What is Abaqus Element Deletion? | When use it: Abaqus Element Deletion Criteria

In simulations, materials often experience damage or even break apart under stress. This is a common issue in industries like aerospace, automotive, and civil engineering, where structures must withstand high-impact forces or fatigue. Abaqus offers a technique known as “Abaqus element deletion” to handle such scenarios, where portions of the material are removed from the model once, they fail.

Element deletion Abaqus allows for realistic simulation of material degradation and failure. It works by removing mesh elements based on predefined damage criteria, like stress or strain limits, once they can no longer support a load; so when we refer to Abaqus element deletion criteria, we are referring to setting these damage criteria to determine when element deletion should occur. This is especially useful for modeling impacts, fractures, and fatigue in materials. By understanding and applying this technique, engineers can improve the accuracy of their failure models.

In this blog, we will explore how the element deletion technique works in Abaqus. We will explain the mechanical theories behind it, discuss the material models you can use, and provide step-by-step instructions for setting it up in your simulations.

1. What is the Abaqus Element Deletion Technique?

Abaqus Element Deletion is a simulation technique used to model material failure or fracture by removing elements from the Abaqus mesh once they meet predefined failure criteria, such as excessive strain, stress, or energy dissipation. By removing these elements, Abaqus simulates the degradation or total failure of material in real-world scenarios.

Abaqus element deletion is commonly employed in damage mechanics and failure modeling, particularly in problems involving fracture, impact, and fatigue, where materials or structures break apart due to stress or strain. This is achieved by using material models with damage criteria that monitor when the material degrades beyond a threshold, triggering element removal.

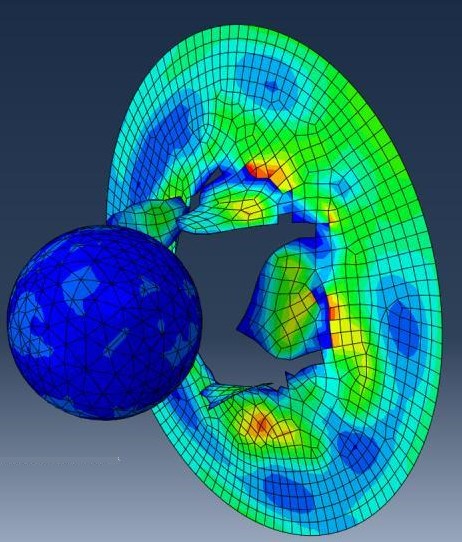

For example, consider an impact analysis where a projectile hits a metal plate. In this case, the plate may undergo large deformation, and portions of the material may crack or break away. Using an element deletion technique, elements in the plate mesh would be removed as soon as a material model’s failure criterion (such as critical plastic strain) is met.

Figure 1: Element deletion in Abaqus

1.1. Why Use the Element Deletion Abaqus Technique?

Benefits of element deletion Abaqus technique in simulations:

- Accurate failure representation: In real-world structures, failure leads to the removal of load-carrying capacity, and simulating this behavior improves the realism of the model.

- Fracture and damage analysis: It allows the simulation of fractures, cracks, and other forms of material separation.

- Efficient simulation of complex phenomena: For problems like high-velocity impacts, explosions, or machining processes, element deletion can simulate material ejection or fragmentation.

- Fatigue and progressive failure analysis: It provides a way to predict failure in materials subject to repeated loading and cyclic stresses, helping in fatigue life predictions.

| If you need deep training, our Abaqus Course offerings have you covered. Visit our Abaqus course today to find the perfect course for your needs and take your Abaqus knowledge to the next level! |

2. What are Abaqus Element Deletion Criteria? | Mechanical Failure Theory

The mechanical basis of the element deletion technique stems from continuum damage mechanics (CDM) and fracture mechanics. In CDM, a material’s degradation due to stress, strain, or energy dissipation is described by a damage variable (D). This variable ranges from 0 (undamaged material) to 1 (completely damaged). When the damage variable reaches 1, the element is no longer capable of carrying any load and is removed from the simulation.

So again, when we refer to Abaqus element deletion criteria, we are referring to setting these damage criteria to determine when element deletion should occur.

Key principles of the mechanical theory of element deletion include:

- Damage initiation: This phase is governed by criteria such as maximum strain, energy dissipation, or stress reaching critical values. These values are often defined through empirical tests and material properties.

