What is Abaqus Contact Damping and how to apply it in Abaqus?

Abaqus contact damping is a technique used in finite element analysis to stabilize interactions between surfaces or bodies by introducing a viscous damping force at the contact interface.

This force mitigates instabilities and oscillations caused by rapid changes in contact conditions, ensuring stability and convergence in simulations involving large displacements, high strain rates, or significant material nonlinearities. The importance of contact damping spans various applications, including automotive crash simulations, metal forming processes, earthquake engineering, biomechanical simulations, aerospace design, robotics, and consumer electronics testing.

In this blog post, you will learn the definition and significance of Abaqus contact damping, explore its diverse applications, and discover how to effectively implement it in both ABAQUS/Standard and ABAQUS/Explicit both in Abaqus/CAE and input file to enhance the accuracy and stability of your simulations.

1. What is Abaqus Contact Damping?

In Abaqus, contact damping refers to a numerical technique employed to control and stabilize contact interactions between surfaces or bodies in a simulation. It involves adding a damping force or resistance at the contact interface, which helps to mitigate instabilities, oscillations, or chatter that may arise due to rapid changes in contact forces or conditions. This damping force is typically viscous in nature, meaning it acts proportionally to the relative velocity between the contacting surfaces (Abaqus contact damping).

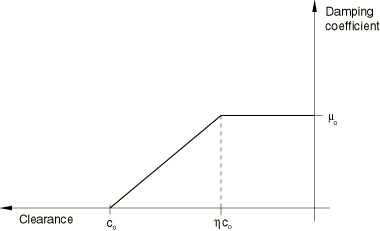

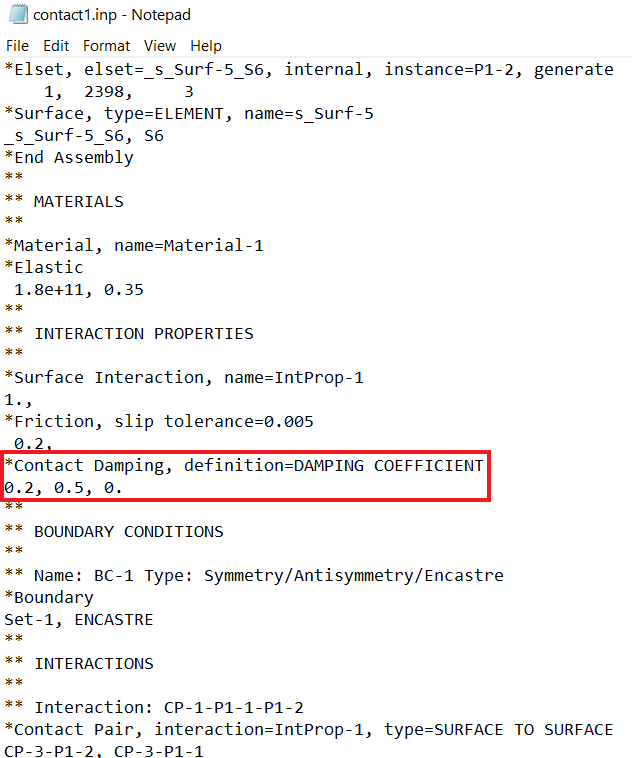

Figure 1: Contact Damping, damping coefficient

Abaqus Contact Damping is a viscous damping force applied between two contacting surfaces to dampen relative motions. It can be defined in two ways:

- As a proportionality constant with units of pressure divided by velocity

- As a unitless fraction of critical damping

The damping coefficient can be specified as a function of surface clearance in Abaqus/Standard, allowing for more refined control over the damping behavior.

1.2. Why is Abaqus Contact Damping important?

Contact damping is crucial in ensuring the stability and convergence of contact simulations. During these simulations, especially those involving large relative displacements, high strain rates, or significant material nonlinearities, the contact forces can change rapidly. These rapid changes can lead to numerical instabilities or oscillations, which affect the accuracy and convergence of the analysis.

By applying contact damping, Abaqus dissipates energy from the system, thereby reducing the likelihood of unstable or oscillatory contact forces. This stabilization is essential for maintaining the integrity and reliability of the simulation results.

1.3. When we need Abaqus Contact Damping?

Abaqus Contact damping is particularly useful in the following scenarios:

- Problems with large amounts of friction

- Post-buckling analyses

- Simulations involving large deformations

- Cases with material softening

- Multi-step analyses with significant changes in model stiffness

- Convergence issues: When sudden changes in contact constraints lead to convergence problems, such as in buckling problems involving contact.

- Softened or penalty contact: In Abaqus/Explicit, it helps dampen oscillations in these types of contact formulations.

