1. Introduction

In the field of material science and civil engineering, the application of recycled materials is gaining momentum. Notably, this includes the use of steel fibers recycled from used tires to reinforce concrete, a material known as Steel Fiber Reinforced Concrete (SFRC). in particular, this simulation presents a comprehensive study that delves into the stress-strain characteristics of SFRC utilizing these recycled fibers. It highlights the experimental methods, analytical techniques, and finite element analysis (FEA) employed to understand and optimize the material’s performance. Additionally, the training provides valuable insights into the potential of using recycled steel fibers in concrete. Finally, it includes an Abaqus simulation, emphasizing the relevance of this approach for sustainable construction practices.

2. Properties of Materials: Applications and Importance in Industry

Steel Fiber Reinforced Concrete (SFRC) with Recycled Steel Fibers

Steel Fiber Reinforced Concrete (SFRC) significantly enhances concrete’s tensile strength, ductility, and flexural performance by incorporating steel fibers. Specifically, these fibers are randomly distributed throughout the concrete. As a result, they improve toughness by arresting crack propagation. Additionally, this enables the material to sustain higher loads even after initial cracking. SFRC is particularly effective in applications with flexural stress, like slabs, pavements, and beams. also, SFRC is effective in seismic regions requiring durability and energy absorption.

Its enhanced properties make SFRC ideal for industrial floors, airport runways, and tunnel linings, offering superior crack resistance and load-bearing capacity. In other words, SFRC significantly improves the strength and longevity of concrete structures. This is especially true in demanding environments.

Recycled steel fibers (RSF) are obtained through pyrolysis or shredding. Pyrolysis heats steel cords from tires without oxygen, preserving the steel’s integrity. This process results in consistent, high-tensile-strength fibers; on the other hand, some may have carbon residue. These fibers are ideal for uniform concrete reinforcement. Shredded steel fibers (SRSF) are mechanically broken down from tires. This process leads to less consistent size and shape, often with rubber residues. however, they still provide strong reinforcement, especially in applications prioritizing crack resistance over uniform strength.

3. Applications in Industry

SFRC is widely used in construction for its durability and toughness. It is especially common in industrial floors, pavements, precast elements, and tunnel linings, where it resists dynamic loads and cracking. consequently, the addition of recycled steel fibers enhances tensile strength and structural integrity while also addressing economic and environmental concerns by reducing the need for virgin steel. The performance of SFRC with recycled fibers matches that of conventional SFRC, making it a sustainable construction option.

4. Importance and Application of Stress-Strain Characteristics of SFRC Using Recycled Fibers

Understanding the stress-strain characteristics of SFRC is essential for predicting its behavior under various loading conditions. Also, the stress-strain curve of SFRC provides critical information on how the material responds to tensile stress. for instance, in the post-cracking phase, where the concrete’s ductility and toughness are tested.

Stress-Strain Behavior

The findings indicate that recycled fibers offer comparable performance in terms of tensile strength and toughness. This is especially true for PRSF. This is a crucial finding, as it suggests that recycled fibers can effectively replace traditional steel fibers in many applications.

The stress-strain curve of SFRC typically exhibits an initial linear elastic region, followed by a plateau where the material absorbs energy through crack propagation and fiber pull-out. moreover, the presence of steel fibers enhances the concrete’s ability to withstand higher stress levels beyond the elastic limit. That is to say, this is particularly true for fibers with high tensile strength. So, the concrete’s toughness and ductility are significantly improved.

Applications in Structural Design

Moreover, the stress-strain characteristics of SFRC are particularly important in structural design. The material’s ability to absorb energy and resist cracking is crucial. for instance, in the construction of industrial floors or pavements, where heavy loads and traffic are common, SFRC provides the necessary durability and crack resistance to extend the structure’s lifespan. Moreover, the use of recycled steel fibers further enhances the sustainability of these projects, making them both economically and environmentally beneficial.

5. Common Methods for the Analysis of Stress-strain characteristic of SFRC using recycled fibres

Consequently, understanding the stress-strain characteristics of Steel Fiber Reinforced Concrete (SFRC) with recycled fibers is crucial for evaluating structural performance. Key techniques include:

- Bending Test: Evaluates flexural behavior using notched concrete prisms in a four-point bending setup to minimize overestimation of bending resistance.

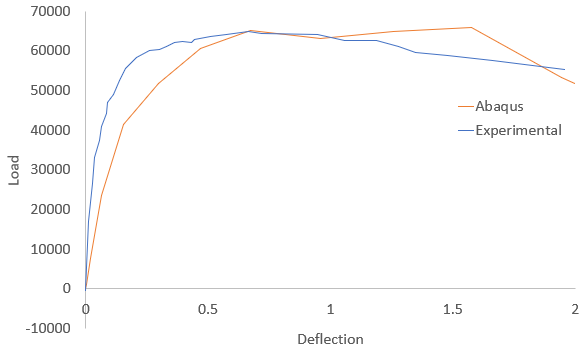

- Load-deflection analysis: it monitors the load-deflection behavior during bending tests. Also, it derives key parameters like the limit of proportionality (Fu). Therefore, calculates equivalent flexural tensile strengths (feq,2 and feq,3) and residual tensile strengths (fR,1 and fR,4).

- Crack Mouth Opening Displacement (CMOD): Measures crack propagation to assess how steel fibers bridge cracks and contribute to post-cracking strength.

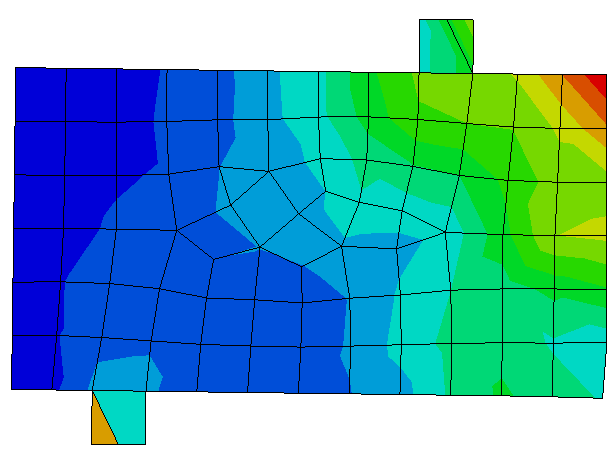

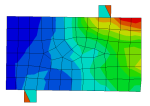

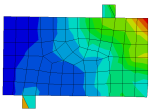

- Finite Element Analysis (FEA): Uses ABAQUS to simulate SFRC behavior, modeling stress-strain relationships and also validating experimental results, emphasizing the need for refined models.

- Strain and Neutral Axis Measurement: Assesses the neutral axis position and strain distribution within SFRC prisms, crucial for developing accurate stress-strain relationships and understanding structural behavior.

Zuhura –

This package was exactly what I needed for my SFRC beam analysis. The modeling of fibers and the concrete matrix worked flawlessly. The results were accurate, and I had no issues with the installation or setup. The documentation was comprehensive, making it easy to implement the necessary steps.

Laila –

This package offers everything I needed for my SFRC beam analysis. It’s user-friendly, powerful, and compatible with Abaqus, making it a great addition to my toolbox. The results were accurate, and I could easily simulate the impact of various fiber contents. The documentation was a huge help throughout the process.

Mosi –

This package allowed me to simulate steel fiber reinforced concrete beams with great accuracy. The process was straightforward, and the results were highly reliable. I particularly liked the ability to adjust fiber parameters to see their effects on beam performance. The results aligned well with experimental findings.