Abaqus Concrete structure Modeling | Practical Examples (Part 2)

If you are a researcher, student, university professor, or Engineer in the company in the field of civil engineering, Abaqus concrete structure modeling package in simulating concrete and structural Engineering is the best selection.

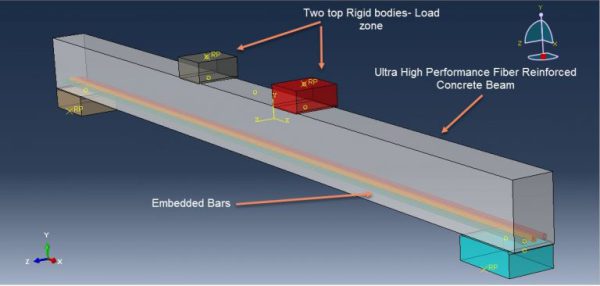

The package includes 5 workshops on topics such as concrete, beam-column structures, composites, steel rebars, Ultra-High-Performance-Fiber-Reinforcement Concrete columns, CFRP bars, hollow-core square reinforced concrete columns wrapped, damaged concrete beams, High Strength Concrete(HSC),ECC/Concrete Composite Beam-Column Joints, circular concrete-encased concrete-filled steel tube (CFST) stub columns, and etc.

You can see the syllabus and details of this project below or the drop-down menu on the right side of this product page.

![]() It will guide you going from the basics up to complex simulation techniques. It is very fluid, and comprehensive and every single detail is explained.

It will guide you going from the basics up to complex simulation techniques. It is very fluid, and comprehensive and every single detail is explained.

![]() Every workshop goes straight to the point, without any worthless piece of content. You will learn what you need at every stage and you will be putting it into practice from the very first day.

Every workshop goes straight to the point, without any worthless piece of content. You will learn what you need at every stage and you will be putting it into practice from the very first day.

![]() Most importantly, we support you as you learn in this course. You can contact our experts to ask your questions and enjoy our modelling and simulations step-by-step support.

Most importantly, we support you as you learn in this course. You can contact our experts to ask your questions and enjoy our modelling and simulations step-by-step support.