- High-frequency oscillations: When rapid changes in contact forces cause numerical instabilities or oscillations that affect the accuracy of the analysis.

2. Applications of Contact Damping

Automotive Crash Simulations:

Description: During crash tests, vehicles undergo large deformations, and the interaction between different parts of the vehicle can lead to rapid changes in contact forces.

Importance: Contact damping helps stabilize the simulation by reducing oscillations and ensuring accurate modeling of the energy dissipation during the crash.

Metal Forming Processes:

Description: Processes like stamping, forging, or rolling involve large plastic deformations and significant contact interactions between the tool and the workpiece.

Importance: Contact damping aids in achieving convergence and stability in simulations where the material and tool surfaces are in constant dynamic contact.

For forming process, we have these video tutorial packages:

Earthquake Engineering:

Description: Buildings and structures subjected to seismic loads experience dynamic contact interactions between structural components, especially in base isolation systems.

Importance: Incorporating contact damping in simulations helps model the energy dissipation accurately and predict the structural response during an earthquake.

Biomechanical Simulations:

Description: In simulations of joints, such as the knee or hip, contact damping is used to model the interaction between bones and cartilage.

Importance: This helps in studying the effects of joint movements, prosthetics, and orthopedic implants by providing stable and realistic contact interactions.

Aerospace Landing Gear Design:

Description: The landing gear of aircraft undergoes significant contact forces upon touchdown, involving large displacements and dynamic impacts.

Importance: Contact damping in simulations helps in designing landing gear systems that can absorb impact energy efficiently, ensuring safety and structural integrity.

Robotics and Automation:

Description: Robots often perform tasks that involve contact with various surfaces, such as gripping objects or interacting with environments.

Importance: Contact damping ensures smooth and stable operation by preventing oscillations and improving the precision of robotic movements.

Assembly Processes in Manufacturing:

Description: During the assembly of mechanical components, contact damping is used to simulate the interactions and fitment of parts.

Importance: It helps in predicting the behavior of components during assembly, ensuring proper alignment and reducing the risk of damage.

Bridge and Infrastructure Engineering:

Description: Bridges and large infrastructure projects experience dynamic loads and contact interactions, especially in joints and support structures.

Importance: Contact damping stabilizes simulations under dynamic loading conditions, aiding in the design and analysis of resilient infrastructure.

Consumer Electronics:

Description: Devices like smartphones and tablets undergo drop tests to assess their durability. These tests involve dynamic impacts and contact interactions.

Importance: Contact damping helps in accurately simulating the impact forces and predicting potential damage, leading to the design of more robust devices.

Sports Equipment Design:

Description: Equipment such as helmets, pads, and other protective gear undergo impact testing to ensure safety standards.

Importance: Contact damping in simulations helps in understanding how these products dissipate energy and protect users during impacts.

By applying contact damping in these scenarios, engineers can achieve more accurate, stable, and reliable simulations, leading to better-designed products and structures that can withstand real-world conditions effectively.

3. How to apply Contact damping in Abaqus?

Contact damping in Abaqus is applied in both ABAQUS/Standard and ABAQUS/Explicit. The damping coefficient, which can be specified as a proportionality constant with units of pressure divided by velocity or as a unitless fraction of critical damping, defines the viscous damping force.

- ABAQUS/Standard: The damping coefficient is applied independent of the open/close state of the contact.

- ABAQUS/Explicit: The damping coefficient is applied only when the surfaces are in contact.

The contact damping option can be set up through the GUI or input files, with specific damping coefficients tailored to the problem at hand.

