Abaqus Examples: Your Learning Hub for FEA

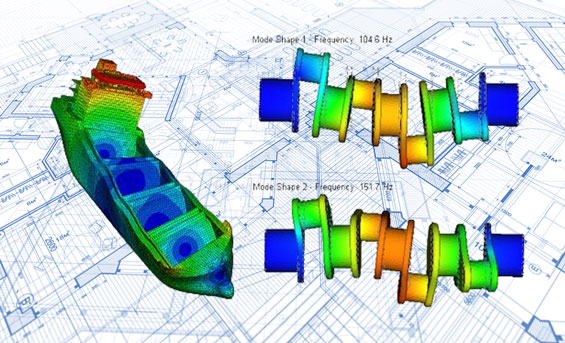

Whether you’re a student, engineer, or researcher, mastering Abaqus can open doors to powerful, real-world simulations in structural, thermal, and coupled field analysis. Here, we offer Abaqus examples designed to take you from the basics of finite element modeling to intermediate-level problem-solving techniques.

Our carefully curated content is meant to provide a step-by-step learning experience. With free video tutorials, Abaqus example problems, and downloadable Abaqus inp file examples, you’ll gain hands-on experience to build your skills confidently. Whether you are analyzing a simple beam or solving complex non-linear simulations, our examples are crafted to meet the learning needs of both beginners and intermediate users.

What You Will Find Here

- Abaqus Examples for Beginners: Start with simple Abaqus example problems to get familiar with the software’s interface, basic commands, and simulation setup. Learn how to create models, define materials, apply loads, and interpret results.

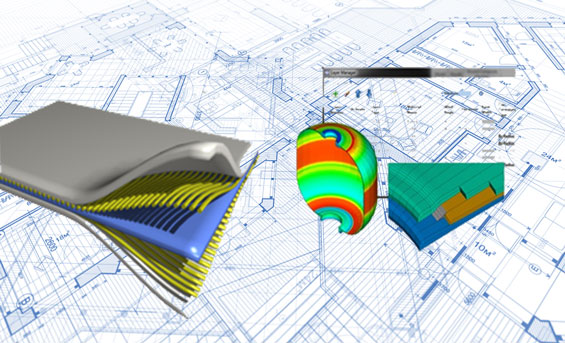

- Intermediate Abaqus Examples: For those looking to deepen their knowledge, our Abaqus example files cover more advanced topics, including non-linear analyses, contact problems, and dynamic simulations. Each example includes detailed instructions and downloadable input files to follow along.

- Hands-On Learning: We believe the best way to learn is through doing. That’s why we provide real-world scenarios, downloadable Abaqus inp file examples, and Abaqus example files to practice with. You can use these to test your own simulations, explore different approaches, and build up your portfolio of Abaqus skills.

What to Expect

By following our examples, you’ll learn how to:

- Create and modify 3D models in Abaqus.

- Set up and run static, dynamic, and thermal analyses.

- Understand and troubleshoot common Abaqus example problems.

- Use Abaqus inp file examples to streamline your workflow and automate tasks.

Our mission is to make learning Abaqus accessible to everyone, from students just starting their journey to engineers and researchers applying advanced simulation techniques. With our video tutorials and downloadable Abaqus example files, you’ll gain the knowledge and confidence to tackle a wide range of engineering challenges using Abaqus.

As the saying goes, ‘everything can be learned more easily with practical examples.’ That’s why we’ve provided eight free PDF files with comprehensive Abaqus example problems. Each file includes step-by-step explanations, figures, and practical examples to help you learn Abaqus effectively.

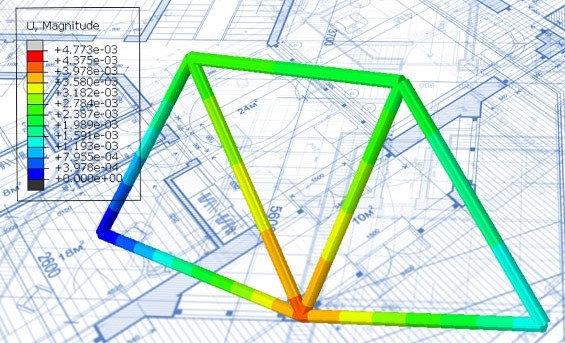

- First PDF: An overview of the Abaqus software with 2D and 3D truss example

- Second PDF: introduction to finite element analysis with an example “simulation of pipe buckling under external pressure”

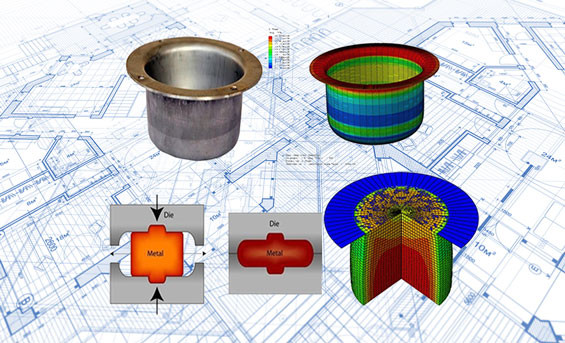

- Third PDF: Level up your skills with a “Deep drawing analysis”

- Fourth PDF: Learn about natural frequency with a simple “mass-spring” example

- Fifth PDF: Learn how to model composite materials in Abaqus with Analysis of a composite sheet with a hole.

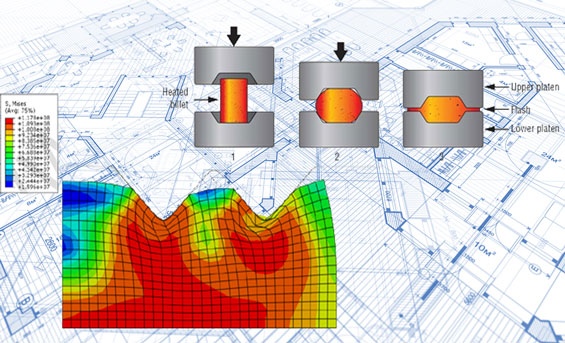

- Sixth PDF: Learn thermal analysis in Abaqus with a “Forging” problem and “Sheet deformation caused by welding”

- Seventh PDF: Lean impact analysis and ALE Adaptive mesh method

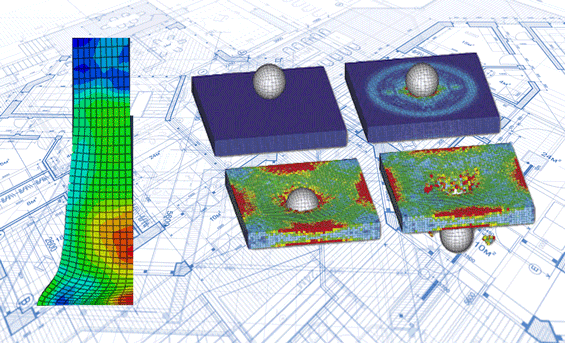

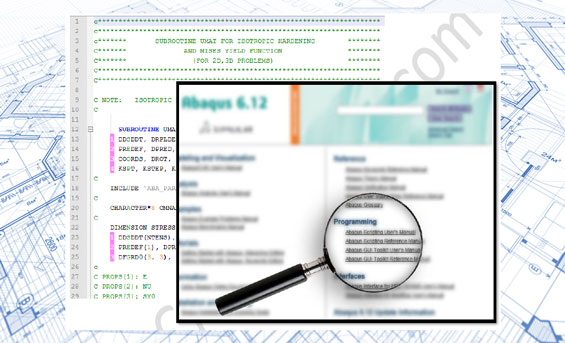

- Eighth PDF: Advanced Abaqus examples using subroutines

FREE ABAQUS TUTORIAL PDF

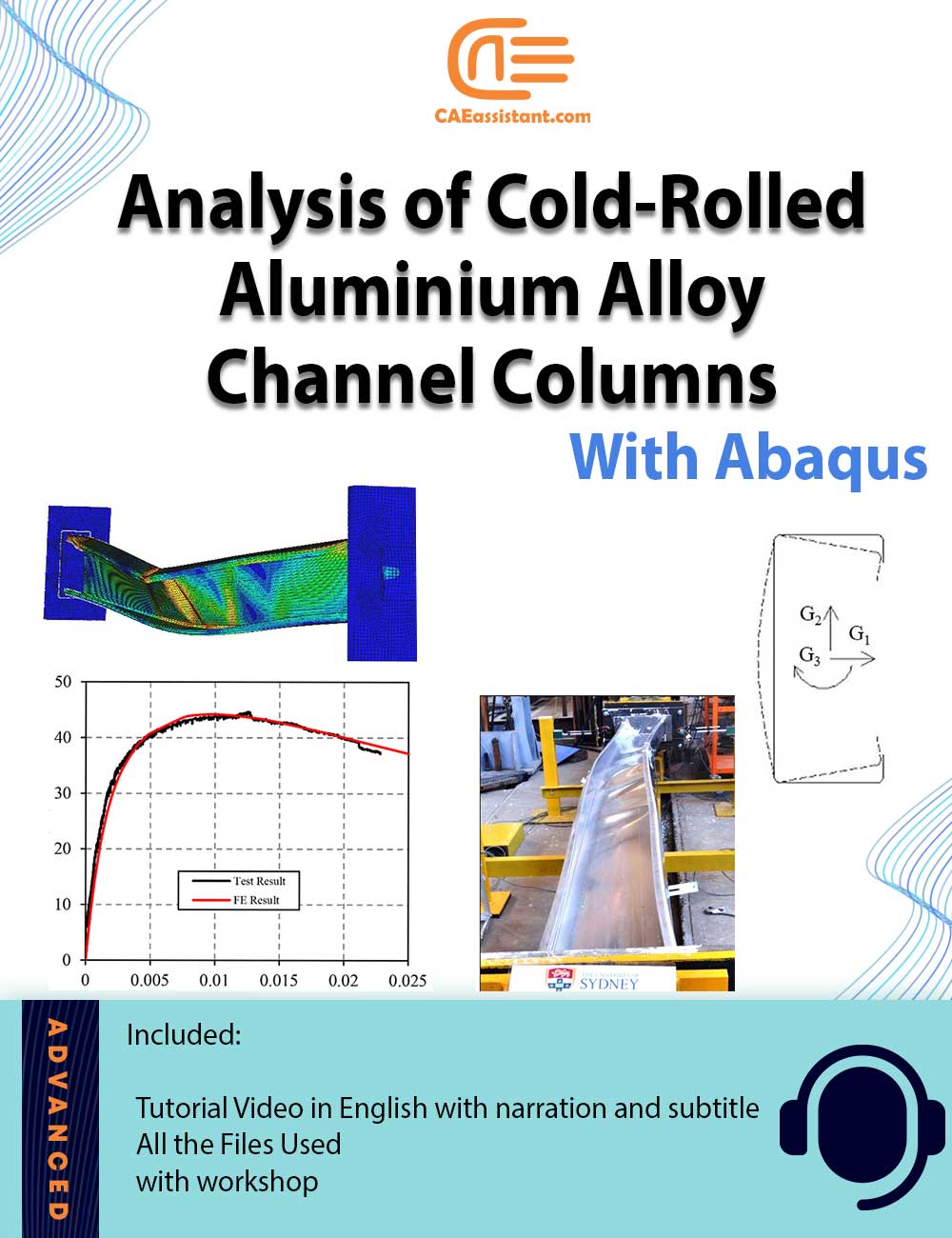

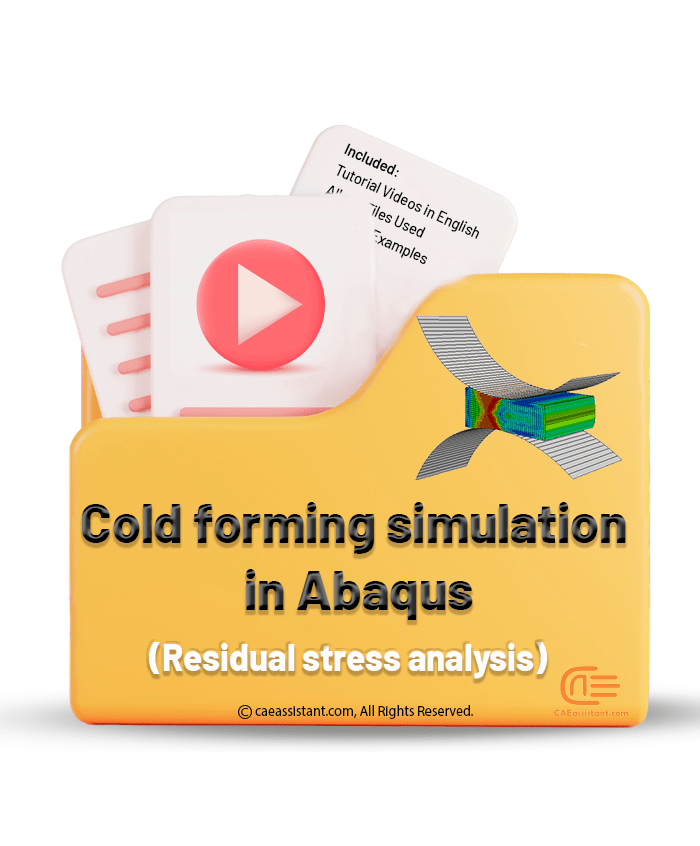

For forming process, we have these video tutorial packages:

