Li Wei, an accomplished expert in heat transfer analysis using Abaqus, is a resident of China. With a strong educational background, extensive experience, and deep expertise in Abaqus, Li has established himself as a leading authority in the field of thermal analysis.

Education:

Li Wei completed his Bachelor’s degree in Mechanical Engineering from Tsinghua University in Beijing, China. During his undergraduate studies, he developed a keen interest in heat transfer phenomena and computational methods for thermal analysis. This passion led him to pursue further education in the field, and he obtained a Master’s degree in Thermal Engineering from Shanghai Jiao Tong University.

Career and Professional Accomplishments:

Li began his professional career as a thermal engineer at a prestigious technology company in Shanghai. His exceptional skills in heat transfer analysis and his proficiency in utilizing Abaqus for thermal simulations quickly gained recognition. Li’s expertise enabled him to work on a wide range of projects, including electronic cooling, thermal management of industrial processes, and energy system optimization.

Expertise and Contributions:

Li Wei’s expertise lies in the field of heat transfer analysis, with a focus on utilizing Abaqus software for accurate and efficient simulations. He is well-versed in conducting steady-state and transient thermal analyses, evaluating conduction, convection, and radiation heat transfer mechanisms. Li specializes in modeling heat transfer in complex geometries, such as electronic components, heat exchangers, and industrial systems.

Using Abaqus, Li has successfully simulated and optimized thermal management solutions for various industries, including electronics, automotive, aerospace, and energy. He is skilled in performing coupled thermal-mechanical analyses to evaluate the effects of thermal loads on structural integrity. Li’s expertise also extends to multiphysics simulations, where he combines heat transfer analysis with other engineering disciplines to provide comprehensive solutions.

Li is known for his ability to accurately model material properties and boundary conditions to capture realistic thermal behavior. He leverages advanced techniques such as phase change modeling, heat source modeling, and heat transfer coefficient estimation to ensure precise predictions. His insights have helped clients improve design efficiency, optimize energy consumption, and enhance product performance.

Li Wei actively stays updated with the latest advancements in heat transfer analysis and Abaqus capabilities. He attends conferences, participates in workshops, and engages in continuous professional development to expand his knowledge and refine his skills. Li is also passionate about sharing his expertise and frequently contributes to technical publications and presents at industry events.

Friction Stir Welding simulation Tutorial | FSW Advanced level

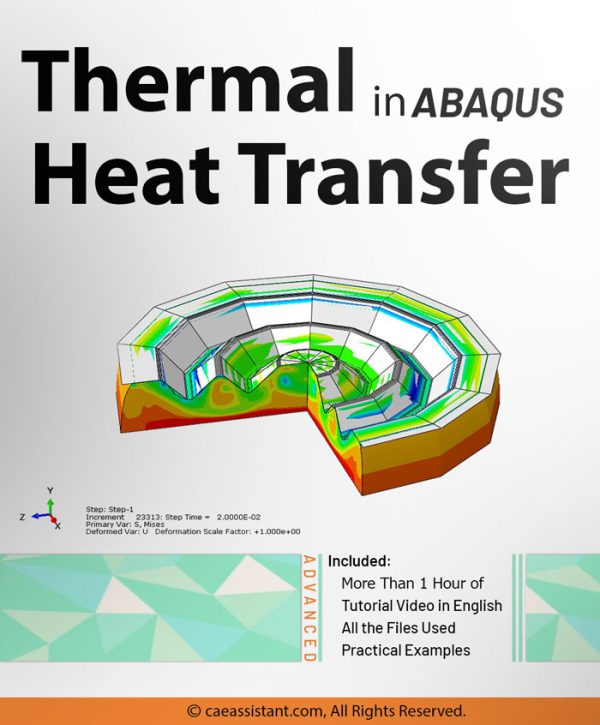

Thermal Heat Transfer in Abaqus

- Uncoupled heat transfer analysis

- Sequentially coupled thermal-stress analysis

- Fully coupled thermal-stress analysis

- Adiabatic analysis