- Damage evolution: Once initiated, the material’s stiffness is progressively reduced based on the accumulation of damage until it can no longer sustain any load.

- Failure and deletion: When the damage reaches its critical threshold (D=1), the material element is assumed to have completely failed, and the element is deleted from the analysis, representing material fracture or rupture.

In terms of fracture mechanics, element deletion can simulate crack propagation where the removal of elements mimics the growing path of a crack as stress intensifies.

3. How should we use Element deletion? | Abaqus Element Deletion tutorial

To use the element removal technique in Abaqus software, two important points must be observed.

- Material properties

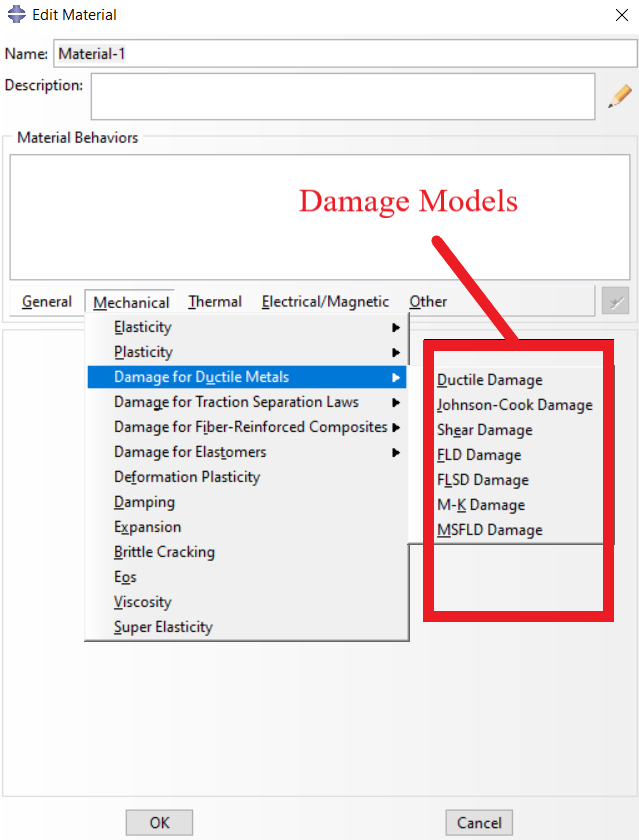

The first point is to determine the properties of the material. The material used must support damage and failure models. This means that in addition to Young’s modulus and Poisson’s ratio, you must assign a damage model to the material. This enables Abaqus to simulate material failure and removal. For example, to assign a damage model for ductile materials, assign a damage initiation criterion such as ductile damage, shear damage, or failure strain. In the following figure damage models for ductile materials in Abaqus are shown.

Figure 2: Damage models for ductile materials in Abaqus

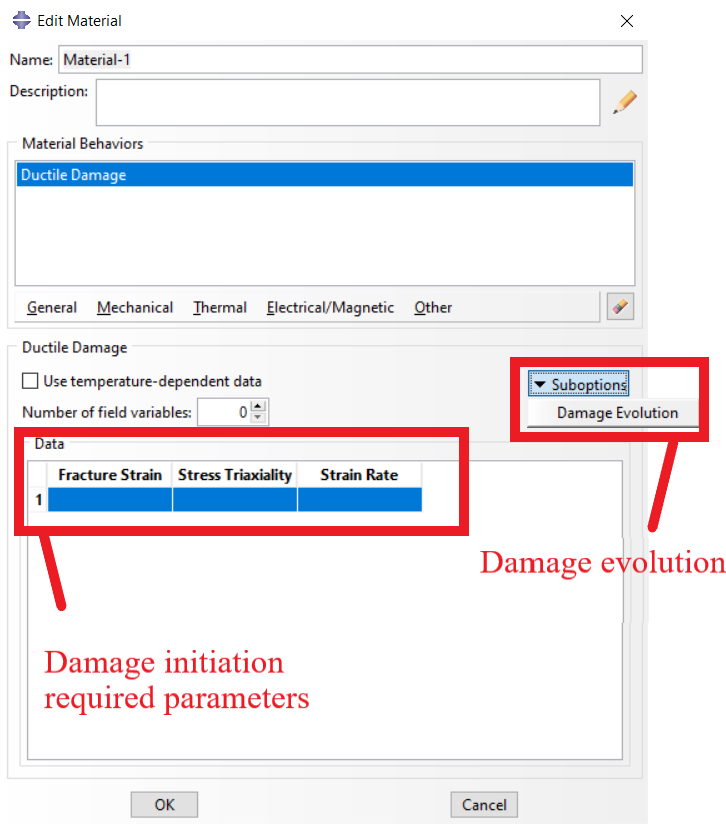

Also, after entering the required initial damage parameters, you can define Damage Evolution to control how the material decays after starting.

