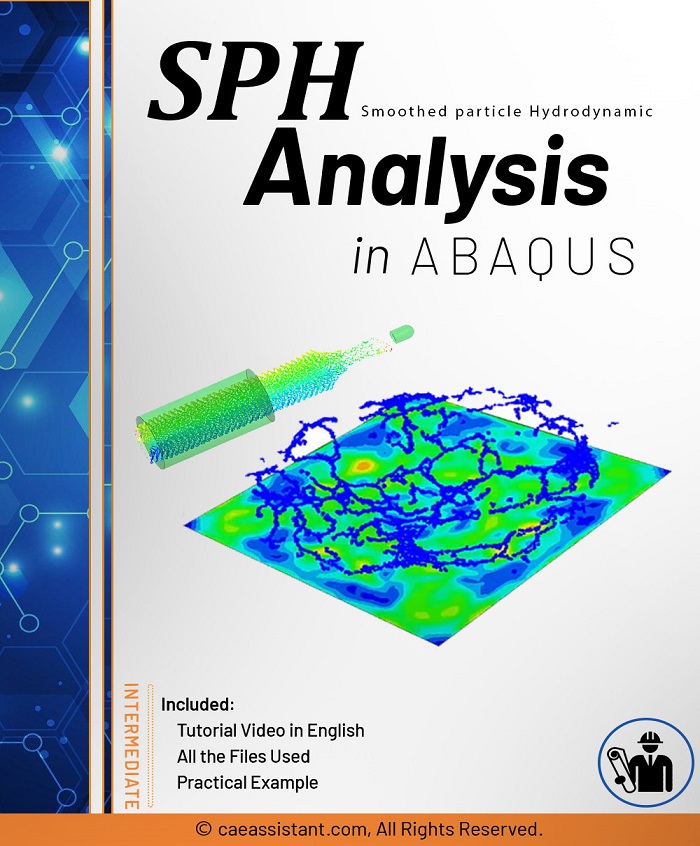

Introduction of Abaqus SPH Tutorial(Smoothed Particle Hydrodynamics Tutorial)

SPH in Abaqus (Smoothed Particle Hydrodynamics) is a numerical method used in Abaqus for modeling fluid-structure interaction problems. It is a meshless approach that uses a set of particles to discretize the fluid domain, allowing for efficient and accurate simulation of complex flows.

The method is particularly useful for problems with large deformations, fragmentation, and free surface effects. Abaqus’ implementation of SPH includes a wide range of capabilities, such as adaptive smoothing lengths, particle splitting and merging, and boundary handling techniques. It can be used in combination with other Abaqus features, such as finite element analysis, to model coupled fluid-structure systems.

Customer insights drive us forward!

If you choose us for your CAE Assistant and have experience with our tutorials, please share your comments in the review section. Your feedback could help others make the best decision and bring us closer to meeting our followers needs.

particles can be generated per parent element, or particles can be generated based on a uniform background grid. These two conversion techniques make use to turn Lagrangian elements to SPH particles.

In this Abaqus SPH modeling tutorial, you will learn that the particle generation technique, intended for use when significant deformations in the original finite element mesh occur, helps address potential element distortion.

Traditionally, in such cases, deletion of the soon-to-be distorted Lagrangian elements would be the only choice to allow the analysis to continue. Converting to SPH particles offers an improvement over the element deletion method because the generated particles can provide resistance to deformation beyond finite element distortion levels. Consequently, element deletion and element conversion can’t use together.

You can learn how to use this method by this smoothed particle hydrodynamics tutorial package; some of them are Projectile impact simulation on a cementitious material, TNT explosion simulation inside a rock with the SPH method, Bullet Movement through Water Pipe in Abaqus.

We have had the honor of assisting thousands of top students and researchers as CAE Assistant. Let’s have a look at 9 practical workshops. first is a famous example from the Abaqus SPH tutorial: Bird Strike Simulation in Abaqus. This example demonstrates two methods for implementing the SPH method in ABAQUS.

