Dr. Hanako Sato

Country: Japan

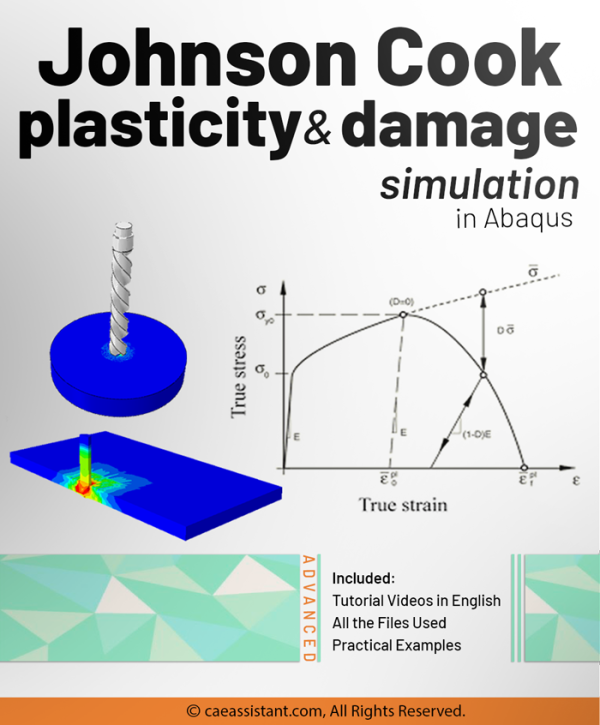

Expertise: Computational Fracture Mechanics using ABAQUS

Dr. Sato is a renowned researcher in Japan specializing in computational fracture mechanics with ABAQUS. Her background blends material science and engineering, allowing her to develop intricate material models within ABAQUS to simulate crack growth and fracture behavior in various materials. Dr. Sato’s work focuses on:

