Introduction to Carbon Fiber Properties

Carbon fibers are widely used in aerospace, automotive, and other high-performance applications due to their exceptional strength and stiffness. However, experimentally determining their properties, such as transverse and shear modulus, is challenging. This tutorial introduces a machine learning-based inverse modeling approach that leverages GPR to predict these properties more efficiently.

You will start by understanding the key challenges in estimating fiber properties and how traditional micromechanical models handle these difficulties. The limitations of these models, particularly in accurately predicting properties due to the spatial distribution of fibers, are addressed in detail.

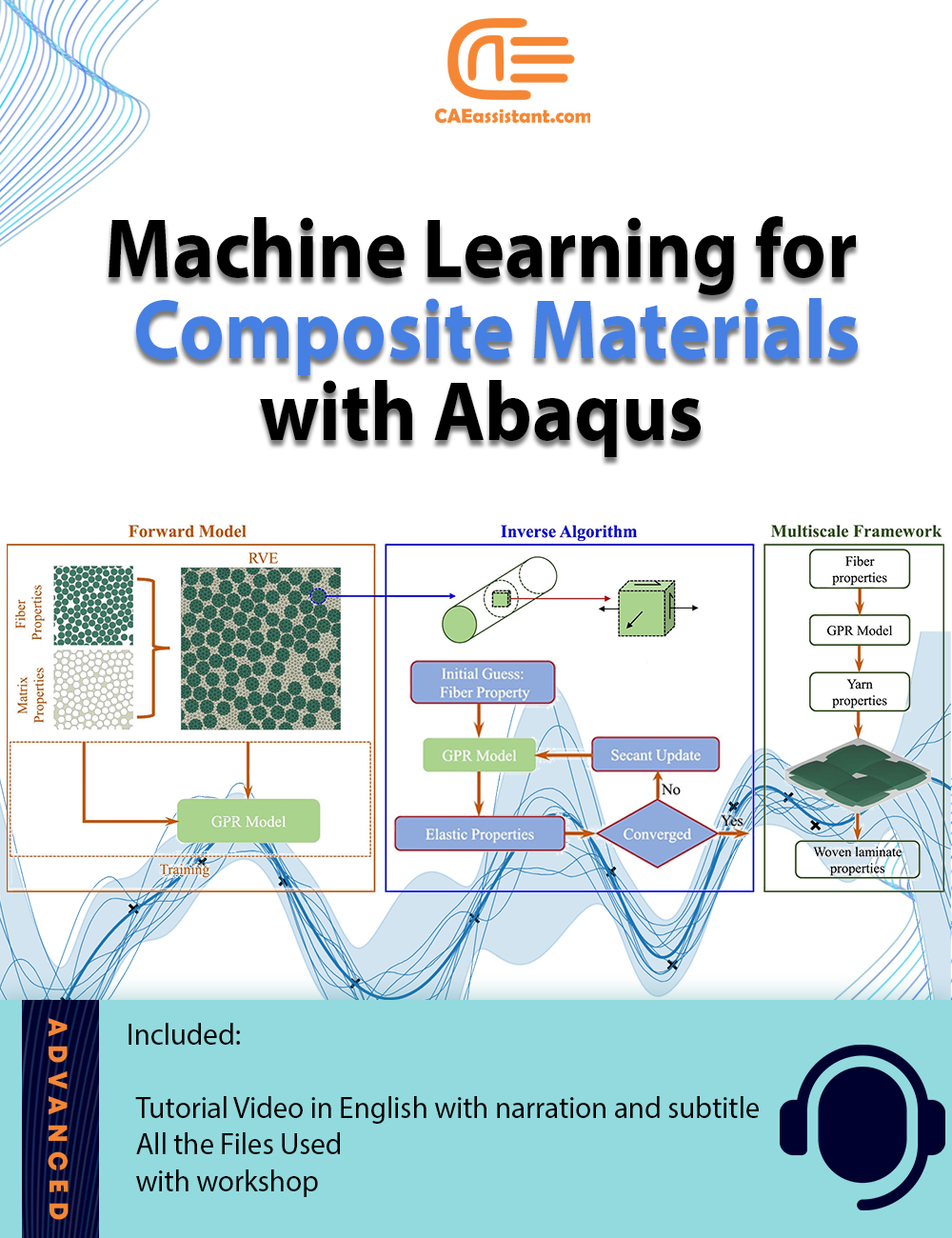

Machine Learning Framework with Gaussian Process Regression

Finite Element Homogenization and Data Generation

Finite Element (FE) homogenization is used to generate synthetic data for training the GPR model. You will be guided through the process of FE modeling in Abaqus, focusing on generating realistic representations of fiber-matrix composites. This involves:

- Setting up the model in Abaqus: Defining geometric dimensions and material properties.

- Meshing and boundary conditions: Applying periodic boundary conditions (PBCs) to the representative volume element (RVE) to capture microstructural details.

- Data generation: Generating data for various combinations of fiber and matrix properties, including different volume fractions and distributions.

Inverse Modeling Approach

The inverse modeling approach presented in this tutorial is a powerful method for predicting elastic properties of carbon fibers. In this section, the GPR-based inverse model is explained in detail, showing how machine learning for composite materials applications can significantly enhance prediction accuracy. The process involves:

- Training the GPR Model: Using the synthetic data generated via FE homogenization, the GPR model is trained to predict properties like the transverse and shear modulus of carbon fibers.

- Comparison with Experimental Data: The predictions from the GPR model are validated against experimental results from the literature, demonstrating the model’s accuracy with regression coefficients above 0.93.

This section also covers how the GPR model quantifies uncertainty in predictions, making it a reliable computational tool.

Validation and Robustness of the Model

Validation is a critical step in any simulation. This section details how the model is validated against experimental data, ensuring that the GPR surrogate model’s predictions align with real-world results. The tutorial provides case studies on polyacrylonitrile (PAN)-based fibers, demonstrating how the model performs in predicting properties for composites that were not part of the training data.

Case Studies and Practical Applications

The tutorial offers hands-on exercises and case studies to apply the concepts learned. These exercises will allow users to predict the properties of various fiber composites and compare them with published experimental values. By applying machine learning for composite materials analysis, users will explore different weave patterns such as Plain, Twill, and 5-Harness Satin, illustrating the model’s versatility across multiple composite types.

Conclusion and Future Directions

This tutorial package concludes by summarizing the advantages of using machine learning-based surrogate models, specifically GPR, for predicting composite fiber properties. Focused on advancing machine learning for composite materials analysis, the computational efficiency and accuracy demonstrated in this package make it an invaluable tool for professionals in materials science and engineering.

Looking forward, this approach can be expanded to cover more complex composites and different loading conditions, including multiscale simulations. Future developments in integrating machine learning with FEM simulations hold promise for even more sophisticated material property predictions.

Reviews

Clear filtersThere are no reviews yet.