Simulation and analysis of a 6-cylinder V engine with MSC Adams

€ 100.0

A 6-cylinder V engine is a type of internal combustion engine that features six cylinders arranged in a V-shaped configuration. This design allows for a more compact and efficient engine compared to traditional inline configurations. The cylinders are typically divided into two banks, each with three cylinders, set at an angle to each other.

The V configuration provides a more balanced and smoother operation, reducing vibrations and improving overall performance. This engine layout is commonly used in a variety of vehicles, including cars, trucks, and SUVs, due to its combination of power, efficiency, and smooth operation.

| Expert | |

|---|---|

| Package Content |

.inps,video files, Fortran files (if available), Flowchart file (if available), Python files (if available), Pdf files (if available) |

| Tutorial video duration |

25 minutes |

| language |

English |

| Level | |

| Package Type | |

| Software version |

Applicable to all versions |

| Subtitle |

No subtitle |

MSC Adams is a powerful multibody dynamics simulation software that can be very useful for simulating and analyzing the behavior of a 6-cylinder V engine. Here are some ways in which MSC Adams can be utilized for this purpose:

Key Points:

- Dynamic Analysis: in ADAMS you can Create a detailed model or import an existed one to analyze performance, vibration characteristics, and stress distribution within the engine components.

- Motion Analysis: Simulate the motion of engine components during operation to understand interactions and functionality.

- Durability Analysis: Perform durability assessments under various load conditions to identify areas of stress, fatigue, and wear for design optimization.

- Optimization: Utilize optimization capabilities to fine-tune design parameters for improved performance, efficiency, and other desired characteristics.

- Virtual Testing: Conduct virtual tests under different operating conditions to evaluate performance, reliability, and efficiency without physical prototypes.

Workshop 1: simulation and analysis of a 6-Cylinder V engine in MSC Adams

This tutorial will instruct you on how to utilize MSC Adams software to predict the behavior of a 6-cylinder V engine by defining motion parameters for it.

