Tunnel simulation in Abaqus

Tunnels are essential components of infrastructure used for transportation, utility lines, and water pipelines. They are often located in harsh and unpredictable environments, making their safety and reliability critical for ensuring public safety and the smooth functioning of society.

Tunnel simulation in Abaqus is crucial for predicting the behavior of tunnels under different types of loading conditions, such as earthquakes, floods, or explosions. By using Abaqus, engineers can design and simulate tunnels of different shapes and sizes, and predict their response to various loading conditions.

The information obtained from tunnel simulation can be used to assess the safety and reliability of tunnels, identify potential failure modes, and develop strategies to mitigate risks. Additionally, Abaqus offers advanced modeling capabilities, such as contact modeling, to simulate the interaction between the tunnel and surrounding soil or rock. For example, if you want to do a damage analysis on tunnels subjected to explosion loading, the explosion material would be described by the JWL equation of state and the concrete tunnel will be modeled using the Johnson-Holmquist model. More detail are in the description of the workshops below.

Workshop 1: Damage analysis of an underground box tunnel subjected to surface explosion

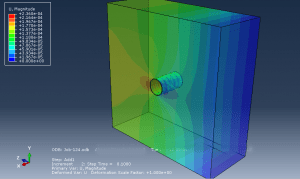

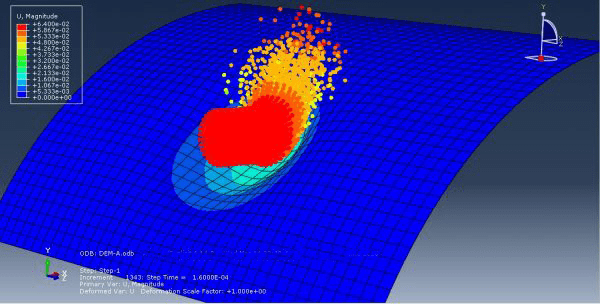

In recent times, the safety of tunnel structures has been significantly impacted by external terrorist activities due to the lack of adequate measures to detect such incidents in a timely manner and prevent them. To investigate the behavior of an underground box frame tunnel subjected to a surface explosion, a simulation was conducted using ABAQUS software. In this simulation, TNT waves were propagated through the air and soil using Explicit analysis, resulting in the creation of stress in the concrete tunnel.

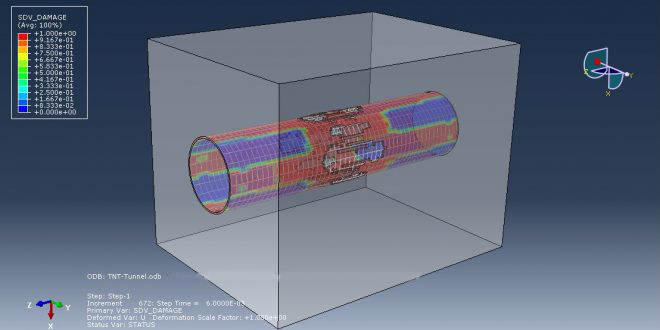

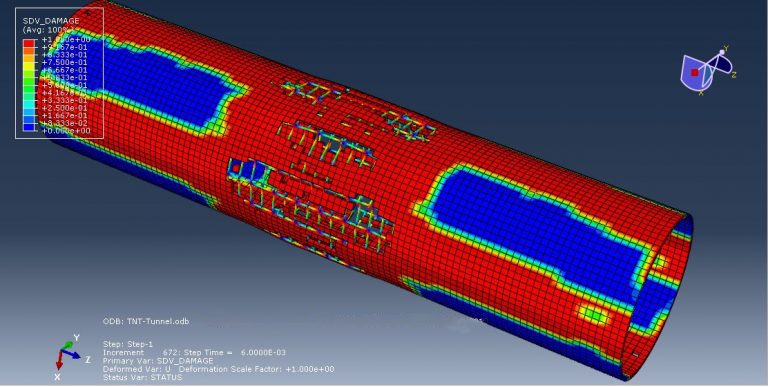

Workshop 2: Tunnel dynamic analysis subjected to internal blast loading using CEL method

