Dr. Vijay Kumar

Country: India

Education

Indian Institute of Technology (IIT): Bachelor’s in Mechanical Engineering

University of California, Berkeley: Master’s in Mechanical Engineering

Massachusetts Institute of Technology (MIT): Ph.D. in Mechanical Engineering

Company History

Aerospace Engineering Pvt. Ltd.: Research Scientist (5 years)

Indian Institute of Science (IISc): Professor (Present)

Expertise

Dr. Kumar is a leading expert in the field of composite materials and failure analysis using ABAQUS. He has extensive experience in modeling and simulating the mechanical behavior of composite structures under various loading conditions. Dr. Kumar’s research focuses on developing novel composite materials with improved strength, stiffness, and damage tolerance. He is also actively involved in developing new methodologies for failure analysis of composite structures using ABAQUS.

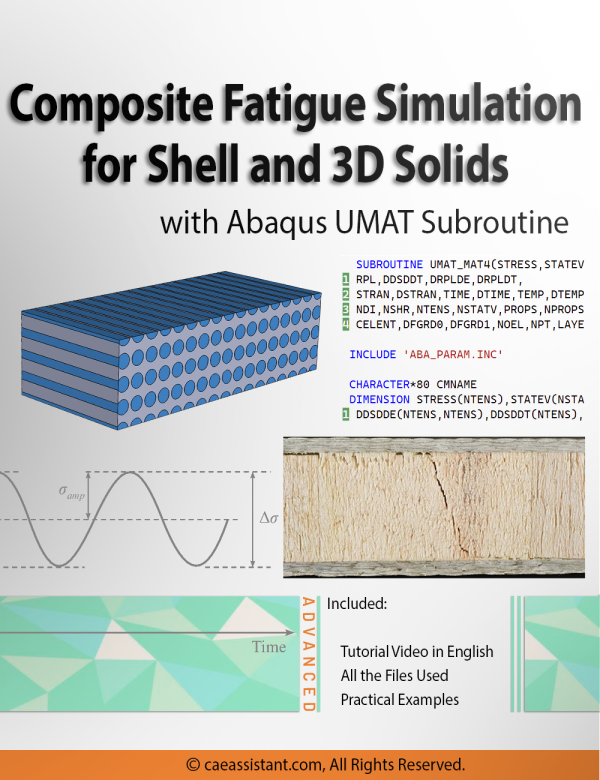

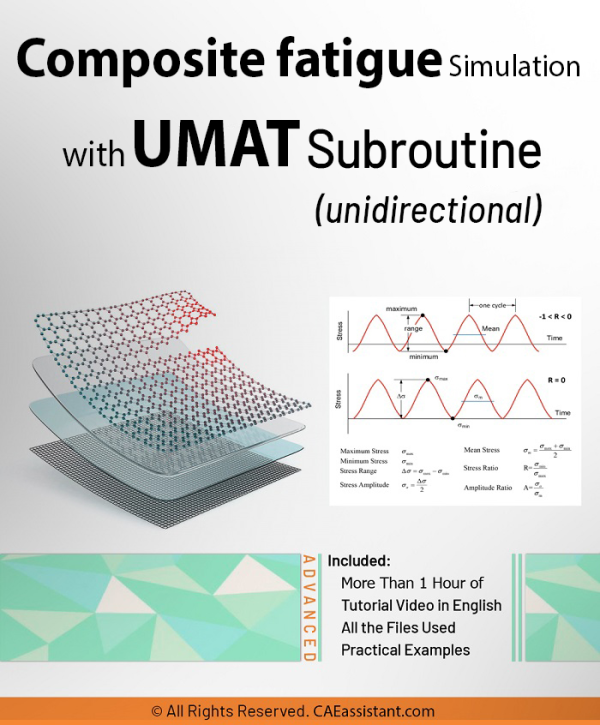

Composite Fatigue Simulation with Subroutine in ABAQUS (unidirectional) for 3D Element

Fatigue in composites refers to the weakening of a material caused by repeatedly applied loads or stress cycles over time. When a composite material is subjected to cyclic loading, small cracks or microdamage can form within the material, which may grow and lead to failure after a certain number of loading cycles. This is a significant consideration in the design and analysis of composite structures, especially in applications subjected to repeated stress, such as in aerospace, automotive, or civil engineering.

In one of our other packages, we have used the UMAT subroutine in Abaqus to simulate fatigue in composites in two-dimensional space. The current project is more comprehensive, as it addresses composite fatigue in both 2D and 3D spaces. So you can use it for the simulation of both shells and solids. In this project, you will first become familiar with simulating composite fatigue in 2D space using the Abaqus UMAT subroutine. Then, we will provide a complete UMAT code along with Abaqus files for extending the simulation to 3D space, enabling the 3D simulation of composite fatigue in Abaqus.

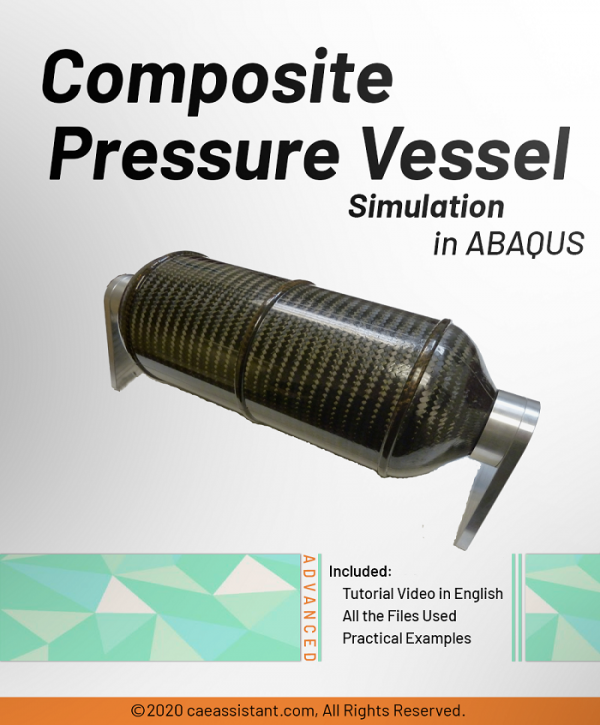

Composite Pressure Vessel simulation in ABAQUS

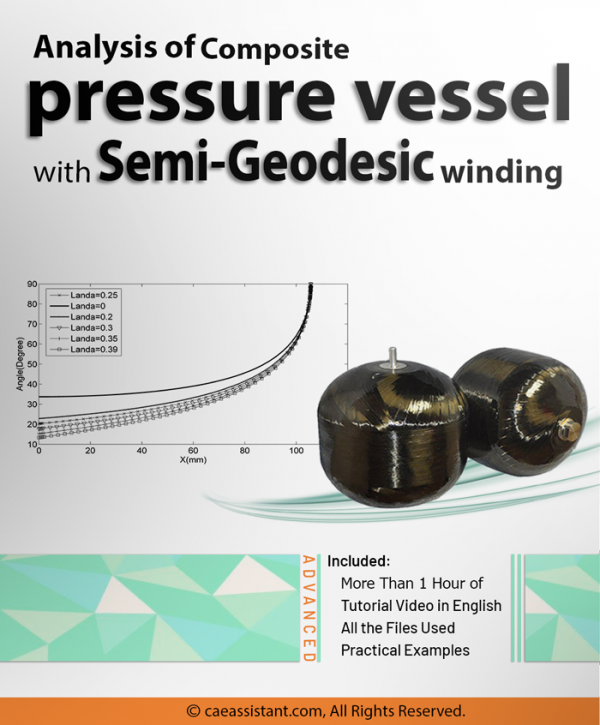

Composite pressure vessel analysis with Semi-Geodesic winding

Full Composite fatigue Add-on (Academic and industrial usage)

Full Composite damage Add-on (Academic and industrial usage)

Composite Fatigue Simulation with VUMAT Subroutine in ABAQUS

Composite simulation for experts-Part-3

Pay attention to the syllabus and availability file details. some of the packages are fully available and some of them are partially available. If this is partially available it takes at least two months to be completely available.

