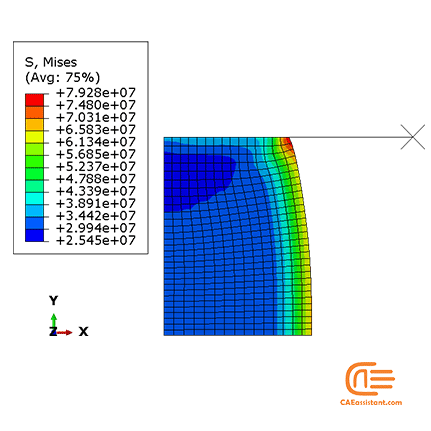

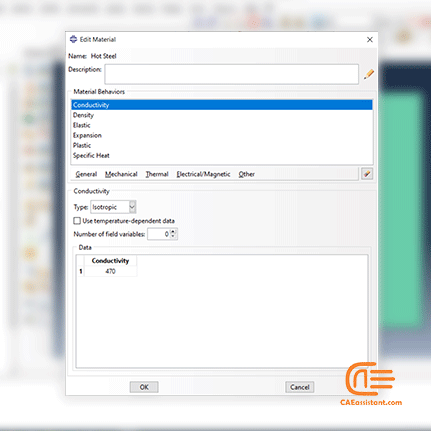

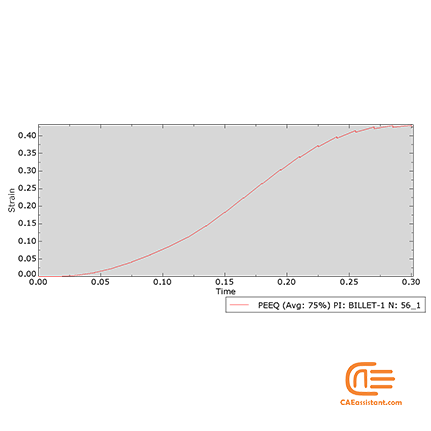

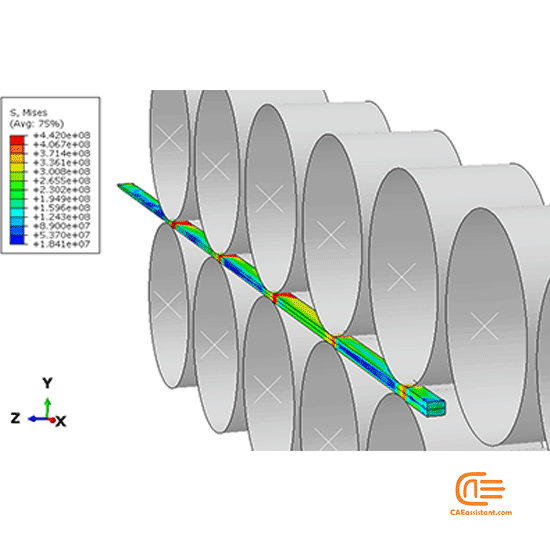

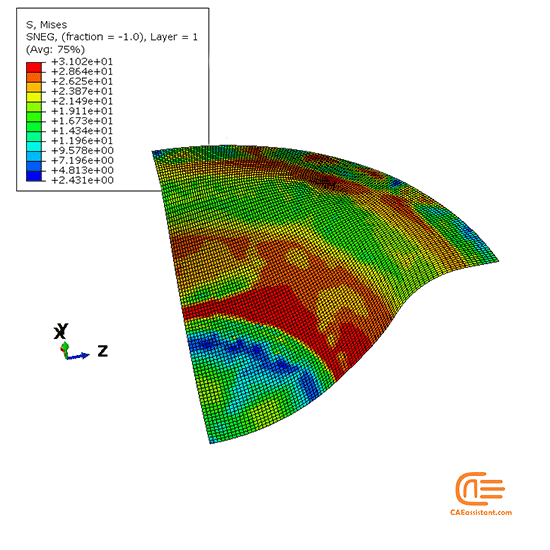

Steel Cylinder Hot Forging Process Simulation in ABAQUS is The hot forging process has been investigated by considering heat transfer through radiation and convection as well as workpiece contact with the punch. In this simulation, all the thermal properties of the material such as heat transfer coefficient, volume expansion coefficient, etc. are defined.

Project package for this subject: