🔥🌡️An overview – Heat Transfer and Thermal Stress Analysis with Abaqus

Heat transfer is a fundamental concept that plays a crucial role in various engineering and scientific applications. It refers to the process by which thermal energy moves from one object or material to another due to a temperature difference. Whether it’s the warmth from a radiator heating a room or the cooling system in your computer preventing overheating, understanding how heat transfer works is essential in designing efficient systems.

1. Introduction to Heat Transfer Phenomena

Heat transfer refers to the movement of thermal energy (heat) between objects or systems that have different temperatures. The study of heat transfer includes a wide range of topics such as the generation, conversion, and exchange of thermal energy among physical systems.

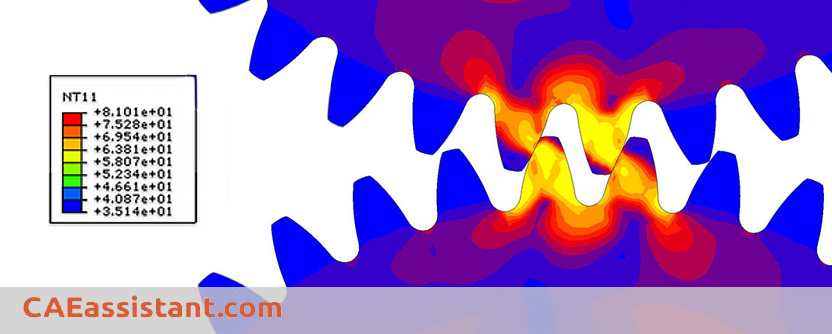

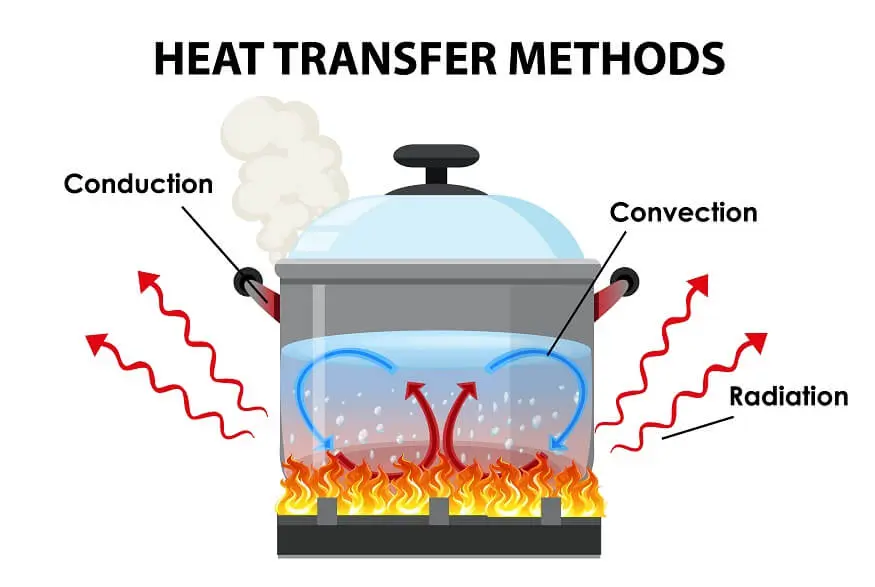

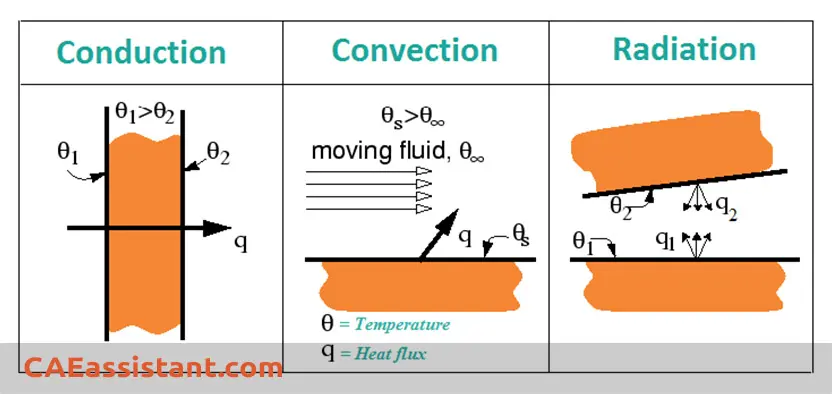

The heat transfer can be categorized into various mechanisms as shown in Figure 1. In the following, we will discuss them in detail.

Figure 1- Various mechanisms of heat transfer [1]

1.1. Exploring the Three Main Types of Heat Transfer

Heat typically moves from one location to another through three methods as outlined below.

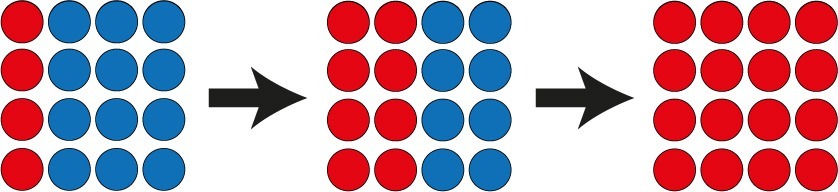

Hotter molecules vibrate at a faster rate, thus transferring energy to cooler molecules. Conduction involves the direct transfer of heat energy between molecules that are in contact with each other. The process continues until both sides of the object(s) reach the same temperature. You can see the process of heat conduction among molecules in Figure 2.

Figure 2- The process of conduction among molecules [2]

Metals show high heat conductivity. So, ironing clothes is a classic example of conduction, where heat flows directly from the iron to the clothes. Another instance is when the heat from your hands transfers to an ice cube upon contact, causing it to melt.

