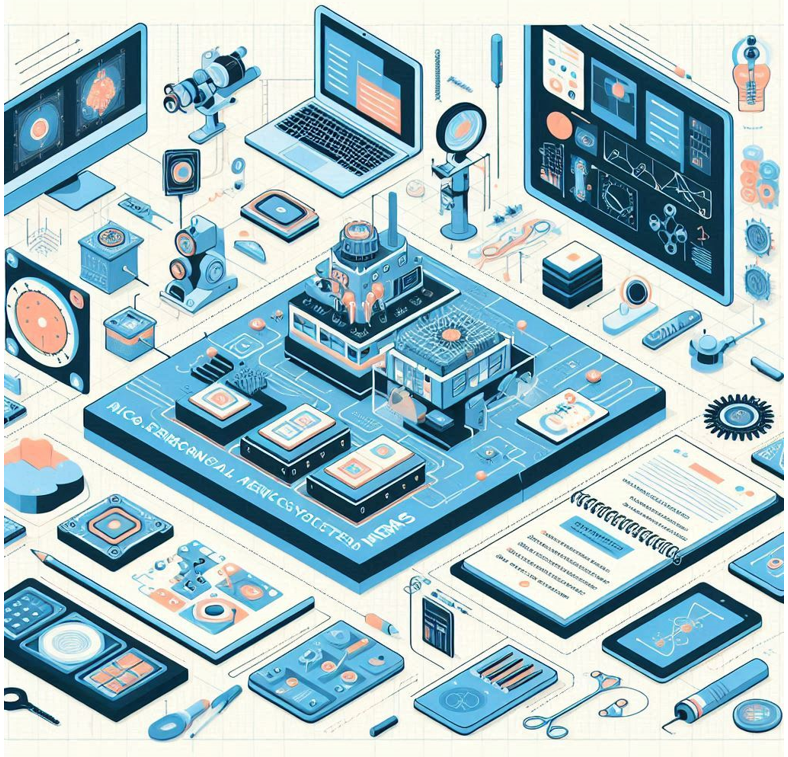

MicroElectromechanical Systems (MEMS) Course

Microelectromechanical Systems (MEMS) Course Overview

This course on MicroElectromechanical Systems (MEMS) offers an in-depth exploration of the fundamental principles, design, fabrication, and applications of MEMS technologies. Participants will gain insights into the rapidly growing field of MEMS, which is at the heart of modern sensors, actuators, and micro-scale devices used in industries such as automotive, biomedical, aerospace, and telecommunications. Through theoretical understanding and practical experience, students will explore MEMS manufacturing techniques, design challenges, and cutting-edge innovations in microfabrication.

Microelectromechanical Systems (MEMS) Course Objectives

- Understand the basic concepts and operating principles of MEMS devices.

- Familiarize participants with MEMS design tools and modeling techniques.

- Provide hands-on experience in MEMS fabrication processes.

- Explore the role of MEMS in modern sensors, actuators, and systems.

- Delve into applications of MEMS in various fields such as biomedical engineering, robotics, and telecommunications.

Learning Outcomes

By the end of the Microelectromechanical Systems (MEMS) course, participants will:

- Understand the core principles and manufacturing processes behind MEMS.

- Be able to design and simulate MEMS devices using advanced software tools.

- Gain hands-on experience in modeling and analyzing MEMS-based sensors and actuators.

- Explore the wide range of MEMS applications in industries such as healthcare, automotive, and telecommunications.

- Be familiar with the current trends and future directions of MEMS technology, including nanotechnology integration.

Microelectromechanical Systems (MEMS) Course Conclusion

This comprehensive course on MicroElectromechanical Systems (MEMS) offers participants a robust learning experience, blending theory with practical applications. From designing and fabricating MEMS devices to exploring their use in sensors and actuators, this course equips participants with the skills to excel in the MEMS field and adapt to future trends.

- Concepts Covered: History and evolution of MEMS; overview of micro-scale devices; key applications in different industries.

- Practical Application: Basic design and function of MEMS sensors and actuators.

- Key Topics:

- Evolution and history of MEMS technology

- Key components and basic operating principles of MEMS devices

- Introduction to micro-scale devices and systems

- Overview of MEMS applications in automotive, biomedical, and aerospace industries

- Concepts Covered: Overview of MEMS materials (silicon, polymers, metals); material properties affecting device performance (mechanical, electrical, thermal).

- Practical Application: Understanding material selection for MEMS applications and their influence on device performance.

- Key Topics:

- Materials used in MEMS fabrication (silicon, metals, polymers)

- Mechanical, electrical, and thermal properties relevant to MEMS

- Material selection for performance optimization in MEMS

- MEMS material processing and testing

- Concepts Covered: Microfabrication techniques, including photolithography, etching, and deposition processes; challenges in scaling down to micro levels.

- Practical Application: Hands-on experience in modeling MEMS fabrication steps using design software.

