Abaqus Concrete structure Modeling | Practical Examples (Part 3)

If you are a researcher, student, university professor, or Engineer in the company in the field of civil engineering, Abaqus concrete structure modeling package in simulating concrete and structural Engineering is the best selection.

The package includes 5 workshops on topics such as concrete, beam-column structures, composites, steel rebars, Ultra-High-Performance-Fiber-Reinforcement Concrete columns, CFRP bars, hollow-core square reinforced concrete columns wrapped, damaged concrete beams, High Strength Concrete(HSC),ECC/Concrete Composite Beam-Column Joints, circular concrete-encased concrete-filled steel tube (CFST) stub columns, and etc.

You can see the syllabus and details of this project below or the drop-down menu on the right side of this product page.

![]() It will guide you going from the basics up to complex simulation techniques. It is very fluid, and comprehensive and every single detail is explained.

It will guide you going from the basics up to complex simulation techniques. It is very fluid, and comprehensive and every single detail is explained.

![]() Every workshop goes straight to the point, without any worthless piece of content. You will learn what you need at every stage and you will be putting it into practice from the very first day.

Every workshop goes straight to the point, without any worthless piece of content. You will learn what you need at every stage and you will be putting it into practice from the very first day.

![]() Most importantly, we support you as you learn in this course. You can contact our experts to ask your questions and enjoy our modelling and simulations step-by-step support.

Most importantly, we support you as you learn in this course. You can contact our experts to ask your questions and enjoy our modelling and simulations step-by-step support.

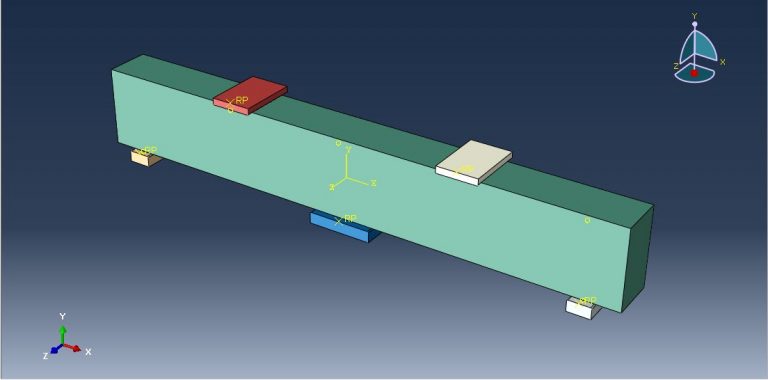

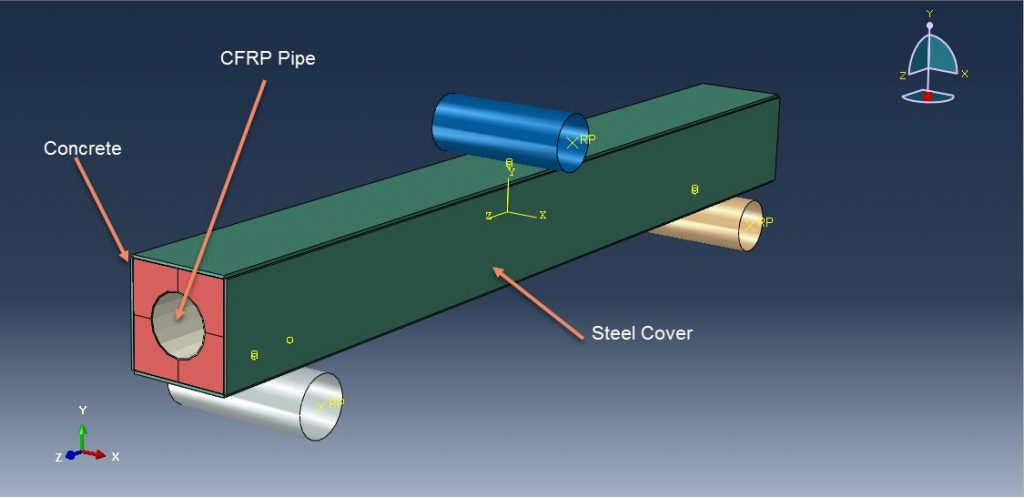

Workshop-1: Finite element simulation of ECC/Concrete Composite Beam-Column Joints in axial loading