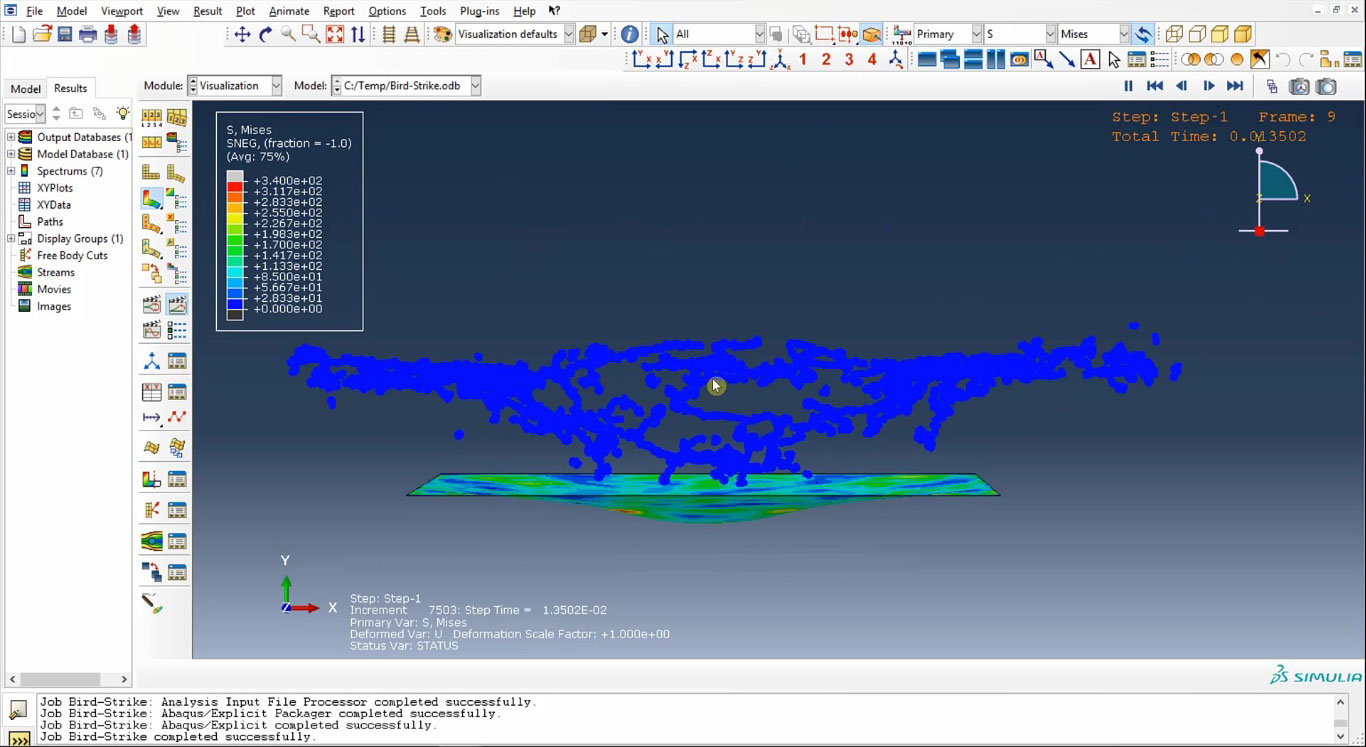

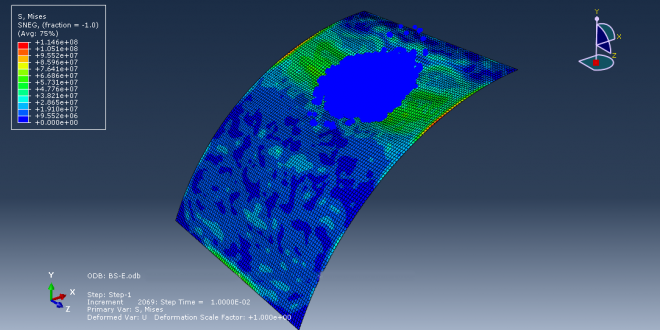

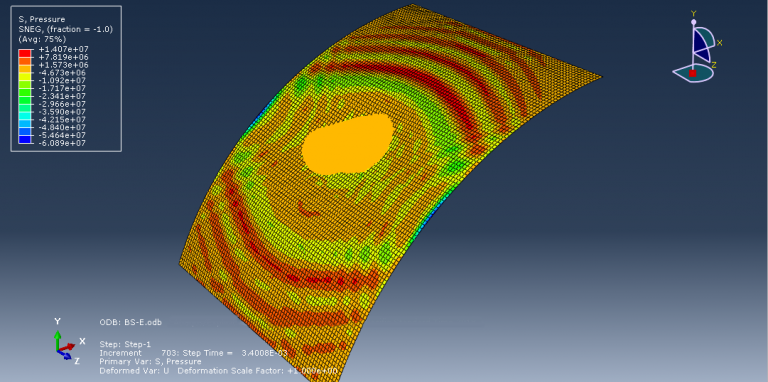

Workshop 1: Bird Strike Simulation in Abaqus

This workshop provides a detailed guide for a bird strike simulation in ABAQUS. During the analysis, the bird collides with the windshield. The SPH formulation is employed to model the bird’s behavior in this particular example. There are two ways to implement the SPH procedure in ABAQUS.

The first method involves using ABAQUS CAE, which can be a bit challenging, while the second method involves modifying the input file. We converted the C3D8R to PC3D and made other changes to facilitate interaction. An Elastic model is used for the windshield, while the Us-Up model is used for the bird.

