Introduction to High-Strength Steel Beam Analysis

Why Accurate Design and Analysis of High-Strength Steel Beams Are Important

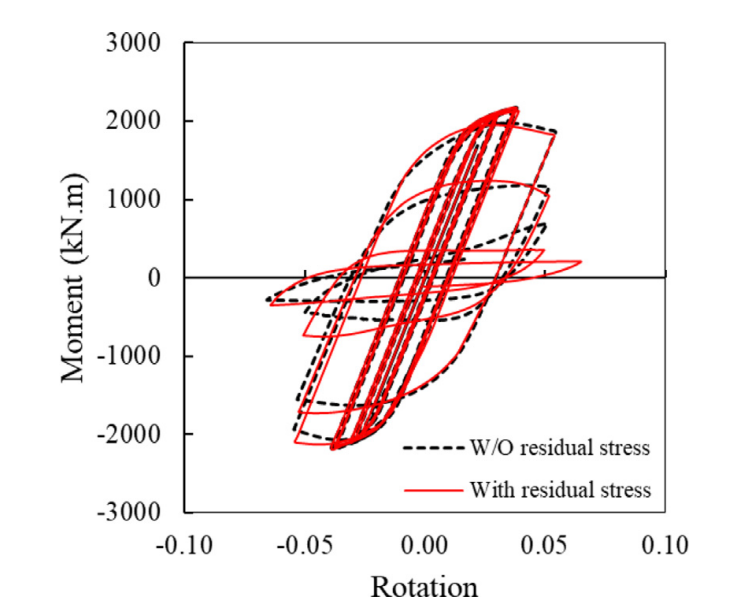

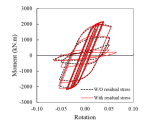

Due to their significance, numerous papers have explored the design of high-strength steel beams. However, researchers have made limited efforts to study the two-way cyclic behavior of these beams. This highlights a potential gap in experimental research. Proper design and high-strength steel beam analysis are crucial because local buckling and low-cycle fatigue can influence structure’s cyclic response. Despite this, there remains a shortage of effective stress-strain relationships or curves for high-strength steel members that consider local buckling, cyclic degradation, and ductile fracture.

Experimental vs. Numerical Methods: Analysis of High-Strength Steel Beams

The Experimental Methods

A thorough investigation of the behavior of high-strength steel members necessitates a validated numerical model in conjunction with experimental studies. This approach ensures that structures can endure higher stresses while minimizing weight, a critical factor for seismic-resistant designs and other demanding structural applications. However, experimental methods for designing such components are costly and difficult to execute. Moreover, relying solely on experiments may not fully capture the complexities of high-strength steel behavior. To address this issue, numerical methods have gained increasing attention for the design and high-strength steel beam analysis and other members.