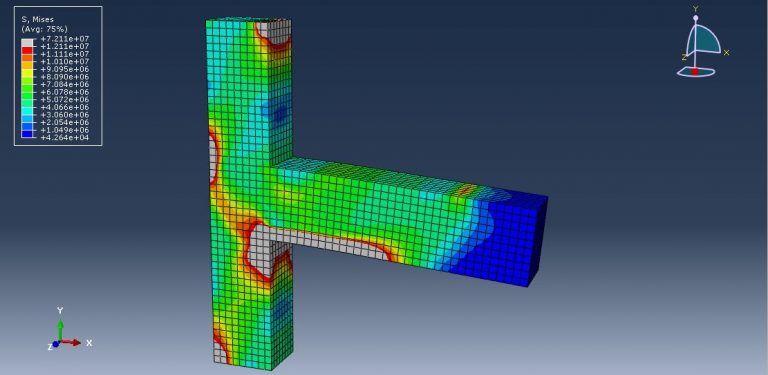

This workshop examines the simulation of ECC/Concrete composite beam-column joints subjected to axial loading in Abaqus. In conventional reinforced concrete frame structures, the seismic response is largely determined by the deformation capacity of critical components like beams, columns, and their joints. During seismic events, these elements must sustain significant inelastic deformations while maintaining their load-bearing capacity. Beam-column joints, in particular, bear vertical loads from beams and slabs, as well as horizontal forces from earthquakes and wind, resulting in complex stress distributions in the joint region.

Recently, high-performance fiber-reinforced cementitious composites, known as engineered cementitious composites (ECC), have been introduced in construction to address concrete’s brittleness. ECC exhibits similar tensile and compressive strength to conventional concrete but differs significantly in deformation behavior. While traditional concrete fails suddenly upon reaching its tensile strength, ECC demonstrates strain-hardening characteristics, allowing for continued load-bearing capacity beyond the initial crack formation through multiple micro-cracks.

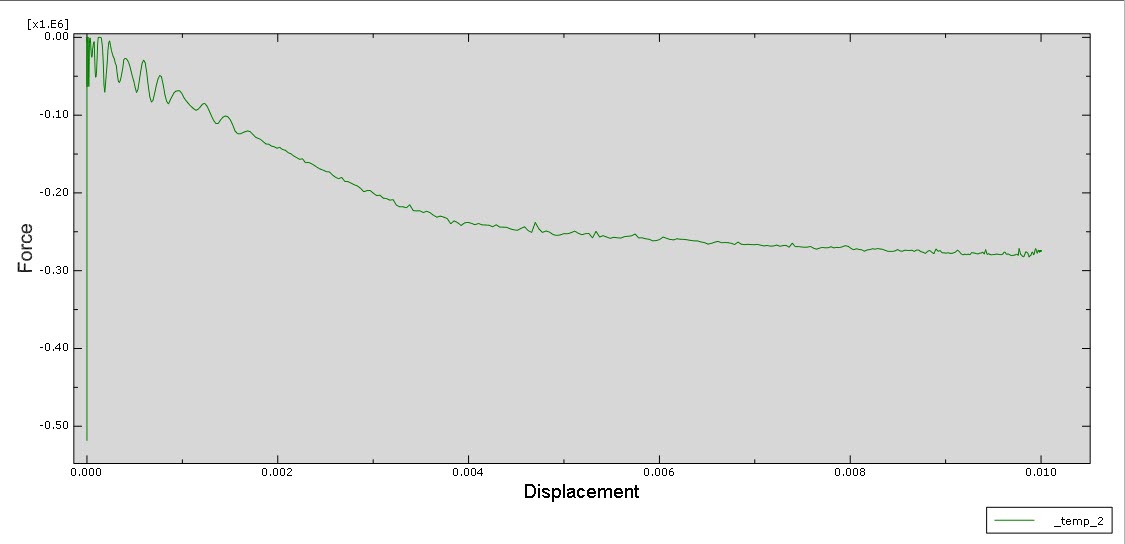

In the simulation, the beam and column are modeled as a single solid part, while reinforcement strips and bars are defined as three-dimensional wire elements. The concrete’s mechanical response is represented using the Concrete Damaged Plasticity model, with material properties sourced from reference literature. Steel reinforcement follows an elastic-plastic behavior. A general static step is applied to the analysis, and a surface-to-surface contact algorithm is used between the rigid plate and the concrete beam. Reinforcement bars and strips are embedded within the concrete, with fixed boundary conditions at both ends of the column and a displacement-controlled loading applied via the rigid plate. A refined mesh is necessary for accurate results.

