Lemaitre damage

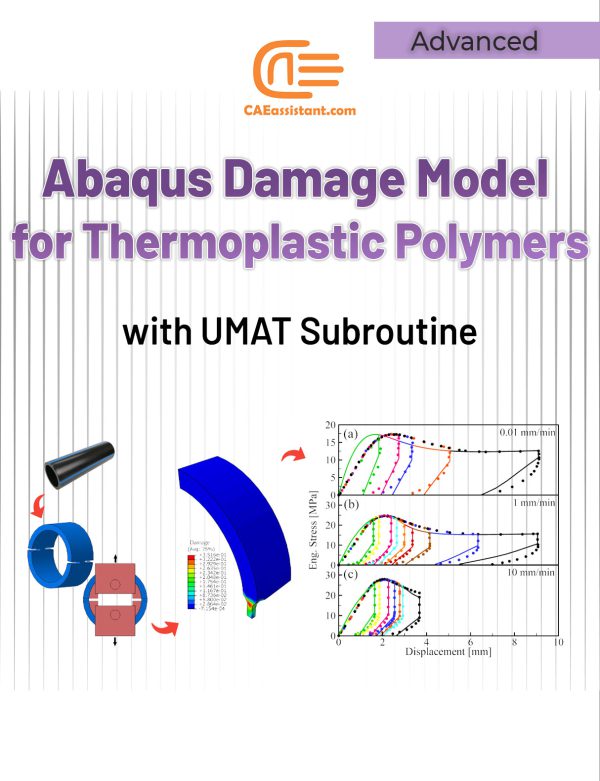

Abaqus Damage Model for Thermoplastic Polymers with UMAT Subroutine

Thermoplastic polymers are materials composed of long molecular chains primarily consisting of carbon. These polymers possess the unique ability to be shaped and molded under heat and pressure while retaining their stability once formed. This high formability makes them widely used in various industries, including furniture production, plumbing fixtures, automotive components, food packaging containers, and other consumer products. This package introduces a thermodynamically consistent damage model capable of accurately predicting failure in thermoplastic polymers. The implementation of this model is explained through the use of an ABAQUS user material (UMAT) subroutine.

The package is structured as follows. The introduction section Provides an overview of thermoplastic polymers and their mechanical properties. In the Theory section, the constitutive damage model and its formulation are reviewed. Then, an algorithm for numerically integrating the damage constitutive equations is presented in the Implementation section. In the UMAT Subroutine section, a detailed explanation of the flowchart and structure of the subroutine is provided. Finally, two simulation examples, namely the T-fitting burst pressure test and the D-Split test, are performed and the obtained results, are investigated.

Notice: Software files and A full PDF guideline (Problem description, theory, ...) are available; Videos are coming soon.

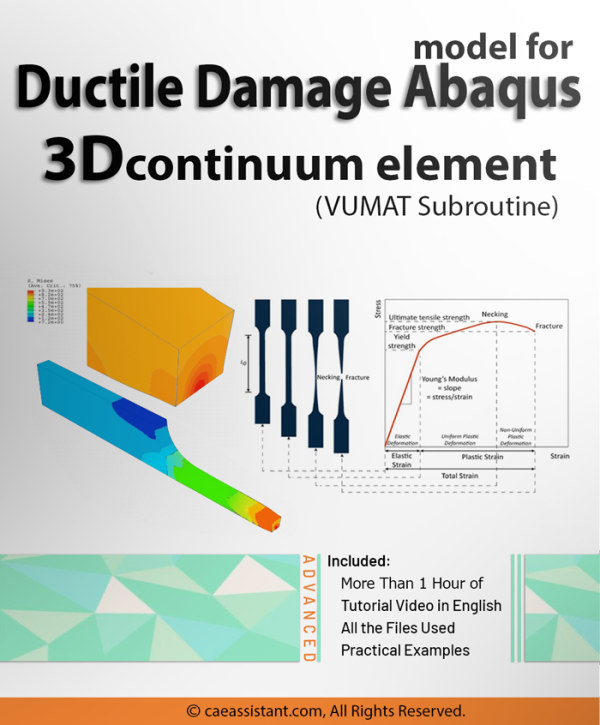

Ductile Damage Abaqus model for 3D continuum element (VUMAT Subroutine)

In this package, the continuum damage mechanics framework for ductile materials is implemented and developed in ABAQUS by VUMAT Subroutine.

Constitutive modeling is treated within the framework of continuum damage mechanics (CDM) and the effect of micro-crack closure, which may decrease the rate of damage growth under compression, is incorporated and implemented.

The present package has been organized as follows. In the Introduction section, the basis of the CDM in ductile materials is explained, and the applications of the CDM are stated. In the Theory section, the CDM model formulation is briefly reviewed, and with micro-crack closure, the effect is described. In the Implementation section, an algorithm for the numerical integration of the damage constitutive equations is presented. In the VUMAT Subroutine section, the flowchart of the subroutine, and the subroutine structure, step by step, are explained in detail. How to run the VUMAT Subroutine in ABAQUS will be presented in this section. In the Verification section, the validation and verification of the numerical implementation will be evaluated, and the stability, convergence and accuracy of the results will be investigated. In the Application section, the applications of using the ductile damage model in mechanical processes are presented, and the prediction of damage growth and failure in mechanical processes is investigated.