The Numerical Methods

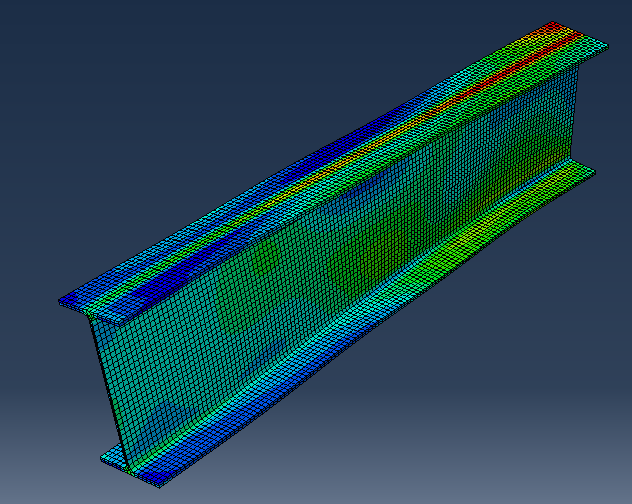

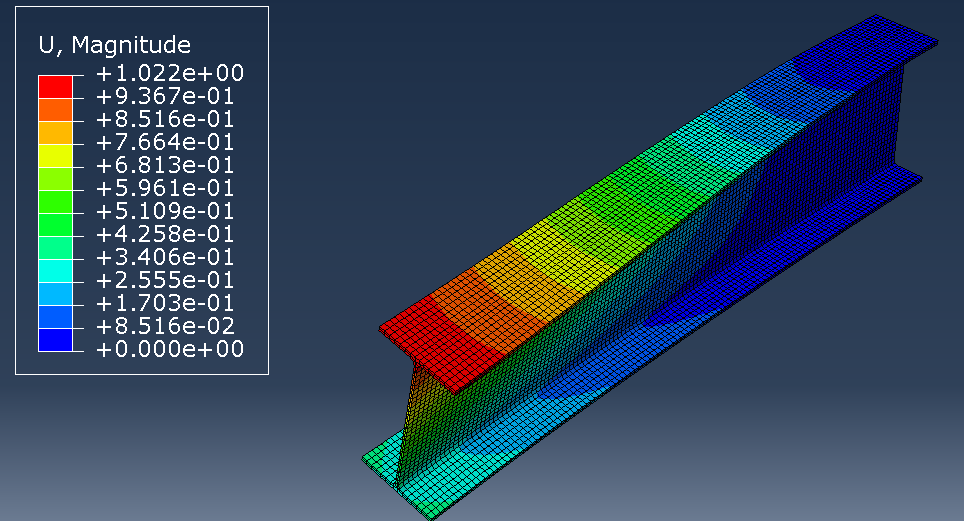

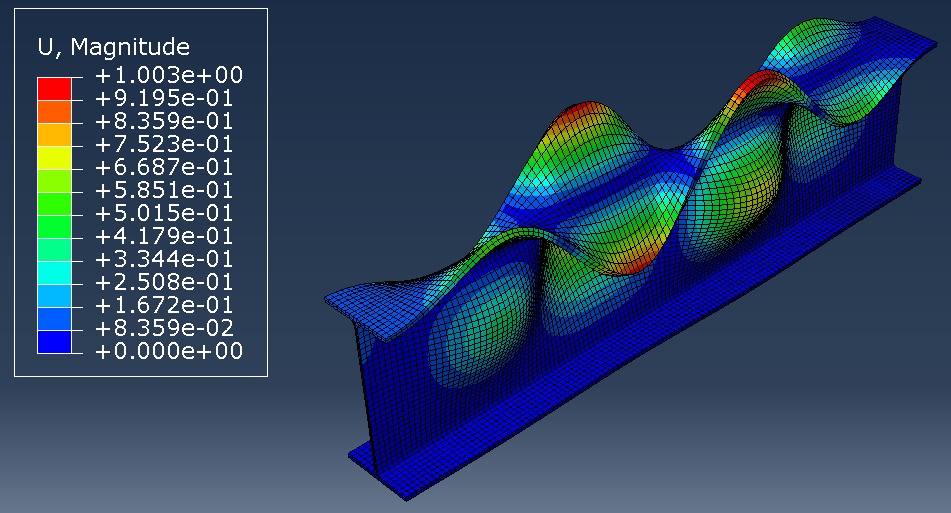

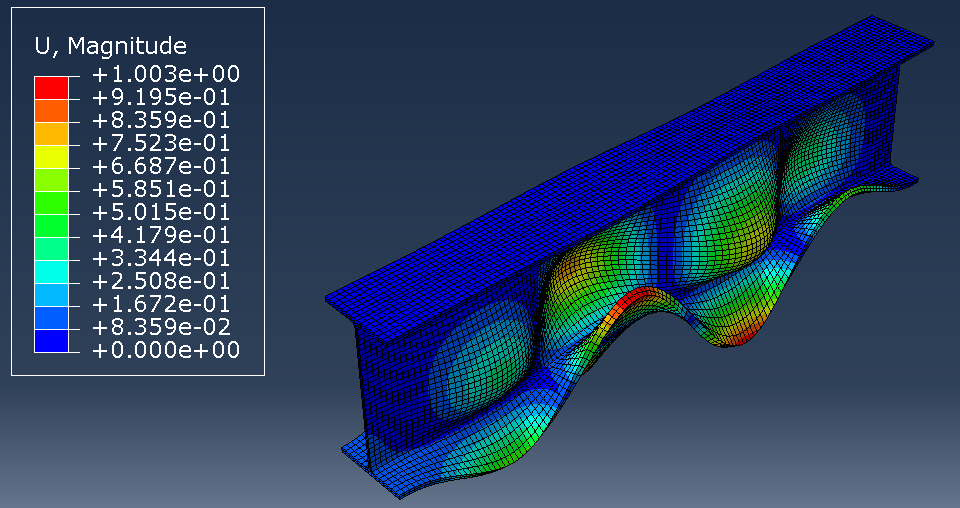

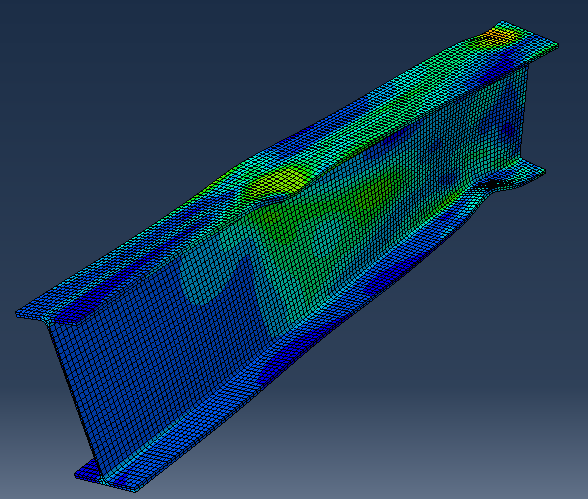

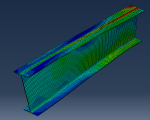

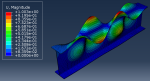

Numerical simulations, especially through 3D finite element models, are essential for designing and high-strength steel beam analysis and other high-strength steel members. You can calibrate these models using experimental data to enhance the accuracy of behavior predictions. They are effective for simulating both monotonic and cyclic responses of high-strength steel beams with a high degree of precision. Additionally, these models can include material damage parameters to accurately represent cyclic degradation. Furthermore, the ability to model member imperfections improves the understanding of structural behavior, which benefits the design process.

The Role of Abaqus CAE in Simulating High-Strength Steel Members

The Benefits of Using Abaqus CAE

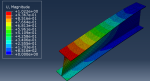

ABAQUS software is a powerful tool for conducting numerical analyses of high-strength steel beams. It facilitates the creation of detailed 3D finite element models that accurately represent the behavior of these steel members. The software allows for the assignment of complex material properties, such as stress-strain curves and plasticity models, which are crucial for simulating realistic behavior. Additionally, ABAQUS supports the implementation of specific loading protocols, including cyclic loading, to analyze steel beam performance. It can also perform buckling analysis to identify appropriate eigenmodes for initial imperfections, which is vital for understanding stability. Furthermore, ABAQUS enables multi-step simulations, providing a comprehensive investigation of various aspects of high-strength steel behavior, including both monotonic and cyclic responses.

These capabilities have led many researchers to choose ABAQUS for analyzing high-strength steel sections, as discussed in this project.

Is Using Abaqus for Simulating High-Strength Steel Sections Challenging?

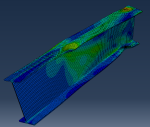

While ABAQUS offers many powerful features, high-strength steel beam analysis presents several complexities and challenges. Accurately capturing the nonlinear isotropic and kinematic hardening behavior of high-strength steels can be intricate. It requires precise definitions of material parameters and stress-strain relationships. Additionally, achieving accurate results necessitates a fine and well-chosen mesh, with careful control of element aspect ratios to prevent distortion and convergence issues, particularly