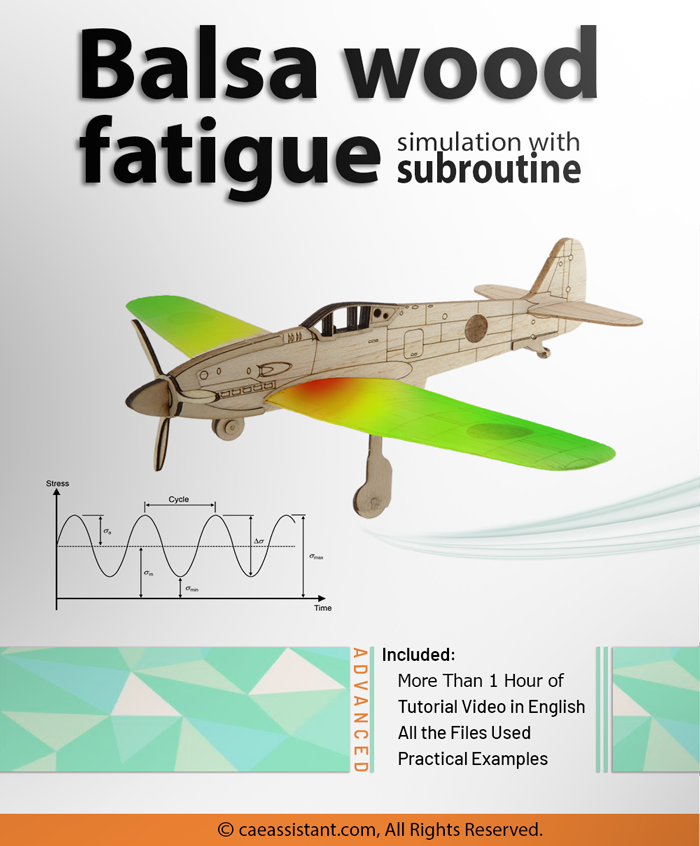

Balsa wood fatigue simulation with Abaqus subroutine

Since the material properties degradation due to wood fatigue can affect the load distribution in the structure in different periods of the structure’s life, in the present package, static failure criteria with rules for elastic and strength reduction are used for fatigue modeling. The appropriate failure criterion in this method is the criterion that has the best performance in predicting material failure under static combined loading. In this case, the success of the criterion in predicting fatigue failure will depend, above all, on setting appropriate rules for the gradual reduction of material strength and stiffness matrix due to fatigue. The formulation of these rules is generally based on Normalized life, which indicates the percentage of life spent. Therefore, calculating the fatigue life for each type of loading and with each stress ratio will be an important step in formulating the problem in this way. Abaqus wood fatigue is fully discussed in this package, and you will understand the main basic points of wood fatigue in an academic lecture.

In the current model, the assumptions used are as follows:

- The difference in the properties of wood in the radial and tangential direction is ignored and the assumption of axial symmetry in the direction of the fibers is used for wood.

- Wood is modeled homogeneously and possible natural defects in its structure and its local effects (such as stress concentration) are not clearly seen.

- The behavior of the material in tension, compression and linear shear is considered.

- Wood humidity is assumed to be constant during its working life, and the mechanical properties of the material at constant humidity are the basis of the calculations.

- The elastic properties are assumed to be the same in tension and compression.

The failure criteria in wood, assuming the presence of axial symmetry in it, are similar to the failure criteria in unidirectional composite materials. In this project, the reduced Hashin failure criterion related to unidirectional composite materials has been used.

This training package focus on writing subroutines based on mentioned theory to simulate wood fatigue in Abaqus. In the “Balsa wood fatigue simulation with subroutine” package, the used fatigue theory of wood has been described. Then, the flowchart of the subroutine and writing subroutine line-by-line is explained. It helps users to developed the subroutine based on customized theory. Finally, the subroutine is implemented on the Abaqus model, and the results are discussed.

After purchase, you can access the subroutine and software files immediately. It should be mentioned video files will be available in the download section soon. If you are working on composites and need some resources about composite FEM simulation, click on the Abaqus composite analysis page to get more than 20 hours of video training packages of composite materials simulation.

The video files will be available 2 months later after purchase.

After purchase, you can access the software files and subroutines immediately.

Carlos –

This tutorial package focuses comprehensively on the theory of wood fatigue and helps simulate wood fatigue in Abaqus using a customized subroutine. It serves as a reliable and comprehensive resource for individuals interested in simulating wood fatigue in the Abaqus software.

Experts Of CAE Assistant Group –

Thank you for your appreciation! We aim to deliver exceptional service to all our customers, and it’s rewarding to know that we achieved that in your case. If you ever need further assistance, don’t hesitate to reach out.