We are proud to offer an extensive example bank filled with comprehensive simulation files and resources, as shown in the table below. This collection includes everything you need for high-quality Abaqus simulations. Browse through the list to find the example that suits your project needs, and simply send the code and title of your chosen example to our support team at support@caeassistant.com or reach out via our live chat. We’ll promptly provide you with the pricing and ensure you receive your files without delay. It’s that simple—explore, select, and get started with your simulation today!

| Num | Code | Title | Level | Software | status | |

|---|---|---|---|---|---|---|

| 1 | Abq-1 | Composite shear wall simulation | Beginner | Abaqus | Available | |

| 2 | Abq-2 | 3D crack Growth analysis with XFEM method | Beginner | Abaqus | Available | |

| 3 | Abq-3 | Crack growth analysis in bolt connection using XFEM method | Beginner | Abaqus | Available | |

| 4 | Abq-4 | Crack Simulation in the tank under internal and external pressure using DLOAD subroutine | Beginner | Abaqus | Available | |

| 5 | Abq-5 | Crack Simulation with Clasic Method | Beginner | Abaqus | Available | |

| 6 | Abq-6 | Simulation of 2D crack propagation with XFEM method | Beginner | Abaqus | Available | |

| 7 | Abq-7 | Analysis of 3D crack in tube with XFEM method | Beginner | Abaqus | Available | |

| 8 | Abq-8 | Simulation of Fatigue Crack growth with XFEM method | Beginner | Abaqus | Available | |

| 9 | Abq-9 | Heat transfer analysis using UTEMP subroutine | Beginner | Abaqus | Available | |

| 10 | Abq-10 | Simulation of heat transfer of welding process | Beginner | Abaqus | Available | |

| 11 | Abq-11 | Simulation of tooth implantation process | Beginner | Abaqus | Available | |

| 12 | Abq-12 | Blast Simulation next to a brick wall | Beginner | Abaqus | Available | |

| 13 | Abq-13 | 3D Heat Transfer in plate | Beginner | Abaqus | Available | |

| 14 | Abq-14 | Bike Brake Simulation | Beginner | Abaqus | Available | |

| 15 | Abq-15 | Bird Strike Simulation | Beginner | Abaqus | Available | |

| 16 | Abq-16 | Bridge Optimization | Beginner | Abaqus | Available | |

| 17 | Abq-17 | Brinell hardness test simulation | Beginner | Abaqus | Available | |

| 18 | Abq-18 | Buckling and post-buckling analysis of single-walled carbon nanotubes | Beginner | Abaqus | Available | |

| 19 | Abq-19 | Can Drop simulation with CEL Method | Beginner | Abaqus | Available | |

| 20 | Abq-20 | Can Drop simulation with Lagrangian Method | Beginner | Abaqus | Available | |

| 21 | Abq-21 | Cohesive Damage Simulation | Beginner | Abaqus | Available | |

| 22 | Abq-22 | Cold Forging SIMULATION | Beginner | Abaqus | Available | |

| 23 | Abq-23 | COMPOSITE Aircraft wing simulation and buckling analysis | Beginner | Abaqus | Available | |

| 24 | Abq-24 | Impact Analysis of a bullet on a composite plate | Beginner | Abaqus | Available | |

| 25 | Abq-25 | Simulation of a composite pipe under pressure | Beginner | Abaqus | Available | |

| 26 | Abq-26 | Simulation of delamination in composite layers | Beginner | Abaqus | Available | |

| 27 | Abq-27 | Simulation of Pulse Pressure on Composites tube | Beginner | Abaqus | Available | |

| 28 | Abq-28 | Earthquake analysis of concrete dam | Beginner | Abaqus | Available | |

| 29 | Abq-29 | Porosity analysis and find the Phreatic surface of an earthen dam | Beginner | Abaqus | Available | |

| 30 | Abq-30 | Seismic analysis of a dam usung Semi infinite elements | Beginner | Abaqus | Available | |

| 31 | Abq-31 | Simulation of concrete dam FAILURE test | Beginner | Abaqus | Available | |

| 32 | Abq-32 | Simulation of the elastic dam deformation process | Beginner | Abaqus | Available | |

| 33 | Abq-33 | Buckle and post-buckling of cylindrical shell | Beginner | Abaqus | Available | |

| 34 | Abq-34 | Impact simulation with element removal | Beginner | Abaqus | Available | |

| 35 | Abq-35 | progressive Damage SImulation in the grooved body with Johnson cook material model | Beginner | Abaqus | Available | |

| 36 | Abq-36 | Simulation of Chip Formation | Beginner | Abaqus | Available | |

| 37 | Abq-37 | Simulation of High Deformation Twisting | Beginner | Abaqus | Available | |

| 38 | Abq-38 | Disc brake simulation | Beginner | Abaqus | Available | |

| 39 | Abq-39 | Domino Simulation | Beginner | Abaqus | Available | |

| 40 | Abq-40 | Drilling simulation | Beginner | Abaqus | Available | |

| 41 | Abq-41 | ECAP Simulation | Beginner | Abaqus | Available | |

| 42 | Abq-42 | Elastoplastic analysis using Coulomb-Mohr criterion | Beginner | Abaqus | Available | |

| 43 | Abq-43 | Extrusion simulation | Beginner | Abaqus | Available | |

| 44 | Abq-44 | Hydroforming and annealing simulations | Beginner | Abaqus | Available | |

| 45 | Abq-45 | Hydroforming simulation of four-way pipe | Beginner | Abaqus | Available | |

| 46 | Abq-46 | Impact analysis on Balloon with Bullet | Beginner | Abaqus | Available | |

| 47 | Abq-47 | Impact analysis on plate with bullet | Beginner | Abaqus | Available | |

| 48 | Abq-48 | Impact Simulation of aluminum can | Beginner | Abaqus | Available | |

| 49 | Abq-49 | Impact Simulation of metal can | Beginner | Abaqus | Available | |

| 50 | Abq-50 | Impact Simulation of pipe test | Beginner | Abaqus | Available | |

| 51 | Abq-51 | low-cycle fatigue Simulation of crack growth | Beginner | Abaqus | Available | |

| 52 | Abq-52 | Model Change Technique in ABAQUS | Beginner | Abaqus | Available | |

| 53 | Abq-53 | Plate Optimization in bending machine sheet | Beginner | Abaqus | Available | |

| 54 | Abq-54 | Rolling of I section beam Simulation | Beginner | Abaqus | Available | |

| 55 | Abq-55 | Simulation of a perforated plate under sinusoidal pressure | Beginner | Abaqus | Available | |

| 56 | Abq-56 | Simulation of a flat hinge | Beginner | Abaqus | Available | |

| 57 | Abq-57 | Simulation of blood flow in a vessel | Beginner | Abaqus | Available | |

| 58 | Abq-58 | Simulation of bolt, pin and nut connections | Beginner | Abaqus | Available | |

| 59 | Abq-59 | Simulation of buckling and post-buckling of steel frame | Beginner | Abaqus | Available | |

| 60 | Abq-60 | Simulation of Bullet movement through water | Beginner | Abaqus | Available | |

| 61 | Abq-61 | Simulation of can bending | Beginner | Abaqus | Available | |

| 62 | Abq-62 | Simulation of concrete and soil interaction | Beginner | Abaqus | Available | |

| 63 | Abq-63 | Simulation of crack growth in concrete structure with XFEM method | Beginner | Abaqus | Available | |

| 64 | Abq-64 | Simulation of cutting thick sheets using a miniature milling tool | Beginner | Abaqus | Available | |

| 65 | Abq-65 | Simulation of drainage soil experiment | Beginner | Abaqus | Available | |

| 66 | Abq-66 | Simulation of DVD rotation process | Beginner | Abaqus | Available | |

| 67 | Abq-67 | Simulation of elastic beam | Beginner | Abaqus | Available | |

| 68 | Abq-68 | Simulation of elastic beam using UMAT subroutine | Beginner | Abaqus | Available | |

| 69 | Abq-69 | Simulation of Forward extrusion process | Beginner | Abaqus | Available | |

| 70 | Abq-70 | Simulation of frictional heat generation | Beginner | Abaqus | Available | |

| 71 | Abq-71 | Simulation of hydroelastic tensile test | Beginner | Abaqus | Available | |

| 72 | Abq-72 | Simulation of LATERAL crush | Beginner | Abaqus | Available | |

| 73 | Abq-73 | Simulation of limit loading and bearing capacity calculation | Beginner | Abaqus | Available | |

| 74 | Abq-74 | Simulation of masonry wall | Beginner | Abaqus | Available | |

| 75 | Abq-75 | Simulation of non-buckling brace under cyclic load | Beginner | Abaqus | Available | |

| 76 | Abq-76 | Simulation of oil tank full under earthquake load | Beginner | Abaqus | Available | |

| 77 | Abq-77 | Simulation of pile bearing capacity | Beginner | Abaqus | Available | |

| 78 | Abq-78 | Simulation of pipe creep process | Beginner | Abaqus | Available | |

| 79 | Abq-79 | Simulation of pipe hydroforming | Beginner | Abaqus | Available | |

| 80 | Abq-80 | Simulation of plate with hole | Beginner | Abaqus | Available | |

| 81 | Abq-81 | Simulation of pressing process | Beginner | Abaqus | Available | |

| 82 | Abq-82 | Simulation of pressure on hyperelastic materials | Beginner | Abaqus | Available | |

| 83 | Abq-83 | Simulation of radiation heat transfer | Beginner | Abaqus | Available | |

| 84 | Abq-84 | Simulation of reinforced concrete beams | Beginner | Abaqus | Available | |

| 85 | Abq-85 | Simulation of reinforced concrete beams in ABAQUS WITH REBARS, BRACE AND FRP | Beginner | Abaqus | Available | |

| 86 | Abq-86 | Simulation of reverse tube extrusion process | Beginner | Abaqus | Available | |

| 87 | Abq-87 | Simulation of Ring Rolling | Beginner | Abaqus | Available | |

| 88 | Abq-88 | Simulation of rolling process by a rigid roller | Beginner | Abaqus | Available | |

| 89 | Abq-89 | Simulation of Rolling with two rollers | Beginner | Abaqus | Available | |

| 90 | Abq-90 | Simulation of sheet bending using a roller | Beginner | Abaqus | Available | |

| 91 | Abq-91 | Simulation of sinusoidal forging process | Beginner | Abaqus | Available | |

| 92 | Abq-92 | Simulation of sinusoidal loading using Disp Subroutine | Beginner | Abaqus | Available | |

| 93 | Abq-93 | Simulation of soil consolidation using semi-infinite elements | Beginner | Abaqus | Available | |

| 94 | Abq-94 | Simulation of spring collision with ground | Beginner | Abaqus | Available | |

| 95 | Abq-95 | Simulation of tensile test | Beginner | Abaqus | Available | |

| 96 | Abq-96 | Simulation of the effect of obstacle presence in the fluid path in ABAQUS CFD | Beginner | Abaqus | Available | |

| 97 | Abq-97 | Simulation of Truss type bridge | Beginner | Abaqus | Available | |

| 98 | Abq-98 | Simulation of Turbulence inside the pipe | Beginner | Abaqus | Available | |

| 99 | Abq-99 | Simulation of valve | Beginner | Abaqus | Available | |

| 100 | Abq-100 | Simulation of water flow inside the pipe | Beginner | Abaqus | Available | |

| 101 | Abq-101 | Simulation of water jet cutting | Beginner | Abaqus | Available | |

| 102 | Abq-102 | Simulation of water mixing | Beginner | Abaqus | Available | |

| 103 | Abq-103 | Simulation of Waterjet cleaning | Beginner | Abaqus | Available | |

| 104 | Abq-104 | Simulation of Wave Propagation in plate | Beginner | Abaqus | Available | |

| 105 | Abq-105 | Simulation of xfem crack growth in composite plate | Beginner | Abaqus | Available | |

| 106 | Abq-106 | Simulation Water Sloashing inside the flash tank | Beginner | Abaqus | Available | |

