Performing Brittle Damage Simulation in Abaqus | Brittle Cracking Abaqus

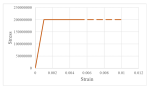

To perform a brittle damage simulation in Abaqus, users start by setting up a material model that accurately captures the brittle nature of the material. Abaqus provides several methods for brittle damage modeling, each with its own approach and suitable application scenarios. Among these, simulating brittle cracking Abaqus is essential for capturing the relationship between damage and crack formation in brittle materials. This analysis allows users to observe how damage evolves and leads to crack initiation and propagation under various conditions, ensuring that simulations align closely with real-world material responses.

-

Johnson-Holmquist (JH) Model: For materials like ceramics, rocks, or concrete exposed to high-strain-rate impacts, Abaqus can implement the JH model, particularly the JH-2 version, which incorporates damage evolution and simulates brittle cracking behavior (Brittle cracking Abaqus). This model requires defining properties such as the intact strength, fractured strength, and specific damage parameters based on strain rate, stress, and pressure. By capturing how damage progresses to crack formation, the JH model in Abaqus provides insights into the brittle response of materials under extreme loading. The JH model can be set up using Abaqus/Explicit with custom material parameters that represent material degradation under dynamic loads. Depending on the specific application, user-defined subroutines (VUMAT) might be necessary to integrate the JH-2 model fully, as it may not be directly available in standard Abaqus libraries.

- Energy-Based Method: The energy-based approach is advantageous for quasi-static applications where the brittle material absorbs energy up to a specific threshold before fracturing. In this method, the focus is on defining a critical strain energy density or fracture energy value that, when reached, leads to crack initiation. This approach is effective for analyzing how brittle cracking Abaqus can be simulated for materials like glass or certain ceramics under static or slow-loading conditions. It can be implemented by defining material parameters related to energy dissipation and assigning suitable boundary conditions to allow for controlled, progressive crack propagation. This method helps capture the intricate relationship between energy absorption and crack formation, providing a comprehensive understanding of brittle failure.

To set up a brittle damage simulation in Abaqus (brittle cracking Abaqus):

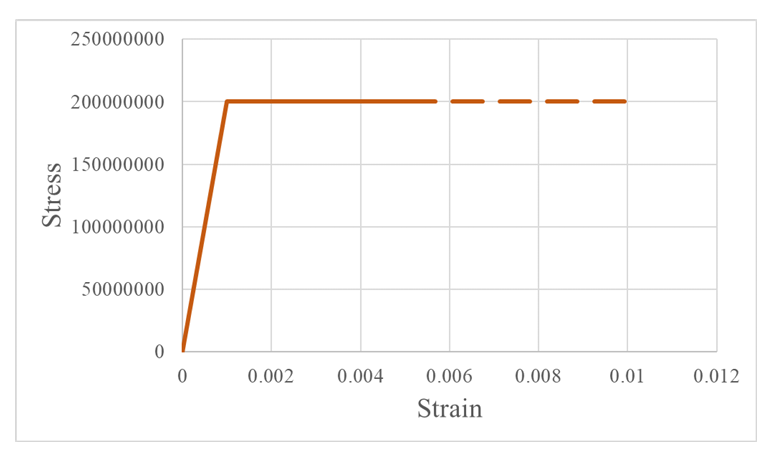

- Define Material Properties: Start by inputting the material’s mechanical properties, such as Young’s modulus, Poisson’s ratio, and specific damage-related parameters based on the chosen method (e.g., energy threshold for the energy-based method or damage parameters for JH-2).

- Choose the Method and Define Damage Criteria: Depending on the model, select the appropriate Abaqus module. For high-strain-rate impacts, use Abaqus/Explicit and implement JH-2 parameters. For XFEM or energy-based models, Abaqus/Standard or Abaqus/Explicit may be used, with damage initiation criteria set based on stress or energy levels.

- Set Loading Conditions and Mesh Strategy: Apply loading and boundary conditions representative of the actual use case (e.g., impact for JH model or slow compression for energy-based methods). Use a refined mesh in areas expected to experience damage to capture fracture details accurately.

