Abstract

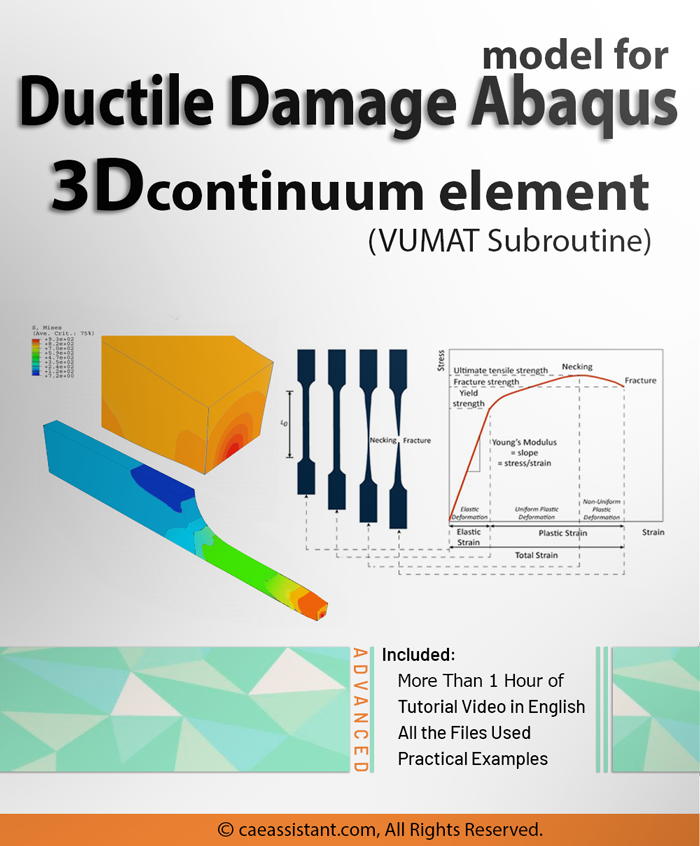

In this package, the continuum damage mechanics framework for ductile materials developed by Lemaitre is implemented and developed in ABAQUS by VUMAT Subroutine. A wide range of element types, material models and other facilities, such as efficient equation solvers, are available for the user in the ABAQUS software. A fully coupled constitutive elastic-plastic-damage model is used. Ductile Damage Abaqus modeling is fully described here in this training package.

Constitutive modeling is treated within the framework of continuum damage mechanics (CDM), and the effect of micro-crack closure, which may decrease the rate of damage growth under compression, is incorporated and implemented.

The present package has been organized as follows. In the Introduction section, the basis of the CDM in ductile materials is explained, and the applications of the CDM are stated. In the Theory section, the CDM model formulation is briefly reviewed, and with micro-crack closure, the effect is described. In the Implementation section, an algorithm for the numerical integration of the damage constitutive equations is presented. In the VUMAT Subroutine section, the flowchart of the subroutine, and the subroutine structure, step by step, are explained in detail. How to run the VUMAT Subroutine in ABAQUS will be presented in this section. In the Verification section, the validation and verification of the numerical implementation will be evaluated, and the stability, convergence and accuracy of the results will be investigated. In the Application section, the applications of using the ductile damage model in mechanical processes are presented, and the prediction of damage growth and failure in mechanical processes is investigated. You can get more information about Ductile Damage Abaqus modeling on the right-side of this page.

Read More: ddsdde abaqus umat

Introduction

The damage of materials is the progressive physical process by which they break. Damage mechanics is the study, through mechanical variables, of the mechanisms involved in this deterioration when the materials are subjected to loading. In the section, the phenomenological aspects of damage with a description of the different kinds of damage are introduced. Particularly damage models in ductile metals are proposed by Chaboche [1], and Lemaitre [2] are discussed. Under compressive loading, voids and micro-cracks that would grow under tension will partially close, reducing the damage growth rate. This phenomenon can be important in the simulation of forming processes. In this section, all the necessary conditions and parameters affecting ductile damage modeling are introduced.

If you are a beginner in Abaqus simulation, it would be helpful to check out our free Abaqus tutorials on the Free Abaqus Training page.

Read More: damage mechanics

Users ask these questions

In social media, users asked questions regarding Abaqus ductile damage issues, and we answered a few of them; you can see them below.

I. Necking in Abaqus

Q: Dear all, I am modeling a steel pipe under cyclic loading. The ultimate strain demand of the pipe is expected to be around 10%. So theoretically necking is not expected. However, during the analysis, at final cycles with strain demand of 9-10 %, the pipes starts to neck . I refined the mesh but the necking still occurs. Oks note that the model does not include damage model and only a combined hardening rule has been specified fir steel. Does anyone know what is the origin of such a necking?

A: Greetings, The Ductile damage in abaqus package can help a lot. Your model needs to be checked. Just visit our consultancy and get help from our experts. https://caeassistant.com/consultancy/

Best wishes.

II. Shear testing in tension

Q: In a tensile shear test, I’m using AA2024 and other aluminum alloys for the blank, but I need the Ductile Damage (Fracture strain, stress triaxiality, strain rate) and Shear Damage (Fracture strain, stress triaxiality, strain rate) as well as plasticity.

How can I acquire AA2024’s “Ductile Damage” and “Shear Damage” in Abaqus?

A: To have these properties, you should check for a handbook that might contain these sorts of properties. Visit the manufacturer’s website. Check for related articles that might have material properties. Or, you could do a simple tensile test in a laboratory yourself.

Theory

The theory assumes that the state of damage at any material point is isotropic and is represented by a single scalar internal variable, D, associated with the fraction of load carrying area across any surface at that point. The damage variable assumes values between 0 (for the undamaged material) and 1 (for the completely damaged material).