| 107 | Abq-107 | Stool optimization | Beginner | Abaqus | Available | |

| 108 | Abq-108 | thermal-electrical analysis of a fuse | Beginner | Abaqus | Available | |

| 109 | Abq-109 | Thermomechanical Analysis Bimaterial Strip | Beginner | Abaqus | Available | |

| 110 | Abq-110 | Three Point Bending ssimulation | Beginner | Abaqus | Available | |

| 111 | Abq-111 | Tube bending simulation with three rollers | Beginner | Abaqus | Available | |

| 112 | Abq-112 | two-dimensional heat transfer Simulation of a concrete-brick oven | Beginner | Abaqus | Available | |

| 113 | Abq-113 | Underwater explosion simulation | Beginner | Abaqus | Available | |

| 114 | Abq-114 | Welding Simulation using the birth of the element | Beginner | Abaqus | Available | |

| 115 | Abq-115 | Simulation of projectile penetration analysis in a thick foam sheet | Intermediate | Abaqus | Available | |

| 116 | Abq-116 | Aluminum cone crumpling simulation and its inside foam compression | Intermediate | Abaqus | Available | |

| 117 | Abq-117 | Creep simulation of viscoelastic bush under quasi-static loading | Intermediate | Abaqus | Available | |

| 118 | Abq-118 | Blast simulation between two pipes with the Lagrangian method | Intermediate | Abaqus | Available | |

| 119 | Abq-119 | Underwater blast simulation with the Lagrangian method | Intermediate | Abaqus | Available | |

| 120 | Abq-120 | Underwater blast simulation on a reinforced sheet with UNDEX method | Intermediate | Abaqus | Available | |

| 121 | Abq-121 | Underwater blast simulation on a submerged structure | Intermediate | Abaqus | Available | |

| 122 | Abq-122 | Analysis of underwater blast simulation effects on a floating structure | Intermediate | Abaqus | Available | |

| 123 | Abq-123 | Underwater blast simulation near a concrete barrier with the acoustic method | Intermediate | Abaqus | Available | |

| 124 | Abq-124 | Simulation of a rod impact to a steel target with SPH method | Intermediate | Abaqus | Available | |

| 125 | Abq-125 | Blast simulation in a concrete tunnel with SPH method | Intermediate | Abaqus | Available | |

| 126 | Abq-126 | Steel ball impact simulation to a multilayer composite with the SPH method | Intermediate | Abaqus | Available | |

| 127 | Abq-127 | Analysis of waterjet simulation effects on a steel sheet | Intermediate | Abaqus | Available | |

| 128 | Abq-128 | Simulation of a bird collision to an aluminum target with MSFLD criterion | Intermediate | Abaqus | Available | |

| 129 | Abq-129 | Bullet shooting simulation with SPH method | Intermediate | Abaqus | Available | |

| 130 | Abq-130 | Simulation of a bird collision to an airplane glass with SPH method | Intermediate | Abaqus | Available | |

| 131 | Abq-131 | Blast simulation in a steel room with SPH method | Intermediate | Abaqus | Available | |

| 132 | Abq-132 | Blast simulation in a steel pipe with SPH method | Intermediate | Abaqus | Available | |

| 133 | Abq-133 | Blast simulation in a steel sphere with SPH method | Intermediate | Abaqus | Available | |

| 134 | Abq-134 | Simulation of a floating object on water with the Eulerian method | Intermediate | Abaqus | Available | |

| 135 | Abq-135 | Simulation of a rigid object collision with water surface with the Eulerian method | Intermediate | Abaqus | Available | |

| 136 | Abq-136 | Blast simulation in a steel pipe with the Eulerian method | Intermediate | Abaqus | Available | |

| 137 | Abq-137 | Blast simulation near concrete barrier with the Eulerian method | Intermediate | Abaqus | Available | |

| 138 | Abq-138 | Bubble blast simulation into the water with the Eulerian method | Intermediate | Abaqus | Available | |

| 139 | Abq-139 | Blast simulation on a concrete object with the Eulerian method | Intermediate | Abaqus | Available | |

| 140 | Abq-140 | Blast simulation near a steel wall with the Eulerian method | Intermediate | Abaqus | Available | |

| 141 | Abq-141 | Blast simulation on a sandwich panel | Intermediate | Abaqus | Available | |

| 142 | Abq-142 | Incremental forming simulation | Intermediate | Abaqus | Available | |

| 143 | Abq-143 | Blast simulation on a concrete guard structure with Coupled Eulerian-Lagrangian (CEL) method | Intermediate | Abaqus | Available | |

| 144 | Abq-144 | Blast simulation on concrete slab | Intermediate | Abaqus | Available | |

| 145 | Abq-145 | Blast simulation on a steel foam sandwich panel | Intermediate | Abaqus | Available | |

| 146 | Abq-146 | Impact simulation of a DShK bullet to a reinforced concrete wall | Intermediate | Abaqus | Available | |

| 147 | Abq-147 | Steel rod high velocity impact simulation to the ceramic composite plate | Intermediate | Abaqus | Available | |

| 148 | Abq-148 | Fluid flow simulation on a wind turbine blade in ABAQUS/CFD | Intermediate | Abaqus | Available | |

| 149 | Abq-149 | Fluid flow simulation in a mixer with different temperatures in ABAQUS/CFD | Intermediate | Abaqus | Available | |

| 150 | Abq-150 | High velocity impact simulation of a bullet to steel plate | Intermediate | Abaqus | Available | |

| 151 | Abq-151 | Simulation of two nonisothermal flows in a T shape pipe with ABAQUS/CFD | Intermediate | Abaqus | Available | |

| 152 | Abq-152 | Explosive welding simulation between aluminum and copper pipes | Intermediate | Abaqus | Available | |

| 153 | Abq-153 | Eulerian blast simulation on a concrete arch dam | Intermediate | Abaqus | Available | |

| 154 | Abq-154 | Eulerian blast simulation on a concrete wall | Intermediate | Abaqus | Available | |

| 155 | Abq-155 | Butterfly valve simulation in ABAQUS/CFD | Intermediate | Abaqus | Available | |

| 156 | Abq-156 | Pure Eulerian blast simulation on a retaining wall | Intermediate | Abaqus | Available | |

| 157 | Abq-157 | Fluid flow simulation in a multiway pipe with ABAQUS/CFD | Intermediate | Abaqus | Available | |

| 158 | Abq-158 | Bending simulation of a rectangle aluminum shell with damage properties | Intermediate | Abaqus | Available | |

| 159 | Abq-159 | Fluid flow simulation on an airfoil in ABAQUS/CFD | Intermediate | Abaqus | Available | |

| 160 | Abq-160 | Friction stir welding simulation of copper-steel | Intermediate | Abaqus | Available | |

| 161 | Abq-161 | Impact simulation of a high velocity projectile on concrete surface in ABAQUS-Damage model | Intermediate | Abaqus | Available | |

| 162 | Abq-162 | Fluid flow simulation on a escarpment with ABAQUS/CFD | Intermediate | Abaqus | Available | |

| 163 | Abq-163 | Simulation of springback process in tube bending | Intermediate | Abaqus | Available | |

| 164 | Abq-164 | Piezoelectric effects simulation on the natural frequency of an aluminum beam | Intermediate | Abaqus | Available | |

| 165 | Abq-165 | Writing UMAT Subroutine for Non-Isothermal Elasticity | Advanced | Abaqus | Available | |

| 166 | Abq-166 | Writing VUMAT Subroutine for Kinematic Hardening Plasticity | Advanced | Abaqus | Available | |

| 167 | Abq-167 | Simulation of elastic properties of soil in different depth with USDFLD subroutine | Advanced | Abaqus | Available | |

| 168 | Abq-168 | Analyzing a crack path in Spherical FGM | Advanced | Abaqus | Available | |

| 169 | Abq-169 | Composite shell plane explosion with a sticky connector in the layers.: | Advanced | Abaqus | Available | |

| 170 | Abq-170 | Writing UMAT Subroutine for Isotropic Isothermal Elasticity | Advanced | Abaqus | Available | |

| 171 | Abq-171 | Writing UMAT Subroutine for Elasticity and TSAI failure criterion of composite material | Advanced | Abaqus | Available | |

| 172 | Abq-172 | Writing VUMAT Subroutine for Brittle Materials + Element Removal | Advanced | Abaqus | Available | |

| 173 | Abq-173 | Writing VUMAT Subroutine for Isotropic Hardening Plasticity | Advanced | Abaqus | Available | |

| 174 | Abq-174 | Simulation of a cantilever beam by Python scripting | Advanced | Abaqus | Available | |

| 175 | Abq-175 | Python scripting for Running a number of jobs sequentially - Multiple Running | Advanced | Abaqus | Available | |

| 176 | Abq-176 | Python scripting of a 3D Truss frame of I beam | Advanced | Abaqus | Available | |

| 177 | Abq-177 | Python scripting for optimization of a planar shell bending | Advanced | Abaqus | Available | |

| 178 | Abq-178 | Writing UEL subroutine for planar beam element with nonlinear section behaviour | Advanced | Abaqus | Available | |

| 179 | Abq-179 | Writing UEL subroutine for beam Element with specific boundary conditions and loading | Advanced | Abaqus | Available | |

| 180 | Abq-180 | Analysis of a one-element truss structure using VUEL subroutine | Advanced | Abaqus | Available | |

| 181 | Abq-181 | Analysis of a one-element truss using user-coded external loads (VUEL subroutine) | Advanced | Abaqus | Available | |

| 182 | Abq-182 | Analysis of multiple truss elements connected in series using VUEL subroutine | Advanced | Abaqus | Available | |

| 183 | Abq-183 | FSW welding simulation with Eulerian Elements | Advanced | Abaqus | Available | |

| 184 | Abq-184 | Explosive welding simulation | Advanced | Abaqus | Available | |

| 185 | Abq-185 | Simulation of FSW welding with SPH method | Advanced | Abaqus | Available | |

| 186 | Abq-186 | Butt welding with death and birth of an element method | Advanced | Abaqus | Available | |

| 187 | Abq-187 | Simulation of Arc welding between two tube with DFLUX subroutine (Thermomechanical Analysis) | Advanced | Abaqus | Available | |

| 188 | Abq-188 | Writing UMESHMOTION subroutine in Forming Process (2D wear) | Advanced | Abaqus | Available | |

| 189 | Abq-189 | Writing UMESHMOTION subroutine in Rolling Process (2D wear) | Advanced | Abaqus | Available | |

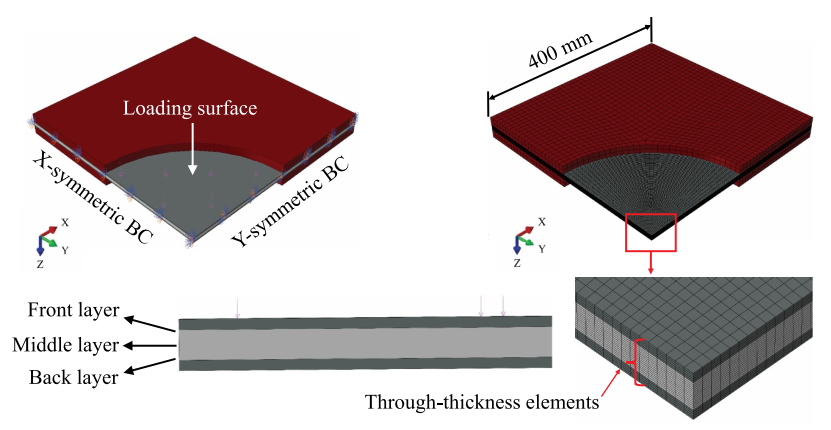

| 190 | Abq-190 | Stress Analysis of woven composite plate under tensile edge load | Advanced | Abaqus | Coming soon | |

| 191 | Abq-191 | Stress Analysis of unidirectional multilayered composite plate under pressure | Advanced | Abaqus | Coming soon | |

| 192 | Abq-192 | Stress Analysis of composite by RVE (micro modeling) under normal displacement | Advanced | Abaqus | Coming soon | |

| 193 | Abq-193 | ABAQUS Sequential Solution Software | Intermediate | Abaqus | Available | |

| 194 | Abq-194 | Implementation of Neo-Hookean material behavior in ABAQUS via UHYPER subroutine | Advanced | Abaqus | Available | |

| 195 | Abq-195 | Simulation of Rigid ball pressing against a Hollow Block in ABAQUS via UHYPER subroutine | Advanced | Abaqus | Available | |

| 196 | Abq-196 | Safety factor calculation of Hemispherical Metal with crack under internal pressure using UVARM subroutine | Intermediate | Abaqus | Available | |