Following the simulation, various results such as stress distribution, strain, and force-displacement responses can be extracted.

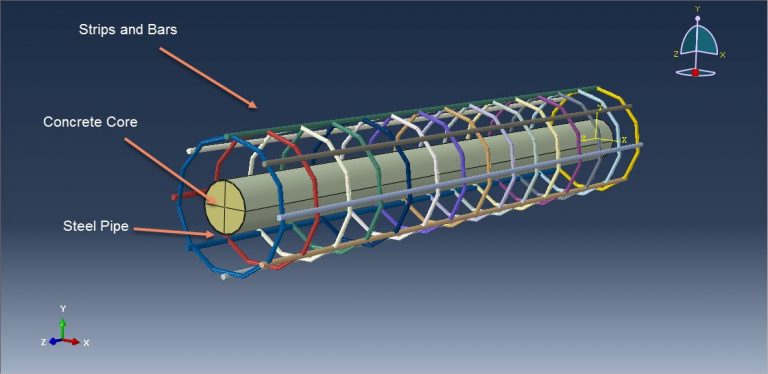

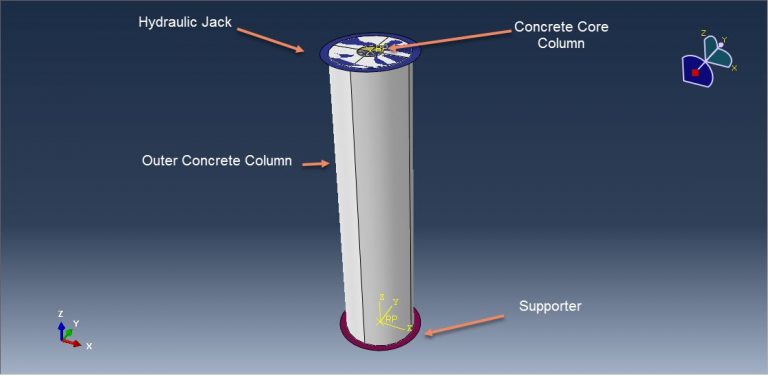

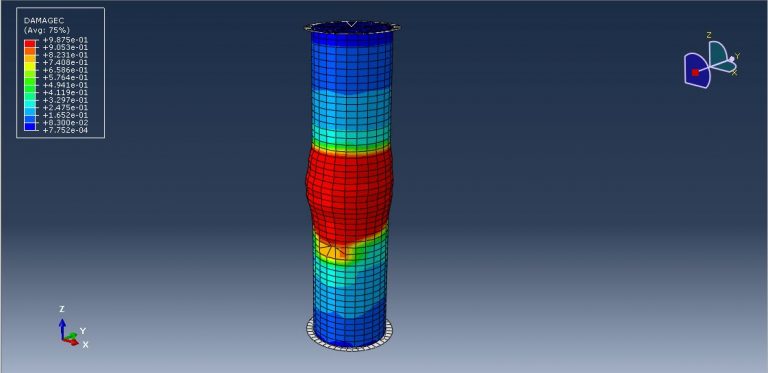

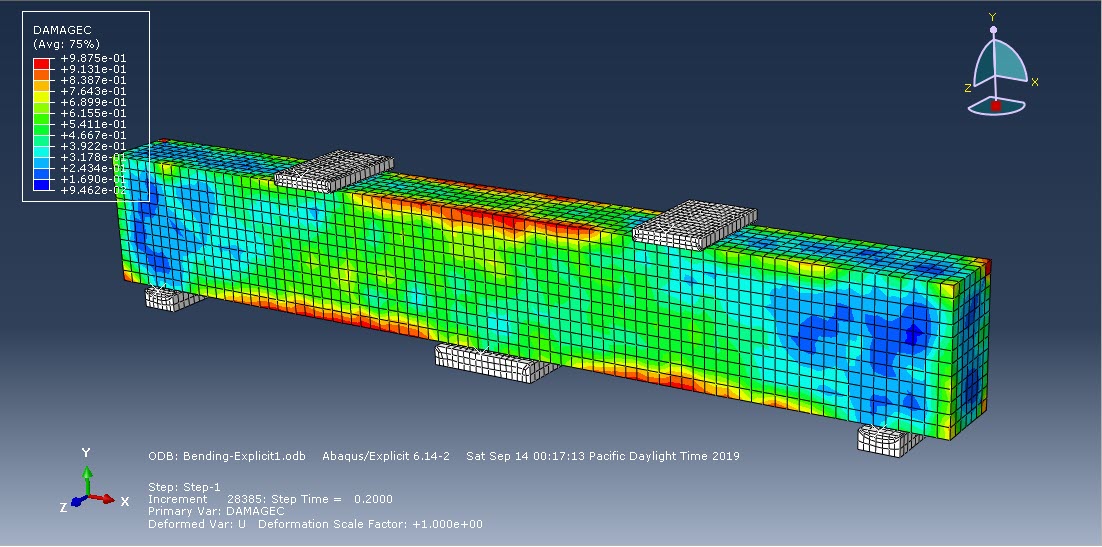

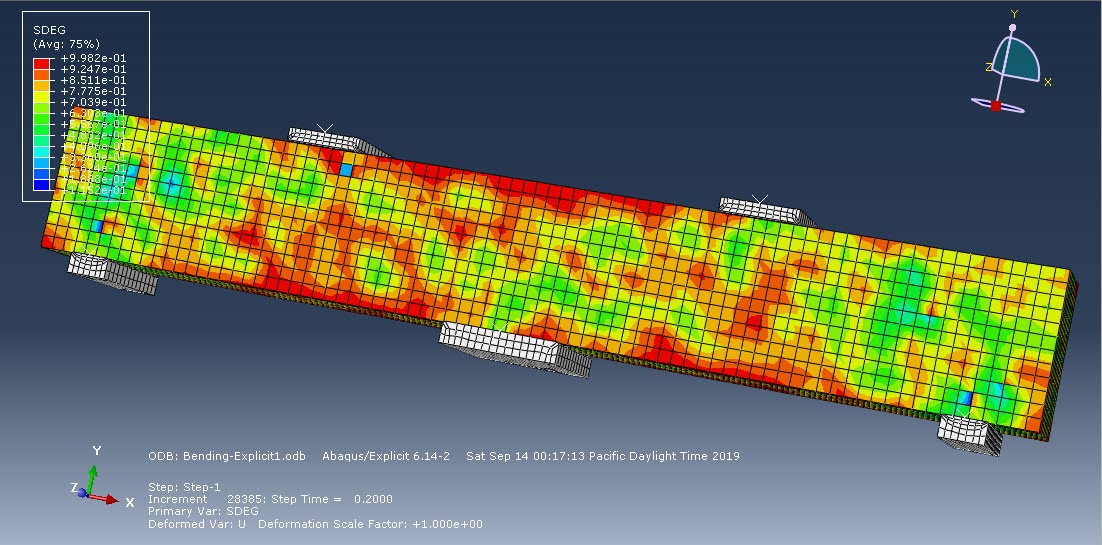

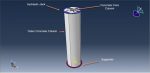

Workshop-2: Circular concrete-encased concrete-filled steel tube (CFST) stub columns simulation subjected to axial compression

This workshop explores the simulation of circular concrete-encased concrete-filled steel tube (CFST) stub columns under axial compression in Abaqus. Compared to conventional CFST columns, concrete-encased CFST columns offer advantages such as increased stiffness, improved connectivity with reinforced concrete (RC) beams, and enhanced resistance to fire and corrosion. Additionally, the presence of both inner and outer concrete layers allows for the use of thinner steel tubes while maintaining structural integrity. When compared to traditional RC columns, these composite columns exhibit superior strength and ductility, enabling the incorporation of high-strength concrete in the inner CFST, which reduces the required cross-sectional area.