This Abaqus SPH modeling tutorial offers several workshops, ensuring you’ll find one that closely aligns with your project. It will help you implement your own ideas. The next workshop focuses on water movement in a pipe.

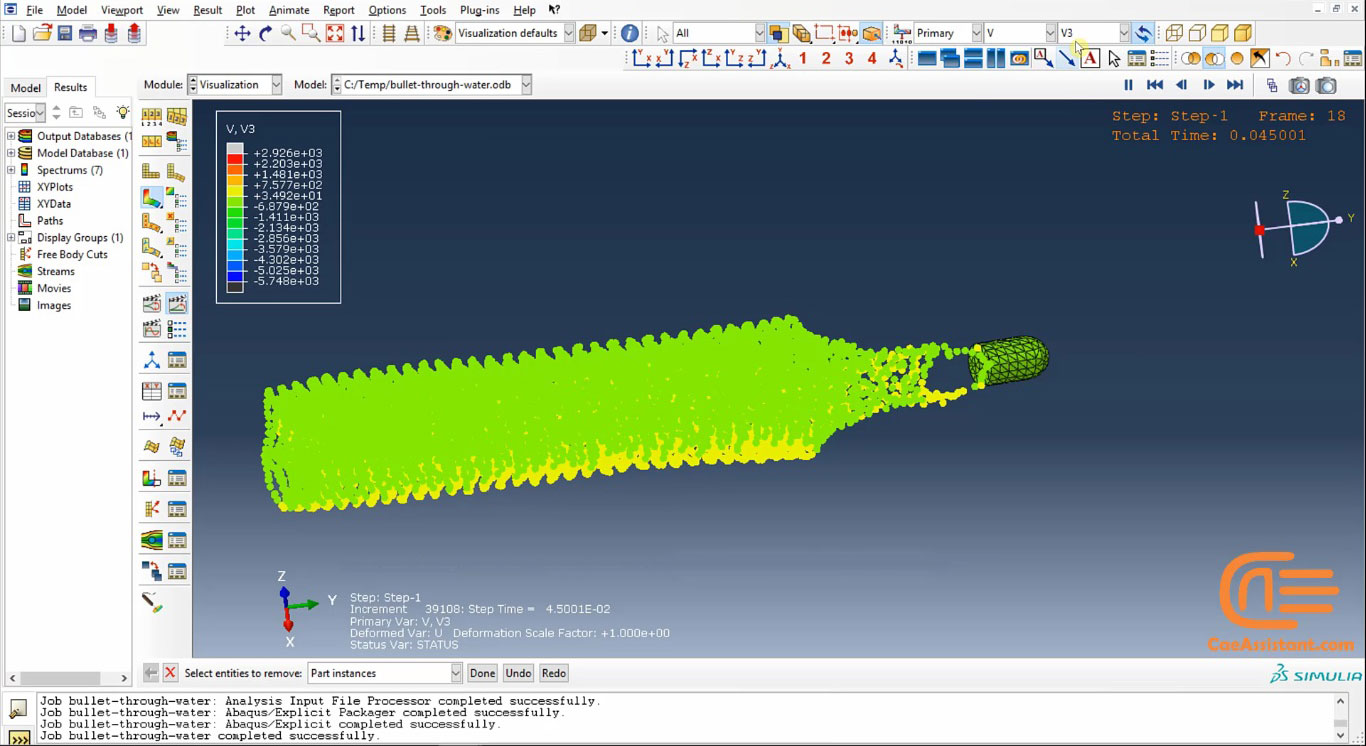

Workshop 2: Bullet Movement Through Water Pipe in Abaqus

The second workshop of this Abaqus SPH tutorial describes water movement in a pipe after the bullet’s passage. For severe collisions between water and solid, it is necessary to define SPH in the mesh module and consider specified boundary conditions.