| 197 | Abq-197 | 3D Hashin Failure Criterion in Composite Cylinder with liner under torsion using UVARM subroutine | Intermediate | Abaqus | Available | |

| 198 | Abq-198 | Complete 2D BESO implementation through linking ABAQUS & MATLAB | Intermediate | Abaqus | Available | |

| 199 | Abq-199 | Simulation Single Lap joint under tension with Cohesive element | Advanced | Abaqus | Available | |

| 200 | Abq-200 | Simulation of masonry wall in Abaqus usingcohesive surface behavior | Advanced | Abaqus | Available | |

| 201 | Abq-201 | Debonding behavior of a double cantilever beam using cohesive behavior via surface-based method in implicit solver | Advanced | Abaqus | Available | |

| 202 | Abq-202 | Composite shell structure in cylindrical bending with Sine loading with Dload subroutine | Advanced | Abaqus | Available | |

| 203 | Abq-203 | Damage analysis of Explosion loading on the steel plate using DLoad Subroutine | Advanced | Abaqus | Available | |

| 204 | Abq-204 | Applied load on Semi-spherical body in water in different heights with DLoad Subroutine | Advanced | Abaqus | Available | |

| 205 | Abq-205 | Simulation of Hydroforming with Advanced functional fluid pressure load using VDload subroutine | Advanced | Abaqus | Available | |

| 206 | Abq-206 | Simulation of the effect of vehicle loading on the bridge using DLOAD subroutine | Advanced | Abaqus | Available | |

| 207 | Abq-207 | Simulation interaction between deformable cubic and rigid surface for Mohr Coloumb model (VFRIC) | Advanced | Abaqus | Available | |

| 208 | Abq-208 | Rolling Simulation with rate-dependent Mohr Coulomb interaction (VFRIC) | Advanced | Abaqus | Available | |

| 209 | Abq-209 | Simulation interaction between 3D deformable cubic and rigid surface with Mohr Coulomb and rate-dependent Mohr Coulomb model (VFRICTION) | Advanced | Abaqus | Available | |

| 210 | Abq-210 | Hydro Deep Drawing simulation with rate-dependent Mohr Coulomb model (VFRICTION) | Advanced | Abaqus | Available | |

| 211 | Abq-211 | Simulation of welding between two plate with DFLUX subroutine (Heat transfer Analysis) | Advanced | Abaqus | Available | |

| 212 | Abq-212 | Simulation of different types of functional heat flux(Body-surface-Element) in plate with Johnson-cook plasticity with VDFLUX subroutine(Thermomechanical Analysis) | Advanced | Abaqus | Available | |

| 213 | Abq-213 | Implementation of UHARD Subroutine for isotropic hardening (formulation based) in simple model | Advanced | Abaqus | Available | |

| 214 | Abq-214 | Deep Drawing simulation with VUHARD Subroutine or isotropic hardening Data-based with element removal | Advanced | Abaqus | Available | |

| 215 | Abq-215 | Simulation of material under pressure with UHARD Subroutine as internal subroutine combined with UMAT | Advanced | Abaqus | Available | |

| 216 | Abq-216 | Simulation of incremental forming with VUHARD Subroutine Dharmasena modified Based | Advanced | Abaqus | Available | |

| 217 | Abq-217 | Static analysis of damage initiation and progressive damage based on HASHIN failure criterion in holed composite plate under non-uniform loading (shell element) | Advanced | Abaqus | Available | |

| 218 | Abq-218 | Static analysis of stress based damage initiation criterion on holed composite plate under complex non-uniform loading (continuum shell element) | Advanced | Abaqus | Available | |

| 219 | Abq-219 | Investigation of damage initiation and progressive damage based on criteria in the impact of a bullet on the a multilayer composite cylinder shell (shell element) | Advanced | Abaqus | Available | |

| 220 | Abq-220 | High-speed Impact analysis on multi-layered composite plate based on HASHIN failure criterion (damage initiation and progressive damage/ Physical based criterion/ shell element)) | Advanced | Abaqus | Available | |

| 221 | Abq-221 | Impact analysis on composite plate with continuum shell element (damage initiation and progressive damage) | Advanced | Abaqus | Available | |

| 222 | Abq-222 | 3 points bending of concrete cylinder with isotropic elastic behavior | Intermediate | Abaqus | Available | |

| 223 | Abq-223 | Bucklimg Analysis of Glass-Epoxy Composite materials | Intermediate | Abaqus | Available | |

| 224 | Abq-224 | Hashin damage initiation for Umat subrouitne for 3d continum element | Advanced | Abaqus | Available | |

| 225 | Abq-225 | Puck damage initiation for Umat subrouitne for 3d continum element | Advanced | Abaqus | Available | |

| 226 | Abq-226 | TSAIH damage initiation for Umat subrouitne for 3d continum element | Advanced | Abaqus | Available | |

| 227 | Abq-227 | Hashin damage initiation for USDFLD subrouitne for 3d continum element | Advanced | Abaqus | Available | |

| 228 | Abq-228 | Puck damage initiation for USDFLD subrouitne for 3d continum element | Advanced | Abaqus | Available | |

| 229 | Abq-229 | TSAIH damage initiation for USDFLD subrouitne for 3d continum element | Advanced | Abaqus | Available | |

| 230 | Abq-230 | TSAIH damage initiation for USDFLD subrouitne for 3d continum element | Advanced | Abaqus | Available | |

| 231 | Abq-231 | TSAIH damage initiation for USDFLD subrouitne for 3d continum element | Advanced | Abaqus | Available | |

| 232 | Abq-232 | TSAIH damage initiation for USDFLD subrouitne for 3d continum element | Advanced | Abaqus | Available | |

| 233 | Abq-233 | Composite Pressure vessel with 3d element | Intermediate | Abaqus | Available | |

| 234 | Abq-234 | Automatic Loading to apply load | Intermediate | Abaqus | Available | |

| 235 | Abq-235 | V-bending with springback | Intermediate | Abaqus | Available | |

| 236 | Abq-236 | U-bending with springback | Intermediate | Abaqus | Available | |

| 237 | Abq-237 | S-bending with springback | Intermediate | Abaqus | Available | |

| 238 | Abq-238 | Blast on composite plate with progressive damage (VUSDFLD) | Advanced | Abaqus | Available | |

| 239 | Abq-239 | Simulation of chip forming | Advanced | Abaqus | Available | |

| 240 | Abq-240 | Simulation of Centrifugal movment of disk | Intermediate | Abaqus | Available | |

| 241 | Abq-241 | Simulation of cold extrusion | Intermediate | Abaqus | Available | |

| 242 | Abq-242 | Cold Rotary forging in Abaqus | Intermediate | Abaqus | Available | |

| 243 | Abq-243 | Static and buckling analysis of composite cylinder under external pressure | Intermediate | Abaqus | Available | |

| 244 | Abq-244 | Puck damage initiation criterion for 3D continuum element composite material subroutine (USDFLD) | Advanced | Abaqus | Available | |

| 245 | Abq-245 | Simulation of 2d crack with J-integral method | Advanced | Abaqus | Available | |

| 246 | Abq-246 | Simulation of Asphalt Creep | Advanced | Abaqus | Available | |

| 247 | Abq-247 | Deep drawing simulation | Intermediate | Abaqus | Available | |

| 248 | Abq-248 | Simulation of Elastomer-structure behavior under side load | Advanced | Abaqus | Available | |

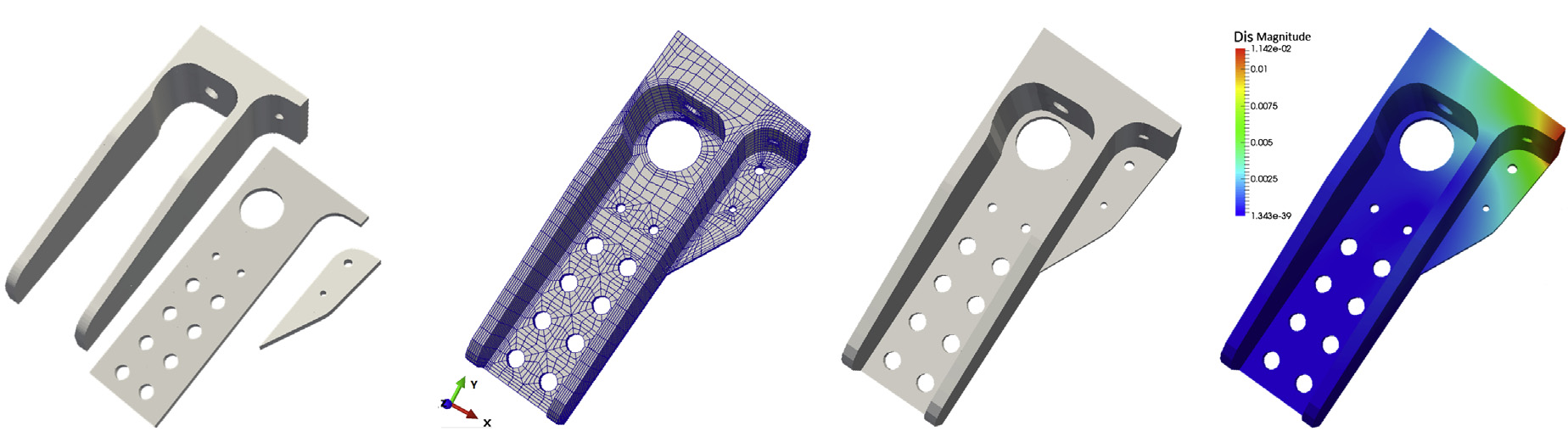

| 249 | Abq-249 | Stress analysis of motor chasis frames in elevator | Intermediate | Abaqus | Available | |

| 250 | Abq-250 | Extrusion simulation in Abaqus | Intermediate | Abaqus | Available | |

| 251 | Abq-251 | Failure analysis of bonded structures using Cohesive Elements in | Advanced | Abaqus | Available | |

| 252 | Abq-252 | Forge Analysis in Abaqus | Intermediate | Abaqus | Available | |

| 253 | Abq-253 | Rolling Simulation in abaqus | Intermediate | Abaqus | Available | |

| 254 | Abq-254 | sink deep drawing simulation in abaqus | Intermediate | Abaqus | Available | |

| 255 | Abq-255 | inertia welding simulation in abaqus with FRIC and UEL subroutines | Advanced | Abaqus | Available | |

| 256 | Abq-256 | FSW simulation with changing friction with slip rate | Advanced | Abaqus | Available | |

| 257 | Abq-257 | fatigue simulation of chopped composite material with UMAT material | Advanced | Abaqus | Available | |

| 258 | Abq-258 | Fatigue Simulation of woven composite material with UMAT material | Advanced | Abaqus | Available | |

| 259 | Abq-259 | 3d deep drawin simulation | Intermediate | Abaqus | Available | |

| 260 | Abq-260 | Hydroforming simulation in Abaqus | Intermediate | Abaqus | Available | |

| 261 | Abq-261 | Impact and Delamination Analysis of Hybrid Composite Plate with VUMAT | Advanced | Abaqus | Available | |

| 262 | Abq-262 | Impact simulation of kevlar/hyper plate | Intermediate | Abaqus | Available | |

| 263 | Abq-263 | Impact simulation of 3d continuum and shell element in Abaqus | Advanced | Abaqus | Available | |

| 264 | Abq-264 | Simulation of incremental forming in Abaqus to form imperfect cone | Advanced | Abaqus | Available | |

| 265 | Abq-265 | Simulation of incremental forming in Abaqus to form Cylinders with different diameters | Advanced | Abaqus | Available | |

| 266 | Abq-266 | simulation of Mechanobiological bone growth | Advanced | Abaqus | Available | |

| 267 | Abq-267 | simulation of reinforcement concrete structure with braces under load | Intermediate | Abaqus | Available | |

| 268 | Abq-268 | Python to apply load(thermal) proffesionally(functioanlly) and excel Output automatically | Advanced | Abaqus | Available | |

| 269 | Abq-269 | Rubber Analysis | Intermediate | Abaqus | Available | |

| 270 | Abq-270 | rubber pad forming simulation | Intermediate | Abaqus | Available | |

| 271 | Abq-271 | Scripting to Change Ellipse Dimensions Automatically to find Optimum Model in Complex civil Structure | Advanced | Abaqus | Available | |

| 272 | Abq-272 | Scripting via dimension | Advanced | Abaqus | Available | |

| 273 | Abq-273 | centrifigual stress analysis of compressor | Intermediate | Abaqus | Available | |

| 274 | Abq-274 | sheet metal spining simulation | Intermediate | Abaqus | Available | |