Here are the 5 main steps

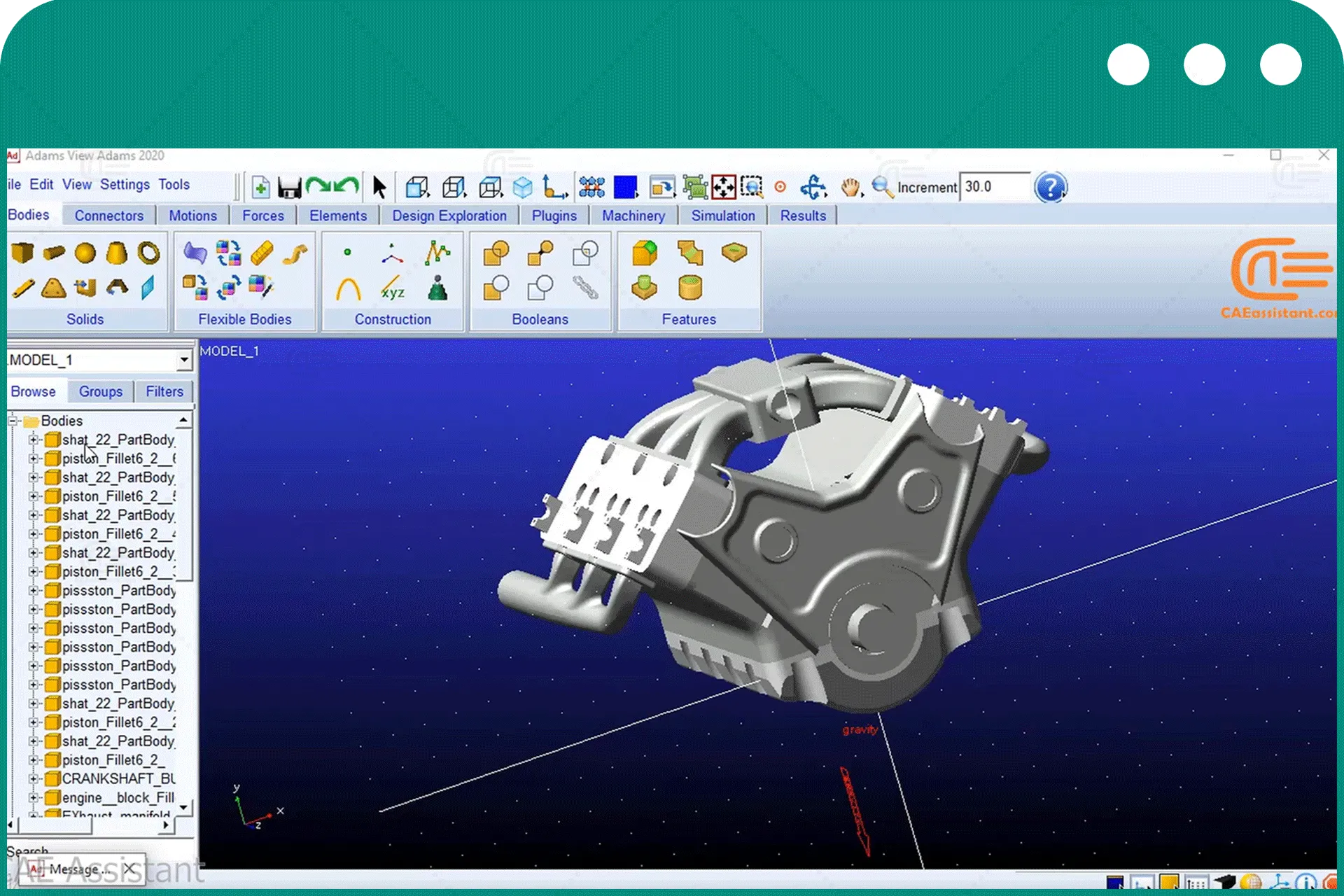

- Importing the Model: To begin, import the provided model into MSC ADAMS that we created beforehand. This step is essential to initiate the entire process and set the foundation for simulating the 6-cylinder V engine.

- Defining Materials: Next, define the materials for each part of the engine within ADAMS. This step allows us to specify the material properties for accurate simulation and realistic behavior of the engine components.

