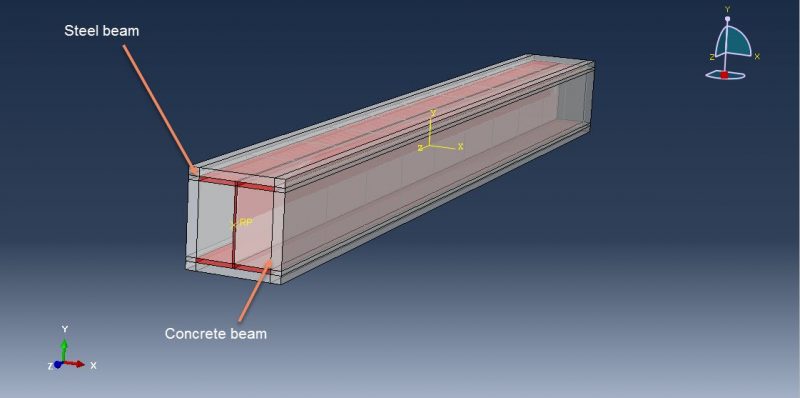

This workshop explores the simulation of a steel-concrete composite column subjected to both vertical and horizontal loading in Abaqus. Steel-concrete composite columns are modern structural elements widely utilized for their high load-bearing capacity, efficient material utilization, enhanced stiffness, ductility, and significant energy absorption. Research highlights that combining reinforced concrete (RC) with structural steel sections offers multiple advantages over conventional RC or steel members. The concrete component enhances fire resistance and helps restrain steel sections from buckling. Additionally, the use of steel-concrete composite columns positively influences concrete strain distribution compared to traditional RC columns. However, to prevent concrete spalling under axial loads, fire exposure, or seismic conditions, SRC columns require both longitudinal and transverse reinforcement.