| 275 | Abq-275 | tube spining simulation | Intermediate | Abaqus | Available | |

| 276 | Abq-276 | Static Analysis of Disk under Flow Pressure | Intermediate | Abaqus | Available | |

| 277 | Abq-277 | Static analysis of Eliptical Crack in tube with internal pressure(k factor calculation) | Advanced | Abaqus | Available | |

| 278 | Abq-278 | Static and Buckling Analysis of composite cylinder with dome | Advanced | Abaqus | Available | |

| 279 | Abq-279 | Stress and Optimization Analysis of Composite Pressure Vessel with Semi-Geodesic winding using scripting and UMAT subroutine | Advanced | Abaqus | Available | |

| 280 | Abq-280 | Thermal Stress Brake Analysis | Intermediate | Abaqus | Available | |

| 281 | Abq-281 | Tube Drawing process | Intermediate | Abaqus | Available | |

| 282 | Abq-282 | Reverse extrusion | Intermediate | Abaqus | Available | |

| 283 | Abq-283 | Vaccum analysis of plate | Intermediate | Abaqus | Available | |

| 284 | Abq-284 | wire drawing simulation in Abaqus | Intermediate | Abaqus | Available | |

| 285 | Abq-285 | Explosion welding simulation of Titanium-steel in ABAQUS | Intermediate | Abaqus | Available | |

| 286 | Abq-286 | Friction stir welding simulation of aluminum-steel with the Eulerian method in ABAQUS | Intermediate | Abaqus | Available | |

| 287 | Abq-287 | High velocity projectile impact simulation to a ceramic reinforced by composite in ABAQUS | Intermediate | Abaqus | Available | |

| 288 | Abq-288 | Tunneling simulation with NTBM method in ABAQUS | Intermediate | Abaqus | Available | |

| 289 | Abq-289 | Friction stir welding simulation of two steel plates in ABAQUS | Intermediate | Abaqus | Available | |

| 290 | Abq-290 | Bullet impact simulation to a military helmet in ABAQUS | Intermediate | Abaqus | Available | |

| 291 | Abq-291 | Explosion welding simulation of Copper-Aluminum in ABAQUS | Intermediate | Abaqus | Available | |

| 292 | Abq-292 | Simulation of high velocity impact penetration into a concrete wall with SPH method in ABAQUS | Advanced | Abaqus | Available | |

| 293 | Abq-293 | Blast simulation in the water near a concrete dam with the Eulerian method in ABAQUS | Advanced | Abaqus | Available | |

| 294 | Abq-294 | Explosion simulation on a concrete slab using CONWEP loading in ABAQUS | Advanced | Abaqus | Available | |

| 295 | Abq-295 | TBM tunneling simulation in ABAQUS | Advanced | Abaqus | Available | |

| 296 | Abq-296 | High velocity impact simulation to a ceramic plate reinforced with a steel plate in ABAQUS | Advanced | Abaqus | Available | |

| 297 | Abq-297 | High velocity impact simulation to a silicon carbide plate in ABAQUS | Advanced | Abaqus | Available | |

| 298 | Abq-298 | Impact simulation of a steel bar to a ceramic plate in ABAQUS | Intermediate | Abaqus | Available | |

| 299 | Abq-299 | Friction stir welding of aluminum plates with the Eulerian method in ABAQUS | Intermediate | Abaqus | Available | |

| 300 | Abq-300 | Friction stir welding of two copper plates in ABAQUS | Intermediate | Abaqus | Available | |

| 301 | Abq-301 | Simulation of water sloshing using the Lagrangian method in ABAQUS | Advanced | Abaqus | Available | |

| 302 | Abq-302 | Steady-state heat transfer analysis in an insulated pipe with ABAQUS | Intermediate | Abaqus | Available | |

| 303 | Abq-303 | Simulation of spinning in ABAQUS | Intermediate | Abaqus | Available | |

| 304 | Abq-304 | Rotary forging simulation in ABAQUS | Intermediate | Abaqus | Available | |

| 305 | Abq-305 | Simulation of concrete dam vibrations analysis with foundation excitation (earthquake) in ABAQUS | Intermediate | Abaqus | Available | |

| 306 | Abq-306 | Water jet cutting simulation in ABAQUS | Advanced | Abaqus | Available | |

| 307 | Abq-307 | Impact simulation of a rigid ball to a balloon in ABAQUS | Intermediate | Abaqus | Available | |

| 308 | Abq-308 | Crack growth simulation in a steel pressure vessel with XFEM method in ABAQUS | Intermediate | Abaqus | Available | |

| 309 | Abq-309 | Cyclic loading simulation on a steel pipe in ABAQUS | Advanced | Abaqus | Available | |

| 310 | Abq-310 | Ball impact simulation to a net using fluid cavity procedure in ABAQUS | Advanced | Abaqus | Available | |

| 311 | Abq-311 | Impact analysis due to the pipe rupture in ABAQUS | Intermediate | Abaqus | Available | |

| 312 | Abq-312 | Curvature simulation of an elastic dam under water pressure with the Eulerian method in ABAQUS | Intermediate | Abaqus | Available | |

| 313 | Abq-313 | Femur bone fracture simulation under rigid impact in ABAQUS | Advanced | Abaqus | Available | |

| 314 | Abq-314 | Bird strike simulation with SPH method in ABAQUS | Advanced | Abaqus | Available | |

| 315 | Abq-315 | Ellipsoid crack simulation in a presure vessel under variable pressure with DLOAD subroutine in ABAQUS | Advanced | Abaqus | Available | |

| 316 | Abq-316 | Welding simulation using the DFLUX subroutine in ABAQUS | Advanced | Abaqus | Available | |

| 317 | Abq-317 | 2D tunneling simulation in ABAQUS | Intermediate | Abaqus | Available | |

| 318 | Abq-318 | Fracture simulation of a steel tensile specimen in a tensile test with ABAQUS | Intermediate | Abaqus | Available | |

| 319 | Abq-319 | Steel sheet cutting simulation with ABAQUS | Intermediate | Abaqus | Available | |

| 320 | Abq-320 | Blast simulation on a concrete wall half planted in the soil with the Eulerian method in ABAQUS | Intermediate | Abaqus | Available | |

| 321 | Abq-321 | Under water explosion simulation with the Eulerian method in ABAQUS | Advanced | Abaqus | Available | |

| 322 | Abq-322 | Fluid- Structure interaction simulation of a butterfly valve in ABAQUS | Intermediate | Abaqus | Available | |

| 323 | Abq-323 | Fluid- Structure interaction thermal simulation of a pipe in ABAQUS | Intermediate | Abaqus | Available | |

| 324 | Abq-324 | Friction stir welding simulation of Titanium plates with the Eulerian method in ABAQUS | Intermediate | Abaqus | Available | |

| 325 | Abq-325 | Blast simulation with the Eulerian method in a Lagrangian pipe in ABAQUS | Advanced | Abaqus | Available | |

| 326 | Abq-326 | Explosion welding simulation of Titanium-steel and temperature analysis in ABAQUS | Intermediate | Abaqus | Available | |

| 327 | Abq-327 | Crack growth simulation in a composite plate with XFEM method in ABAQUS | Intermediate | Abaqus | Available | |

| 328 | Abq-328 | Blast simulation on a concrete slab | Advanced | Abaqus | Available | |

| 329 | Abq-329 | Fluid-Structure interaction simulation of a column in ABAQUS | Intermediate | Abaqus | Available | |

| 330 | Abq-330 | Fluid-Structure interaction simulation of a cylinder in ABAQUS | Intermediate | Abaqus | Available | |

| 331 | Abq-331 | Bullet impact simulation to a concrete wall using Johnson-Cook theory with ABAQUS | Advanced | Abaqus | Available | |

| 332 | Abq-332 | Crack growth simulation in a CT sample with XFEM method in ABAQUS | Intermediate | Abaqus | Available | |

| 333 | Abq-333 | Blast simulation on a concrete slab reinforced by composite layers in ABAQUS | Advanced | Abaqus | Available | |

| 334 | Abq-334 | High velocity bullet impact simulation to a concrete wall in ABAQUS | Advanced | Abaqus | Available | |

| 335 | Abq-335 | Steel bar impact simulation to a reinforced cocrete wall in ABAQUS | Intermediate | Abaqus | Available | |

| 336 | Abq-336 | Crack growth simulation in a pipe with XFEM method in ABAQUS | Intermediate | Abaqus | Available | |

| 337 | Abq-337 | Explosion welding simulation of aluminum-copper and temperature analysis in ABAQUS | Intermediate | Abaqus | Available | |

| 338 | Abq-338 | Friction stir welding simulation of aluminium plates with the Eulerian method in ABAQUS | Advanced | Abaqus | Available | |

| 339 | Abq-339 | Pile-soil interaction simulation with ABAQUS | Advanced | Abaqus | Available | |

| 340 | Abq-340 | 2D tunneling simulation and earthquake analysis in ABAQUS | Advanced | Abaqus | Available | |

| 341 | Abq-341 | Pile penetration simulation to the soil with CEL method in ABAQUS | Advanced | Abaqus | Available | |

| 342 | Abq-342 | Earthquake simulation on gravity dam in contact with water and soil using infinite element in ABAQUS | Advanced | Abaqus | Available | |

| 343 | Abq-343 | CEL explosion simulation inside concrete tunnel in interaction with soil in ABAQUS | Advanced | Abaqus | Available | |

| 344 | Abq-344 | Steel sphere impact simulation to a sand cube with DEM method in ABAQUS | Advanced | Abaqus | Available | |

| 345 | Abq-345 | Thermal analysis of the chipping process with ABAQUS | Advanced | Abaqus | Available | |

| 346 | Abq-346 | Air blast simulation on a sandwich panel (aluminium-Epoxy Glass) in ABAQUS | Advanced | Abaqus | Available | |

| 347 | Abq-347 | Impact simulation of a rigid body to a sandwich panel (aluminium-Epoxy Glass) in ABAQUS | Advanced | Abaqus | Available | |

| 348 | Abq-348 | Soccer ball impact simulation to a human skull in ABAQUS | Advanced | Abaqus | Available | |

| 349 | Abq-349 | 2D crack growth simulation in a concrete plate with XFEM method in ABAQUS | Advanced | Abaqus | Available | |

| 350 | Abq-350 | 3D crack growth simulation in a concrete wall with XFEM method in ABAQUS | Intermediate | Abaqus | Available | |

| 351 | Abq-351 | Cyclic loading simulation on a reinforced circular concrete beam in ABAQUS | Intermediate | Abaqus | Available | |

| 352 | Abq-352 | Earthquake simulation on 2D concrete tunnel in interaction with soil in ABAQUS | Intermediate | Abaqus | Available | |

| 353 | Abq-353 | Rigid projectile impact simulation to a water tank in ABAQUS | Intermediate | Abaqus | Available | |

| 354 | Abq-354 | Buckling and post buckling simulation of a square column in ABAQUS | Advanced | Abaqus | Available | |

| 355 | Abq-355 | Impact simulation of a ball (filled with air) to the water in ABAQUS | Advanced | Abaqus | Available | |

| 356 | Abq-356 | Arc welding simulation with the DFLUX subroutine in ABAQUS | Advanced | Abaqus | Available | |

| 357 | Abq-357 | Impact simulation with DEM method in ABAQUS | Advanced | Abaqus | Available | |

| 358 | Abq-358 | Eulerian-Lagrangian blast simulation in ABAQUS- volume fraction method | Intermediate | Abaqus | Available | |

| 359 | Abq-359 | Fusion welding simulation with the DFLUX subroutine and residual stress analysis during the process in ABAQUS | Advanced | Abaqus | Available | |

| 360 | Abq-360 | Underground blast simulation inside two concrete tunnels with CEL method in ABAQUS | Advanced | Abaqus | Available | |

| 361 | Abq-361 | Arc welding simulation of a steel pipe with the DFLUX subroutine in ABAQUS | Advanced | Abaqus | Available | |

| 362 | Abq-362 | Progressive failure simulation in reinforced concrete structure subjected to the Eulerian blast in ABAQUS | Advanced | Abaqus | Available | |

| 363 | Abq-363 | Air blast simulation inside a reinforced concrete room in ABAQUS | Advanced | Abaqus | Available | |

| 364 | Abq-364 | High velocity bullet impact simulation to a three layers plate in ABAQUS | Advanced | Abaqus | Available |

We offer several free packages that teach you Abaqus through simple examples from the beginning. These packages will cover the following topics:

UMAT and VUMAT Subroutines in Abaqus (Free Version)

This package introduces you to UMAT and VUMAT subroutines, which are crucial when default material models in Abaqus don’t fit your needs. You’ll learn how to write custom subroutines for materials like hyperelasticity, composites, and metals. The free version includes a detailed UMAT Abaqus example to help you get started with subroutine writing, debugging, and verification.

