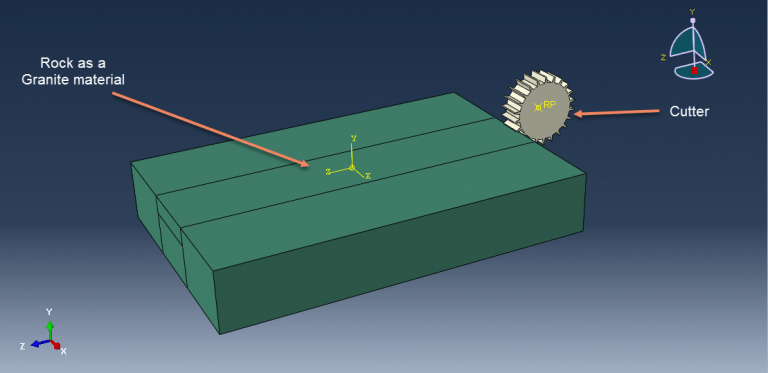

Introduction to tunnel excavation and Tunnel Boring Machines (TBMs)|Abaqus TBM modeling

Tunnel excavation refers to the process of creating underground passages or tunnels for various purposes such as transportation, mining, or utility installations. It involves the removal of soil, rocks, or other materials to create a hollow space.

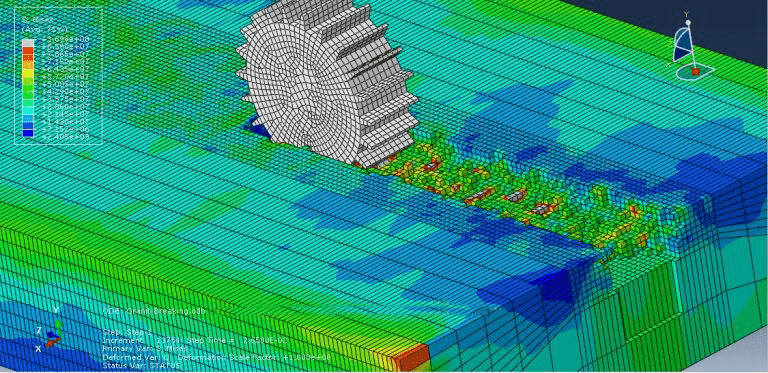

A tunnel boring machine (TBM) is a specialized piece of equipment used for tunnel excavation. It is a massive, self-contained machine that can excavate tunnels with remarkable efficiency. TBMs typically consist of a cylindrical cutting head equipped with disc cutters that grind through the soil or rock, while the excavated material is transported out of the tunnel through a conveyor system.

Notice: This package will be available one week after purchase.

The importance of analyzing and simulating the tunnel excavation process lies in several key aspects. First, it allows engineers to evaluate the feasibility and efficiency of tunneling projects before construction begins. By simulating the process, they can assess potential risks, estimate costs, and optimize the design and construction methodologies. Simulation also enables engineers to study the behavior of the TBM and its interaction with the ground. Factors such as ground conditions, geological formations, and water table levels can significantly impact the excavation process. By analyzing these variables through simulations, engineers can make informed decisions on the type of TBM to use, the excavation speed, and the necessary support systems. Furthermore, simulating tunnel excavation helps in predicting and mitigating potential hazards such as ground settlement, tunnel collapse, or water ingress. It allows engineers to identify potential issues in advance and design appropriate measures to ensure the safety and stability of the tunnel.