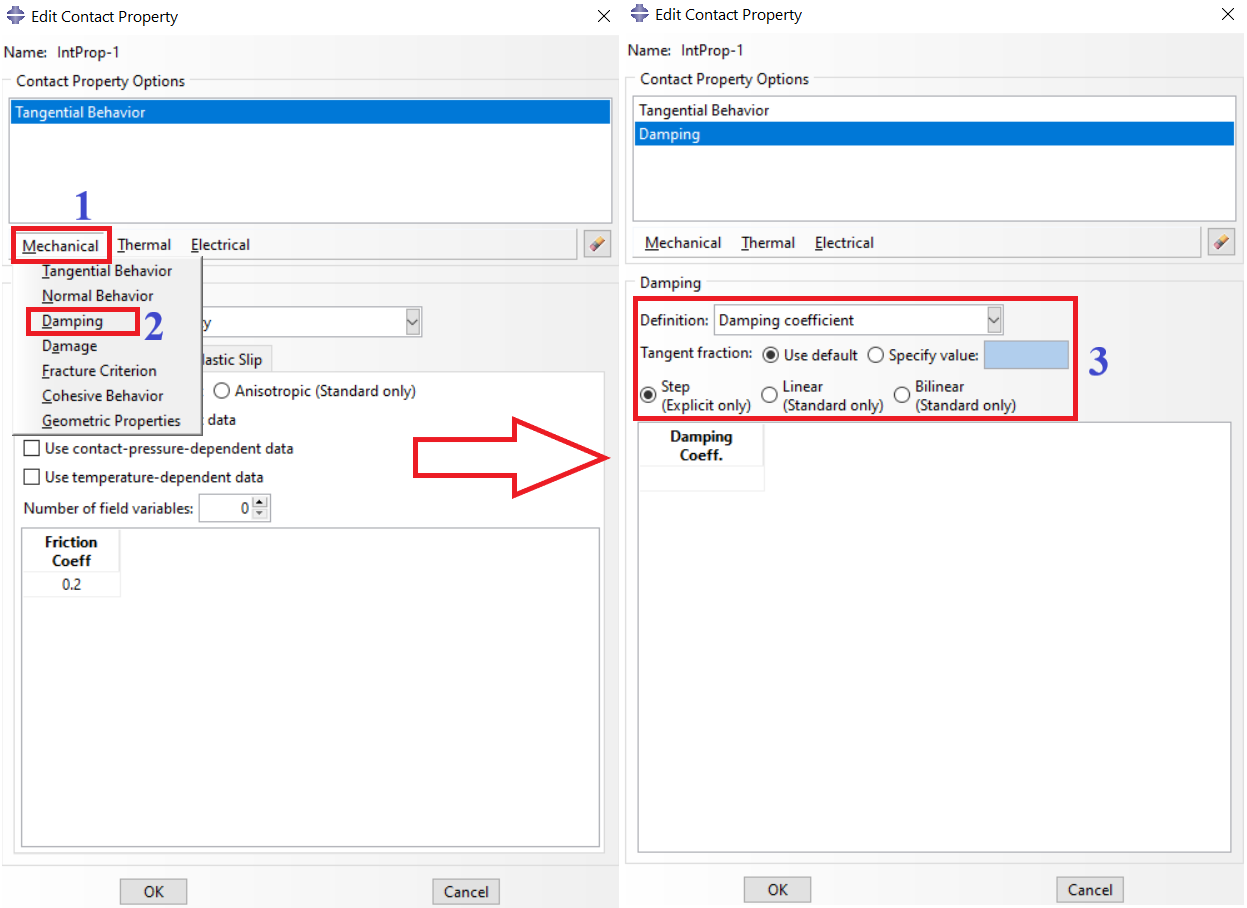

Here’s a step-by-step guide to applying contact damping in Abaqus (GUI):

- Create a contact property:

- In the Interaction module, create a new Contact Property.

- Name the property (e.g., “ContactDamping”).

- Define the contact damping:

- In the Contact Property editor, select the “Damping” category.

- Choose the appropriate definition:

- For Abaqus/Standard: Select “Damping coefficient” and choose either “Linear” or “Bilinear”.

- For Abaqus/Explicit: Select either “Damping coefficient” or “Critical damping fraction”.

- Specify the damping parameters:

- For “Damping coefficient”:

- Enter the damping coefficient value (units of pressure/velocity).

- If using “Bilinear”, specify the clearance values.

- For “Critical damping fraction” (Abaqus/Explicit only):

- Enter the fraction of critical damping (unitless value between 0 and 1).

Figure 2: Applying Abaqus contact damping through Abaqus/CAE (GUI)

4. Apply the contact property to a contact pair:

- Create a contact pair or general contact interaction.

- In the interaction editor, select the contact property you created.

5. Adjust contact controls (optional):

- Create a Contact Control.

- Enable “Automatic stabilization” if needed.

- Apply the contact control to the specific contact pair or globally.

6. Set up analysis steps:

- For complex contact scenarios, consider using multiple steps:

- First step: Apply a small fraction of the load (1-10%) with contact damping.

- Subsequent steps: Ramp up to full load, potentially without damping.

7. Run the analysis and check results:

- Monitor the contact damping energy (ALLSD) against total strain energy (ALLSE).

- Aim to keep ALLSD below 5% of ALLSE, preferably under 1%.

8. Refine the damping parameters:

- If needed, adjust the damping coefficient or critical damping fraction.

- For Abaqus/Standard, you can modify the clearance values for bilinear damping.

9. Verify the impact on results:

- Compare key outputs (e.g., stresses, displacements) with and without damping.

- Ensure damping doesn’t significantly alter the physics of your problem.