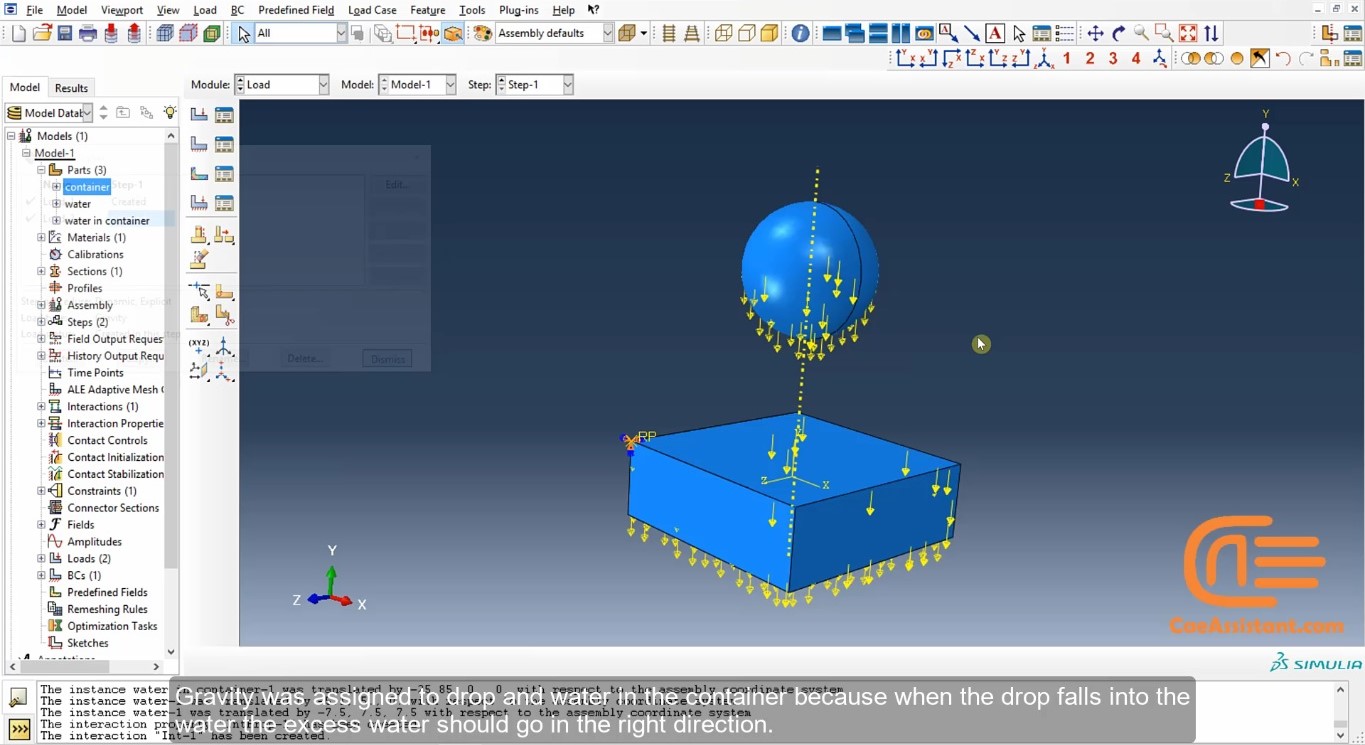

Workshop 3: Simulation of Water Mixing (Ball Drop into the Water Container)

In this workshop, we simulate the drop falling into a container full of water. Gravity assigns to drop and water in the container because the excess water should go in the right direction when the drop falls into the water.

Workshop 4: Simulation of Waterjet Cleaning in Abaqus

This Abaqus SPH modeling tutorial workshop investigated Waterjet cleaning over a plate for cleaning purposes. The modeling of this particle is the hydrodynamics (SPH) method, and for the material model, Us-Up equations have been placed. You can also see the Mises stress pattern of a point in the waterjet path.