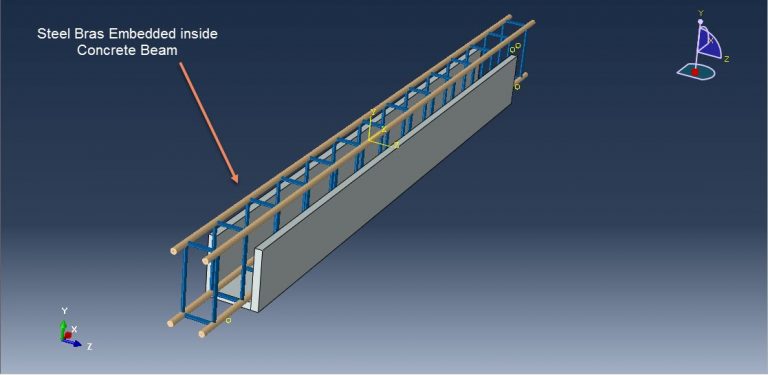

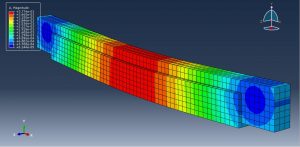

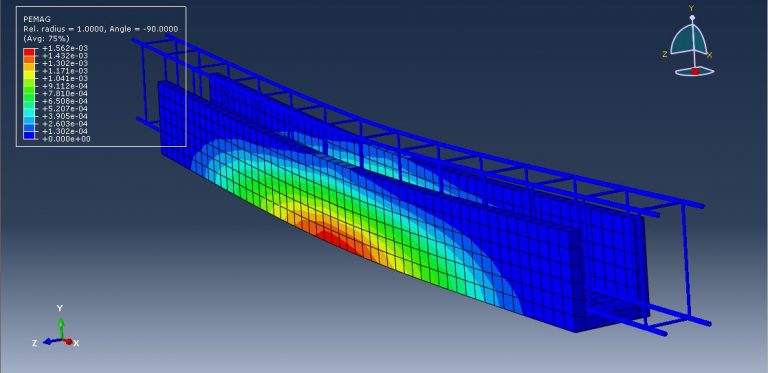

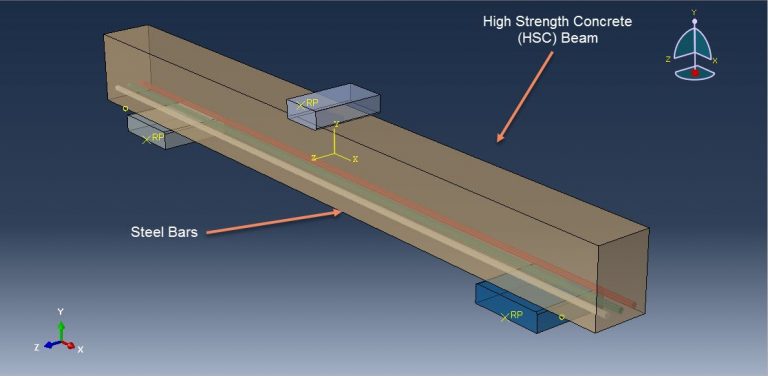

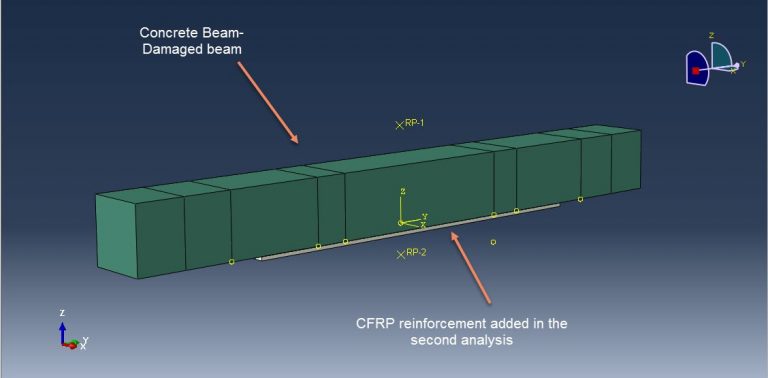

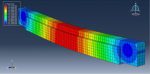

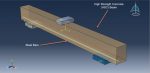

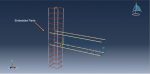

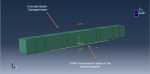

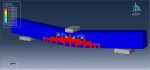

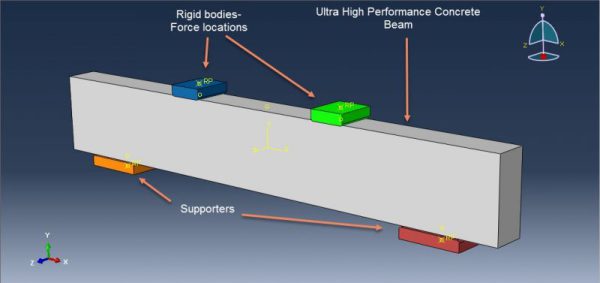

Workshop-1: Damaged concrete beam with initial residual stress reinforced CFRP sheet in bending loading

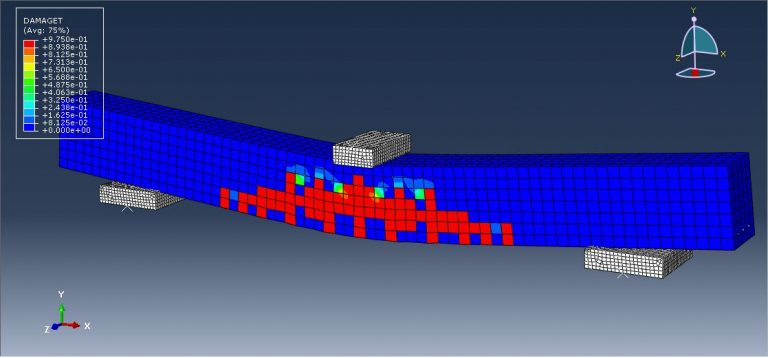

This workshop examines the simulation of a damaged concrete beam with initial residual stress, reinforced with a CFRP sheet under bending load in Abaqus. The concrete beam is modeled as a three-dimensional solid part, while the CFRP sheet is represented as a three-dimensional shell part. The analysis consists of two sequential simulations:

- First Simulation: A four-point bending test is performed on the concrete beam to generate stress distribution and damage patterns. These results are then extracted and used as initial conditions for the second simulation.

- Second Simulation: The CFRP sheet is applied to the damaged areas of the beam, and the residual stress and damage from the first simulation are imported into the new analysis.

In the first simulation, a general static step with modified convergence settings is used. To ensure that data from this analysis is available for the second simulation, the output results must be saved as an output file. The bending load is applied at two zones of the beam, while boundary conditions are assigned at the beam’s ends. Once the simulation is complete, results such as stress, strain, tensile and compressive damage are obtained.

In the second simulation, the CFRP sheet is introduced to reinforce the damaged zones from the previous analysis. The residual stress and damage state from the first simulation are used as the initial condition for the beam. The CFRP reinforcement is expected to enhance the beam’s performance, allowing it to withstand the same or increased load more effectively.

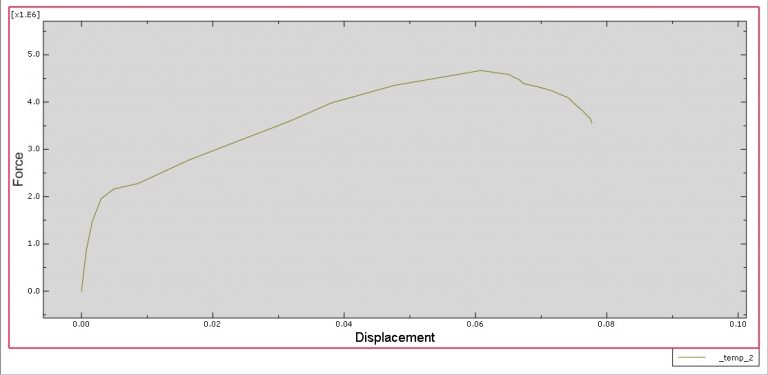

After completing both simulations, results from each phase—including stress distribution, strain, damage evolution, and structural performance—can be analyzed and compared.