Workshops include:

- Writing subroutines for different material behaviors.

- Implementing computational plasticity and damage models such as Johnson-Cook.

You’ll gain the ability to modify complex material models for more accurate simulations, making it ideal for those looking to enhance their skills in advanced material modeling.

Python Scripting in Abaqus (Free Version)

This package is designed to introduce you to Python scripting in Abaqus, a powerful tool for automating tasks and performing parametric studies. Through workshops, you’ll learn how to create scripts for simulating Abaqus example problems such as cantilever beams and running multiple jobs sequentially.

Key lessons include:

- Basics of Python and its role in Abaqus.

- Writing and executing scripts within Abaqus.

- Parametric simulations and optimization loops.

By the end of this package, you’ll be confident in writing your own scripts to streamline finite element simulations and enhance your productivity.

Abaqus for Beginners: Mechanical Engineering (Free Version)

This training package is perfect for those new to Abaqus and FEA, particularly in mechanical engineering. It covers fundamental concepts like meshing, element types, and stress-strain analysis.

Key lessons include:

- Introduction to Abaqus/CAE: Explore the interface and common features of Abaqus.

- Finite Element Method (FEM): Learn how to use FEM to solve mechanical problems with examples like trusses and plane stress elements.

With detailed examples, you’ll understand how to model mechanical systems, interpret results, and create accurate reports for engineering analysis.

Abaqus FEA Training: Cantilever Beam (Free Version)

This package focuses on beam simulation using Abaqus examples to demonstrate different loading conditions and boundary setups.

Workshops include:

- Simulation of cantilever beams under static and dynamic loads.

- Comparing simulation results with theoretical expectations.

Abaqus inp file Example

In all of the free packages, you will receive related inp files and videos.

FREE ABAQUS TUTORIAL VIDEOS

Taste our products

You can find all free packages in different content including Abaqus for beginner and writing UMAT/VUMAT subroutine and Python scripting

UMAT Subroutine (VUMAT Subroutine) in ABAQUS-Free Version- UMAT Abaqus example

by 0-Abaqus-1-caeassistantpartnerm"UMAT Subroutine (VUMAT Subroutine) introduction" is used when the material model is not available in ABAQUS software. If you follow this tutorial package, including standard and explicit solver, you will have the ability to write, debug and verify your subroutine based on customized material to use this in complex structures. These lectures are the introduction to writing advanced UMAT and VUMAT subroutines in hyperelastic Martials, Composites, and Metal, and so on. Watch Demo

"Advanced UMAT Subroutine (VUMAT Subroutine)" training package helps Abaqus users to prepare complex UMAT and VUMAT subroutines. This training package is suitable for those who are familiar with subroutine or want to learn UMAT/VUMAT subroutine Professionally. Equations for computational plasticity based on kinematic stiffness are also discussed. In addition, metal damage has been implemented based on Johnson Cook's model. Watch DemoPython scripting in ABAQUS-(FREE Version)

by 0-Abaqus-1-caeassistantpartnermAbaqus for beginners (Mechanical Engineering)-Free Version

by 0-Abaqus-1-caeassistantpartnermABAQUS FEA Training (Free cantilever beam tutorial)

by 0-Abaqus-1-caeassistantpartnerm1. Introduction of ABAQUS Examples | Subroutines

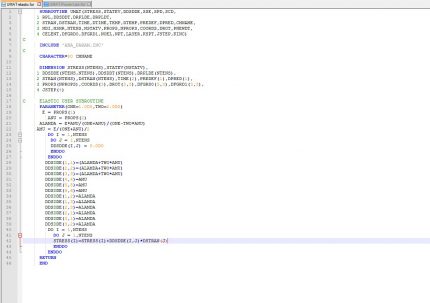

When you want to run a problem in ABAQUS, you commonly use the software’s graphical interface. However, there are instances when the standard procedures fall short in addressing complex issues, whether due to specific equations or problem intricacies. In such cases, ABAQUS provides a solution through its coding platform, offering an Abaqus Fortran subroutine example. This practical feature allows users to customize and extend the software’s capabilities. In this post, some Abaqus subroutine examples are introduced, and some of its applications are presented. If you want to learn how to write your own subroutines and try them out, you can join our ABAQUS course. We take pride in being your CAE Assistant.

2. Abaqus example problems solved by common subroutines | Research Article examples

| The ABAQUS software has many subroutines for different problems. For example, if you want to define a mechanical user-defined distributed load, you have to use the DLOAD subroutine; if you need a user-defined boundary condition, use the DISP subroutine; sometimes, you need a user-defined material behavior, so apply the UMAT subroutine and, etc.

For further guidance, you can find Abaqus Fortran subroutine examples and their applications below. |

Note that both ABAQUS solvers, standard and explicit, are in FORTRAN. To connect with any of the solvers and define functions, you have to use FORTRAN.

The subroutines are applicable in many industries and topics, such as aerospace, military, composite structures, materials science, fracture mechanics, etc.

In this article, we will explore ten important ABAQUS subroutine practical applications:

1) UMAT & VUMAT

2) USDFLD & VUSDFLD

3) DLOAD & VDLOAD

4) UHYPER

5) UEL & VUEL

6) FRIC & VFRIC

7) UMESHMOTION

8) HETVAL

9) DFLUX

10) DISP & VDISP

After introducing each one, we provide several articles as examples to familiarize you with their applications in various industries and scientific fields. These articles are chosen based on five reasons:

1. They are for the last 12 years (mostly the last 5 years).

2. They have a significant number of citations.

3. Most applicable in industries.

4. They have great potential in their content.

5. Almost all of them are highly ranked.

Read More: Abaqus tutorial

3. UMAT & VUMAT

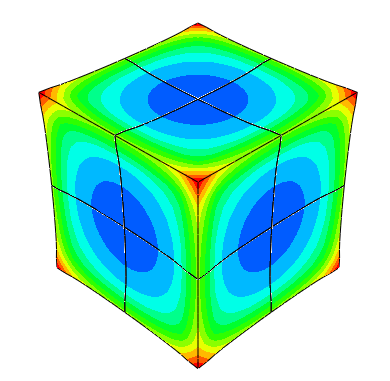

UMAT, short for user-defined material, is a vital subroutine practical for inputting material constants to create custom mechanical models. Also, it is used for user-defined thermal material models (UMATHT). This subroutine uses Cauchy stress components (i.e., true stress). The UMAT is for the ABAQUS standard solver, and the VUMAT subroutine is for ABAQUS explicit solver. These subroutines can be used to:

· Define a material mechanical constitutive behavior

· call at all material calculation points of elements for which the material definition includes a user-defined material behavior;

· Define any procedure that contains mechanical behavior;

If you’re interested in learning how to write UMAT subroutines, you’re welcome to join our ABAQUS course. Now let’s take a look at some examples for UMAT and VUMAT.

3.1. Applications :UMAT & VUMAT

Here are some practical applications for UMAT.

3.1.1. Analyzing Asphalt Pavement

In 2017, the National Natural Science Foundation of China-funded research to investigate asphalt pavement rutting behavior using the ABAQUS subroutine. The UMAT subroutine was developed to learn the asphalt mixture property and analyze asphalt pavement rutting behavior.

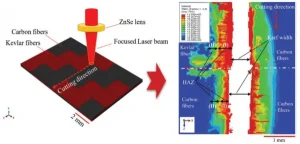

3.1.2. Carbon/Kevlar Hybrid Composite

Ministry of Higher Education Malaysia funded an article in 2020 to research thermal stress prediction of carbon/Kevlar hybrid composite in laser cutting. The researchers modeled the problem in ABAQUS software and used the VUMAT subroutine. The subroutine is used to control material removal during the laser cutting procedure.

3.1.3. Strength Prediction of Composite

Composite structures have broad applications in many industries, such as aviation and the military.

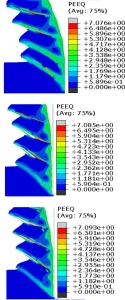

Postdoctoral Science Foundation of Jiangsu Province developed an article in 2017 explaining how to model a 3D braided composite by using the VUMAT to predict the composite stiffness and strength. The VUMAT subroutine did the damage simulation and composite modeling.

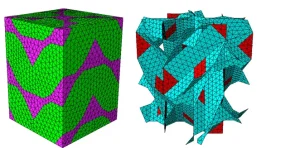

Figure 3 3D braided composite in ABAQUS modeled by VUMAT subroutine [Ref]

3.1.4. Composite Tidal Current Turbine

Nowadays, the energy demand is growing, and considering global warming, recyclable energy is getting more interesting every day in the whole world, such as renewable marine energy.

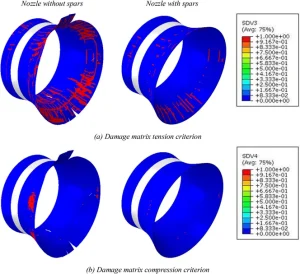

There is an Abaqus Fortran subroutine example in the composite industry In 2020: The Laboratory for Renewable Energy and Dynamic Systems of Morocco published research about environmental exposure effects on the composite tidal current turbine mechanical properties. The investigators used the ABAQUS subroutine to simulate and observe the behavior of the composite under static and dynamic loading. The VUMAT subroutine modeled the damage based on Hashin failure criteria for intralaminar damage.

Figure 4: A tidal current turbine

Figure 5 Nozzle damage zones with and without spars [Ref]

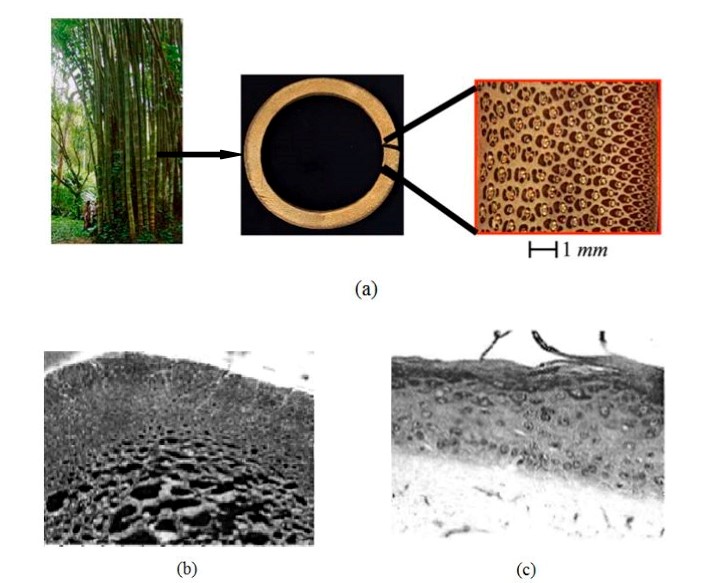

3.1.5. Functionally Graded Materials (FGM)

As you may know, FGM materials have been one of the most important and applicable materials in the past few years. It is used in many industries such as aerospace, nuclear energy, optics, biology, etc.

In 2019, Tunisia’s Engineering Production Mechanics and Materials Unit did a geometrically nonlinear analysis of the FGM elastoplastic behavior. The investigators modeled the FGM with the UMAT. The UMAT subroutine defined the FGM material properties.

Figure 6 Nature examples of FGM; a) Bamboo stalks, b) Bone, c) Human skin [Ref]

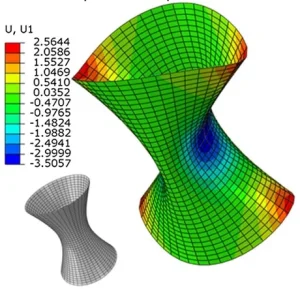

Figure 7 FGM hyperboloid deformed shape [Ref]

These were some examples for UMAT and If your work is related to the UMAT subroutine and you do not know how to start writing your UMAT subroutine, you can get complete and comprehensive information about UMAT in the below package.

|

⭐⭐⭐Free Abaqus Course | ⏰10 hours Video 👩🎓+1000 Students ♾️ Lifetime Access

✅ Module by Module Training ✅ Standard/Explicit Analyses Tutorial ✅ Subroutines (UMAT) Training … ✅ Python Scripting Lesson & Examples |

Note: If you want to start writing your first subroutine, but don’t know where to start, just read this blog and you will all set up: Start Writing user subroutines with Abaqus

4. USDFLD & VUSDFLD

User-defined field (USDFLD: standard solver, VUSDFLD: explicit solver) subroutine allow you to redefine field variables values at a material point within an increment. In other words, you can define field variables as a function of time at any available material point.