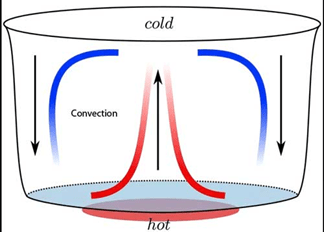

When a fluid warms up, it expands and becomes less dense. This creates a convective current, where the hot fluid rises and cooler fluid takes its place. This cycle of movement transfers heat throughout the fluid, as shown in Figure 3. In the convection process, heat energy can be transferred by the movement of liquids or gases.

Figure 3- Convection: The process of heat transfer throughout the fluid

Warm-blooded animals rely on convection currents within their blood to regulate body temperature. In their body, warmer blood rises towards the surface, releasing heat. At the same time, cooler blood sinks to be reheated. The cycle ensures maintaining a stable body temperature.

The radiation process involves the transfer of heat energy via electromagnetic waves. This is invisible to the naked eye but can be felt as heat. The hotter the object, the more radiation it releases.

Figure 4- Heat radiation from a fire

Heat transfer through radiation occurs every day in our lives, in the form of the warmth we feel from the sun. As shown in Figure 4, the heat you sense from a fire is another sign of the heat radiation experienced by everyone.

1.2. Factors Influencing Heat Transfer

The rate at which heat transfers, depends on different parameters. Understanding these factors enables us to manage heat transfer in diverse applications. We have discussed these factors here.

- Temperature difference: It is a crucial factor among the parameters affecting heat transfer. A greater difference between objects’ temperatures leads to a faster flow of heat.

- Thermal conductivity: The thermal conductivity of a material greatly affects the heat transfer process. For example, metals, known for their dense molecular structure, show rapid heat movement. In contrast, wood and plastic exhibit lower heat conductivity.

- The surface area: The extent of the exposed surface area influences the rate of heat transfer. Larger surfaces enable more efficient heat exchange.

- Objects distance: The distance between objects affects heat transfer by radiation. The closer the objects, the more easily heat radiates from one to the other.

2. Practical Applications of Heat Transfer Analysis

Heat transfer is a fundamental concept applied in different applications. This analysis involves identifying specific regions within objects that may become very hot and addressing barriers to heat transfer within systems. It enables us to prevent catastrophic events and ensures the safety of individuals and the environment.

2.1. Heat Transfer in Manufacturing Processes

Heat transfer analysis is very useful for engineers in different fields. For example, it helps them forecast how a hot liquid metal (Figure 5) behaves when it turns into a solid in the production process. This enables engineers to identify and address potential issues such as shrinkage, porosity, and residual stresses. This results in improved casting quality, refined surface finishing, and ultimately, more efficient and cost-effective manufacturing processes.

Figure 5: A hot liquid metal undergoing the production process [3]

2.2. Heat Transfer Applications in the Welding Industry

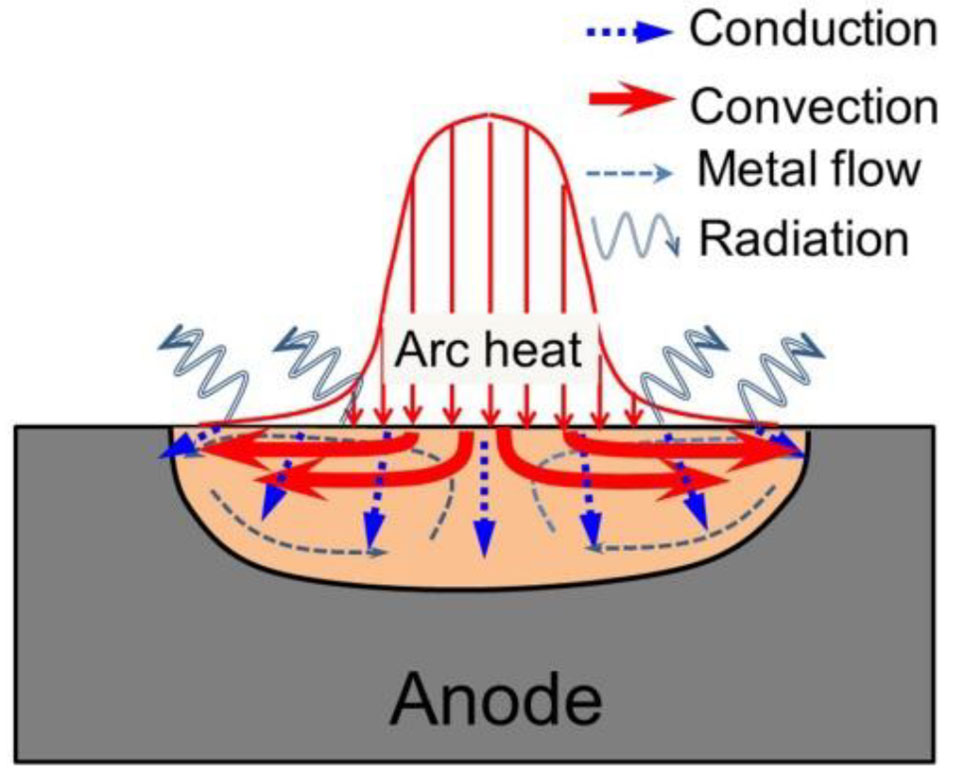

In the realm of welding, the role of heat transfer analysis extends beyond a simple simulation. As you can see in Figure 6, all three types of heat transfer—conduction, convection, and radiation—are present in the welding process.

Figure 6: Heat transfer mechanisms in the welding process [4]

By accurately predicting the thermal fields and residual stresses within the welded structures, engineers can optimize welding and minimize the residual stress. This leads to safer and more efficient applications across diverse industries.