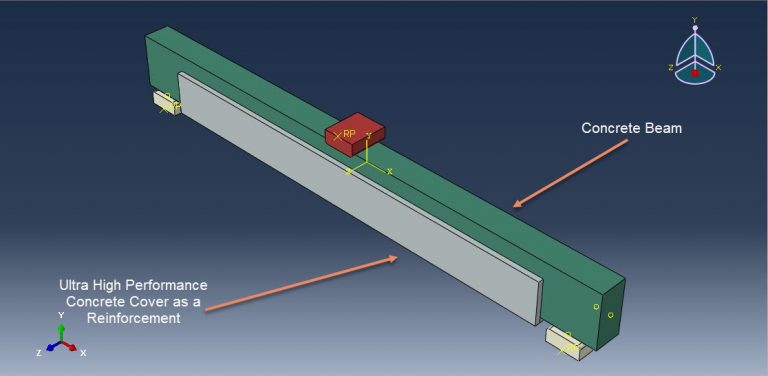

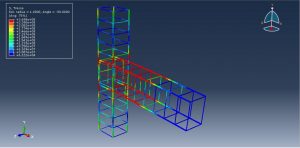

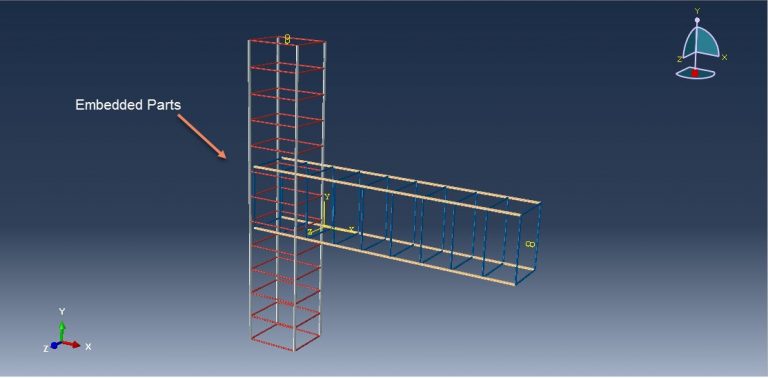

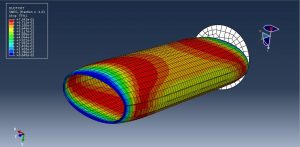

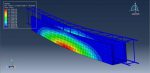

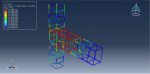

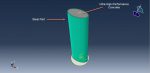

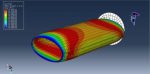

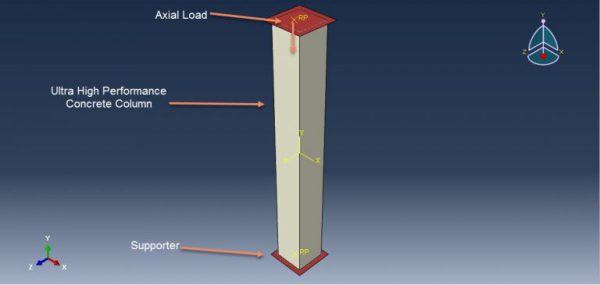

Workshop-3: FEM analysis of Elliptical ultra-high-performance concrete-filled steel tabular column under a compression loading

This workshop explores the simulation of an elliptical ultra-high-performance concrete-filled steel tubular (CFST) column under compression loading in Abaqus. Elliptical CFST columns have gained significant attention due to their enhanced strength and stiffness compared to empty elliptical hollow sections. The UHPC core is modeled as a three-dimensional solid part, while the steel tube is represented as a three-dimensional shell.

CFST columns are widely used in buildings, bridges, transmission towers, and offshore structures because of their high strength, stiffness, ductility, and energy absorption capacity. These composite columns consist of circular or rectangular steel tubes filled with concrete, and the elliptical CFST column is a more recent variation where concrete is filled into an elliptical steel tube.

To model the UHPC core, the Concrete Damaged Plasticity (CDP) model is used, with material properties obtained from reference studies. The steel tube follows an elastic-plastic material model, incorporating a ductile damage criterion. The simulation is performed using a general static step with modifications to improve convergence.

A perfect or ideal contact is assumed between the steel tube and the concrete core, and general contact with frictional properties is applied to all interacting components. The bottom rigid body is fixed, while displacement with an amplitude function is applied to the top rigid body to simulate compression. A fine mesh is essential for achieving accurate results.

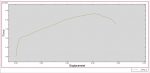

After completing the analysis, results such as stress, strain, damage progression, and the force-displacement diagram are available.

Reviews

Clear filtersThere are no reviews yet.