- Key Topics:

- Introduction to microfabrication: photolithography, etching, deposition

- Top-down vs. bottom-up fabrication techniques

- Overview of cleanroom protocols and equipment for MEMS fabrication

- Challenges in miniaturizing devices for MEMS

- Concepts Covered: Introduction to MEMS design tools (e.g., COMSOL, Coventor); principles of design for micro-scale devices, including mechanical and electrical simulations.

- Practical Application: Simulating a MEMS accelerometer or pressure sensor using modeling tools.

- Key Topics:

- Overview of different MEMS sensors (pressure, accelerometers, gyroscopes)

- Design challenges for MEMS sensors: sensitivity, accuracy, and reliability

- Introduction to design and simulation software for MEMS (COMSOL, Coventor)

- Finite element modeling (FEM) for MEMS devices

- Simulation of MEMS mechanical behavior under different loads and conditions

- Integration of design and simulation into MEMS manufacturing processes

- Concepts Covered: Types of MEMS sensors (pressure, inertial, chemical); principles behind MEMS actuators (thermal, piezoelectric, electrostatic).

- Practical Application: Designing and analyzing MEMS sensors for automotive and biomedical applications.

- Key Topics:

- Different types of MEMS actuators (electrostatic, piezoelectric, thermal)

- Mechanisms of MEMS actuation

- Design principles and applications of MEMS actuators in robotics and automotive

- Real-world examples of MEMS actuators in microfluidics and biomedical devices

- Concepts Covered: MEMS packaging challenges; reliability testing; mechanical, environmental, and electrical testing for MEMS components.

- Practical Application: Developing packaging strategies for MEMS sensors with a focus on maintaining performance and durability.

- Key Topics:

- Packaging challenges specific to MEMS (environmental, mechanical, and thermal stresses)

- MEMS device encapsulation and packaging solutions

- Testing methodologies: electrical, mechanical, thermal, and environmental stress tests

- Reliability and failure analysis of MEMS devices

- Concepts Covered: Role of MEMS in medical devices, such as microfluidic systems, biosensors, and drug delivery systems.

- Practical Application: Case study on MEMS-enabled biomedical devices (e.g., insulin pumps, implantable sensors).

- Key Topics:

- MEMS devices in healthcare: biosensors, microfluidics, and drug delivery systems

- Design principles of MEMS devices for biomedical applications

- Integration of MEMS with diagnostic and therapeutic systems

- Case studies of MEMS in implantable devices (e.g., glucose sensors, micro-pumps)

- Concepts Covered: Innovations in MEMS technology; integration of MEMS with nanotechnology; future trends in microscale devices and applications.

- Practical Application: Exploring the interface between MEMS and nanotechnology through emerging applications such as nanorobotics.

- Key Topics:

- Integration of MEMS with nanotechnology: nano-electromechanical systems (NEMS)

- Future trends in MEMS: digital twins, AI integration, and advanced materials

- Commercial and research frontiers in MEMS technology

- Emerging applications in quantum computing, autonomous systems, and robotics.

Our team of CAE Assistant instructors, renowned experts in their respective domains, will deliver each section of the course, providing you with unparalleled knowledge and insights.

Currently, the course instructor is being finalized, but we are committed to bringing you one of the leading experts in the field. We’re working diligently to ensure that a top researcher will be selected to develop and deliver this course soon.

Our courses are designed for a diverse audience that includes graduate and PhD students, R&D professionals in industry, and university faculty members. Each course is meticulously crafted based on the latest ISI papers and cutting-edge research to ensure that participants receive the most current and relevant knowledge in emerging technology topics.

Graduate and PhD Students: These courses provide advanced insights and practical applications of recent research, equipping students with the latest knowledge and methodologies to enhance their academic work and research capabilities.

R&D Employees: For professionals working in industrial research and development, our courses offer valuable updates on new trends and technologies, fostering innovation and enhancing their ability to address complex challenges in their projects.

University Faculty Members: Academics seeking to stay abreast of the latest developments will benefit from our courses by gaining access to cutting-edge research and emerging technologies, which can be integrated into their teaching and research activities.

By participating in our courses, all these groups will gain a competitive edge through up-to-date knowledge, practical skills, and insights directly derived from the forefront of scientific and technological advancements.

Finite Element Analysis course Certificate

Upon successful completion of this course, you will receive a course completion certificate. This certificate guarantees your skills with the amount of time spent, skills trained, and can be verified online.

This course is designed for:

- Engineers and professionals in mechanical, electrical, and biomedical fields looking to expand their knowledge in MEMS.

- Researchers and academics exploring MEMS technologies for advanced applications.

- Graduates interested in microfabrication, sensing technologies, and the application of MEMS in industry.

- Professionals working in industries such as healthcare, automotive, aerospace, and telecommunications, where MEMS are rapidly evolving.

First Session for Free!