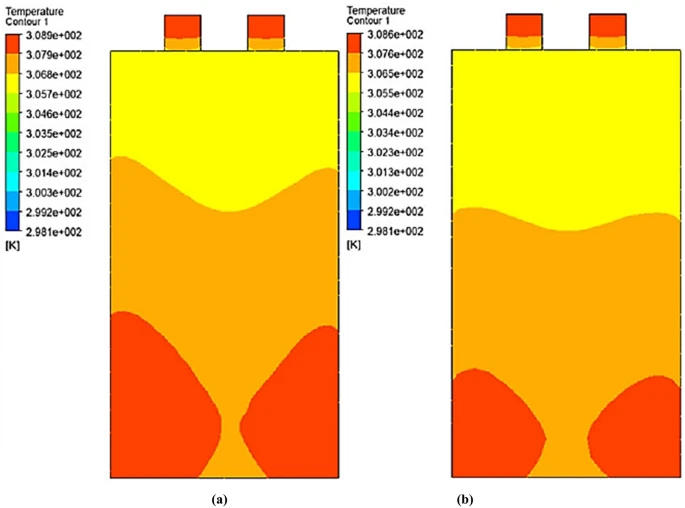

2.3. The Role of Heat Transfer in Battery Design

Beyond casting and welding, the application of heat transfer analysis extends to the realm of batteries. Figure 7 shows the role of heat transfer analysis in optimizing the battery temperature.

Figure 7: The role of heat transfer analysis in optimizing the battery temperature [5]; a) before optimization; b) after optimization

By accurately modeling the heat generation of a battery cell, engineers can prevent hazardous thermal overheating situations. This extends the battery lifespan and ensures the safety and reliability of batteries across various applications.

2.4. Utilizing Heat Transfer Analysis in Electric Part Design

In today’s increasingly compact and powerful electronics, efficient heat management is essential to ensure long-term performance and reliability. This is where heat transfer analysis stands out. To better understand the significance of the issue, Figure 8 displays an electrical chip fired, probably due to a poor heat transfer design.

Figure 8: An electrical chip on fire [6]

The analysis of heat transfer in electronic devices ensures effective cooling and prevents overheating. This empowers engineers to design more compact and powerful electronics.

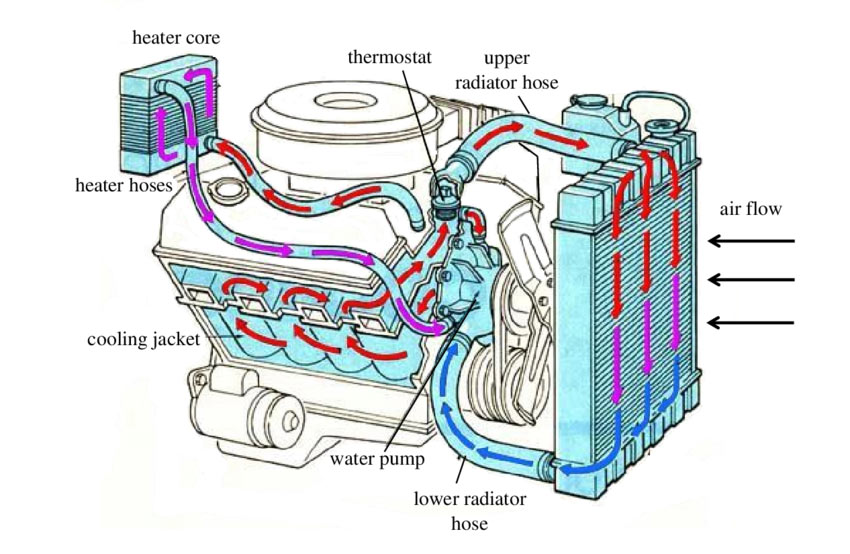

2.5. Heat Transfer Analysis in Engine Design

Heat transfer analysis evaluates the temperature of internal engine components, aiding engineers in optimizing their functionality. This optimization assists engineers in creating methods to maintain lower engine temperatures, improving fuel efficiency, and minimizing energy wastage.

Figure 9: Schematic diagram of a cooling system designed for a car [7]

A very common example illustrating the role of heat transfer analysis is the design of cooling systems in automobile engines. Such a system is depicted in Figure 9, where convection lowers engine temperature.

2.6. Heat Transfer Analysis of Chemical Reactions

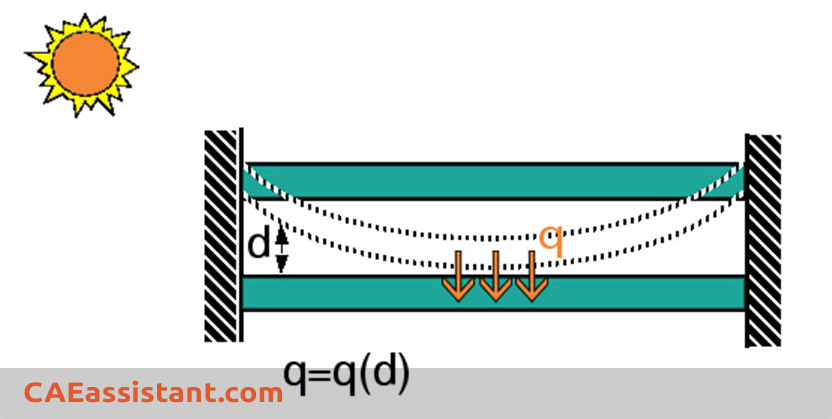

The heat transfer simulation assists scientists and engineers in understanding the mechanisms behind chemical reactions. This understanding holds significant importance for enhancing safety and efficiency across various industries, including materials, energy, and the environment. As a practical application, we can refer to the heat transfer analysis for optimizing the curing process of fiber-reinforced composites, as shown in Figure 10.