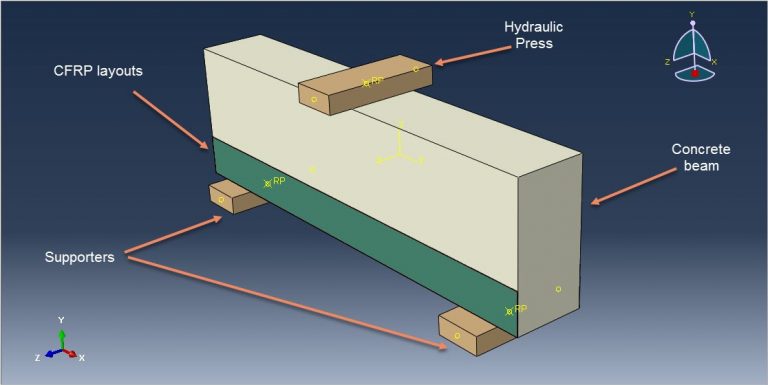

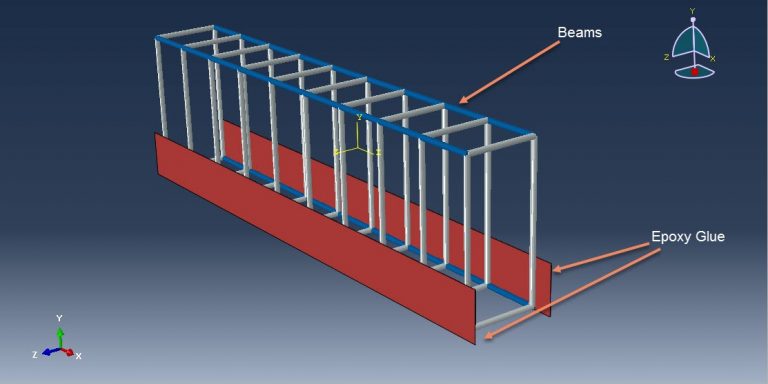

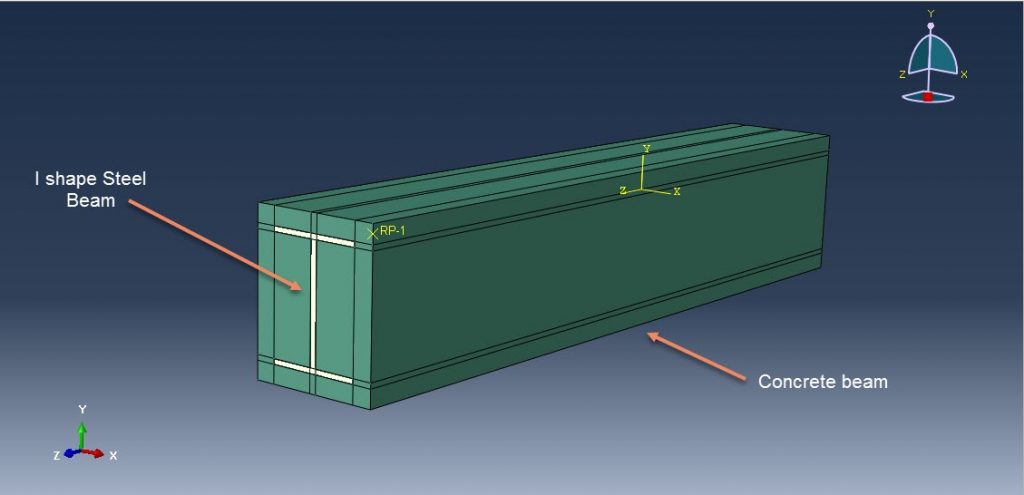

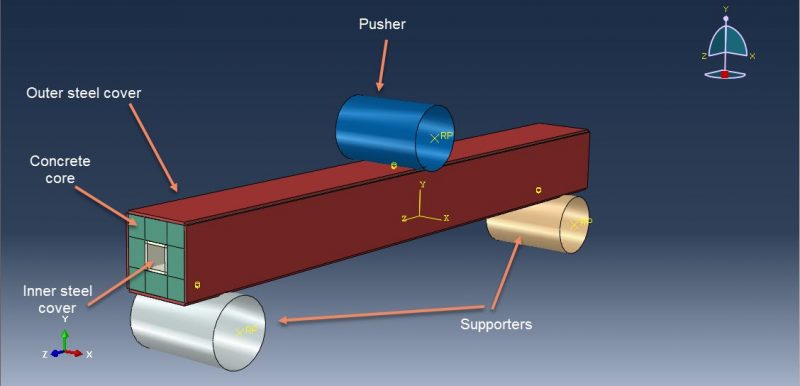

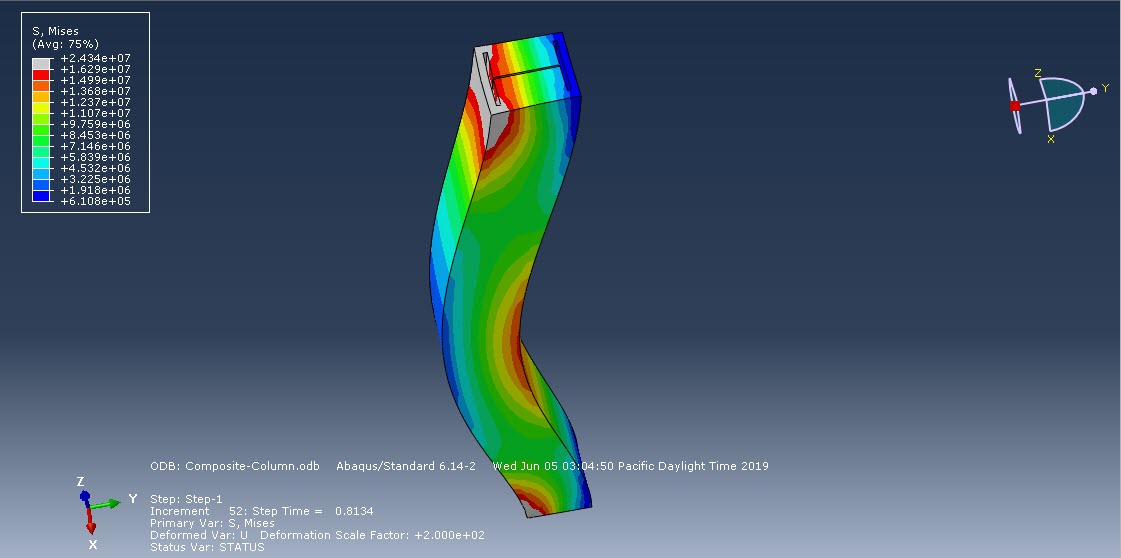

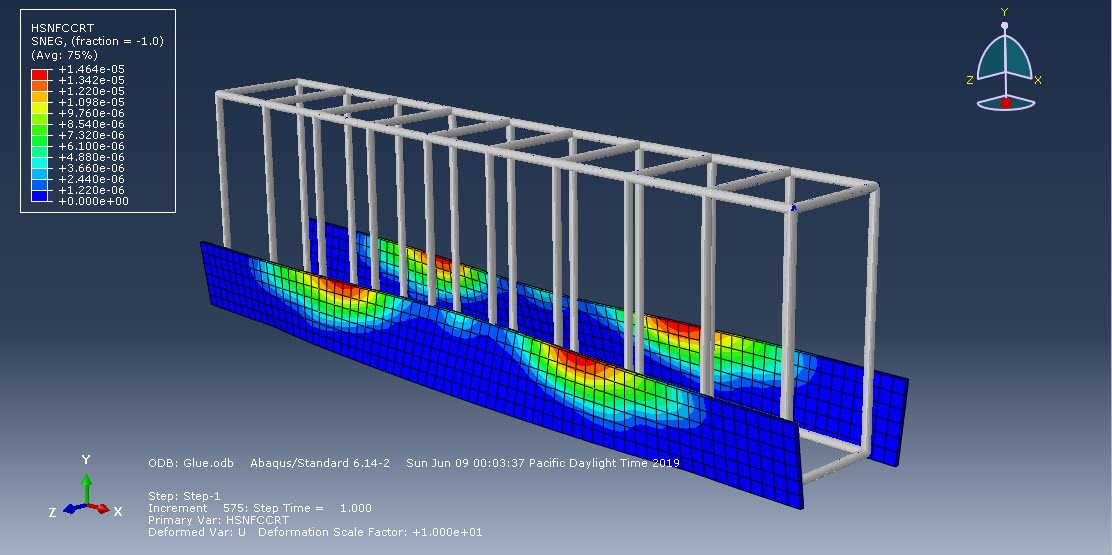

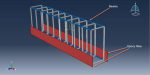

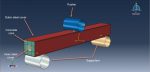

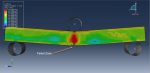

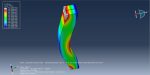