Figure 3: Damage initiation parameters and damage evolution option

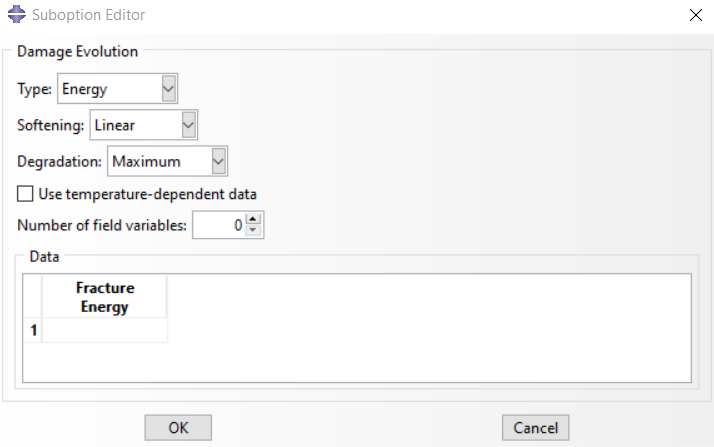

There are various solutions to use the damage evolution according to the chosen model, for example, for the ductile damage model, the fracture energy can be used as a measure for damage evolution. Determining the amount of fracture energy requires an experimental test.