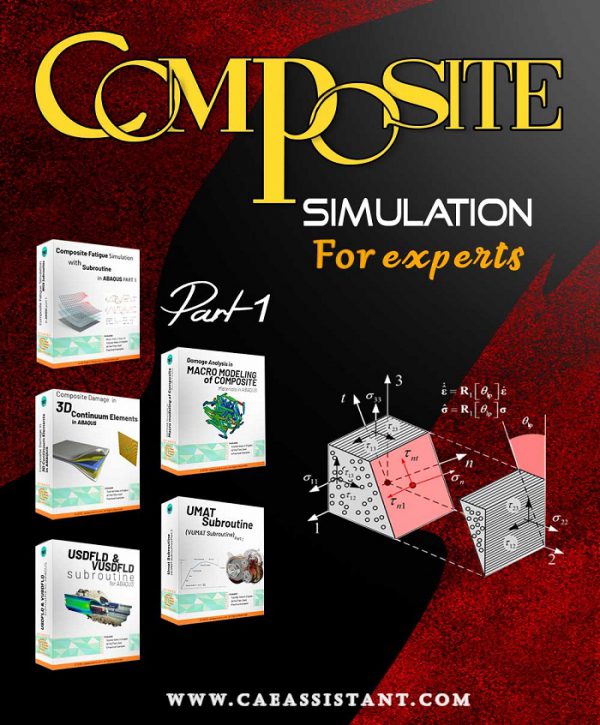

If you are a graduate or Ph.D. student, if you are a university professor or an expert engineer in the industry who deals with simulation software, you are definitely familiar with the limitations of this software in defining the material properties, loading or meshing, interaction properties, and etc. You have certainly tried to define the properties of materials based on advanced fracture theories in finite element software and are familiar with their limitations and problems. Now, here is your solution. Start writing subroutines in finite element software and overcome the limitations. With the tutorials in the Golden Package, you will learn how to write 8 subroutines in Abaqus software professionally.Composite simulation for experts-Part-2

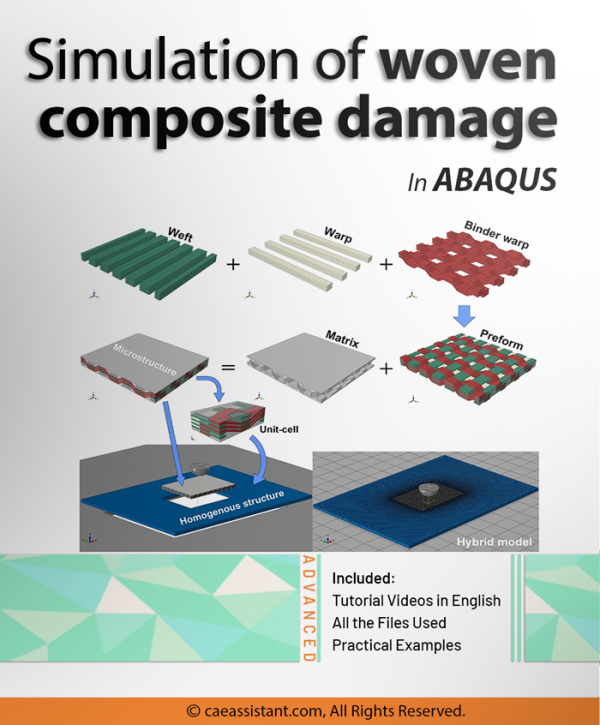

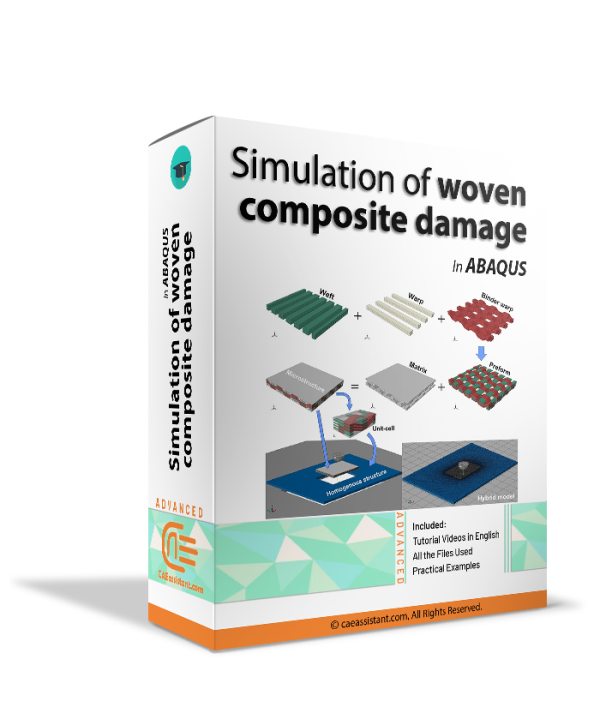

If you are a researcher, student, university professor, or Engineer in the company in the field of composite materials, this training package in simulating these materials in Abaqus software is the best selection. This training package is the second part of the composite for expert package and is focusing on the Simulation of woven composite damage in Abaqus, Composite Fatigue Simulation, Analysis of Composite pressure vessel with Semi-Geodesic winding, Simulation of composite Hashin damage in 3d continuum element (UMAT-VUMAT-USDFLD), and Abaqus composite modeling of Woven & Unidirectional + RVE method.