in regions experiencing significant inelastic deformation. Incorporating initial imperfections into the model is essential for realistic simulations but adds further complexity. Lastly, calibrating the finite element model with experimental data can be demanding, as it requires a deep understanding of material properties and behavior under various loading conditions. These challenges can make simulations in ABAQUS difficult for researchers. To help address these issues, we have provided a step-by-step guide for analyzing high-strength steel sections in this project.

What Does the Tutorial Provide?

The Project Details

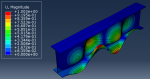

The project examines the behavior of high-strength steel beams, specifically focusing on the stress-strain response in the critical zone of the plastic hinge. It tackles issues related to local instability in I-shaped steel beams, the creation of accurate stress-strain curves, and the numerical simulations used to assess the behavior of these beams. Additionally, the project explores the mechanics of section geometry and in-plane deformations to compute rotations and develop idealized stress-strain curves.

Specifics of ABAQUS Modeling Covered in the Tutorial

Here is a summary of the Abaqus modeling used in this project:

- Material Properties: The engineering stress-strain curve from coupon specimens was used to define material properties, including modulus of elasticity, Poisson’s ratio, and yield stress.

- Plasticity Model: A nonlinear isotropic/kinematic hardening model was employed to replicate the low-rate cyclic behavior of the metal, accounting for the yield surface expansion and the Bauschinger effect.

- Viscosity Assignment: A minimal viscosity was introduced to facilitate convergence during material softening and at high plastic strain levels.

- Multi-step Simulations: ABAQUS allows for multi-step simulations, which enables a comprehensive analysis of various aspects of high-strength steel behavior, including both monotonic and cyclic responses.

- Loading Protocols: The software supports the implementation of specific loading protocols, such as the ATC cyclic loading protocol, to examine the cyclic behavior of steel beams.

- Mesh Details: A reasonably fine mesh was used in the beam model, with C3D20R solid elements chosen for their suitability in handling bending problems and significant strain plasticity.

- Aspect Ratio: The aspect ratio in the critical region of the beam was kept below a critical threshold to prevent element distortion under high inelastic deformation. More relaxed values were permitted in the elastic region, as long as they did not exceed a specified limit to ensure solution accuracy.

Reviews

Clear filtersThere are no reviews yet.