Figure 4: Damage Evolution for Ductile Damage model

- Generating the Mesh

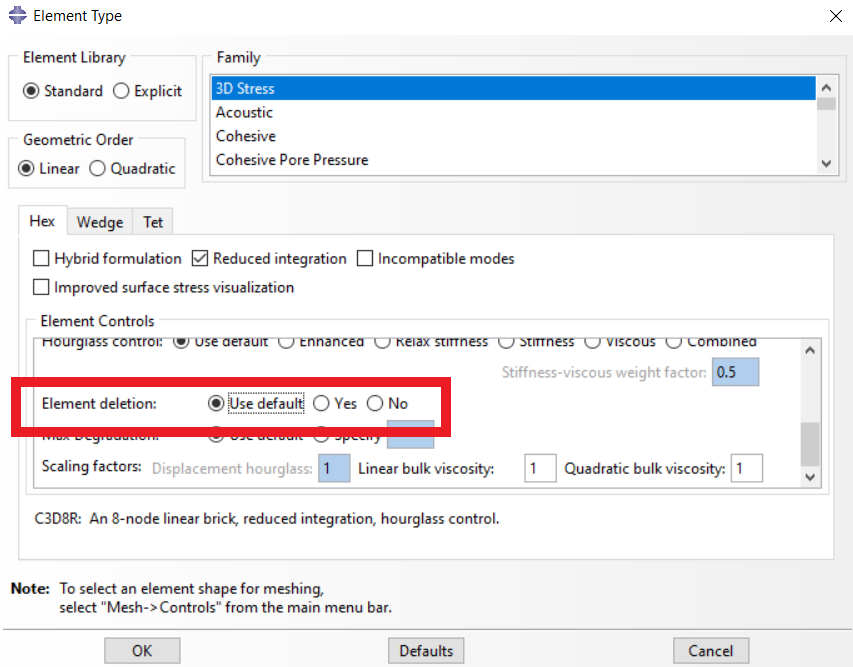

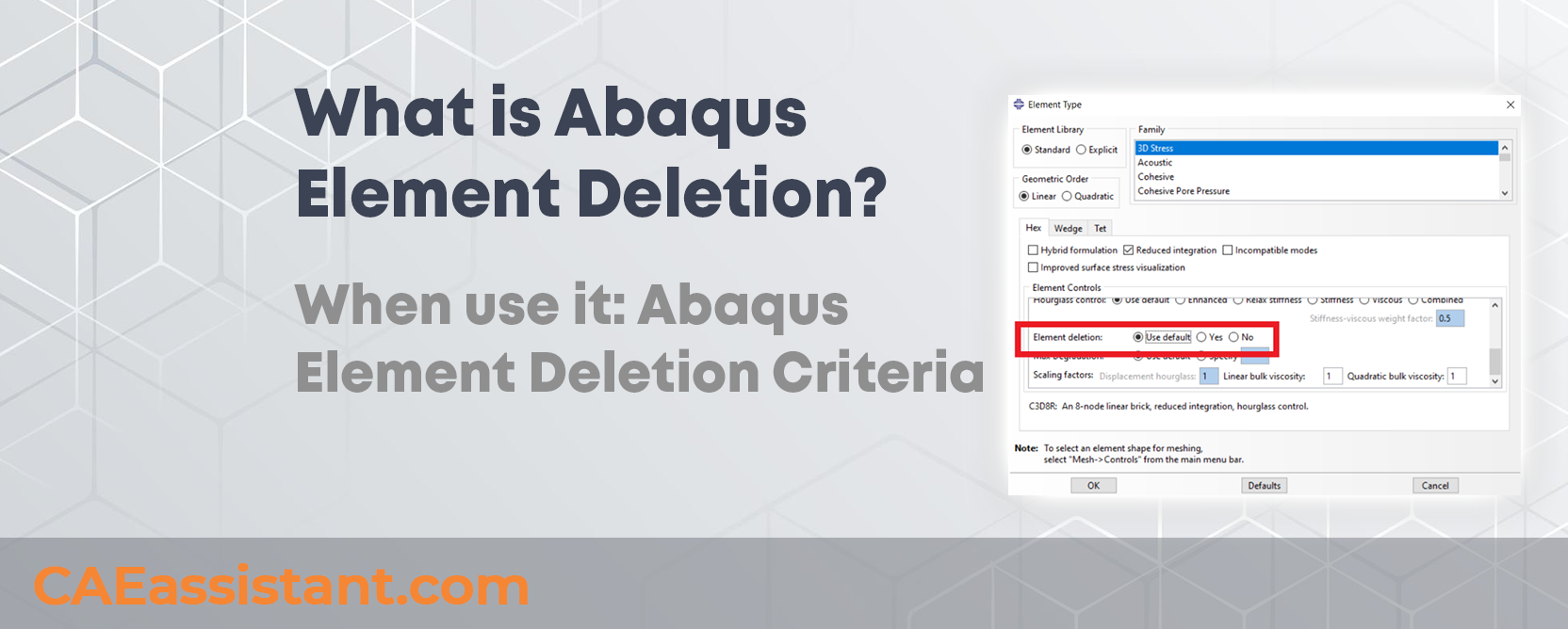

Element deletion happens at the element level, so generating a fine-enough mesh is crucial for accuracy. You can use the deletion element option in the mesh module in the Element Type tab. In this window, there are three approaches depending on the application need: Use default, delete the element and do not delete the element. The figure below shows this window and the available options, which are key elements of any comprehensive Abaqus element deletion tutorial.

Figure 5: Element deletion option in Element Type dialog

3. Conclusion

This article focused on the Abaqus element deletion technique, which is used to simulate material failure by removing elements from a model when specific damage criteria are met. This method is critical in accurately representing material degradation and fracture in various simulations, such as impact, fatigue, and high-stress situations.

We began by explaining what element deletion is and why it’s beneficial for modeling material failures. Next, we covered the theory behind it, focusing on damage mechanics and fracture mechanics, highlighting how damage initiation and evolution lead to element removal, which this is the meaning of Abaqus element deletion criteria. The article then provided practical guidance on how to use this feature in Abaqus, emphasizing the importance of selecting proper material models and generating a fine mesh for accuracy.

In summary, the element deletion technique helps simulate material failure in a realistic manner, enhancing the precision of complex damage simulations. Through this article, we’ve learned how to set up and use element deletion effectively in Abaqus, ensuring better simulation outcomes in scenarios involving material fracture or degradation.

Explore our comprehensive Abaqus tutorial page, featuring free PDF guides and detailed videos for all skill levels. Discover both free and premium packages, along with essential information to master Abaqus efficiently. Start your journey with our Abaqus tutorial now!

The CAE Assistant is committed to addressing all your CAE needs, and your feedback greatly assists us in achieving this goal. If you have any questions or encounter complications, please feel free to share it with us through our social media accounts including WhatsApp.

You can always learn more about Abaqus fatigue analysis from Abaqus Documentation.