Figure 10: Schematic representation of a fiber-reinforced composite during curing [8]

Investigation of heat generation during chemical reactions aids in maintaining precise reaction temperatures and preventing undesired outcomes. This results in safer and more efficient production methods, enhancing the chemical industry, and ensuring a safer environment for all.

2.7. Heat Transfer in Medical and Biomedical Sciences

Heat transfer simulation supports not only physics or engineering but also biology and medicine. Its role in understanding heat mechanisms within our bodies is crucial for the development of novel medical treatments.

In tumor treatment, thermal analysis assists doctors in eliminating cancer cells while preserving healthy tissues. Additionally, it aids scientists in understanding the movement and functioning of drugs within our bodies. This has the potential to enhance the effectiveness of treatments for individuals.

3. Introduction to Heat Transfer Analysis

Do you confuse with the complexities of thermal stress analysis or heat transfer analysis? Do you want to conduct an Abaqus heat transfer analysis or an Abaqus thermal analysis? this article takes you on a journey through the fundamental nuances of transient and steady-state heat transfer, as well as linear and non-linear thermal scenarios, we demystify the complexities surrounding temperature variation and heat flux within systems. From uncoupled heat transfer analysis to fully coupled thermal stress simulations, Abaqus equips engineers and researchers with a versatile toolkit to tackle a multitude of challenges. Join us as we explore the dynamics of heat transfer thermal stress analysis with Abaqus.

To fully comprehend the explanation in this post, the CAE Assistant group has provided a Thermal heat transfer analysis tutorial that you can access through this link: “Thermal heat transfer analysis in Abaqus“.

Additionally, you can enroll in our Abaqus Course, which covers the fundamentals of Abaqus, subroutine writing, and Python scripting.

4. Transient and Steady-state Heat Transfer

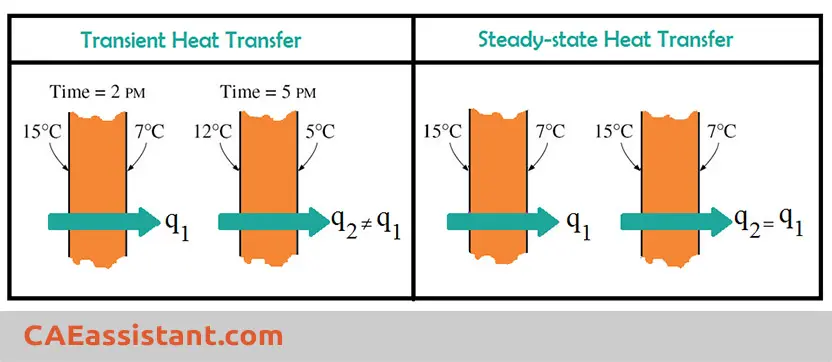

Heat transfer can be either transient or steady-state:

- Transient: Obtain the response over time with heat capacity effects included.

- Steady-state: Obtain long-term solution under a given set of loads and B.C.s

Figure 11: Transient and Steady-state heat transfer

The term steady implies no change with time at any point within the model, while transient means variation with time or time dependence. Therefore, the temperature or heat flux remains unchanged with time at any location, although both quantities may vary from one location to another.

| See the Advanced practical example of heat transfer analysis with HETVAL subroutine. Here are the examples of this package: |  |

5. Linear and Non-linear Heat Transfer

Heat transfer problems can be nonlinear because the material properties are temperature-dependent or because the boundary conditions are nonlinear.

Boundary conditions are very often nonlinear; for example, film coefficients can be functions of surface temperature. Radiation effects always make heat transfer problems nonlinear. Nonlinearities in radiation grow as temperatures increase (with power 4 of temperature).

Abaqus/Standard uses an iterative scheme to solve nonlinear heat transfer problems. The scheme uses the Newton method. To be familiar with more linear and non-linear concepts in the field of heat transfer analysis, you can check the Abaqus thermal stress package.

6. What is thermal stress analysis?

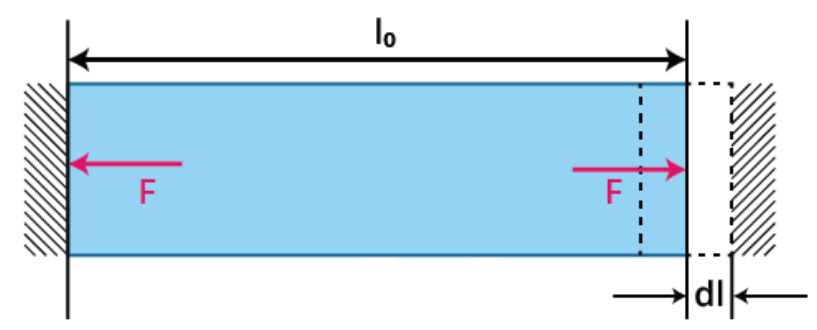

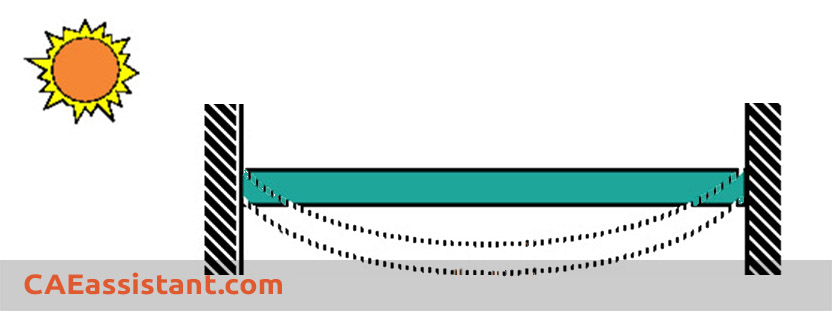

Thermal stress refers to the mechanical stress induced in a material or structure due to changes in temperature. Thermal stress arises when the material is constrained from freely expanding or contracting in response to temperature changes.