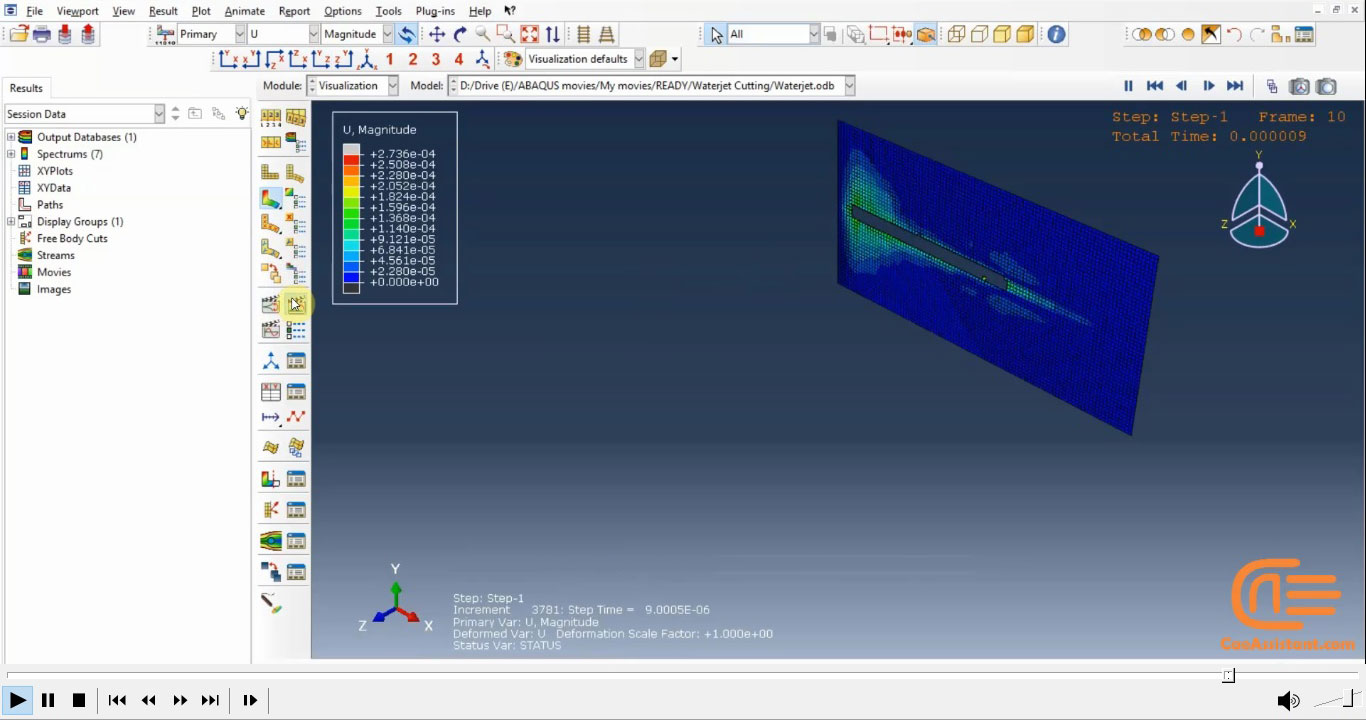

Workshop 5: Simulation of Waterjet Cutting in Abaqus

In this workshop, a plate was cutting with high-pressure water flow. Cutting with a water jet is a method for cutting objects using energy from high speed. The plate is modeled as solid, and for failure, during the impact, use the Johnson-Cook damage model.

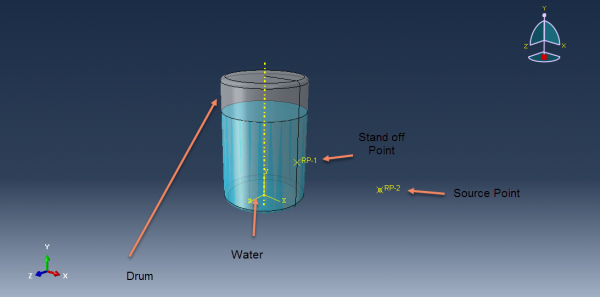

Workshop 6: Investigation of Cylindrical Steel Drums’ Behavior Under Blast Loading with the SPH in Abaqus

This tutorial investigates the behavior of cylindrical steel drums subjected to blast loading conditions using the SPH in Abaqus. Over the last few decades, numerous industrial accidents worldwide have highlighted the importance of understanding the effects of blast waves.

Detonations result in a sudden rise in pressure above atmospheric conditions, reaching a peak over pressure, followed by a gradual decay and a small negative phase. Deflagrations produce a blast wave with a gradual over pressure rise to peak value, followed by a decay and a negative phase with similar scale to the positive phase.

Detonation produces a blast wave with higher peak over pressure but shorter positive duration than deflagration. Deflagration can transform into detonation within a congested region. When a detonation blast wave impinges on a surface, it is reflected, with the magnitude of reflected over pressure depending on the incident wave parameters and target dimensions.

Reflected over pressure for deflagration is more closely related to the incident wave parameters and target dimensions, and does not have a significant enhancement as expected from a detonation blast wave of the same peak incident over pressure.

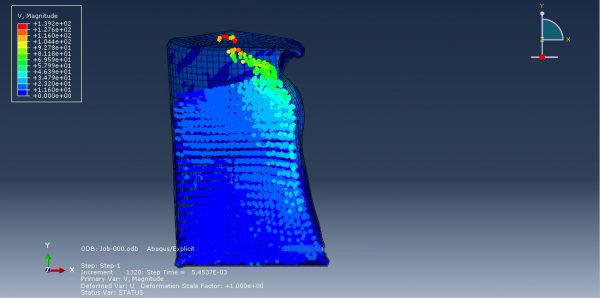

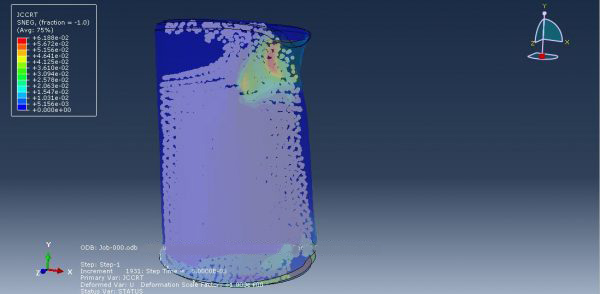

In the analysis, the drum undergoes significant deformation due to blast wave pressure, resulting in a sloshing phenomenon of the water inside the tank. To model the drum’s behavior under blast loading conditions, we have created this Abaqus SPH tutorial workshop. In this workshop, the Johnson-Cook plasticity and damage model was used for the drum, while the Us-Up linear form was utilized to model the water.