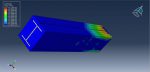

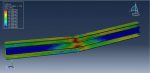

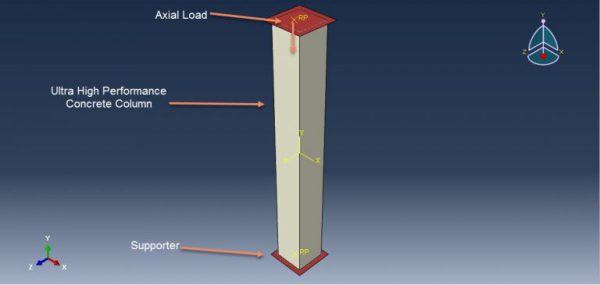

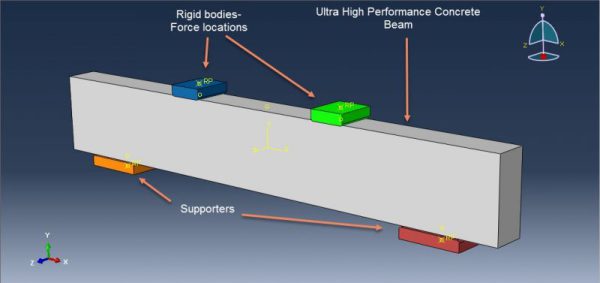

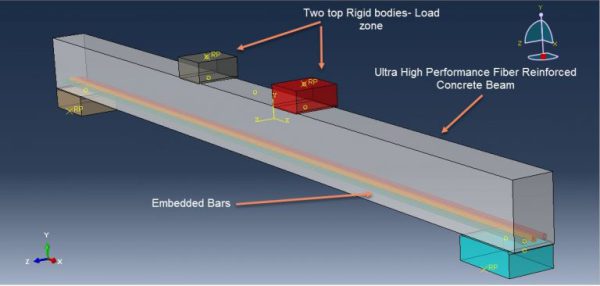

In this study, the concrete column and embedded steel beam are modeled as three-dimensional solid parts, while the reinforcement bars are represented as wire elements, and the pusher plate is treated as a rigid body.

