Introduction to Steel-Fiber Reinforced Concrete (SFRC Concrete)

Steel-Fiber Reinforced Concrete (SFRC) is an advanced composite material that significantly enhances the structural properties of traditional concrete by incorporating steel fibers into the concrete matrix. These steel fibers, which are dispersed throughout the concrete, provide reinforcement against cracking, thus improving the material’s toughness and ductility. This makes SFRC Concrete particularly valuable in construction projects where durability and resistance to dynamic forces, such as seismic activity, are paramount.

In regions prone to earthquakes, the superior mechanical properties of SFRC concrete—such as its ability to absorb and dissipate energy—make it an ideal material for critical infrastructure. The integration of steel fibers allows the concrete to resist the initiation and propagation of cracks, which is vital for maintaining the integrity of structures during seismic events.

Importance of Analysis for SFRC Members

Analysis is an essential process in the design of structures that must withstand the forces generated by different loads. For SFRC members, such as beams, this analysis is particularly critical because these structural elements bear the applied Loads during seismic events. Understanding how SFRC beams respond to different loads allows engineers to design structures that are not only safe but also resilient over time.

Applying different loads to structures can lead to the introduction of complex stress states within SFRC beams. That is to say, these stresses may lead to fatigue, progressive cracking, and eventual failure if not adequately addressed in the design phase. Through analysis, engineers can predict how SFRC beams will behave under such conditions, ensuring that the designs incorporate the necessary safety factors and material properties to prevent catastrophic failure.

Predictive Methods for SFRC Behavior

Predicting the seismic performance of SFRC concrete beams can be approached using both experimental and numerical methods. Each method offers unique insights and has its own set of advantages and limitations.

Experimental Methods:

Experimental methods involve the physical testing of SFRC beams under controlled conditions to observe their behavior under simulated seismic loads. This approach provides direct and tangible data, which is invaluable for understanding the actual performance of the material. Through experiments, engineers can observe crack patterns, measure load capacities, and assess the energy dissipation properties of SFRC concrete beams. These insights are critical for validating theoretical models and ensuring that the assumptions made in the design process are accurate.

However, experimental testing can be resource-intensive. The costs associated with fabricating test specimens, setting up testing rigs, and conducting the tests themselves are often substantial. Additionally, the scale and scope of experiments are typically limited, meaning that only a finite number of scenarios can be tested. This limitation makes it difficult to generalize the findings to all possible real-world situations.

Numerical Methods:

Numerical methods, particularly finite element analysis (FEA), offer a complementary approach to experimental testing. Using software tools like Abaqus, engineers can create detailed models of SFRC concrete beams that simulate their behavior under seismic loads. These models take into account various factors, including material properties, geometric configurations, and boundary conditions, to predict how the beams will perform.

One of the primary benefits of numerical methods is their flexibility. Engineers can easily modify the model parameters to explore different design scenarios, load conditions, and failure mechanisms. This capability allows for a more comprehensive analysis than what is typically possible with physical testing alone. Moreover, numerical simulations can be conducted at a fraction of the cost and time required for experimental methods.

However, the accuracy of numerical methods depends heavily on the quality of the input data and the assumptions made in the model. Inaccurate material properties, inappropriate boundary conditions, or oversimplified assumptions can lead to significant discrepancies between the predicted and actual performance of SFRC concrete beams. Therefore, it is crucial to validate numerical models against experimental data to ensure their reliability.

Moreover, the results from both experimental and numerical analyses show that SFRC concrete beams have a more gradual failure mode compared to traditional concrete beams. This gradual failure provides an additional safety margin, giving occupants more time to evacuate in the event of a severe earthquake.

Benefits and Limitations of Experimental and Numerical Methods

Based on the provided details, both experimental and numerical methods play crucial roles in understanding the performance of SFRC concrete beams. In conclusion, we have briefly discussed their limitations and benefits below.

Benefits of Experimental Methods are:

- Provide direct, observable data.

- Allow for the assessment of actual failure mechanisms.

- Enable validation of theoretical and numerical models.

Limitations of Experimental Methods are:

- High cost and time requirements.

- Limited scope, as only a few scenarios can be tested.

- Requires specialized equipment and expertise.