4.1. Multiple Applications of USDFLD & VUSDFLD

Here are some practical applications for USDFLD & VUSDFLD.

4.1.1. Additive Manufacturing (3D Printing)

In 2019, Alexandria university of Egypt disseminated an article about 3D printing. This article talks about the effects of laser scanning speed on part distortion. The finite element modeling of this part is implemented with the help of the USDFLD subroutine, which serves as an Abaqus Fortran subroutine example, simulating the phase change from powder to solid-state.

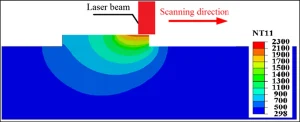

Figure 8 Nodal Temperature (NT11) distribution, deposition of the first layer [Ref]

4.1.2. Bolted Joints Used in Aircraft

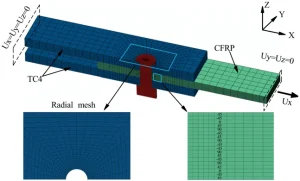

Xi’an Aircraft Industry of china worked on CFRP/Ti bolted joints in 2018, which are increasingly used in aircraft structures. An experimental and numerical investigation was made to find the effects of interference sizes and clearance on the failure and damage of CFRP/Ti bolted joints. The researchers used the ABAQUS USDFLD subroutine to simulate material stiffness degradation and failure analysis in the loading process.

Figure 9 Finite element model of the CFRP/Ti joint [Ref]

4.1.3. Failure Prediction of Composite

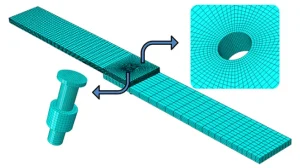

In 2012, Spanish Comisión Interministerial de Ciencia y Tecnología funded an article about failure prediction of composite joints. The investigators modeled progressive damage with the help of the ABAQUS/standard USDFLD subroutine to predict the influence of tightening torque and secondary bending on the composite joints. The material properties became a direct function of predefined field variables through the USDFLD subroutine.

Figure 10 Composite joint model mesh [Ref]

4.1.4. High-Speed Machining

High-speed machining is one of the most critical and helpful chipping processes in manufacturing industries.

The national natural science foundation of china published an investigation in 2016. It worked on the evolution of micro-hardness and grain size during high-speed machining with the help of the ABAQUS subroutine example. The VUSDFLD subroutine was developed based on Zener-Hollomon and Hall-Petch to simulate the grain size modifications and micro-hardness in a machined surface generation. Also, it was used to investigate chip formation under different cutting speeds.

Figure 11 Simulated chip shape under different cutting conditions [Ref]

If your work is related to the USDFLD subroutine and you do not know how to start writing your USDFLD subroutine, you can get complete and comprehensive information about USDFLD in the below package.

5. DLOAD and VDLOAD Subroutines

The DLOAD and VDLOAD subroutines are used for user-defined distributed load. The former is for the standard solver, and the latter is for the explicit solver. They can define the distributed load magnitude variation as a function of time, load integration point number, position, element number, etc.

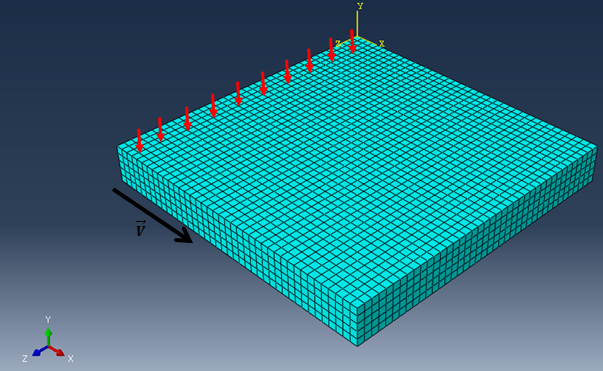

Figure 12 DLOAD subroutine, a moving pressure

5.1. DLOAD & VDLOAD Abaqus examples

Here are some practical applications for DLOAD & VDLOAD.

5.1.1. Asphalt Concrete Pavements

In 2017, the USA Michigan State University developed research to detect a bottom-up crack in the asphalt concrete pavements. The researchers used the DLOAD subroutine to simulate a dynamic moving load on the pavement surface

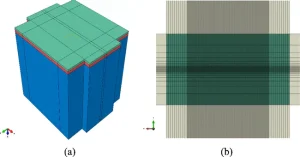

Figure 13 (a) The 3D model of the pavement structure, (b) meshed cross-section of the asphalt concrete layer [Ref]

5.1.2. Wind Turbine Blades

Wind energy is one of the most important and promising renewable energy sources. Having wind energy requires wind turbines, so like other apparatuses, this one also needs maintenance.

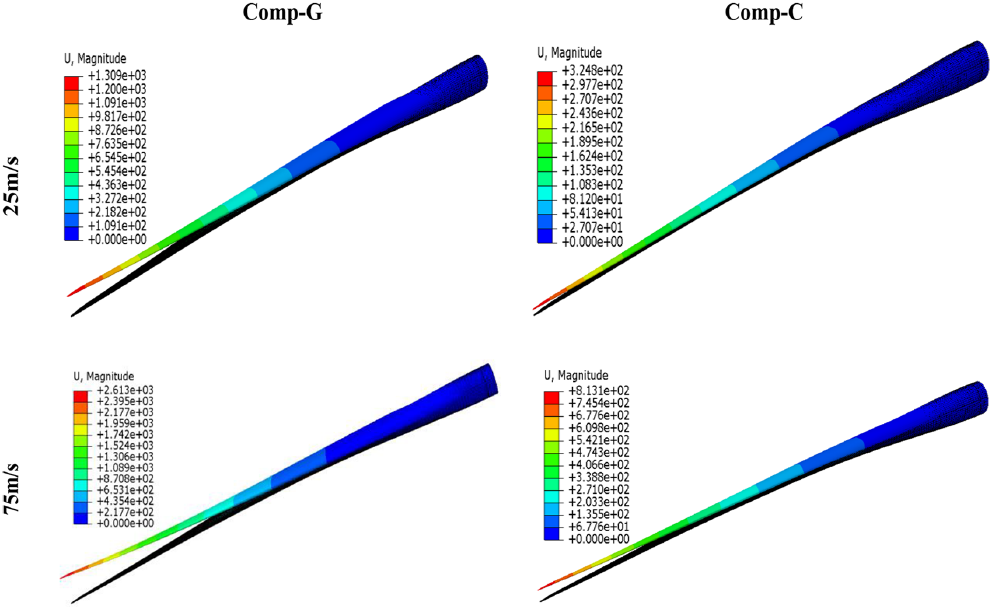

In 2020, an investigation was published by Morocco Laboratory for Renewable Energy and Dynamic Systems. The research goal was to identify and predict critical zones sensitive to failure and damage with the help of the subroutine. The DLOAD subroutine was used as an Abaqus Fortran subroutine example to model the pressure load variation with position.

Figure 14 wind turbine

Figure 15 Displacement (mm) at the tip of the blades with glass fibers (left) and carbon fibers (right)[Ref]

5.1.3. Multi-layered Metallic Plates

In 2019, Texas State University of USA worked on the repeated localized impulsive loading effects on the performance of multi-layered metallic plates by simulating the problem with the subroutine. The VDLOAD subroutine was used to simulate the structure dynamic plastic response and predict the failure modes and deformation profiles of monolithic and multi-layered configurations.

Figure 16 Loading zone, boundary condition, mesh generation, and dimension for a typical multi-layered plate [Ref]

You can find a practical example for DLOAD in the package below.

6. UHYPER Subroutine

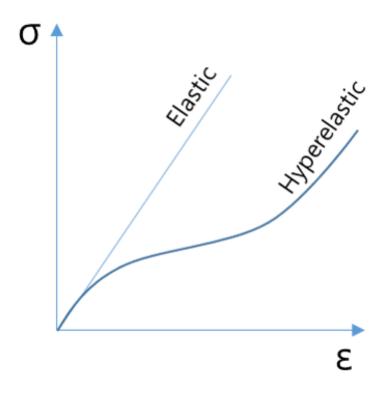

To define a user-defined hyperelastic material behavior, the UHYPER subroutine can be used. Also, it can define the strain energy potential for isotropic hyperelastic material behavior

Figure 17 Definition of hyperelastic in a graph

6.1. Several Applications of the UHYPER Subroutine

Here are some practical applications for UHYPER.

6.1.1. Hydrogels

Hydrogels are used for hygiene products, producing contact lenses, wound dressing, etc. hydrogels are used in tissue engineering and drug delivery as well.

In 2016, the A*STAR Institute of High-Performance Computing (IHPC) supported research that worked on the deformation characteristics of a temperature-sensitive hydrogel. The institute did an analysis with the subroutines UHYPER and UMAT to get some results. They used the UHYPER subroutine to determine the mechanical behavior of the temperature-sensitive gel.

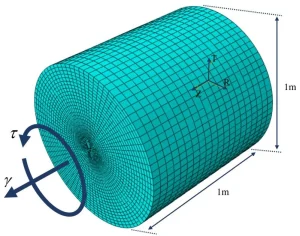

Circular cylinders have many applications almost in all industries, such as military, aerospace, construction, etc.

In 2019, the University of Texas at Arlington presented research. They developed a finite element analysis with the UHYPER and VUMAT to investigate the nonlinear incompressible isotropic elastic solid circular cylinder response under combined torsion and extension. The UHYPER subroutine defined the hyperelastic materials for the invariant-based exp-exp constitutive model in this research.

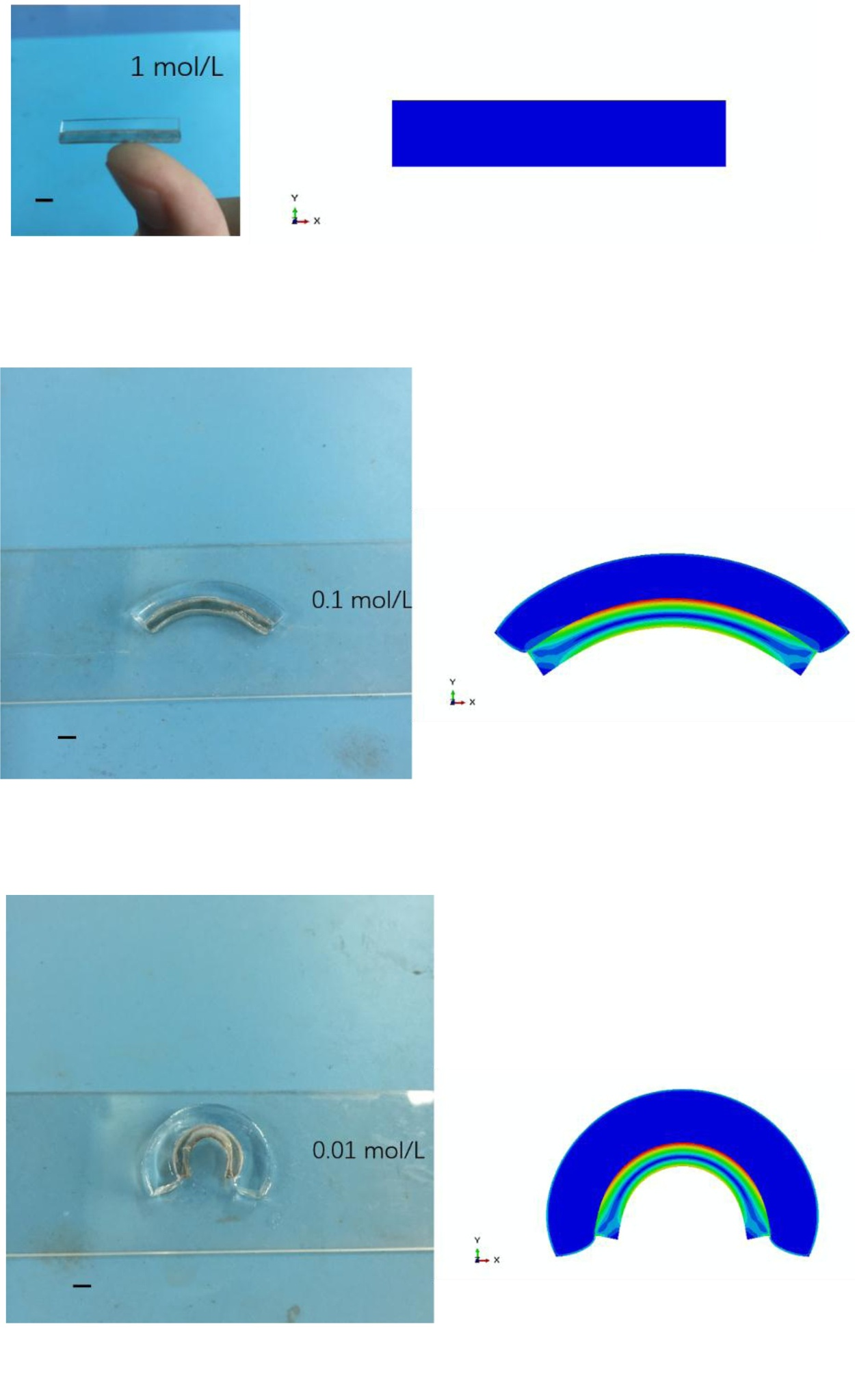

6.1.3. Salt Concentration-sensitive Hydrogel

Salt concentration-sensitive hydrogel is a material that has novel applications in mechanical engineering, and it is widespread in nature.