A prevalent instance of thermal stress involves the breakage of glass when subjected to elevated temperatures followed by rapid immersion in cold water. The resulting cracks and fractures in the glass differ from those caused by physical impact.

As depicted in figure below, when heat is applied or the temperature rises, the rod’s length increases by dl. Conversely, a reduction in heat will result in the opposite effect.

Figure 12: Thermal stress analysis

The thermal stress analysis enables us to anticipate the deformation and stress resulting from temperature variations, aiding in the identification of potential defects. Additionally, within the scope of thermal stress analysis, one can investigate the thermal deformation of an object during its thermal processing.

6.1. Applications of thermal stress analysis

The thermal stress analysis has many applications in different fields, such as manufacturing processes, aerospace, electronic devices, etc. Let’s see some of them:

Thermal stress analysis proves invaluable in manufacturing processes like welding, as it anticipates deformations such as bending, enabling precise predictions of thermal distortion caused by the heat generated during welding operations.

The practical application of thermal stress analysis extends to aerospace engineering, where it plays a vital role in predicting and managing deformations in aircraft components subjected to diverse thermal environments.

In electronic devices like smartphones and flat-screen TVs, thermal stress analysis ensures that temperature-induced deformations do not lead to internal disruptions, maintaining optimal picture quality even if the screen undergoes slight distortion.

6.2. Thermal stress formula

The expansion or contraction of a material is determined by its thermal expansion coefficient. When the material has the freedom to move, it can undergo these changes without generating stresses. However, if the material is affixed to a rigid body at multiple points, thermal stresses can arise in the geometrically constrained area.

You can calculate the thermal stress with the formula presented below:

Where E is the Young’s modulus, is thermal expansion coefficient,

is initial temperature and

is final temperature.

7. Types of Heat Transfer Problems in Abaqus

In general, Abaqus can solve the following types of heat transfer problems (For thermal and thermo-mechanical problems):

- Uncoupled heat transfer analysis

- Sequentially coupled thermal-stress analysis

- Fully coupled thermal-stress analysis

- Adiabatic analysis

We are going to briefly explain each type of Abaqus heat transfer. Let’s start with ‘Uncoupled Heat Transfer Analysis.’

7.1. Uncoupled Heat Transfer

In these analyses, the temperature field is calculated without consideration of the stress/deformation field in the bodies being studied. Pure heat transfer problems may involve conduction, forced convection, and boundary radiation, and can be transient or steady-state and linear or nonlinear. This analysis is just available in Abaqus/Standard.

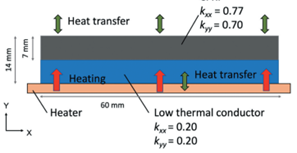

Figure 13: pure heat transfer

You can model solid body heat conduction with general, temperature-dependent conductivity, internal energy (including latent heat effects), and quite general convection and radiation boundary conditions. Forced convection of fluid through the mesh can be modeled by using forced convection/diffusion elements.

Moreover, you can get access to the simulation files and the tutorial video of uncoupled heat transfer analysis in Abaqus via this link.

7.1.1. Applications of uncoupled Abaqus heat transfer analysis

Uncoupled heat transfer analysis (Abaqus thermal analysis) is simpler and less computationally expensive than coupled heat transfer analysis, which models the interaction between heat transfer and structural deformation. However, uncoupled heat transfer analysis is still a powerful tool that can be used to solve a wide range of problems.

Here are some of the applications of uncoupled Abaqus heat transfer analysis:

- Analyzing the thermal performance of electronic components. This includes determining the maximum temperature of a component, identifying hot spots, and predicting the risk of thermal failure.

- Simulating the thermal behavior of aerospace structures. This includes predicting structural deformation due to thermal expansion, evaluating the fatigue life of components under varying thermal loads, and optimizing the design of cooling systems.

| You can find more info about what is fatigue and fatigue parameters and all info about it in this article “What is Fatigue Analysis?“ |

- Modeling the heat transfer in machinery applications. This includes analyzing the thermal stresses in bearings and rotors, optimizing the design of heat exchangers, and predicting the temperature distribution in a combustion engine.

- Simulating heat transfer in chemical processes. This includes analyzing the temperature distribution in reactors, distillation columns, and other chemical processes.

- Assessing thermal comfort and energy efficiency of buildings. This includes modeling the heat transfer through walls, roofs, and windows, and evaluating the effectiveness of HVAC systems.

7.2. Sequentially Coupled Thermal Stress Analysis | Abaqus thermal stress

When the stress/deformation field in a structure depends on the temperature field, but the temperature field can be found without knowledge of the stress response. It is usually performed by first conducting an uncoupled (pure) heat transfer analysis and then a stress/deformation analysis.

Figure 14: Thermal stress

The thermal field affects the mechanical field (for example, Thermal expansion), but the Mechanical field does not affect the thermal field. Besides, mechanical properties can change with temperature.

Two jobs are required to solve the thermal stress problem. Thermal and mechanical fields are solved in sequence (thermal followed by mechanical). The temperatures are read into the stress analysis as a predefined field by reading the output database or the results file from the corresponding heat transfer analysis; the temperature varies with position and is usually time-dependent. It is predefined because it is not changed by the stress analysis solution. However, we have options to apply temperature directly, read it from a file, or be prescribed in a user subroutine.