-

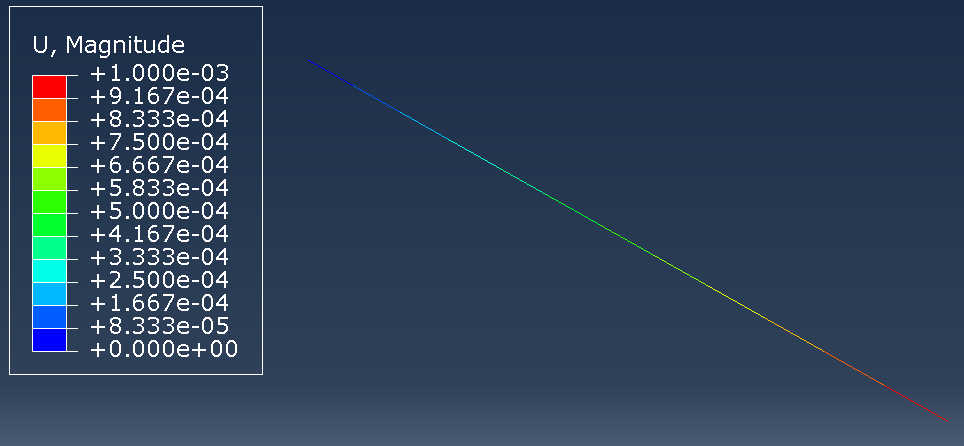

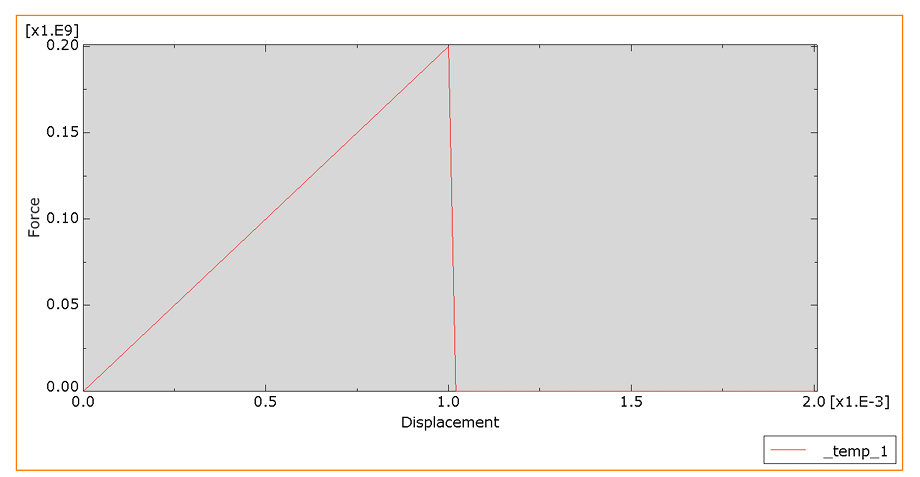

Run the Simulation: Once all parameters are defined, execute the simulation to observe how the material responds to loading. In the context of brittle cracking Abaqus, the simulation should reveal stress distribution, crack initiation, and propagation patterns based on the chosen model. This analysis helps predict critical failure points and assess material performance under given conditions. By accurately modeling brittle behavior, users can gain deeper insights into material limitations and optimize designs to mitigate potential failures.

Introduction to Brittle Materials

Brittle materials are those that fracture or break easily when subjected to stress, typically without significant plastic deformation. Unlike ductile materials, which can withstand considerable stretching or bending before breaking, brittle materials tend to snap or shatter suddenly upon reaching their breaking point. Common examples of brittle materials include ceramics, glass, concrete, and some metals at low temperatures. These materials are characterized by low tensile strength compared to their compressive strength and often have limited energy absorption before failure, making them prone to cracking under stress (brittle cracking Abaqus).

The brittle nature of these materials is due to their atomic structure, which generally lacks the ability to rearrange under stress. This leads to a sharp, sudden failure instead of gradual deformation. Brittle materials are usually hard and strong under compression but exhibit weak performance under tension, meaning they can withstand pressure from a direct push but will fracture if stretched or pulled. Brittle behavior is significant in structural and manufacturing applications, especially for components exposed to high stress, where a sudden failure could have critical implications.

Brittle Material Damage and Its Importance

Understanding and predicting brittle material damage is essential in designing and evaluating components in fields such as civil engineering, aerospace, automotive, and manufacturing. Brittle fracture often occurs suddenly, without visible warning signs, making it potentially catastrophic in applications where safety and reliability are critical. Studying the mechanisms and factors that influence brittle fracture can help in designing more resilient structures or selecting appropriate materials that minimize the risk of sudden failure.

Simulating brittle material damage is crucial in engineering, as it allows for virtual testing of materials under various stress scenarios, assessing failure modes, and determining critical points of failure before real-world testing or use. By utilizing finite element analysis (FEA) tools, engineers can model how brittle materials respond to specific conditions, which can help inform design decisions, optimize material selection, and reduce costs by preventing over-design or under-design. This brings us to brittle damage simulations, which are typically conducted in software like Abaqus to analyze how and where a material may fail under given loads.

Reviews

Clear filtersThere are no reviews yet.