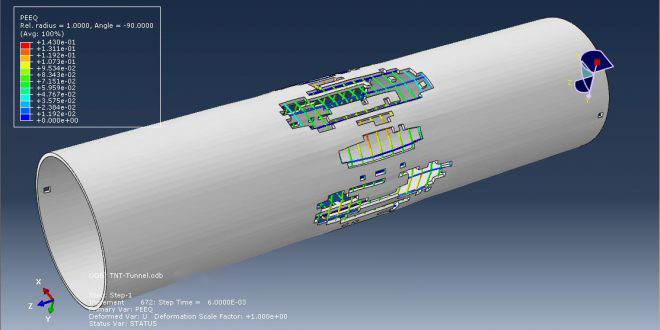

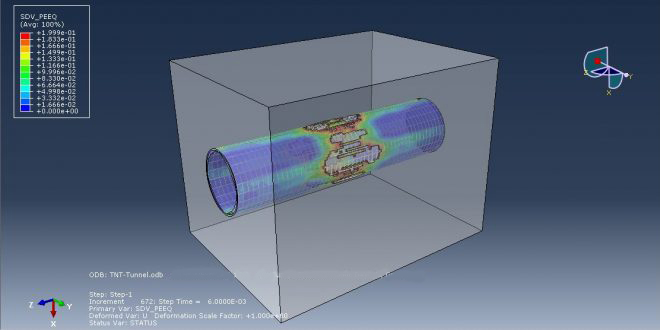

This tutorial uses the CEL method in Abaqus to explore the dynamic analysis of a soil tunnel subjected to internal blast loading. The concrete tunnel is modelled as a solid part, while the domain is represented by an Eulerian part. Additionally, the TNT and soil are modeled as solid parts, while the wire part represents the beam.

Underground tunnels, including roadways, railways, utility lines, and water pipelines, are essential components of civil infrastructure. However, in recent decades, the threat of explosion incidents caused by terrorist activities within these tunnels has increased, posing a significant risk to human safety. Internal explosions in tunnels can be particularly dangerous due to the multiple reflections of the shock wave on the tunnel walls, causing channeling of the shock wave. To protect tunnels from such incidents, it is necessary to design them to withstand blast loading, which requires a thorough understanding of their response to such loading, both experimentally and numerically. The current study focuses on advanced numerical analysis of tunnels subjected to blast loading, with the aim of improving their safety and resilience against potential terrorist threats.

In this study, the materials used for the beams, soil, TNT, and concrete tunnel were selected based on their specific properties. The beams were made of steel with elastic-plastic behavior and a ductile damage criterion, while the soil was modeled with elastic and Mohr-Coulomb plasticity. The TNT was described using the JWL equation of state, and the concrete tunnel was modeled using the Johnson-Holmquist model due to the high pressure and potential for failure. A dynamic explicit procedure was considered appropriate for this type of analysis. General contact was used for all contacts in the domain, and an embedded region was used for the beams inside the concrete host. The volume fraction method was used to determine the location and amount of TNT in the Eulerian model. Proper boundary conditions were assigned to the Eulerian domain and concrete tunnel. The mesh size had a significant effect on the results, and a smaller mesh size was deemed necessary.

Once the simulation is complete, all results, including variables such as concrete damage, stress, damage to beams, and strain, can be obtained.

It would be useful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial.

Freya –

Thank you for this insightful Tunnel Simulation course in Abaqus. It has been incredibly helpful in enhancing my understanding and utilization of the tunnel simulation capabilities within Abaqus. The course was concise, yet comprehensive, covering all the key concepts related to tunnel analysis and design. I would like to express my gratitude to the CAE Assistant team for delivering this excellent course.

Experts Of CAE Assistant Group –

Thanks. We are producing new packages in this field. I will let you know from official email when it is ready