FIG= Predefined Field Window

7.2.1. Applications of Sequentially Coupled Abaqus Heat Transfer Analysis

Sequentially coupled Abaqus heat transfer analysis (Abaqus thermal analysis) is a type of analysis that models the interaction between heat transfer and structural deformation. This type of analysis is more complex and computationally expensive than uncoupled heat transfer analysis, but it is necessary for analyzing systems where thermal deformation is important.

Here are some of the applications of sequentially coupled Abaqus heat transfer analysis:

- Analyzing thermal stresses in structures. This includes predicting cracking and deformation in components due to thermal expansion and contraction.

- Simulating the thermal cycling of components. This includes predicting the fatigue life of components under repeated thermal loads.

- Optimizing the design of thermal structures. This includes finding the optimal geometry and material properties for a structure to minimize thermal stresses and maximize heat transfer efficiency.

7.2.2. Abaqus Thermal Stress Analysis: Performing Sequential Type

To perform a sequential heat transfer and thermal stress analysis with Abaqus/Explicit, first we run a heat transfer job in Abaqus/Standard. Then we define an Abaqus/Explicit job and Pass temperatures to the Abaqus/Explicit job via the output database or results file.

To fully understand the concepts we’ve discussed, complete the exercise on Abaqus thermal stress analysis related to sheet deformation caused by welding. In this exercise, you will examine the distortion of two steel sheets resulting from butt welding. Simply click on ‘Abaqus thermal stress PDF‘ to access it for free.

7.3. Fully Coupled Thermal Stress

A coupled temperature-displacement procedure (just one job) is used to solve simultaneously for the stress/displacement and the temperature fields. The thermal field affects the mechanical field as above, but here, the mechanical field also can affect the thermal field.

Figure 15: fully coupled thermal stress

This is used when the thermal and mechanical solutions affect each other strongly: Deformation can change conduction, radiation, etc. and when the heat is generated mechanically due to plastic work or friction. For example, in rapid metalworking problems, the inelastic deformation of the material causes heating, and in contact problems, the heat conducted across gaps may depend strongly on the gap clearance or pressure.

Both Abaqus/Standard and Abaqus/Explicit provide coupled temperature-displacement analysis procedures, but the algorithms used by each program differ considerably. In Abaqus/Standard, the heat transfer problems can be transient or steady-state and linear or nonlinear but Abaqus/Explicit can just model transient thermal (linear or nonlinear) response due to its inherent properties of an explicit integration method.

7.4. Adiabatic Analysis

In cases where mechanical deformation causes heating, but the event is so rapid that this heat has no time to diffuse through the material, we can use adiabatic analysis in Abaqus. This analysis is available in both Abaqus/Standard and Abaqus/Explicit.

An adiabatic analysis is typically used to simulate high-speed manufacturing processes involving large amounts of inelastic strain, where the heating of the material caused by its deformation is an important effect because of temperature-dependent material properties. The temperature increase is calculated directly at the material integration points according to the adiabatic thermal energy increases caused by inelastic deformation; temperature is not a degree of freedom in the problem. No allowance is made for the conduction of heat in an adiabatic analysis.

Note: you can claim the tutorial videos and simulation files of all 4 types of heat analysis in Abaqus (coupled, uncoupled, transient, steady-state) in this tutorial: “Thermal Heat Transfer in Abaqus“.

Now, you might be wondering, “How do we dive into the fascinating world of Abaqus Heat Transfer Analysis?” Follow us to the next section.

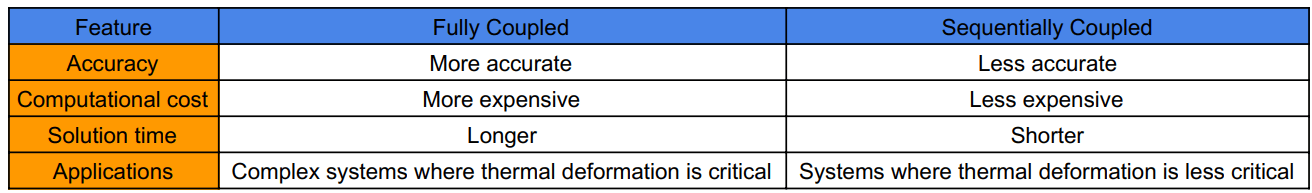

8. The difference between sequentially coupled and fully coupled Abaqus heat transfer analysis

Fully coupled heat transfer analysis solves for the temperature and displacement fields simultaneously. This means that the temperature changes that occur due to heat transfer are immediately taken into account by the structural analysis. This method is more accurate than sequentially coupled heat transfer analysis, but it is also more computationally expensive. (Abaqus thermal analysis)

Sequentially coupled heat transfer analysis solves for the temperature field first, and then uses the results to solve for the displacement field. This method is less accurate than fully coupled heat transfer analysis, but it is also less computationally expensive.

Here is a table that summarizes the key differences between fully coupled and sequentially coupled heat transfer analysis:

Here are some examples of applications where fully coupled heat transfer analysis is appropriate:

- Analyzing the thermal deformation of a rocket engine. The rapid heating and cooling of the engine during operation can cause significant structural deformation. Fully coupled heat transfer analysis can be used to accurately predict this deformation and ensure the safety of the engine.

- Simulating the thermal cycling of a metal part. Metal parts can experience fatigue failure if they are subjected to repeated thermal cycling. Fully coupled heat transfer analysis can be used to predict the fatigue life of the part and optimize its design to minimize fatigue damage.