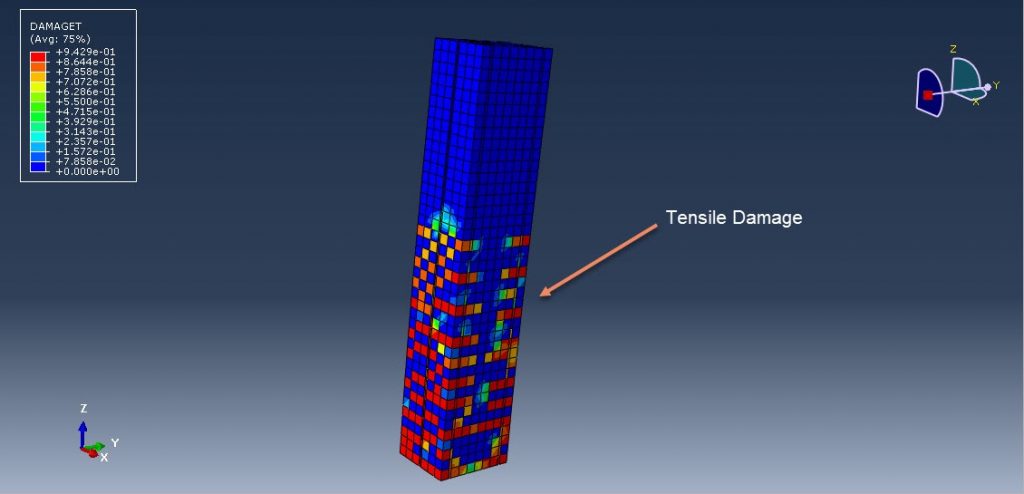

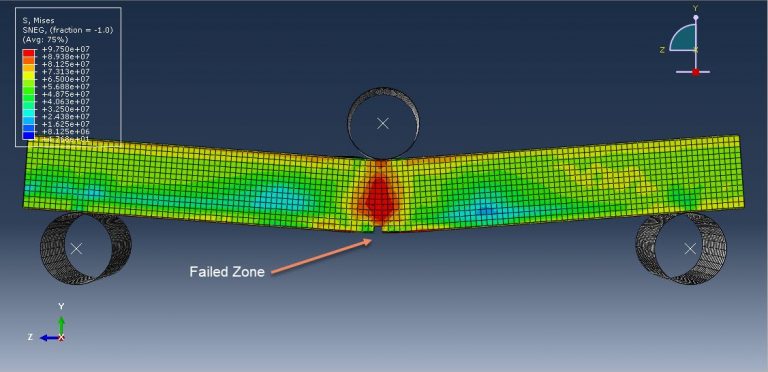

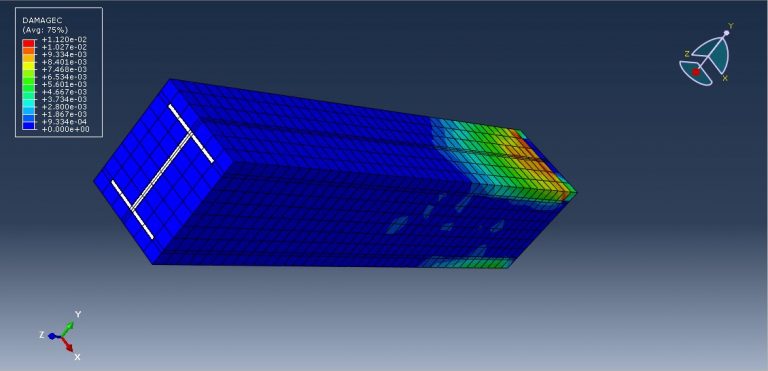

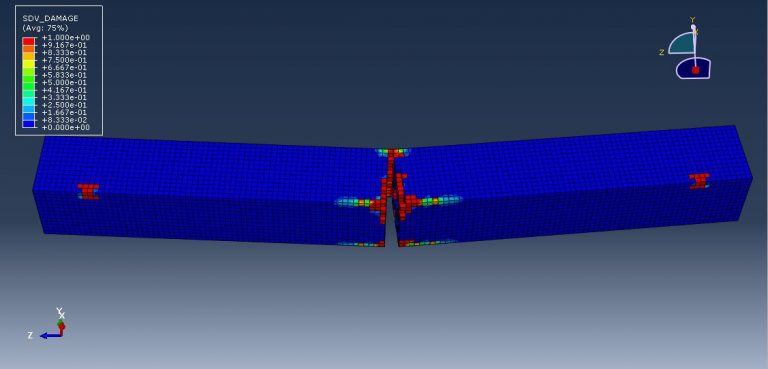

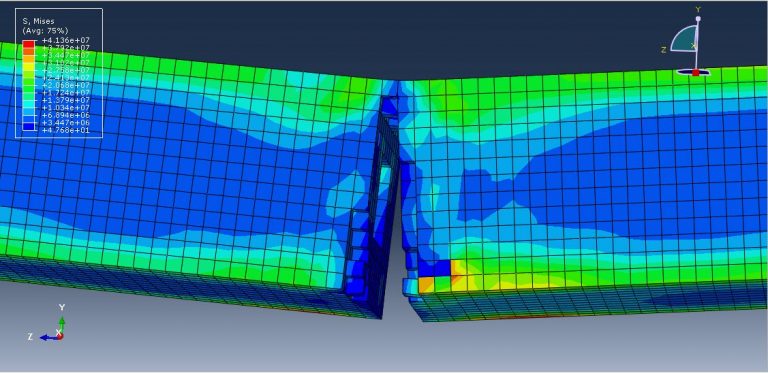

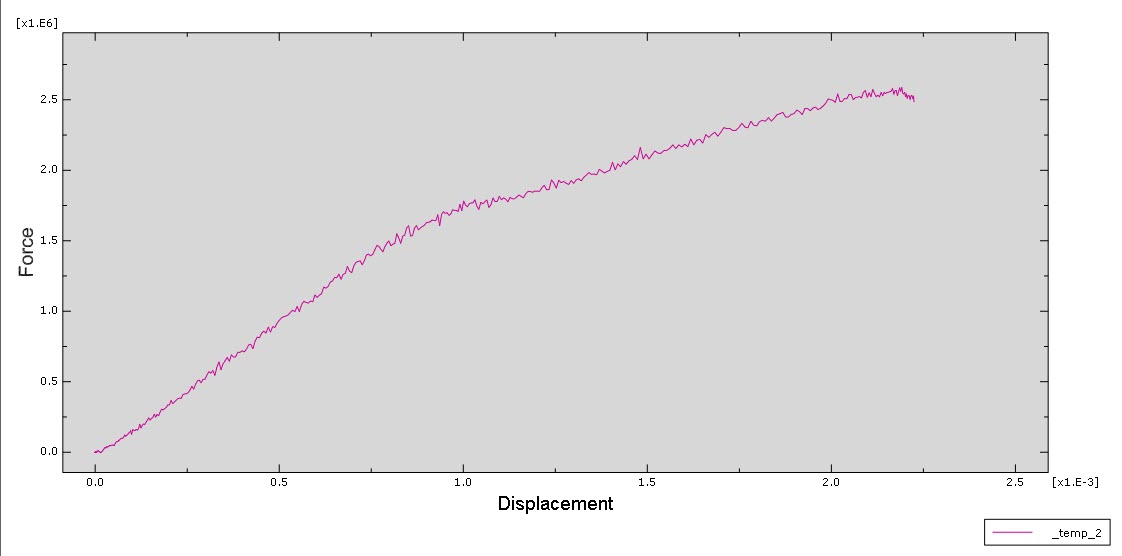

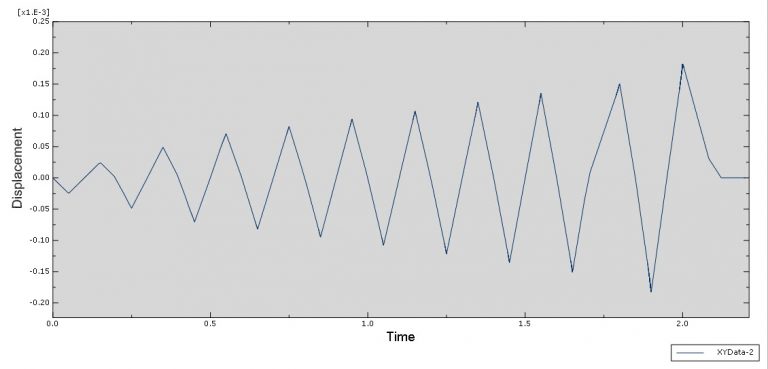

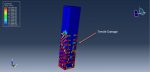

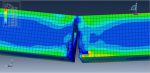

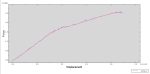