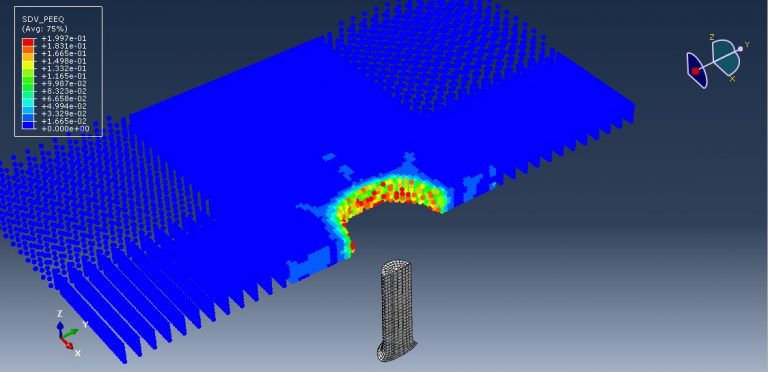

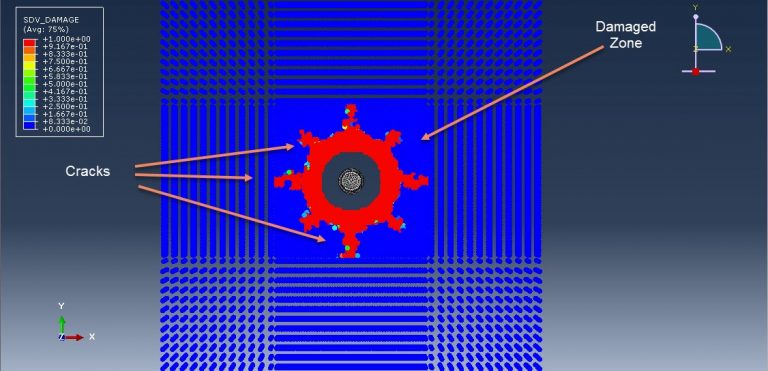

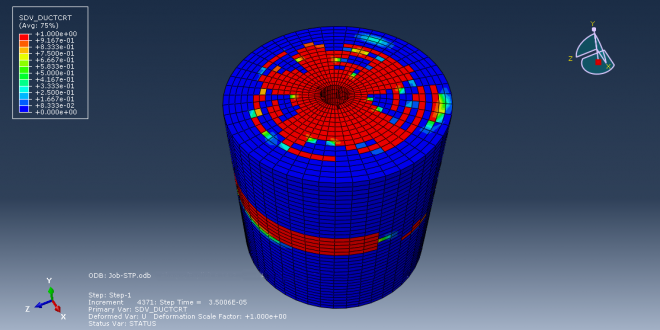

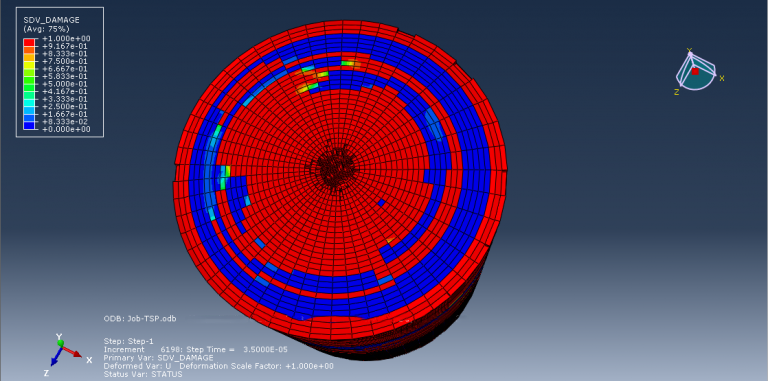

Workshop 7: Projectile Impact Simulation on a Cementitious Material with the SPH Method

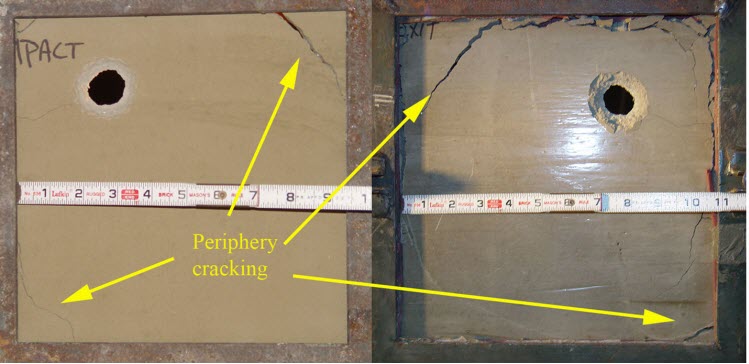

This smoothed particle hydrodynamics tutorial explores the finite element analysis of smooth particle hydrodynamics to study the effects of projectile impact on a cementitious material. The effectiveness of brittle, cementitious armor panels under high-rate impact is influenced by various factors, such as the geometries of the projectile and target, the velocity of impact, the material of the projectile, and the angle of impact.