Remember to start with small damping values and increase gradually as needed. Excessive damping can lead to non-physical behavior or convergence issues.

You can always learn more in Abaqus documentation; click on the link to open the Abaqus help regarding Contact damping.

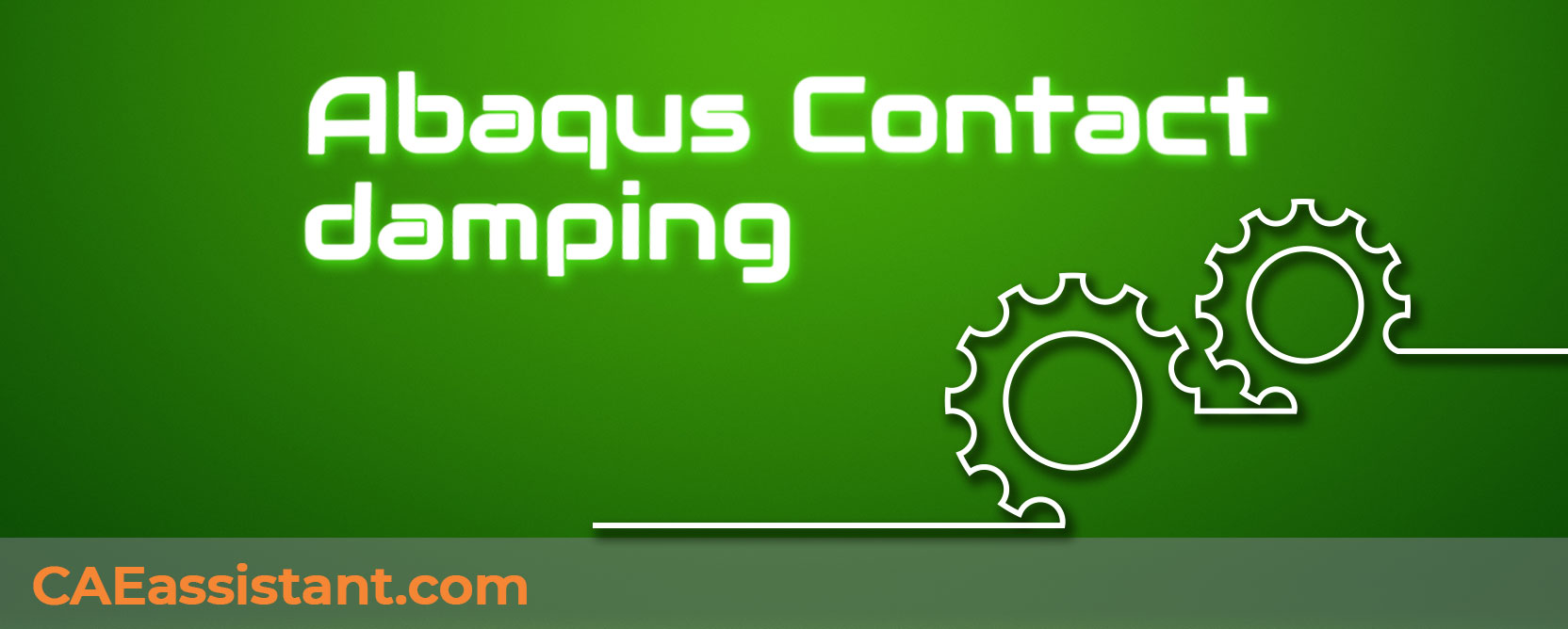

To apply contact damping through the input file, just look at the figure below and use the command “*Contact Damping”.

Figure 3: Abaqus Contact damping through the input file

4. Conclusion

In conclusion, Abaqus contact damping is an essential technique in finite element analysis, designed to stabilize interactions between surfaces or bodies by introducing a viscous damping force at the contact interface. This force effectively reduces instabilities and oscillations caused by rapid changes in contact conditions, thereby ensuring stability and convergence in simulations involving large displacements, high strain rates, or significant material nonlinearities.

By understanding and implementing contact damping in both ABAQUS/Standard and ABAQUS/Explicit, engineers can achieve more accurate and reliable simulation results. This blog post has provided insights into the definition and significance of Abaqus contact damping, its wide range of applications, and practical steps for its application. Equipped with this knowledge, you can enhance the stability and accuracy of your finite element analyses, leading to better-designed products and structures that withstand real-world conditions effectively.

Question: How to define the contacts? General or surface to surface contact?

Explore our comprehensive Abaqus tutorial page, featuring free PDF guides and detailed videos for all skill levels. Discover both free and premium packages, along with essential information to master Abaqus efficiently. Start your journey with our Abaqus tutorial now!