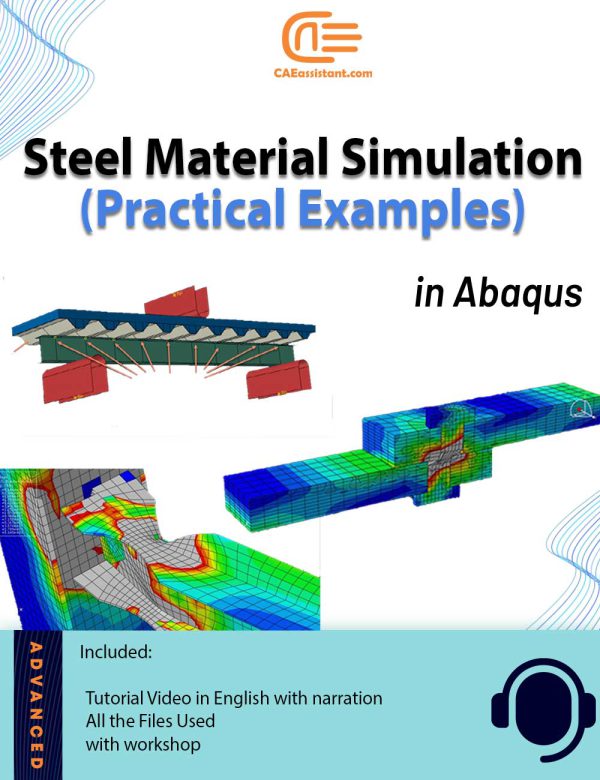

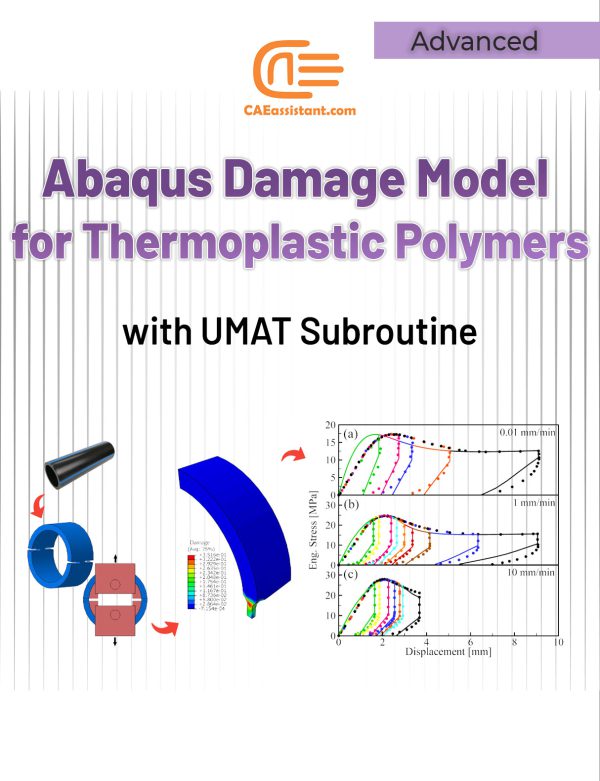

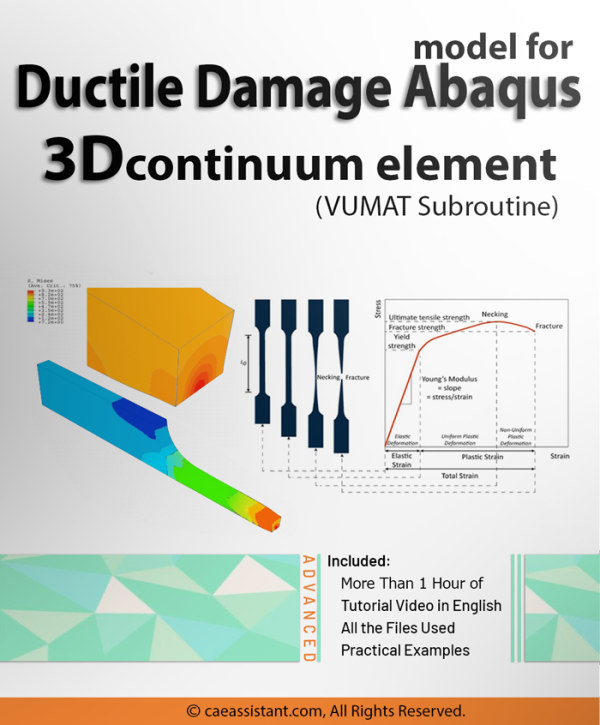

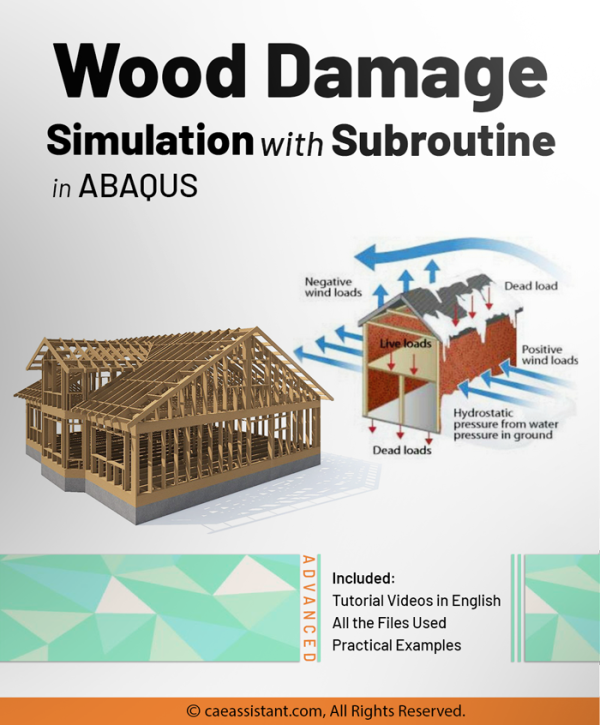

Material Constitutive Modeling: She creates and refines material behavior models within ABAQUS to accurately represent the fracture response of metals, composites, and other engineering materials.

Fracture Mechanics Simulations: Dr. Sato leverages ABAQUS to simulate crack initiation and propagation under diverse loading scenarios, including fatigue, stress corrosion cracking, and impact.

Failure Prediction: Her expertise allows her to predict the service life and potential failure points of components by analyzing the simulated fracture behavior within ABAQUS.

This focus on material modeling and its application in fracture simulations using ABAQUS makes Dr. Sato a valuable asset in fields like aerospace, automotive, and civil engineering, where understanding fracture behavior is crucial for design and safety.