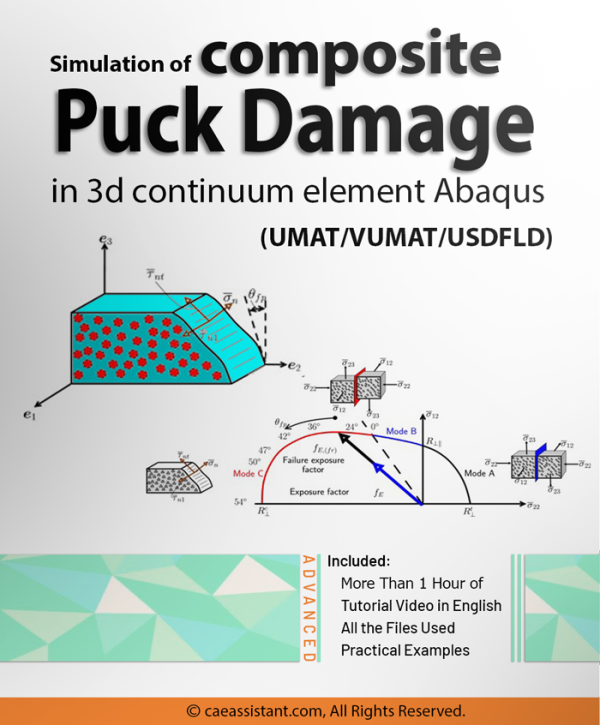

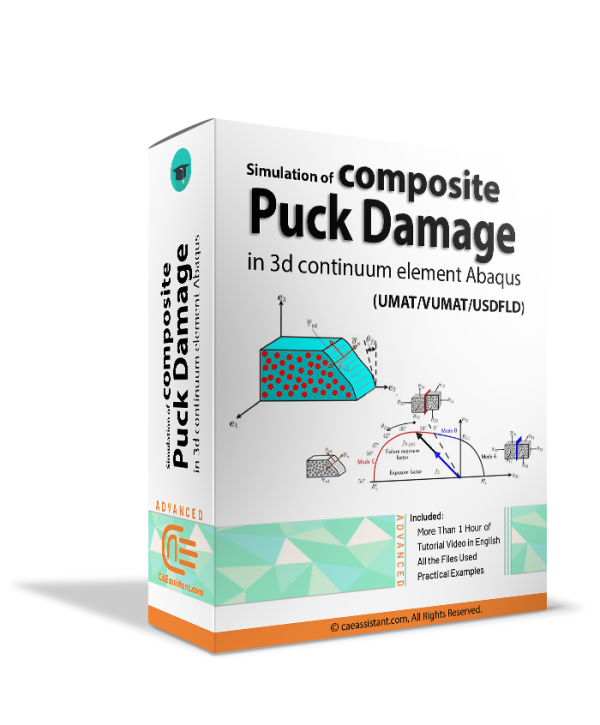

Simulation of composite Puck damage in 3d continuum element in Abaqus (UMAT-USDFLD-VUMAT)