- Optimizing the design of a thermal-structural system. Fully coupled heat transfer analysis can be used to find the optimal geometry and material properties for a system to minimize thermal stresses and maximize heat transfer efficiency.

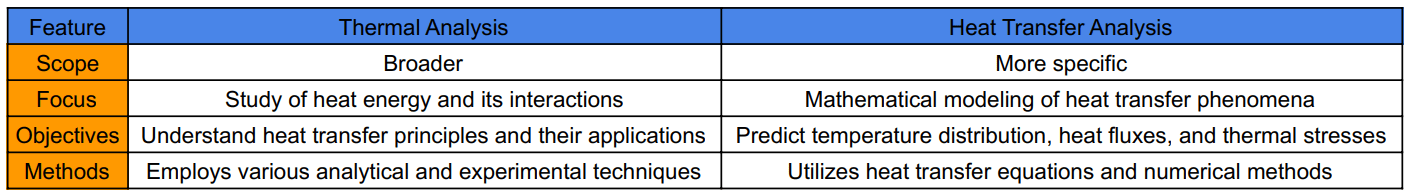

9. Difference between “Thermal analysis” and “Heat transfer” analysis

Thermal analysis and heat transfer analysis are often used interchangeably, but there is a subtle distinction between the two terms.

Thermal analysis is a broader term that encompasses the study of how heat energy is transferred, stored, and transformed within a system. It includes the study of heat transfer mechanisms such as conduction, convection, and radiation, as well as the influence of temperature on materials and processes.

Heat transfer analysis is a more specific subset of thermal analysis that focuses on the mathematical modeling and simulation of heat transfer phenomena. It applies the principles of heat transfer to analyze the temperature distribution, heat fluxes, and thermal stresses within a system.

In other words, thermal analysis is the overarching field of study that investigates the behavior of heat, while heat transfer analysis is a specialized technique within thermal analysis that focuses on the mathematical modeling of heat transfer processes.

Here’s a table summarizing the key differences between thermal analysis and heat transfer analysis:

10. How to Conduct an Abaqus Thermal Analysis? | Abaqus Heat Transfer Tutorial Package

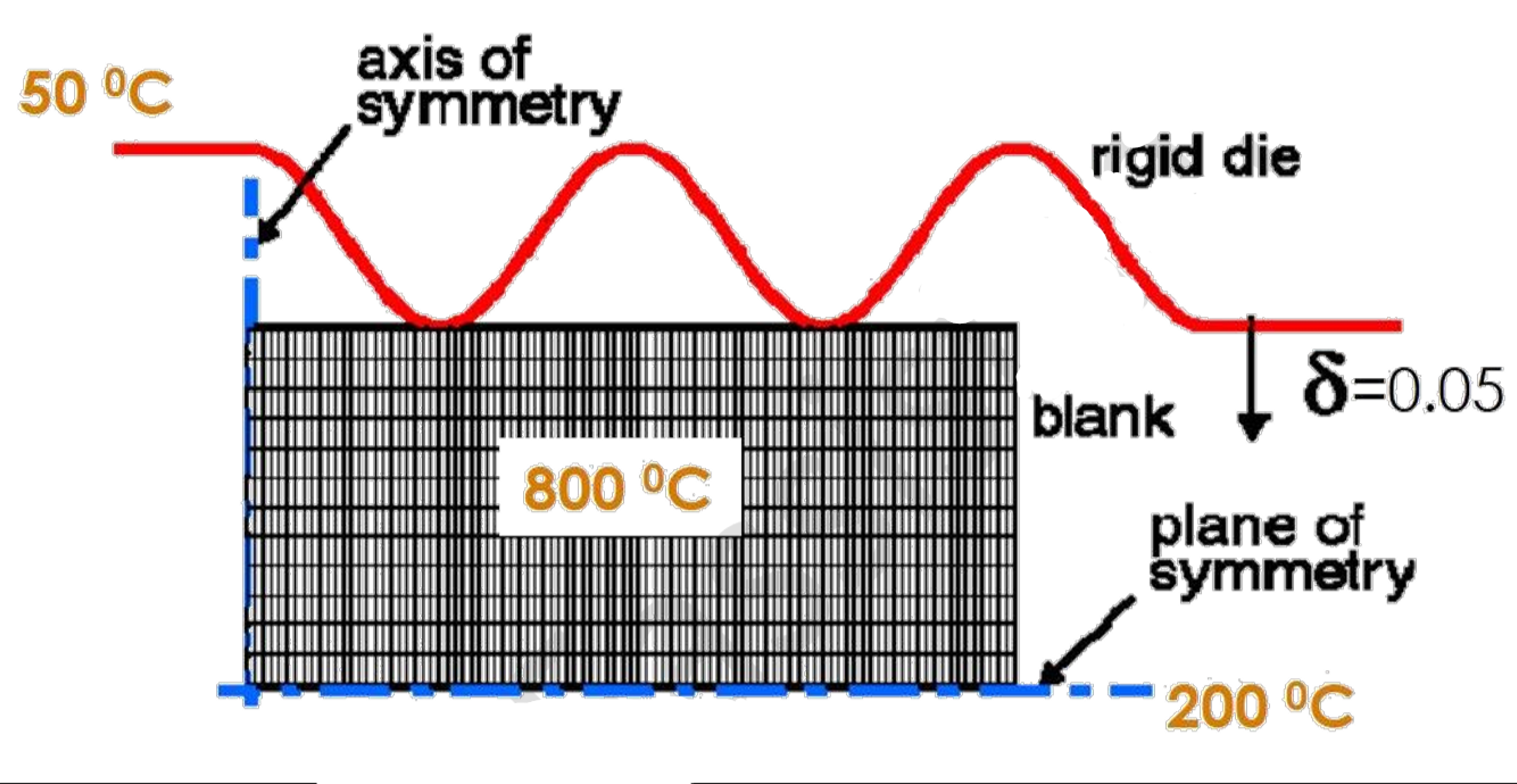

To complete the tutorial in this post, we provide an example. Consider a cylindrical block with a radius of 150 mm and a height of 80 mm (axial symmetry). This block will undergo a hot forging process with an initial temperature of 800 degrees Celsius. The upper mold temperature is 50 degrees, and the lower edge temperature is 200 degrees. We want to Determine both the maximum force required for this operation and the final shape of the block after completing the process.