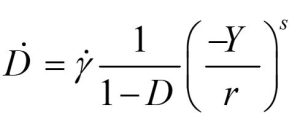

The evolution of the damage internal variable is assumed to be governed by the relation:

The effect of damage on plastic behaviour can be presented by von Mises yield function:

where is the accumulated plastic strain, r, s are material constants, The quantity

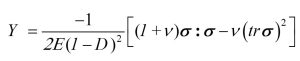

and Y, is the damage energy release rate, with E and n denoting, respectively, Young’s modulus and Poisson’s ratio of the undamaged material.

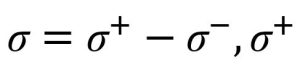

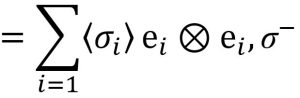

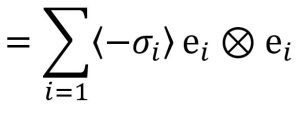

For the crack closure effect; the compressive/tensile additive split of the stress tensor:

where and

are, respectively, the tensile and compressive components of

. The numerical prediction of material degradation, based on the damage model without crack closure effects, is not in agreement with experimental evidence, which shows that only a relatively small damage accumulation results from the process.

The theory required for the implementation of the ductile damage model according to the modified Lemaitre model will be presented

Implementation

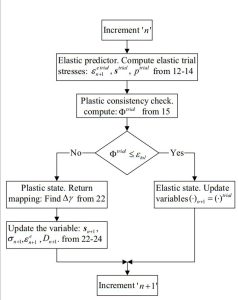

This section yields to describe an algorithm for the implementation of the elastic-plastic-damage constitutive equations including the effect of crack closure. Algorithms based on the operator split concept, resulting in the standard elastic predictor/plastic corrector format, are widely used in computational plasticity. The flow chart of the elastic predictor/return mapping algorithm for the elastic-plastic-damage model is implemented as shown in figure 1 based on article titled” Numerical analysis of damage evolution in ductile solids“:

Figure 1: Flow chart of elastic predictor/return mapping algorithm for the elastic-plastic-damage model / Ductile Damage Abaqus.

VUMAT Subroutine

To introduce the ductile damage Abaqus model, a user material subroutine VUMAT is developed in ABAQUS software package. In the VUMAT subroutine, the damage variable will be calculated in each the integration points (or Gauss points) locally. The element deletion option is used with VUMAT to induce ductile crack growth. The developed VUMAT subroutine has the ability to analyze ductile damage in three-dimensional and plane strain cases. 3D and 2D plane strain problems. According that the VUMAT subroutine is run in the ABAQUS/Explicit, it can be used in various problems that require complex contact algorithms. How to run the VUMAT subprogram in ABAQUS will be explained in this section for loading in simple models, such as one element.

Verification VUMAT Subroutine

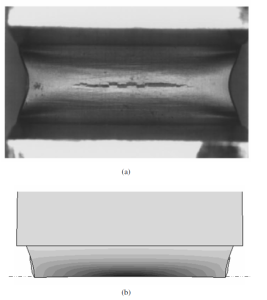

Validation and verification of the numerical implementation will be evaluated in various examples. The ductile damage Abaqus model has been verified by solving two numerical examples using ABAQUS/Explicit in two- and three-dimensional solid elements. The first example is the simulation of a two- and three-dimensional tensile test on a specimen subjected to monotonic axial loading. In the second example, the simulation of a three-point bending test is investigated (figure 2). The stability, convergence, and accuracy of the results in these two examples are also evaluated.

Read More: abaqus damage

Figure 2: Comparison of experimental crack initiation location in three-point bending test

Application of the VUMAT Subroutine

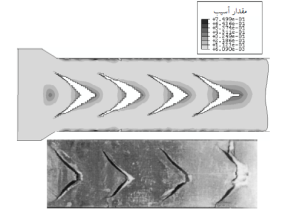

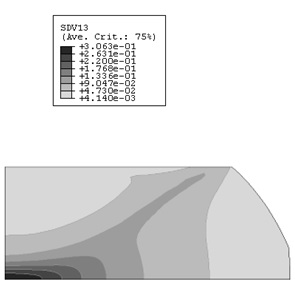

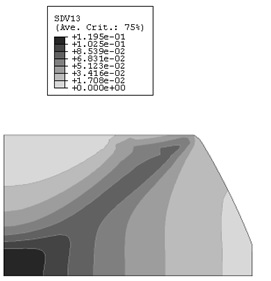

The modified ductile damage Abaqus model can be used to predict prediction of damage growth and failure in various mechanical processes. For example; the modified ductile damage model is applied to predict initiation of the micro-void as a central burst along the bar axis during the forward extrusion (Figure 3), and prediction of fracture initiation area in the upsetting test of tapered axisymmetric specimen (Figure 4).

Figure 3: Prediction of central burst along the bar axis during the forward extrusion

Figure 4: Evolution of damage in tapered axisymmetric specimen

What is the Lemaitre damage model?

This model is a model whose hardening is isotropic and rate-dependent. Also, the yield is based on the von Mises criterion, which is combined with the Lemaitre damage model.

Is the Lemaitre damage model very different from the ductile damage models? And what is the difference between them?

Yes, this model is different from the normal damage model that exists in ABAQUS and other software. In the Lemaitre damage model, yielding and plasticization occur simultaneously with damage, but in the normal models that exist, the damaged area and the plasticity area are two separate areas.

Gottfried –

Using this package, I was able to quickly implement the ductile damage model in Abaqus and use it in my own analyses. The explanations provided were very comprehensive and easy to understand.

Gerhard –

This package has completely taught the process of implementing the ductile damage model in Abaqus. Using the provided explanations, I was able to successfully use this model in my projects.