Simulation of woven composites damage in Abaqus

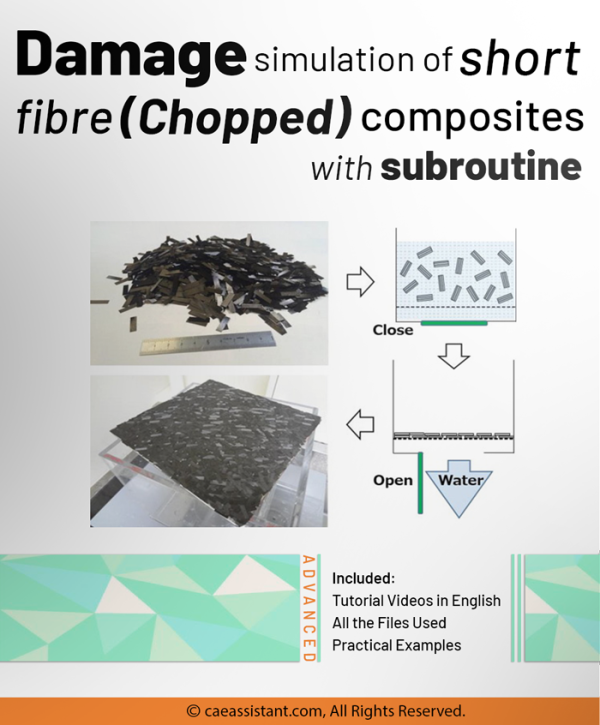

Damage simulation of short fibre composites with subroutine

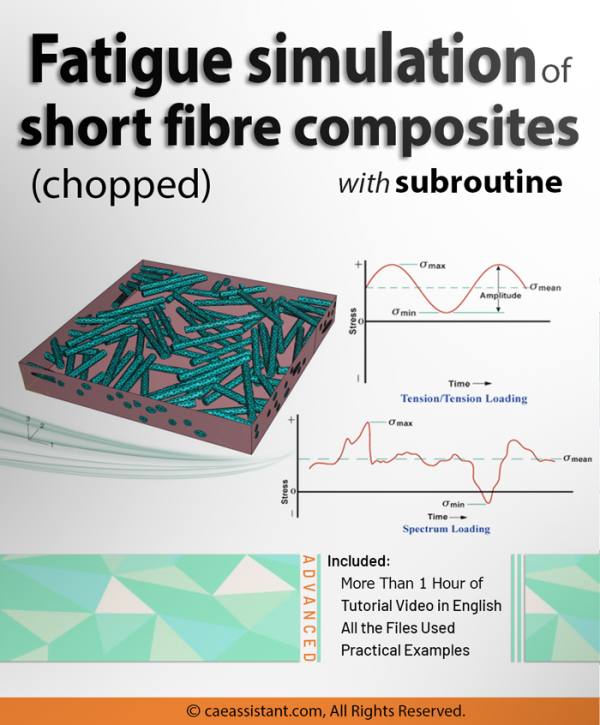

Fatigue damage simulation of short fibre composites with subroutine

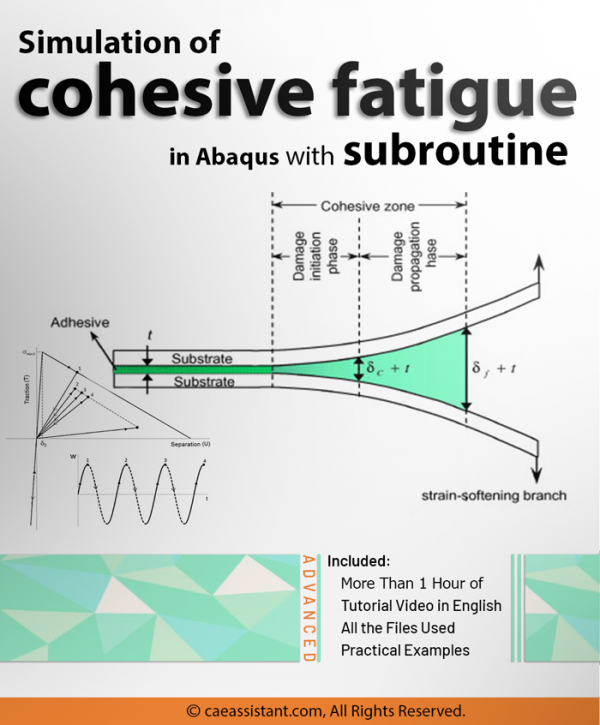

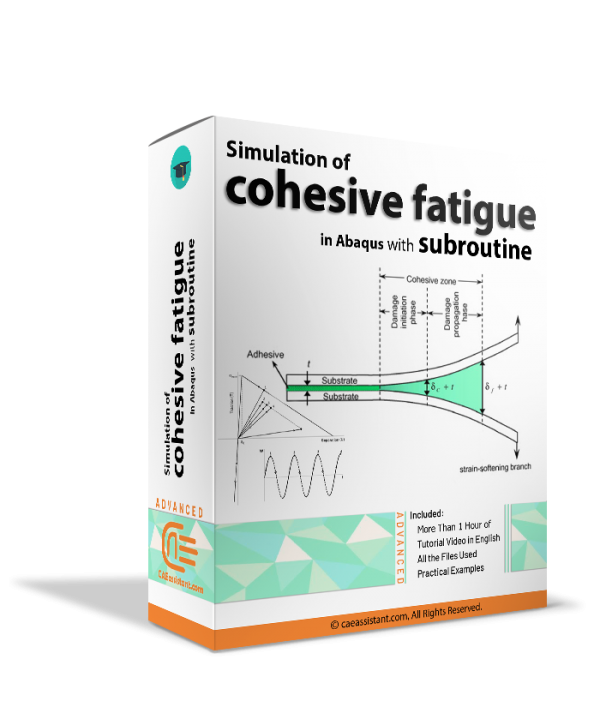

Simulation of cohesive fatigue in Abaqus with subroutine

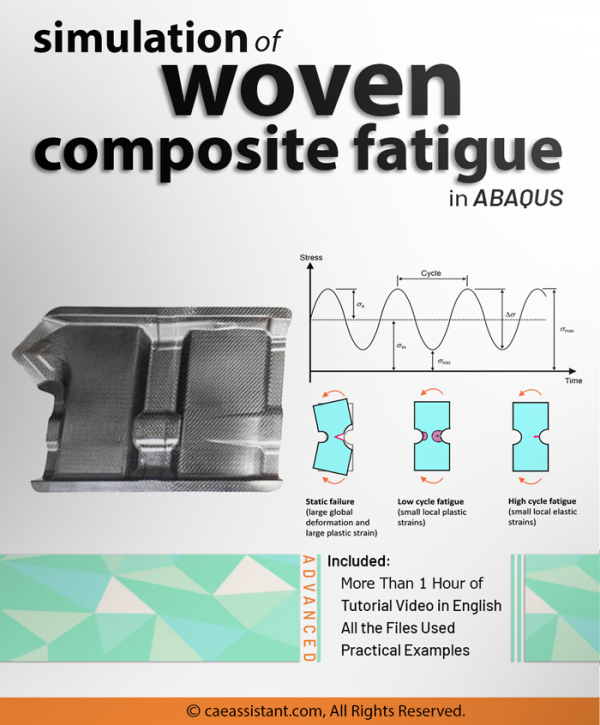

Simulation of woven composite fatigue in Abaqus

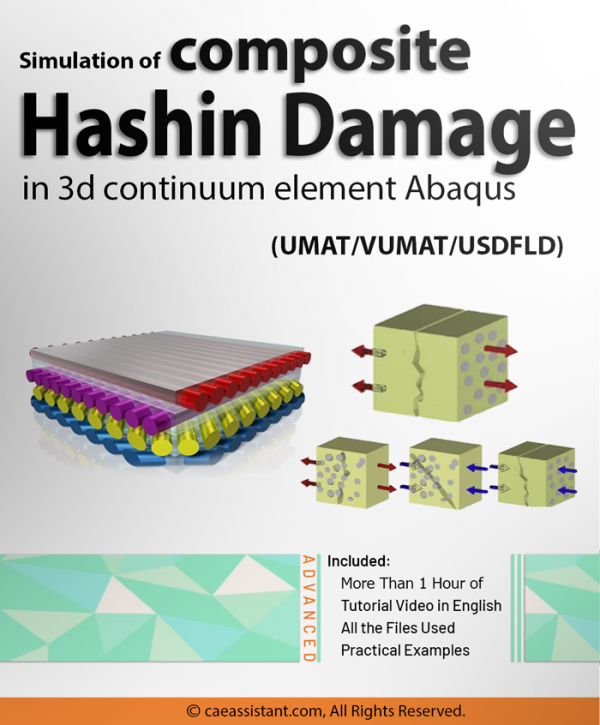

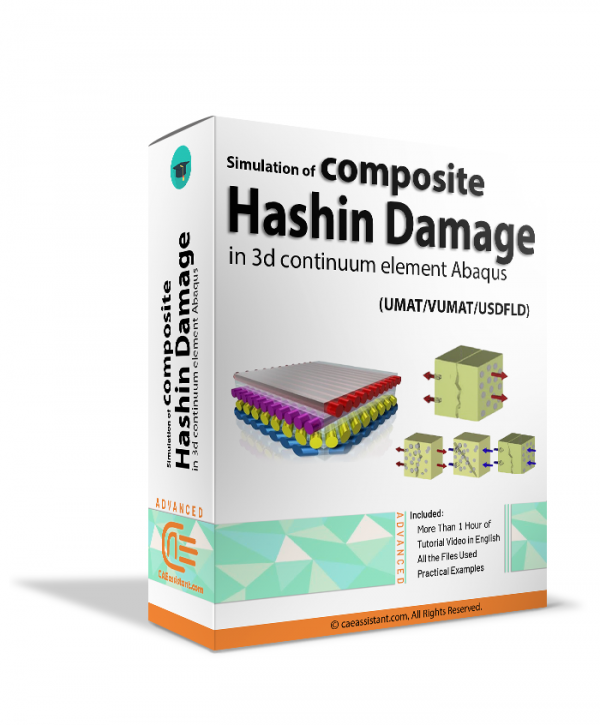

Simulation of composite Hashin damage in 3d continuum element in Abaqus (UMAT-VUMAT-USDFLD)

Composite simulation for experts-Part-1

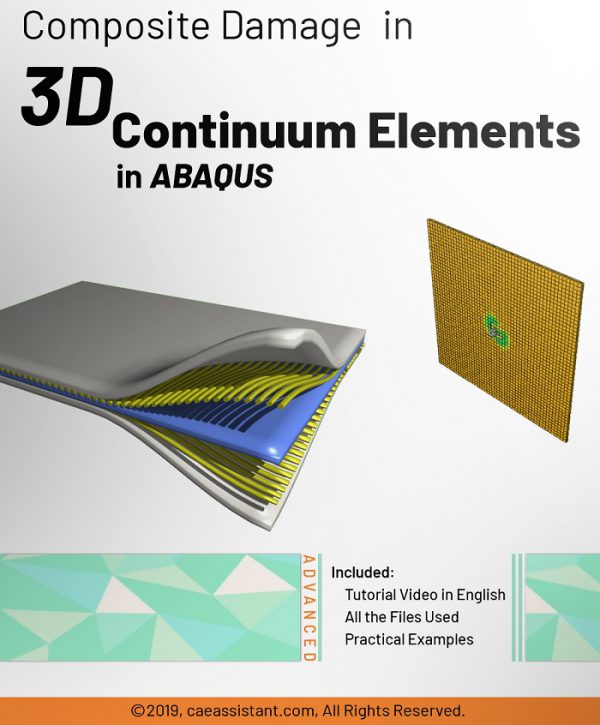

3D continuum Abaqus HASHIN progressive Damage for composite materials (VUMAT Subroutine)

The Hashin failure criteria is a set of failure criteria developed specifically for composite materials. It predicts different failure modes in composites based on the stresses experienced by their constituents (fiber and matrix). The criteria are widely used in engineering