For material modeling, an elastic-plastic approach with a ductile damage criterion is applied to the steel sections, while the Concrete Damaged Plasticity (CDP) model is used for the concrete column. Two separate analysis procedures are conducted: a general static step and a dynamic explicit step, with the results compared at the end of the simulations. The interface between the concrete and steel beam is assumed to be perfectly bonded, and the reinforcement bars are embedded within the concrete. A vertical concentrated force is applied to the top of the column, while a lateral pressure load is applied to the side of the concrete section.

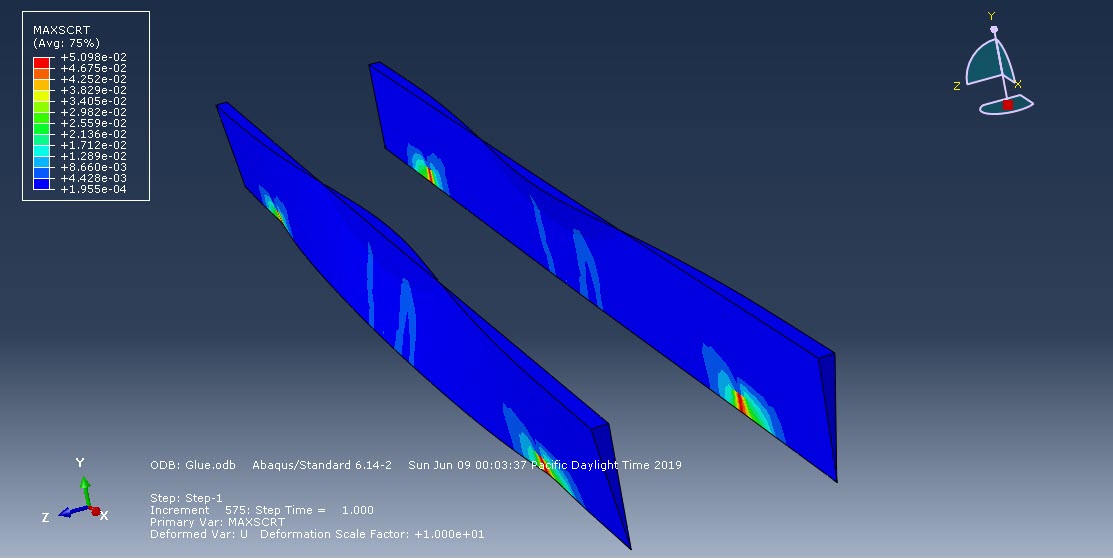

Following both static and dynamic simulations, various results—including stress, strain, damage, displacement, and force-displacement relationships—are obtained.

Reviews

Clear filtersThere are no reviews yet.