You can access the step-by-step solution to this example for free by simply clicking on Abaqus thermal stress analysis. We also provide a free comprehensive Abaqus course, divided into four sections to cater to different skill levels and needs. Section 1 covers fundamental concepts, while Section 2 focuses on analyzing a cantilever beam under various loads. Section 3 covers creating custom UMAT subroutines for complex material behaviors, and finally, Section 4 explores Python scripting to streamline and automate simulations. Oh! By the way we have blog that completely explains the Abaqus Material Models.

As we aim to provide all your CAE needs, especially Abaqus heat transfer and Abaqus thermal analysis, the package below helps you understand the theory behind these concepts. This passage offers a comprehensive overview of Abaqus thermal analysis, covering both theory and practical applications, including heat transfer analysis, mechanical analyses, and workshops on topics such as impact analysis and the Johnson-Cook model for materials with temperature and strain rate-dependent properties. It provides detailed explanations and software implementation steps for these topics.

We’ve made an effort to provide you with all the necessary resources for conducting your Abaqus heat analysis. This includes a free course, a complimentary Abaqus heat transfer tutorial PDF, and an extensive tutorials package. This post serves as an introduction to the field of heat transfer and thermal stress analysis using Abaqus. We are enthusiastic about receiving your feedback. Please feel free to share any comments or questions with us. Your input will bring us one step closer to achieving our goal of becoming your ultimate CAE assistant. Our primary reference is the Abaqus Documentation, and you can also explore other available packages by checking out the Abaqus tutorial.

Get this post as a PDF file: CAE Assistant-Heat Transfer Thermal Stress Analysis with Abaqus

|

⭐⭐⭐Free Abaqus Course | ⏰10 hours Video 👩🎓+1000 Students ♾️ Lifetime Access

✅ Module by Module Training ✅ Standard/Explicit Analyses Tutorial ✅ Subroutines (UMAT) Training … ✅ Python Scripting Lesson & Examples |

What are 3 methods of heat transfer?

- Conduction in Solids: This happens when vibrating molecules pass heat through collisions. Examples include ice melting in a glass and cooking food on a hot pan.

- Convection in Fluids: Occurring in liquids and gases, warmer fluid rises while cooler fluid descends, creating currents. This is seen in phenomena like ocean currents, cooling fans in laptops, car radiators, and the wind chill effect.

- Radiation via Electromagnetic Waves: Heat is transferred through electromagnetic waves, commonly observed around campfires and in devices like toaster ovens. Radiation is also used in technologies like thermal imaging and night vision goggles for detection.

What is meant by unsteady state heat transfer?

Heat transfer can be either transient(unsteady state) or steady-state:

- Transient: Obtain the response over time with heat capacity effects included.

- Steady-state: Obtain long-term solution under a given set of loads and B.C.s.

What is coupled heat transfer?

A coupled temperature-displacement procedure used to simultaneously solve stress/displacement and temperature fields. This approach is applied when thermal and mechanical effects strongly interact, such as in rapid metalworking or contact problems.

What is sequentially coupled thermal analysis?

When the stress/deformation field in a structure depends on the temperature field, but the temperature field can be found without knowledge of the stress response. It is usually performed by first conducting an uncoupled (pure) heat transfer analysis and then a stress/deformation analysis. Read more

In which method does the thermal and structural analysis solved simultaneously?

A coupled temperature-displacement procedure (just one job) is used to solve simultaneously for the stress/displacement and the temperature fields. The thermal field affects the mechanical field as above, but here, the mechanical field also can affect the thermal field.

What is the difference between coupled and uncoupled analysis?

Uncoupled analysis calculates the temperature field independently, without taking into account the stress and deformation within the studied bodies. In contrast, a coupled temperature-displacement procedure, accomplished within a single job, simultaneously solves for both the stress/displacement and temperature fields.

Users ask these questions

In social media and websites such as ResearchGate, users ask questions regarding the thermal analysis in Abaqus; so, we decided to answer some of them, which you can see them below:

I. Heat transfer

Q: My model is being heated but the clt section is getting hotter faster when the conductivity is 0.12 compared to the steel section which has a conductivity of 50. Does anyone know the reason for this?

A: Hello,

I suggest checking your model. See if anything is wrong with the material properties specified. It could be for their units, or you did something wrong. My recommendation is to find an example from YouTube and follow the steps like in the video to see what is wrong.

Also, check the links below. The first one is an article about heat analysis, and the other two are two packages that could help you out.

An overview – Heat Transfer and Thermal Stress Analysis with Abaqus

Thermal Heat Transfer in Abaqus

Thermal Heat Transfer in Abaqus-2

Best regards.

Thank you for preparing this article. Do you have a training package about thermal analysis?

The detailed insights into thermal Stress Analysis Services were particularly commendable, offering practical guidance on how to effectively utilize ABAQUS for such simulations. The author’s ability to present technical information in a clear and concise manner is truly praiseworthy.

You’re very welcome! It’s fantastic to hear that you had a great experience with us. We strive to deliver the best service possible, and your satisfaction is our top priority