In 2019, the International Center for Applied Mechanics of China developed a finite element model with the ABAQUS software and UHYPER subroutine to predict the Salt concentration-sensitive hydrogel deformation behavior.

Figure 20: Hyperelastic circular cylinder under extension-torsion loading with mesh network [Ref]

Figure 21 Deformation behavior of the salt, experiment, and the simulation [Ref]

Are you working on the Uhyper subroutine, and you do not know how to start writing your Uhyper subroutine? You can get complete and comprehensive information about Uhyper in the below package.

7. UEL & VUEL Subroutine

When you want to define various element shape functions, UEL would be your choice. UEL stands for user-defined element. The V version (VUEL) is for the explicit solver like the previous sections. Note that this subroutine is for advanced users only because even for the simplest examples, it requires considerable coding by the user.

When you use the UEL subroutine, it will be called for each element of a general user-defined element type. Each time element calculation is required appropriate to the current activity in the analysis.

7.1. Several Applications for UEL & VUEL

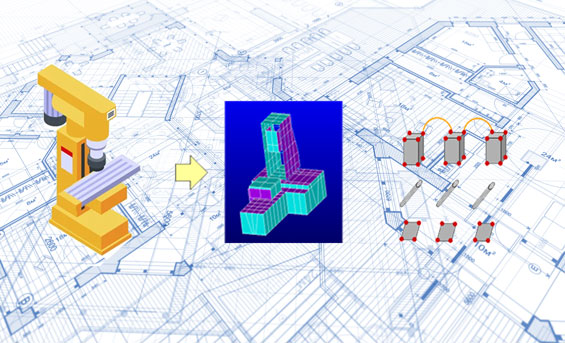

7.1.1. Linking CAD with ABAQUS

Isogeometric analysis applications in the industry suffer from a lack of automatic or semi-automatic software platforms.

Department of Mechanical Engineering of the Carnegie Mellon University of USA developed research in 2017 to integrate ABAQUS with CAD to present a platform to overcome the mentioned issue. They worked on this issue with the advantages of the ABAQUS user-defined element (UEL) and other matters.

Figure 22: An example of linear elasticity analysis [Ref]

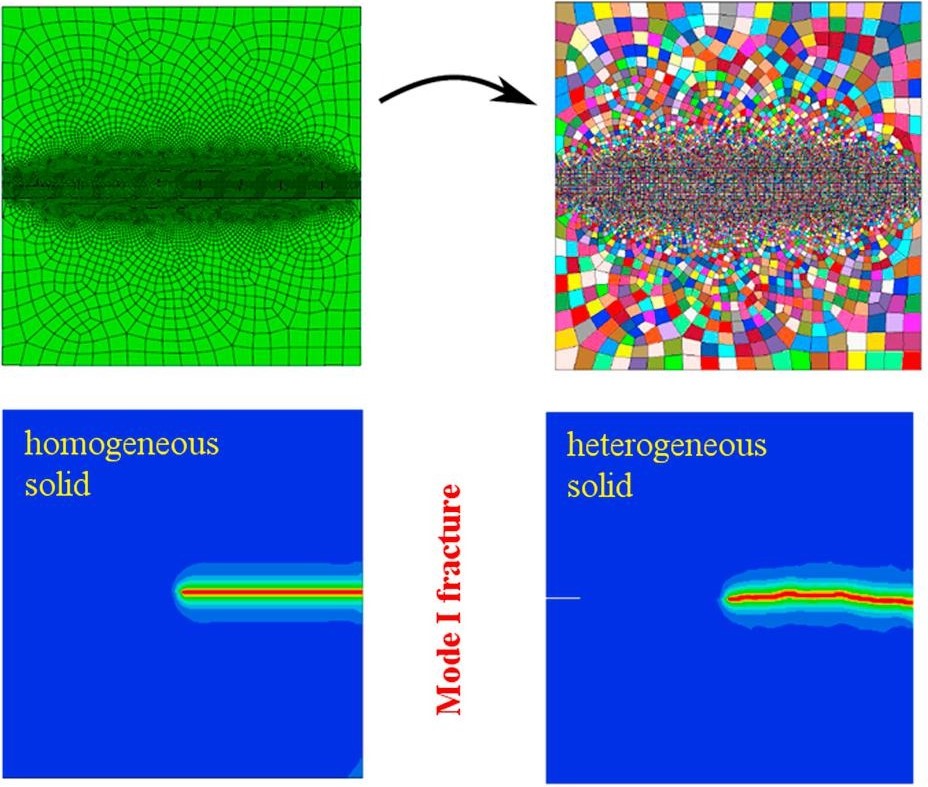

7.1.2. Heterogeneous Solids and Porous Saterials

In the year 2018 Institute of General Mechanics, RWTH Aachen University of Germany, investigated on a brittle fracture model of heterogeneous solids and porous materials with the help of the ABAQUS UEL subroutine. The subroutine was developed to model the Phase-field modeling (PFM) and Theory of Porous Media (TPM) for brittle fracture simulation.

Figure 23 From a spatially homogeneous to a statistically heterogeneous via Weibull distribution in ABAQUS UEL [Ref]

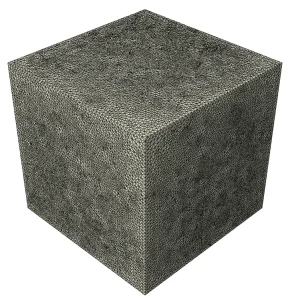

7.1.3. Nanocomposites Materials

Division of Computational Mechanics of Ton Duc Thang University published an investigation in 2016 that can predict clay/epoxy nanocomposites’ tensile strength with the help of the UEL and UMAT. The UEL subroutine modeled a phase-field model for brittle fracture simulation.

Figure 24 3D representative volume element (RVE) of the polymeric nanocomposite (PNC)[Ref]

In 2019, The University of Technology Sydney (UTS) supported research explaining phase-field fracture in elastoplastic solids, implemented by the ABAQUS UEL and UMAT subroutine. The UEL subroutine is used for the phase-field fracture.

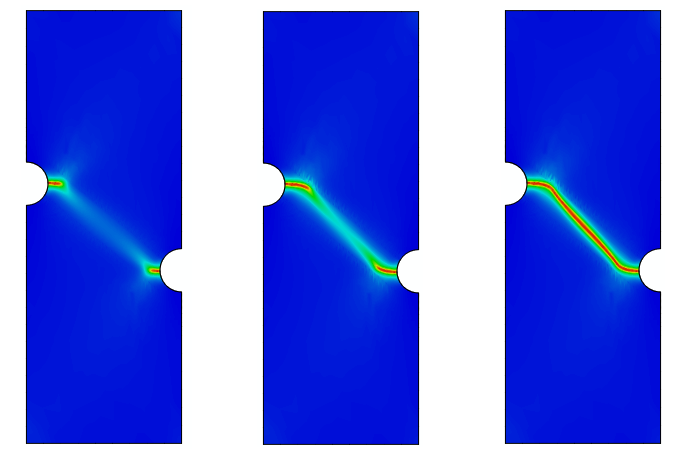

Figure 25: Crack propagation of the flat grooved specimen [Ref]

Do you want to define User-defined elements, and you do not know how to start writing your UEL subroutine? You can get complete and comprehensive information about UEL in the below package. We’re delighted to be your CAE Assistant.

|

|

We are enthusiastic about receiving your feedback. Please feel free to share any comments or questions with us. Your input will bring us one step closer to achieving our goal of becoming your ultimate CAE assistant. You can continue reading this topic in the following article 10 Useful ABAQUS Fortran Subroutine Example (Part2).

[learn_press_recent_courses]

Get this article as a PDF file: CAE Assistant – Abaqus Practical examples

8. Frequent asked questions

What are the Examples of utilizing the UMAT subroutine in ABAQUS?

UMAT subroutine in ABAQUS is widely used for different applications, including:

- Analyzing Asphalt Pavement: Used to study asphalt properties and assess rutting behavior.

- Carbon/Kevlar Hybrid Composite: Employed for thermal stress prediction in composite laser cutting.

- Strength Prediction of Composites: Enables modeling of 3D braided composites, predicting their strength and damage behavior.

- Composite Tidal Current Turbines: Utilized to analyze mechanical properties under environmental exposure.

- Functionally Graded Materials (FGM): Helps define material properties for FGMs in various industries.

What are the Real project applications of USDFLD & VUSDFLD?

USDFLD and VUSDFLD in ABAQUS have practical applications in real projects:

- Additive Manufacturing (3D Printing): Used for simulating phase changes in 3D printing due to laser scanning speed.

- Bolted Joints in Aircraft: Investigated the effects of interference sizes and clearance on aircraft bolted joints, analyzing material stiffness and failure.

- Failure Prediction of Composite Joints: Predicted failure in composite joints by modeling progressive damage and evaluating factors like tightening torque and secondary bending.

- High-Speed Machining: Studied micro-hardness and grain size evolution during high-speed machining, including simulating grain size modifications and chip formation under different cutting speeds.

Where are DLOAD & VDLOAD applications in the real world?

DLOAD and VDLOAD in ABAQUS are utilized in practical applications in the real world:

- Asphalt Concrete Pavements: Used for simulating dynamic loads on pavement surfaces, aiding in the detection of cracks and structural analysis.

- Wind Turbine Blades: Applied to identify critical areas susceptible to damage in wind turbine blades, modeling pressure load variations.

- Multi-Layered Metallic Plates: Utilized to predict failure modes and deformation profiles in multi-layered metallic plates subjected to repeated localized impulsive loading.

Where are the Practical applications of the UHYPER subroutine?

- Hydrogels: These adaptable materials find uses in contact lenses, wound dressings, and tissue engineering. In 2016, an Institute of High-Performance Computing utilized ABAQUS subroutines UHYPER and UMAT to analyze the mechanical properties of temperature-sensitive hydrogels.

- Circular Cylinders: With applications spanning military, aerospace, and construction, circular cylinders are vital components. In 2019, the University of Texas at Arlington conducted research using ABAQUS subroutines UHYPER and VUMAT to investigate the behavior of incompressible elastic solid circular cylinders under various loads.

- Salt Concentration-Sensitive Hydrogel: This innovative material with applications in mechanical engineering was studied in 2019 by the International Center for Applied Mechanics of China. They employed ABAQUS and the UHYPER subroutine to predict the deformation behavior of salt concentration-sensitive hydrogels.

What are the practical applications for UEL & VUEL subroutines?

- CAD Integration: In 2017, Carnegie Mellon University in the USA bridged the gap between Computer-Aided Design (CAD) and ABAQUS. They utilized the ABAQUS UEL subroutine to streamline isogeometric analysis by creating an integrated platform.

- Heterogeneous Materials: In 2018, RWTH Aachen University in Germany employed the ABAQUS UEL subroutine to model brittle fracture in heterogeneous solids and porous materials. This advanced the understanding of Phase-field modeling and the Theory of Porous Media.

- Nanocomposite Strength: Researchers at Ton Duc Thang University investigated the tensile strength of clay/epoxy nanocomposites in 2016. The UEL subroutine was used to create a phase-field model for simulating brittle fracture.

- Elasto-Plastic Solids: In 2019, the University of Technology Sydney explored phase-field fracture in elastoplastic solids. They used the ABAQUS UEL and UMAT subroutines, with UEL specifically designed for phase-field fracture simulations.

| ✅ Subscribed students | +80,000 |

| ✅ Upcoming courses | +300 |

| ✅ Tutorial hours | +300 |

| ✅ Tutorial packages | +100 |

Hi!

Which tutorial package I should buy for conducting research on the following topic:

NiTi, Electroactive polymer, PVDF, Poly (methyl methacrylate) (PMMA), SME in hydrogel

Acoustic and Auxetic Metamaterials

Lattice structure analysis.

Please help me to know so that I can buy them.

I can tell it is one of the good subroutine tutorial article for beginners. What package do you recommend me?