Because of its low cost, ease of on-site manufacturing, and high early strength, HSC material has become an appealing option for passive protection against weapon effects. It is crucial to comprehend the performance of such armor panels under high-rate ballistic impact to ensure the safety of personnel in combat zones.

Accurately simulating the structural response of armor panels to dynamic loads can significantly reduce the cost of research and development for new materials and applications. The projectile and concrete panel are represented as a three-dimensional solid part in the simulation.

To model the behavior of the projectile, steel material with elastic properties and Johnson-Cook plasticity and damage criterion is utilized. Abaqus offers various models for concrete material, such as CDP, Brittle cracking, and more. Among these models, the Johnson-Holmquist model performs better and can be implemented using the VUMAT subroutine or input file.

The dynamic explicit step is suitable for this type of analysis, and the general contact algorithm with a friction coefficient for contact property is used. The concrete panel has a fixed boundary condition, while the initial velocity is set for the projectile. The SPH formulation is used for the concrete panel, and a fine mesh is required for the contact zone.

During the simulation, the projectile penetrated the concrete, resulting in significant damage at the impact zone. Various outputs can be obtained and analyzed, such as damage variables, stress, strain, and failure.

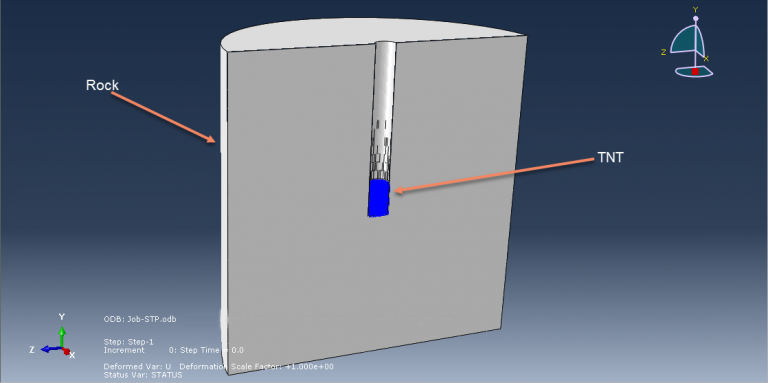

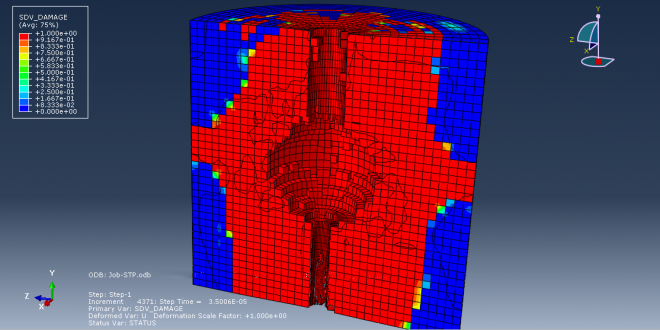

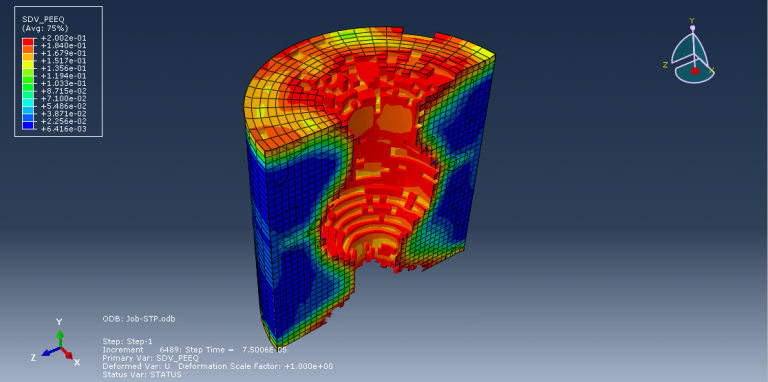

Workshop 8: TNT Explosion Simulation Inside a Rock With the SPH Method

This tutorial explores the Numerical Simulation of the Fracturing of Rock under Blast Using Coupled Finite Element Method and Smoothed Particle Hydrodynamics. Drill and blast methods are still widely used for excavation in industries such as hydro power, transportation, and mining due to their adaptability to various geological conditions.

With the advancement of explosion theory and computer technology, numerical simulation has become a promising approach for studying blast and wave propagation. Researchers around the world have been utilizing various numerical methods to investigate the propagation of stress waves in rock masses.

