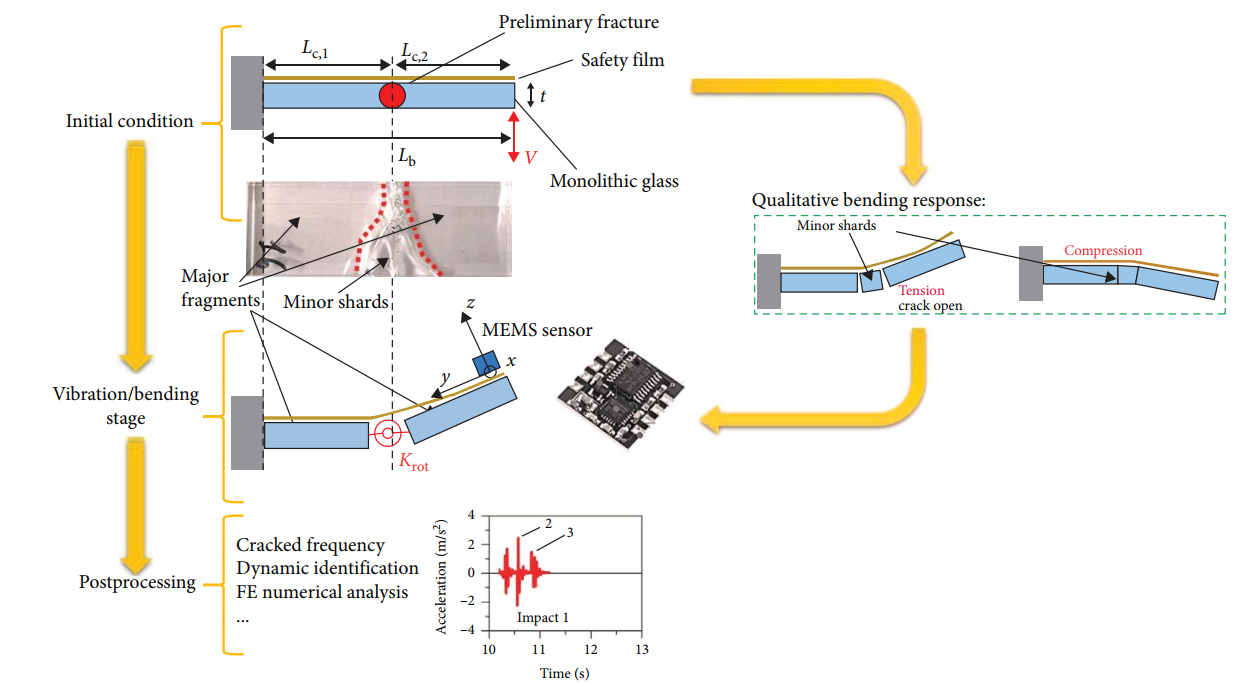

Experimental investigations also involve repeated impact testing to simulate real-world scenarios, such as accidental collisions or extreme weather conditions. By analyzing vibration frequency changes in cracked glass, researchers can quantify damage progression and develop strategies to enhance durability.

So, let’s wrap it up. Even after fracturing, glass—especially laminated types—can retain a degree of load-bearing capacity. This section explains how interlocking shards and bonding layers (like polymer interlayers or safety films) help maintain structural integrity. Underlying this resilience are several key assessment techniques:

2.1. Cracked Vibration Frequency Analysis: Revealing Hidden Damage

One of the most effective ways to assess the severity of glass damage is through vibration frequency analysis. When glass fractures, its structural integrity diminishes, altering its natural vibration frequency. By analyzing these changes, engineers can determine the extent of damage and predict failure risks.

Experimental studies utilize accelerometers to measure vibration responses in cracked glass. These responses are compared against control samples to quantify frequency shifts. Researchers use operational modal analysis techniques to evaluate how the cracked glass interacts with its surrounding environment.

Figure 2: Vibration frequency measurement setup for cracked glass

2.2. Simulation Insights: Using Abaqus to Model Fracture Behavior

Numerical modeling plays a critical role in glass fracture analysis. Using Abaqus, researchers can simulate fracture propagation, post-fracture stiffness, and dynamic response. The simulation process involves:

- Defining Material Properties: Setting the mechanical properties of glass and any bonded materials, such as safety films.

- Applying Boundary Conditions: Establishing constraints and force applications to replicate real-world conditions.

- Running Simulations: Observing stress distribution and fracture behavior through finite element analysis.

Abaqus allows researchers to refine models based on experimental data, making it possible to predict how glass will behave under various conditions. By integrating material degradation models, engineers can account for progressive failure and residual capacity.

Figure 3: 3 modes of frequency

You can learn how to do this modal analysis in our glass post fracture tutorial.

3. How External Factors Influence Residual Strength

Repeated impacts can accelerate crack growth, while thermal gradients—caused by sudden heating or cooling—can further concentrate stress at crack tips. Experimental setups and simulation studies in this area help determine how these external factors reduce residual capacity, guiding the development of reinforcement strategies like safety films and support frames.

3.1. Dynamic Impact Analysis and Structural Safety

Repeated impacts significantly degrade the mechanical integrity of fractured glass. Research shows that even minor collisions can accelerate crack propagation, reducing a structure’s ability to withstand external forces. Engineers use impact simulations to evaluate how glass responds to various stressors over time.

Dynamic impact analysis involves subjecting glass to controlled impact forces and recording its response. This helps determine whether additional reinforcement, such as polymer interlayers or support frames, is necessary.

Structural safety is a key concern in glass applications, especially in high-rise buildings, automotive windshields, and protective barriers. Implementing findings from cracked vibration frequency analysis and simulation studies enables engineers to design safer glass structures that account for potential fractures.

Figure 4: impact on glass

Learn the impact analysis above from the very beginning and also get the verified files through our glass fracture tutorial.

3.2. Thermal Gradient Effects on Glass Fracture

Temperature fluctuations significantly impact the behavior of fractured glass. Sudden heating or cooling can cause stress concentration at crack tips, leading to accelerated failure. Researchers use thermal analysis simulations to study the interaction between temperature changes and fracture propagation.

Laboratory experiments have shown that glass exposed to extreme thermal gradients exhibits increased crack growth rates. Understanding these effects is essential for applications where temperature variations are common, such as in facades, automotive windows, and aerospace structures.

4. Practical Applications and Future Research Directions

The insights gained from glass fracture analysis have broad applications:

- Structural glass safety: Developing shatter-resistant windows and load-bearing glass elements.

- Forensic engineering: Investigating causes of failure in cracked glass structures.

- Materials science: Advancing polymer films and interlayers for improved performance.

Future research aims to enhance fracture simulation accuracy, integrate AI-driven predictive models, and explore novel glass compositions for superior post-fracture performance.

Working with glass structures and safety retrofits? Dive into this advanced Abaqus tutorial on glass fracture and post-fracture analysis, perfect for engineers tackling real-world structural glass behavior under impact and temperature variations. This package guides you through simulating cracked glass members retrofitted with safety films, focusing on vibration response and residual strength evaluation. With practical modeling techniques, dynamic identification concepts, and performance assessment, it’s a must-have for those working with glass retrofit technologies. Ready to explore? Discover the full package here:

|