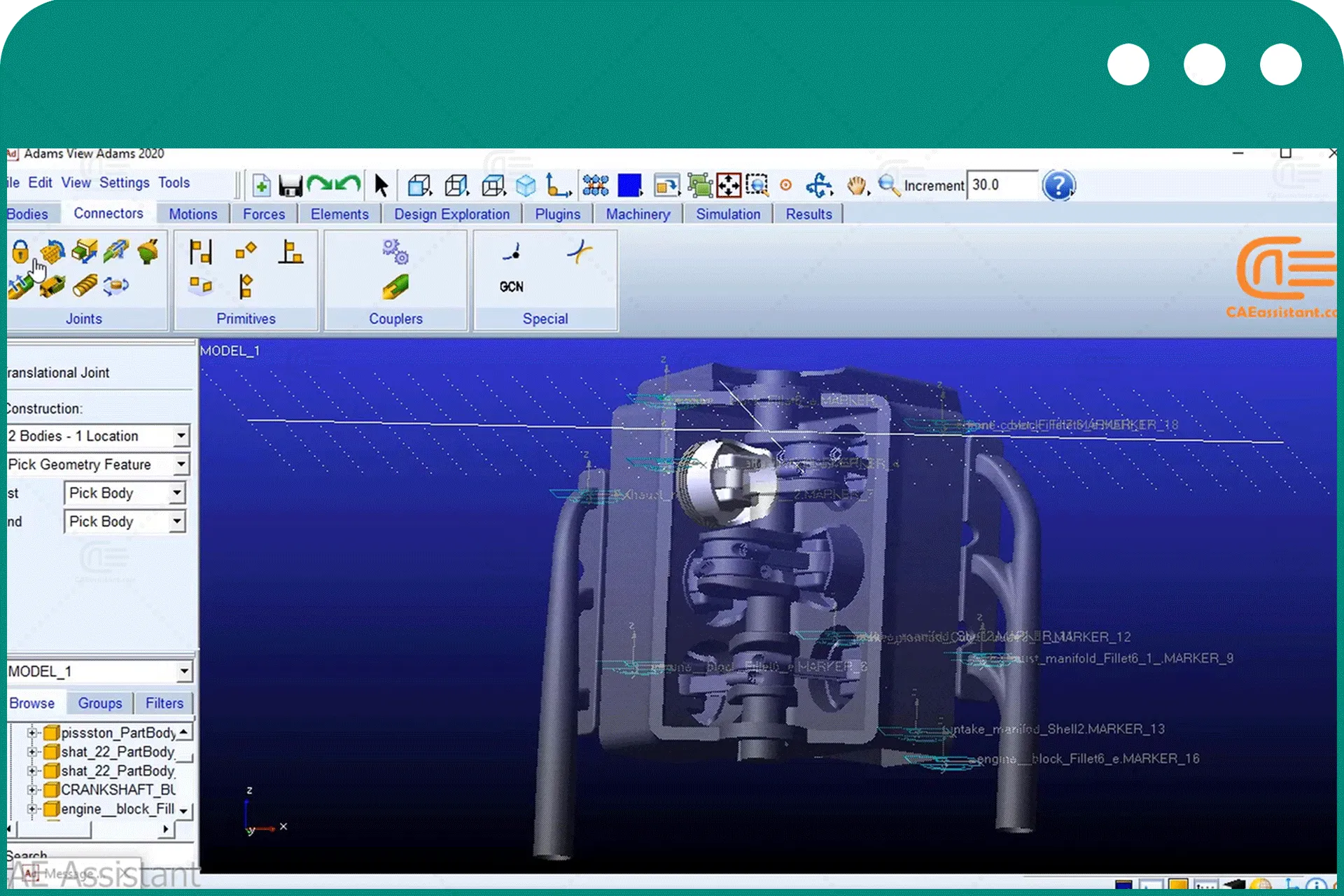

- Applying Joints: After identifying the engine in MSC ADAMS and defining materials, create joints to bond the various parts together. These joints play a crucial role in ensuring the proper movement and interaction of the engine components during the simulation. This can be done in connectors section.

- Simulation Illustration: In this stage, after applying the motion, the simulation of the 6-cylinder V engine is demonstrated. Watch as the parts move consecutively and along each other, showcasing the dynamic behavior of the engine in action.

- Analysis and Plots: Finally, analyze the simulation results and generate plots to understand the performance of the engine model. This step provides valuable insights into the functionality and efficiency of the simulated 6-cylinder V engine.

- Introduction and problem description

- Description of modeling steps

- Result and plots

All the package includes Quality assurance of training packages. According to this guarantee, you will be given another package if you are not satisfied with the training, or your money is returned. Get more information in terms and conditions of the CAE Assistant.

All packages include lifelong support, 24/7 support, and updates will always be sent to you when the package is updated with a one-time purchase. Get more information in terms and conditions of the CAE Assistant.

Notice: If you have any question or problem you can contact us.

Ways to contact us: WhatsApp/Online Support/Support@CAEassistant.com/ contact form.

Projects: Need help with your project? You can get free consultation from us here.

- Online payment: with MasterCard, VisaCard and etc.

- Offline payment: In this payment method, you should pay via PayPal and send your payment receipt as an attached file in the offline payment form.

- via download link After purchase, a download link will be sent to you a zip file included training videos, documents and software files.

- Send us your machine ID

To access tutorial video run the .exe file on your personal pc and send the generated code to shop@caeassistat.com and wait for your personal code, which is usable only for that pc, up to 24 hours from CAE Assistant support.

Here you can see the purchase process of packages: Track Order

You must be logged in to post a review.

Reviews

Clear filtersThere are no reviews yet.