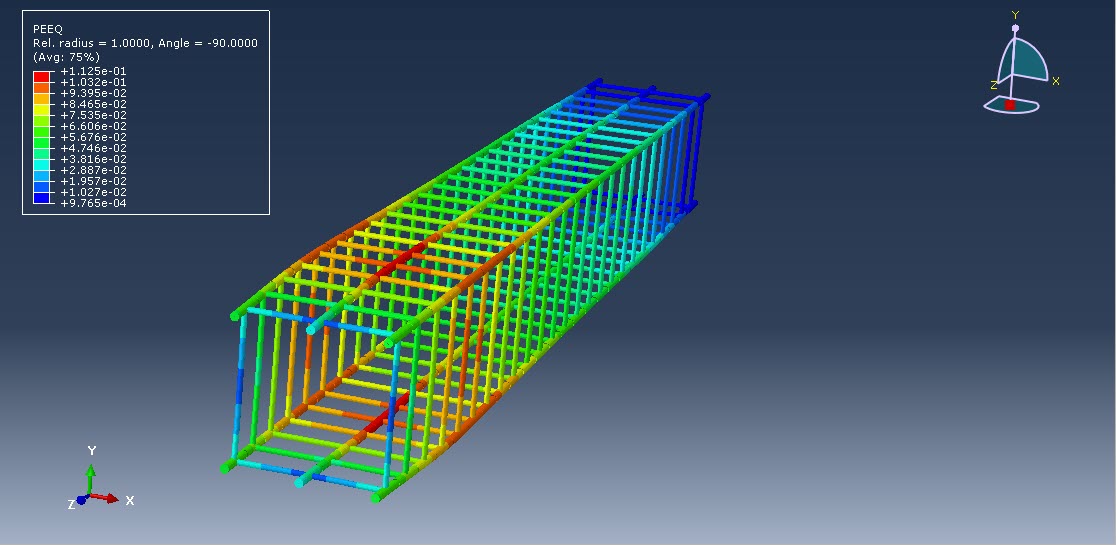

During construction, the inner CFST is assembled first, providing temporary support to bear construction loads before the outer RC component is added. Once the external formwork and reinforcement are installed, the outer concrete is cast. Various configurations exist depending on the combination of section shapes, including square or circular inner CFST and square or circular outer RC. The concrete core, steel tube, and external concrete components are represented as three-dimensional solid elements, while reinforcement strips and bars are modeled as wire elements.

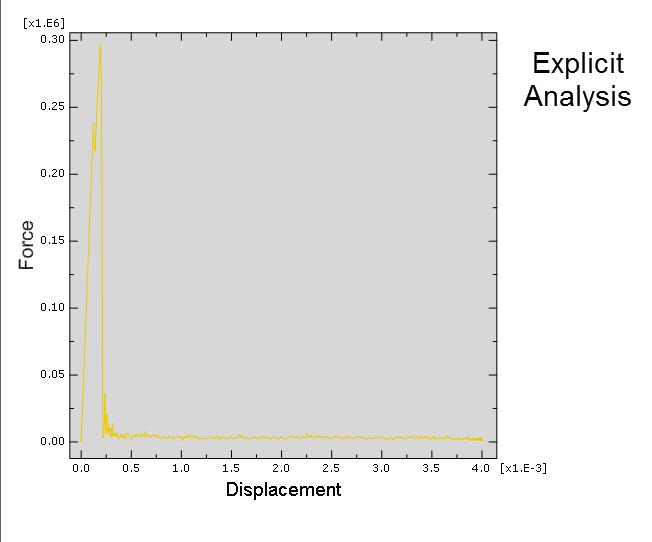

For material modeling, an elastic-plastic behavior is assigned to the steel strips and bars. The steel tube is also defined with an elastic-plastic model, incorporating a ductile damage criterion to capture failure mechanisms. Concrete components are modeled using the Concrete Damaged Plasticity approach, which accounts for tensile cracking and compressive crushing as primary failure modes. Two different analysis procedures are performed in this study: a general static step for static compression, which provides highly reliable results but requires longer computation time, and a dynamic simulation to reduce processing time while maintaining accuracy. The contact interactions are modeled using a general contact algorithm, assuming perfect contact between the concrete core and the steel tube’s inner surface, as well as between the steel tube’s outer surface and the surrounding concrete. A fixed boundary condition is applied at the base, while displacement-controlled loading is introduced at the top. A refined mesh is necessary for achieving stable convergence.

Upon completion of the simulation, results such as stress, strain, tensile and compressive damage, and force-displacement behavior can be extracted.