and computational models to assess composite material performance under mechanical loading. The criteria, while highly efficient and widely used, pose challenges when implemented in numerical simulations. Abaqus has emerged as a powerful tool to address these challenges, enabling the prediction of damage initiation and its progression (via stiffness reduction) based on the Hashin criteria. However, a key limitation of Abaqus is its applicability being restricted to 2D plane stress elements. To overcome this limitation, we developed a VUMAT subroutine in this project. This custom subroutine extends the capabilities of Abaqus, allowing for the simulation of damage initiation and propagation in 3D problems in accordance with the Hashin criteria. It should be mentioned that this subroutine includes gradual progressive damage based on the energy method. This complex subroutine could be used for static and dynamic problems.

A notable point is that in one of our other packages, we also provide training on using Abaqus subroutines to analyze the Hashin criterion. However, in that package, damage occurs instantaneously. In the current package, we have modeled the progressive Damage, which is more complex but could be more beneficial for solving your specific problems.

Composite Fatigue Simulation with UMAT Subroutine in ABAQUS (unidirectional)

Simulation of Unidirectional Composite Damage in ABAQUS

Abaqus composite modeling of Woven & Unidirectional + RVE method

This training package provides comprehensive basic information and examples on for composite modeling in ABAQUS FEM software in accordance with subsequent packages. The methods of modeling these materials are in two ways: micro and macro, which vary according to the type of material selected and how they are used. Next packages focus on two modeling types professionally.

Implementation of Cohesive by interaction & element based methods in ABAQUS

This package teaches you how to choose the method and apply cohesive modeling for various simple and complex problems. The training package also teaches you how to define the basic geometry of the adhesive elements and how to define the mechanical behavior in elastic and damaged regions in ABAQUS FEM software.