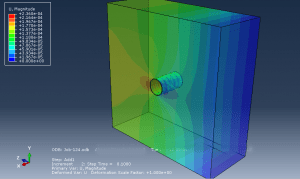

Workshop 1: TBM Tunneling simulation in Abaqus

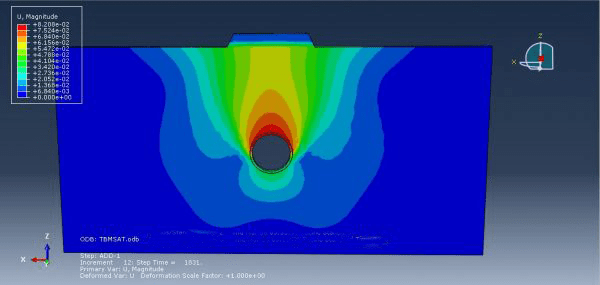

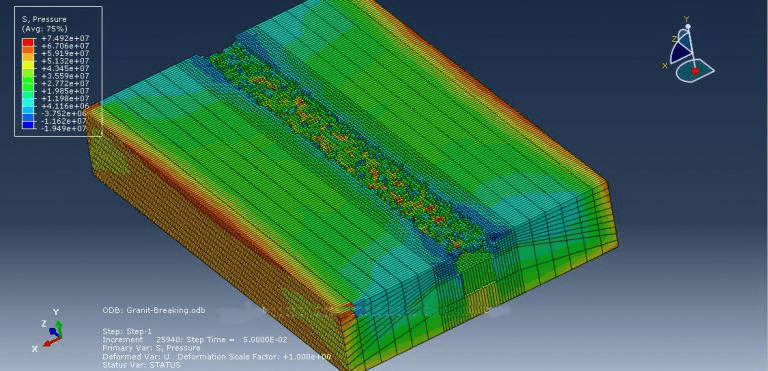

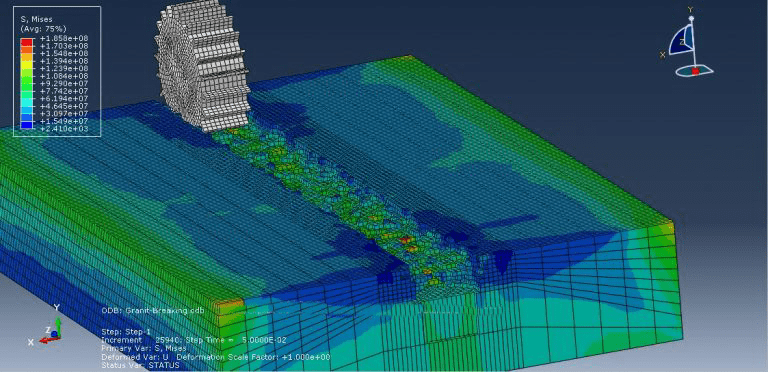

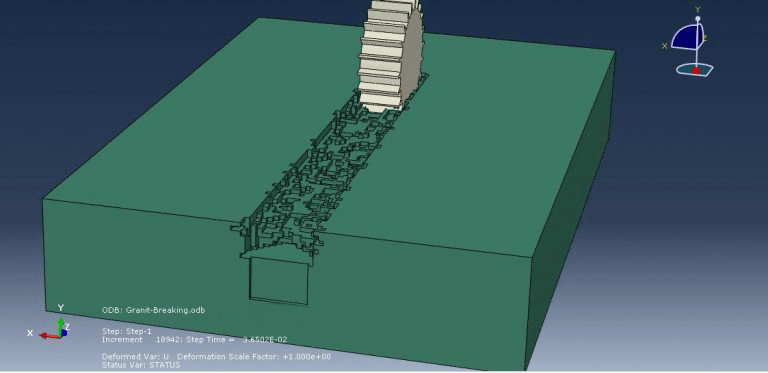

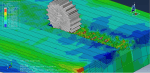

This tutorial provides a comprehensive demonstration of TBM (Tunnel Boring Machine) simulation in Abaqus. The video is in English and showcases the creation of two parts for analysis: the soil and the liner. The simulation consists of six stages. In each stage, the soil section is removed from the original model, and the liner section is added. The GEOSTATIC step is utilized to define the weight of the soil during the analysis.

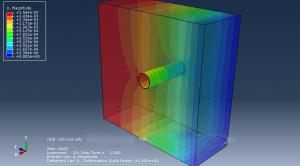

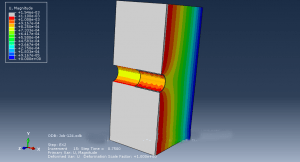

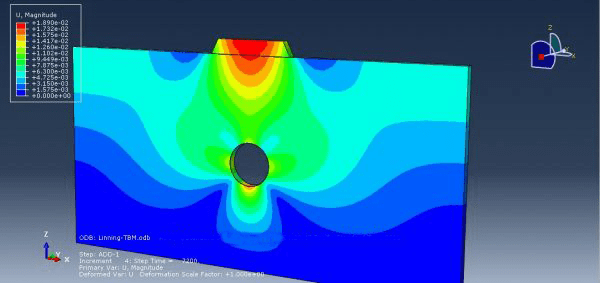

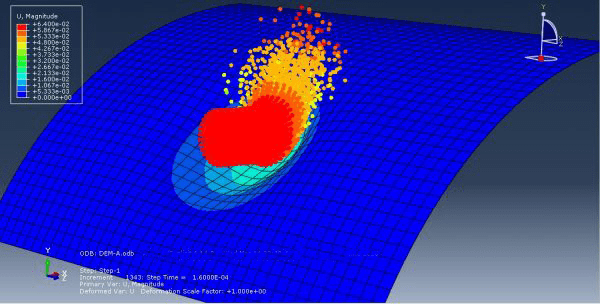

Workshop 2: TBM simulation into the saturate soil with dry mix

This tutorial provides a detailed demonstration of utilizing TBM (Tunnel Boring Machine) tunneling technique in Abaqus, specifically focusing on incorporating dry and saturated soil. The soil is represented as a three-dimensional component, divided into two distinct zones to represent the dry and saturated conditions using Mohr-Coulomb plasticity. Additionally, the lining is modeled as a three-dimensional shell composed of concrete material. The analysis consists of several stages: the first stage involves applying soil body force, the second stage involves excavation, the third stage involves relaxation, and finally, the fourth stage applies the lining. For this type of analysis, the soil transient step is deemed appropriate.

Dorota –

Our team is currently working on a project with the same title, aiming to reduce costs, and we encountered some issues during the simulation of the drilling stages. However, these problems were resolved using this package.

Experts Of CAE Assistant Group –

I am happy that this could solve your problem.

Charles –

This website discusses tunnel excavation simulation using TBM modeling in Abaqus software. Its comprehensive and clear explanations help engineers assess the feasibility and efficiency of excavation projects before construction begins. Additionally, tunnel excavation simulation aids in predicting and mitigating potential risks such as ground deformation, tunnel collapse, and water ingress.

Experts Of CAE Assistant Group –

Thanks for your clear explanation of our products