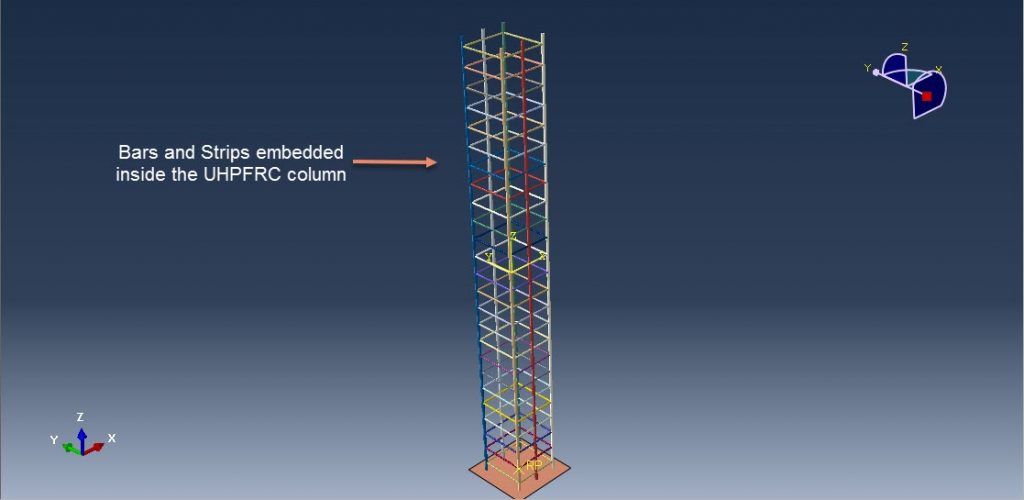

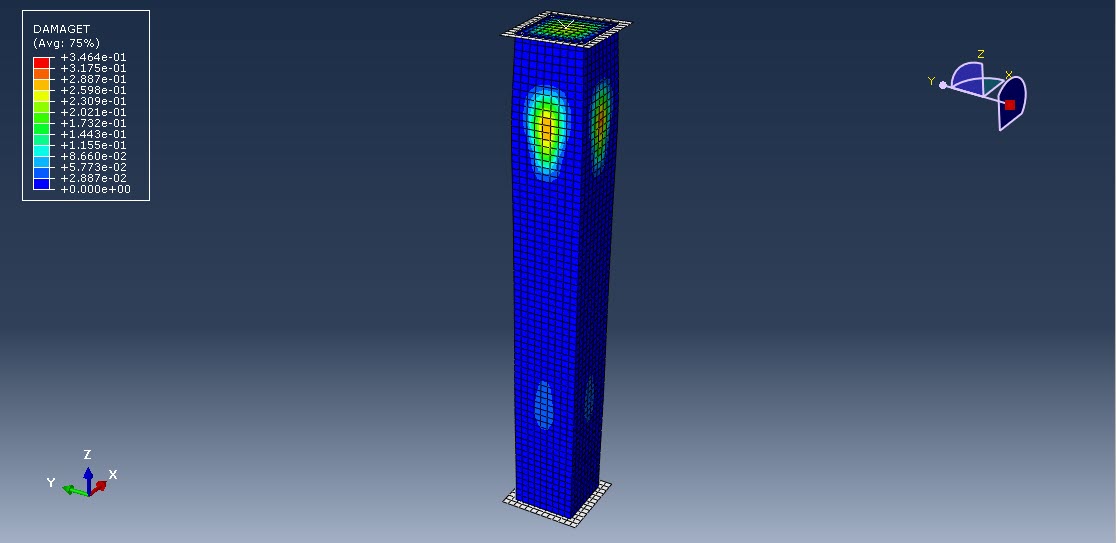

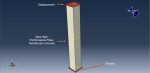

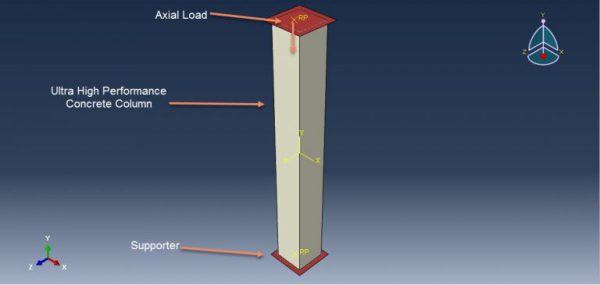

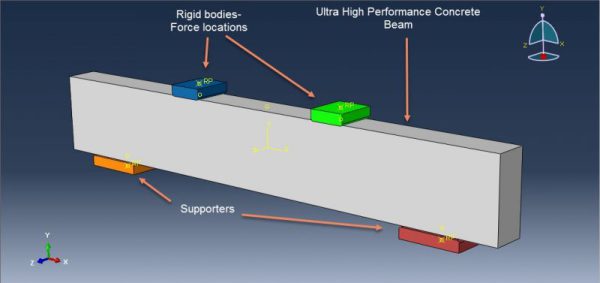

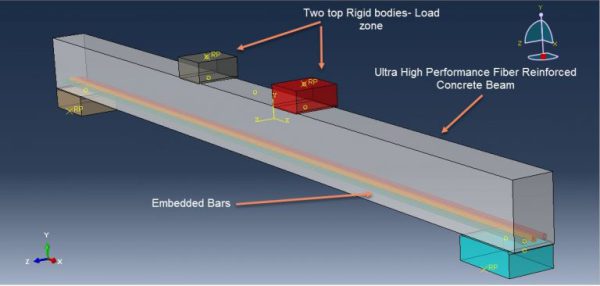

Workshop-3: Axial compression loading simulation in the Ultra-High-Performance Fiber Reinforced Concrete Column

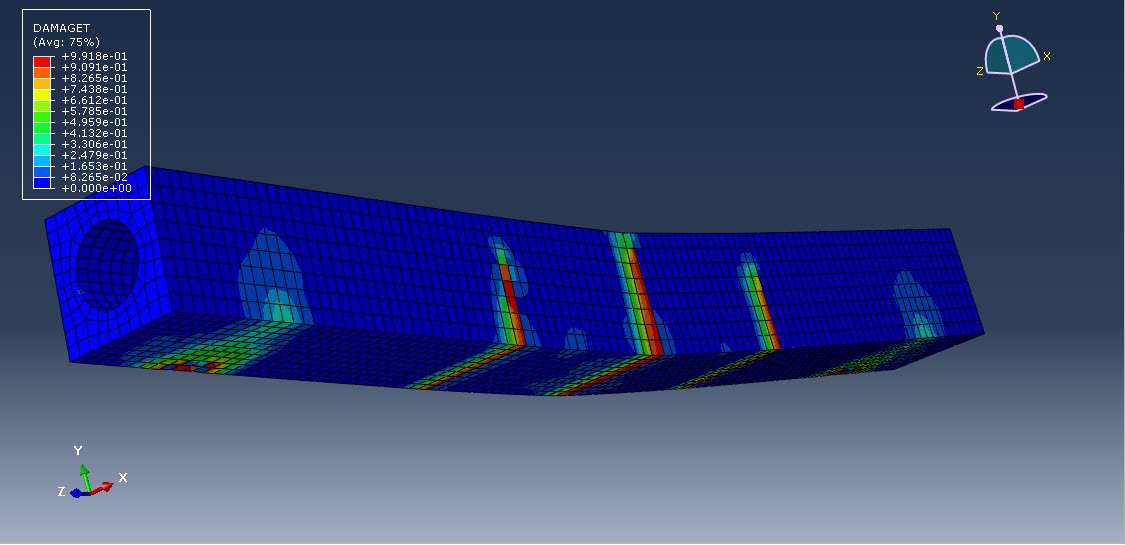

This workshop examines the simulation of a reinforced concrete (RC) column incorporating ultra-high-performance fiber-reinforced concrete (UHP-FRC) under compressive loading in Abaqus. UHP-FRC represents an advanced class of concrete with superior mechanical properties, including a compressive strength exceeding 150 MPa, tensile strength ranging between 8-12 MPa, and significantly higher fracture energy compared to conventional concrete. The column is modeled as a three-dimensional solid component, while reinforcement bars and strips are represented as three-dimensional wire elements.

The nonlinear behavior of the concrete is characterized using the Concrete Damage Plasticity (CDP) model available in Abaqus. This model is well-suited for capturing the response of both plain and reinforced concrete under various loading conditions. The CDP approach is chosen due to its ability to define independent yield strengths, strain rates, and damage parameters in both tension and compression. Additionally, it enables a refined representation of different concrete types through experimentally determined parameters, primarily used to establish the yield surface and flow rule in three-dimensional stress space. Tension and compression damage parameters are incorporated to predict material degradation during the compression test.

For the simulation setup, a general static step is employed, and surface-to-surface interaction properties are applied between the rigid bodies and the concrete column. Reinforcement bars and strips are embedded within the concrete. The base is assigned a fixed boundary condition, while a displacement-controlled load is applied at the top. A well-refined mesh is essential to ensure accurate results.

Upon completing the simulation, various results such as stress, strain, tensile and compressive damage, and the force-displacement response can be obtained.

Reviews

Clear filtersThere are no reviews yet.