Benefits of Numerical Methods are:

- Cost-effective and time-efficient.

- Flexible, allowing for the exploration of various scenarios.

- Useful for large-scale analysis that is impractical to test experimentally.

Limitations of Numerical Methods are:

- Dependent on the accuracy of input data and model assumptions.

- Validation against experimental data is required to ensure reliability.

Based on the provided details, both experimental and numerical methods have their own limitations and benefits. In conclusion, the best approach is to use both methods together to analyze a problem in an accurate and reliable manner.

Abaqus, a Powerful tool for the Analysis of SFRC Beams

Abaqus is one of the most powerful tools for simplifying the numerical analysis of various problems in an accurate manner. That is to say, one of the fields where Abaqus has demonstrated significant capability is the analysis of concrete structures, including Steel Fiber Reinforced Concrete (SFRC). To achieve this, Abaqus offers a variety of material models, including the shear crack model, brittle crack model, and the Concrete Damage Plasticity (CDP) model. Additionally, Abaqus provides different solvers, such as the well-known Static-General and Explicit solvers, which offer various options for the analysis of concrete specimens. Consequently, we have utilized this software for the analysis of SFRC beams in this project.

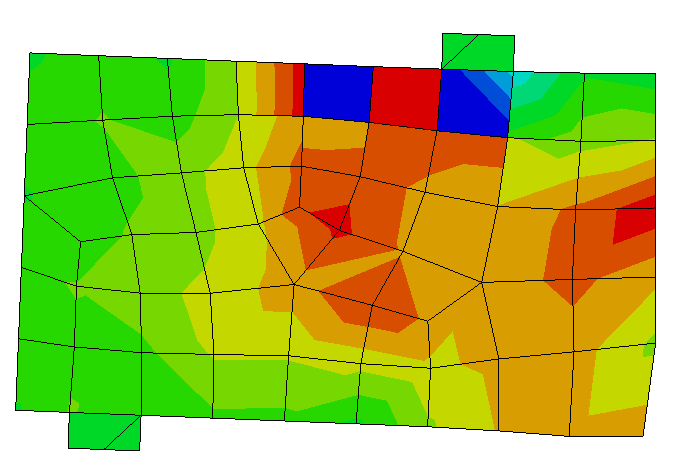

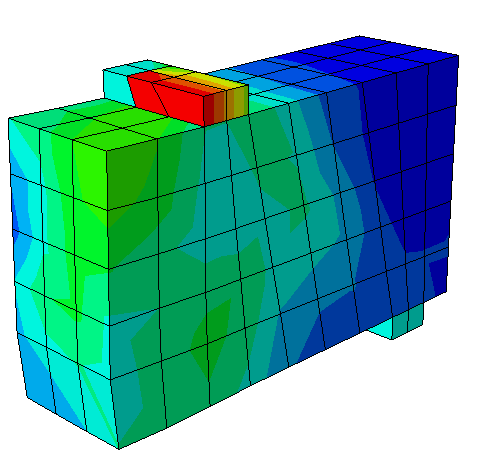

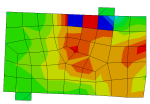

Details of the Abaqus implementation in this project

In this project, we used Abaqus with both 2D and 3D models to analyze the behavior of SFRC beams. The model was considered in a two-dimensional space to minimize computational costs. However, the 3D model represents more accurate results. To analyze the behavior of concrete, both shear crack and brittle crack criteria were considered to capture the nonlinear behavior of concrete using Abaqus’s built-in material model libraries. To define this behavior, we used two well-known concrete nonlinear models: one introduced by Lok and Pei in 1998, and the other by Lok and Xiao in 1999. The titles of their papers are as follows:

- Flexural Behavior of Steel Fiber Reinforced Concrete

- Flexural Strength Assessment of Steel Fiber Reinforced Concrete

The models are provided to represent the nonlinear behavior of SFRC specimens, and for simplification in this project, we have considered SFRC beams to be homogeneous.

To solve the problem, a challenge is choosing between Explicit and General Static solvers. While the General Static solver is preferred over the Explicit one due to its ability to check the convergence of the solution, there is no guarantee that the solution will converge in nonlinear problems, and the step may fail to solve. To address this, we have used the Explicit step here.