To simulate the effects of an explosion, the granite rock and TNT are represented as three-dimensional parts. The JWL equation of state is used to model the high-explosive material TNT, converting the chemical energy released by the explosion into mechanical pressure. The JH2 model is utilized to model the behavior of granite under the intended blast load.

To perform this type of analysis, a dynamic explicit step with general contact is deemed suitable. The rock is assigned a fixed boundary. To model the smooth particle hydrodynamic mesh from the TNT part, CAE and input files are utilized for defining PC3D elements. The quality of the mesh significantly affects the results and the propagation of radial cracks.

Following the explosion, it is possible to obtain the damage parameter and other results, such as stress and plastic strain.

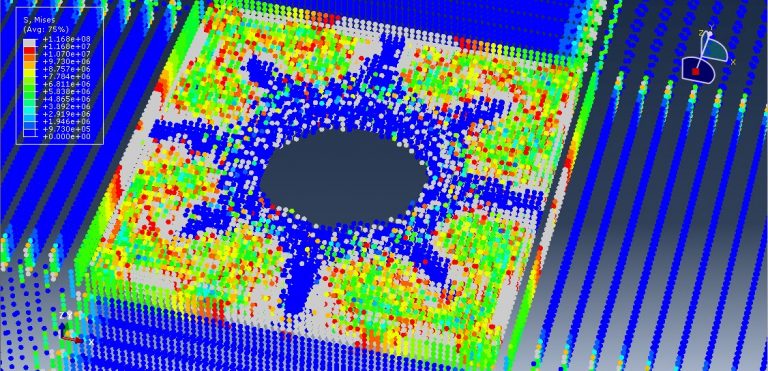

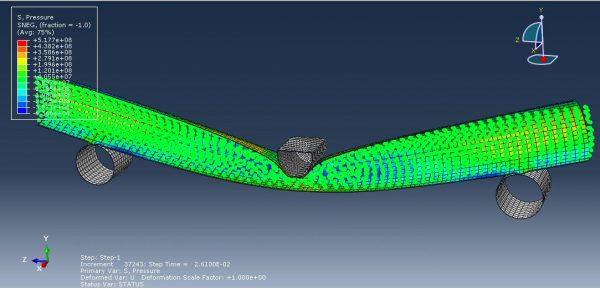

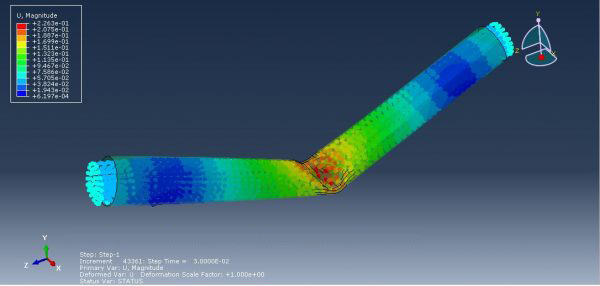

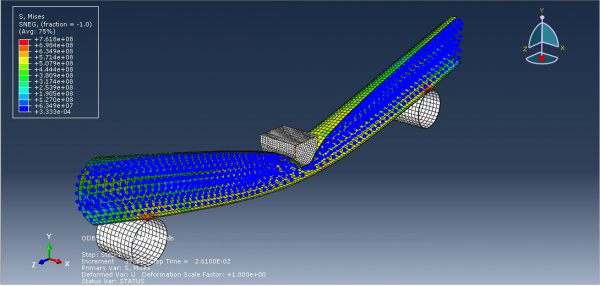

Workshop 9: Water-Filled X65 Steel Pipes Impact Simulation with the SPH Method

The final workshop of the Smoothed Particle Hydrodynamics tutorial focuses on Impact Simulation with the SPH method. It is common for offshore pipelines to experience unexpected hits, such as those from anchors or trawl gear.

Several factors, including the shape of the pipe, its materials, the contents of the pipeline, and the speed of impact, can affect the outcome. In this video, the use of SPH (Smooth Particle Hydrodynamics) in ABAQUS is demonstrated to simulate the impact of water-filled X65 steel pipes. An explicit method is suitable for this type of analysis. When a pipe is bent due to impact, water moves out of it.

It would be useful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial.

Robert Brown –

It is an awesome course, I really learned so much about SPH in Abaqus

Oliver Davies –

That is great. Could I use SPH method to simulate FSW welding?

claos.Ivanov –

Why don’t you put some of the package free so we know what we are buying? It may not solve our problem after buying this .

elliot –

It was totally worth it. With all workshop files, English subtitles and a professional yet simple explanation.

Volker –

The Abaqus SPH tutorial package is very comprehensive and practical. All steps are well-explained, and I have improved my projects using these tutorials. Do you offer similar courses for other simulation methods?

Hartmut –

This tutorial package helped me gain a better understanding of the SPH method and perform my simulations with greater confidence. Do you have plans for more advanced SPH training in the future?