Key Results from Seismic Analysis of SFRC Beams

The analysis of SFRC beams yields several important findings that highlight the material’s potential in earthquake-resistant construction. SFRC beams demonstrate superior energy absorption and dissipation capabilities compared to traditional reinforced concrete beams. This is largely due to the presence of steel fibers, which bridge cracks and prevent their propagation, allowing the beam to maintain its load-carrying capacity even after significant deformation.

Another key finding is the enhanced ductility of SFRC beams. Ductility is a critical property in seismic design, as it allows structures to undergo large deformations without failing. SFRC beams can sustain greater deformations than conventional concrete beams, reducing the likelihood of sudden, catastrophic failure during an earthquake. This ductility, combined with the material’s toughness, makes SFRC an ideal choice for structures that need to withstand the unpredictable and often severe forces generated by seismic events.

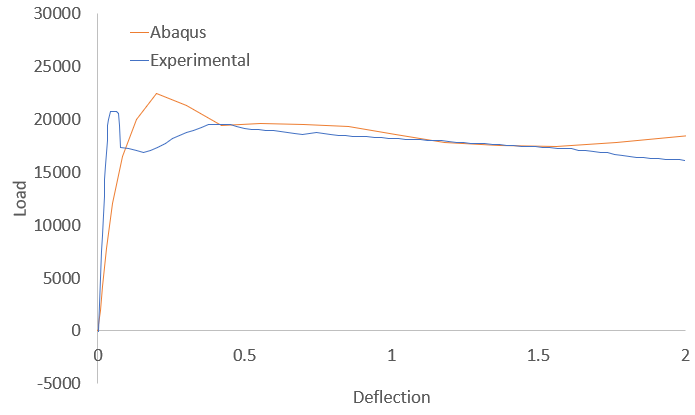

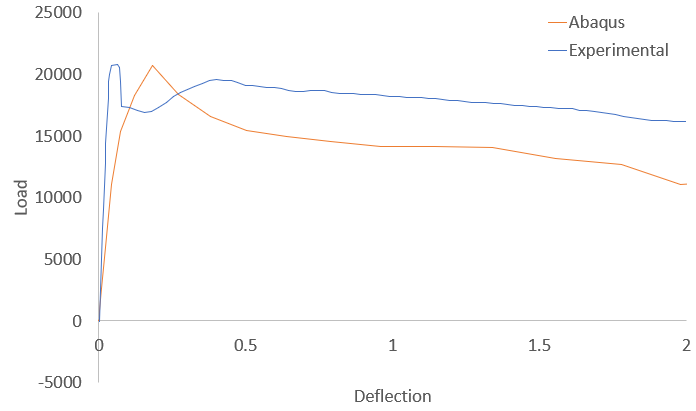

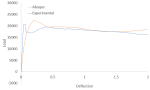

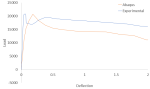

You can use the project to analyze and examine the mentioned subjects through numerical simulation in Abaqus without the need for experimental tests. However, to verify the accuracy of the method, we applied it to analyze the behavior of concrete beams in the paper “Toughness Characterization of Steel‐Fiber Reinforced Concrete”. We then extracted the load-displacement curve and compared it with experimental data.

Who Benefits from This Project?

The insights that can be gained from analysis of SFRC beams are invaluable to various stakeholders within the construction and engineering industries.

Structural Engineers benefit from having a deeper understanding of how SFRC behaves under different loads. Accordingly, this knowledge allows them to design safer, more resilient structures that can withstand the forces generated by earthquakes.

Construction Companies can utilize SFRC in their projects to achieve higher durability and longer service life, particularly in earthquake-prone regions. This can lead to significant cost savings in terms of maintenance and repair over the life of the structure.

Researchers and Academics can build on the findings from seismic analysis to further explore the potential of SFRC and other advanced materials in structural applications. This can lead to innovations in material science and engineering design.

Policymakers and Building Code Regulators can use the results of seismic analysis to update and refine building codes and standards. Accordingly, by incorporating the latest research, they can ensure that new structures are built to withstand the challenges posed by seismic activity, ultimately protecting public safety.

Reviews

Clear filtersThere are no reviews yet.